Week 12 : Assignment

- add an output device to a microcontroller board you've designed, and program it to do something

In week 12 assignment was to add an output device in microcontroller and I have to program it to do something ! I thought it will be a good idea to use the input devices I used in week 11.

All Details of 328p board is uploaded in week 11.

Humidity sensor with OLED

I already used the humidity sensor and print details on serial Monitor, I wanted to print them on my OLED now.

OLED (Organic Light-Emitting Diode) is a self light-emitting technology composed of a thin, multi-layered organic film placed between an anode and cathode. In contrast to LCD technology, OLED does not require a backlight. OLED

possesses high application potential for virtually all types of displays and is regarded as the ultimate technology for the next generation of flat-panel displays. my

reference for this code.

Click here to know more.

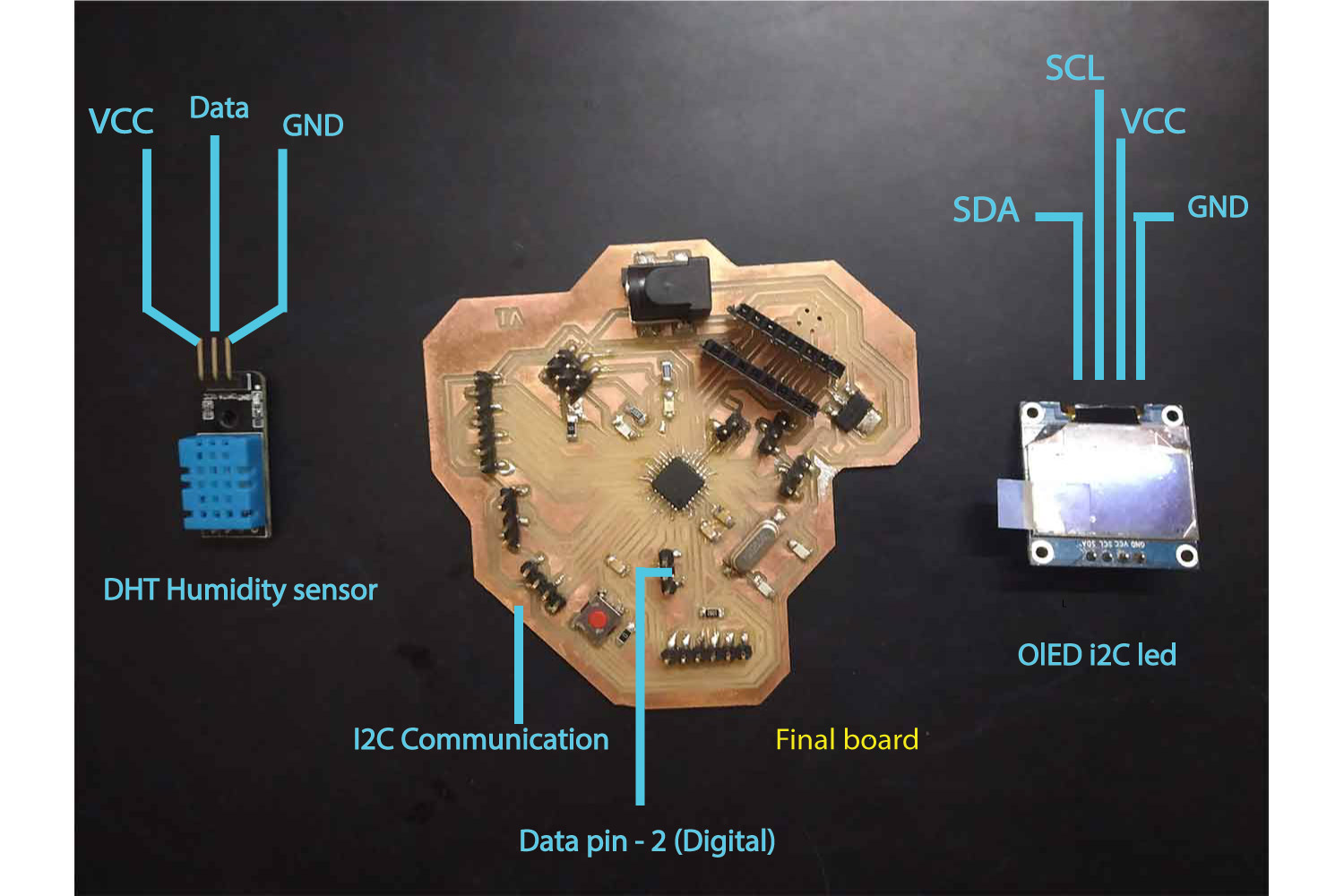

setup

in setup, I connected

Code

I got these codes from Random Tutorials and About OLED and DHT sensor. I still needed to understand this code, I wrote in every comment what each line is doing, the way

I understand...The below code will show Humidity and temperature.

Don’t forget to include

/*

* Random Nerd Tutorials - Rui Santos

* Complete Project Details https://randomnerdtutorials.com

*/

// require libraries one will need to run the code

#include <Wire.h> // wire library for I2C communication

// Adafruit library for the OLED printing

#include <Adafruit_GFX.h>

#include <Adafruit_SSD1306.h>

#include <DHT.h>// library for Dht sensor

#define DHTPIN 2 // digital pin is defined to humidity sensor

#define DHTTYPE DHT11 // defined reading

#define OLED_RESET 4 // OLED HAS TO DEFINE RESET IN EVEN IT IS NOT IN PINOUT

Adafruit_SSD1306 display(OLED_RESET); //FOR DISPLAY

// Initialize DHT sensor

DHT dht(DHTPIN, DHTTYPE);

void setup() {

Wire.begin();

dht.begin();

display.begin(SSD1306_SWITCHCAPVCC, 0x3C);// initialize with the I2C addr 0x3C

}

void displayTempHumid(){

delay(2000);

// Reading temperature or humidity takes about 250 milliseconds!

// Sensor readings may also be up to 2 seconds 'old' (its a very slow sensor)

float h = dht.readHumidity();

// Read temperature as Celsius

float t = dht.readTemperature();

// Read temperature as Fahrenheit

float f = dht.readTemperature(true);

// Check if any reads failed and exit early (to try again).

if (isnan(h) || isnan(t) || isnan(f)) {

// if sensor failed to received any of three data it will fullfill this condition, if readings are available it will skip this loop

display.clearDisplay(); // clearing the display

display.setTextColor(WHITE); //setting the color

display.setTextSize(1); //set the font size

display.setCursor(5,0); //set the cursor coordinates

display.print("Failed to read from DHT sensor!");

return; // it will return to start if condition fulfilled

}

display.clearDisplay();

display.setTextColor(WHITE);

display.setTextSize(1);

display.setCursor(0,10);

// prints on display from below

display.print("Humidity: ");

display.print(h);

display.print(" %\t");

display.setCursor(0,20);

display.print("Temperature: ");

display.print(t);

display.print(" C");

// you can get tempreture values from below in fahrenheit

// display.setCursor(0,20);

// display.print("Temperature: ");

// display.print(f);

// display.print(" F");

}

void loop() {

displayTempHumid();

display.display();

}

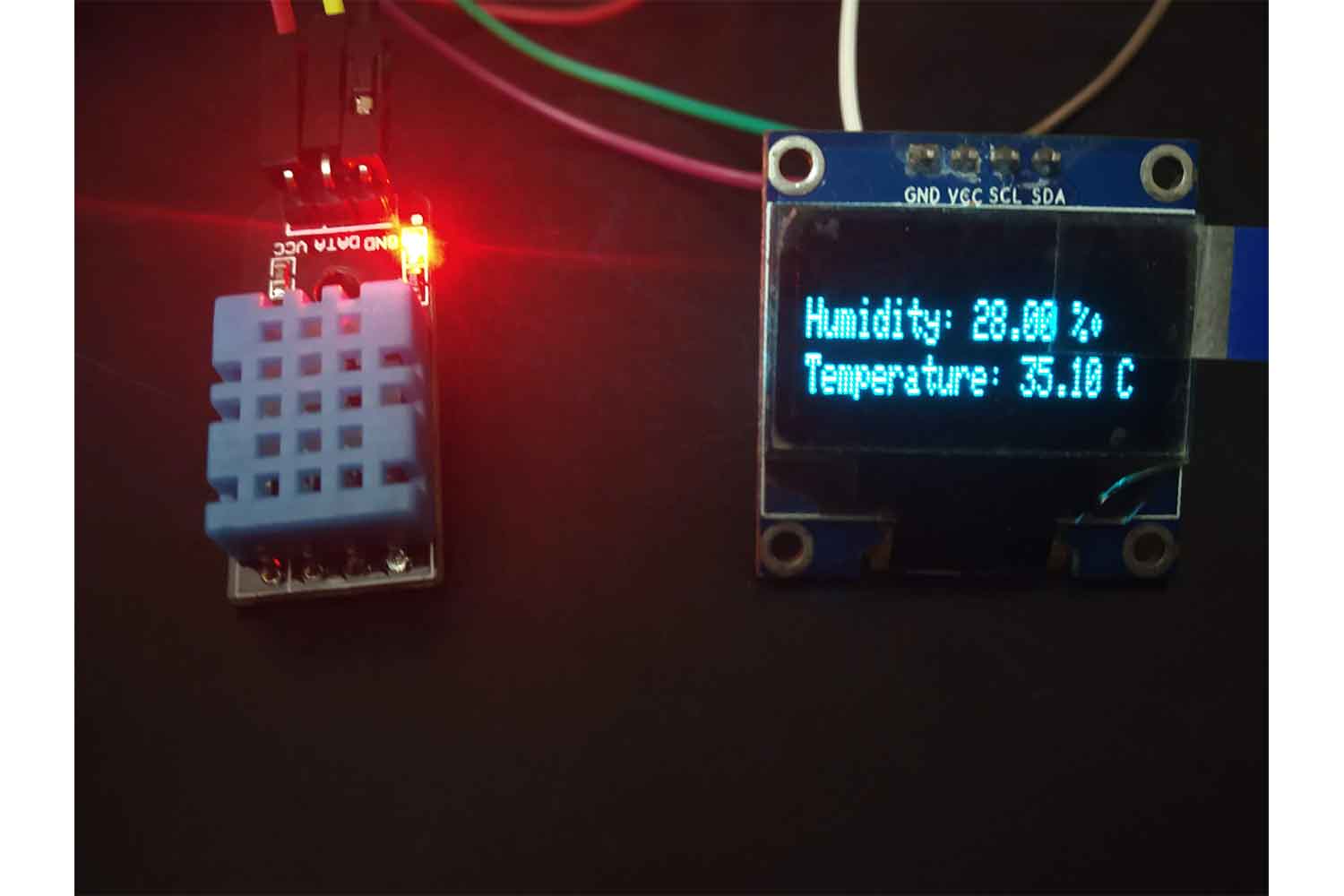

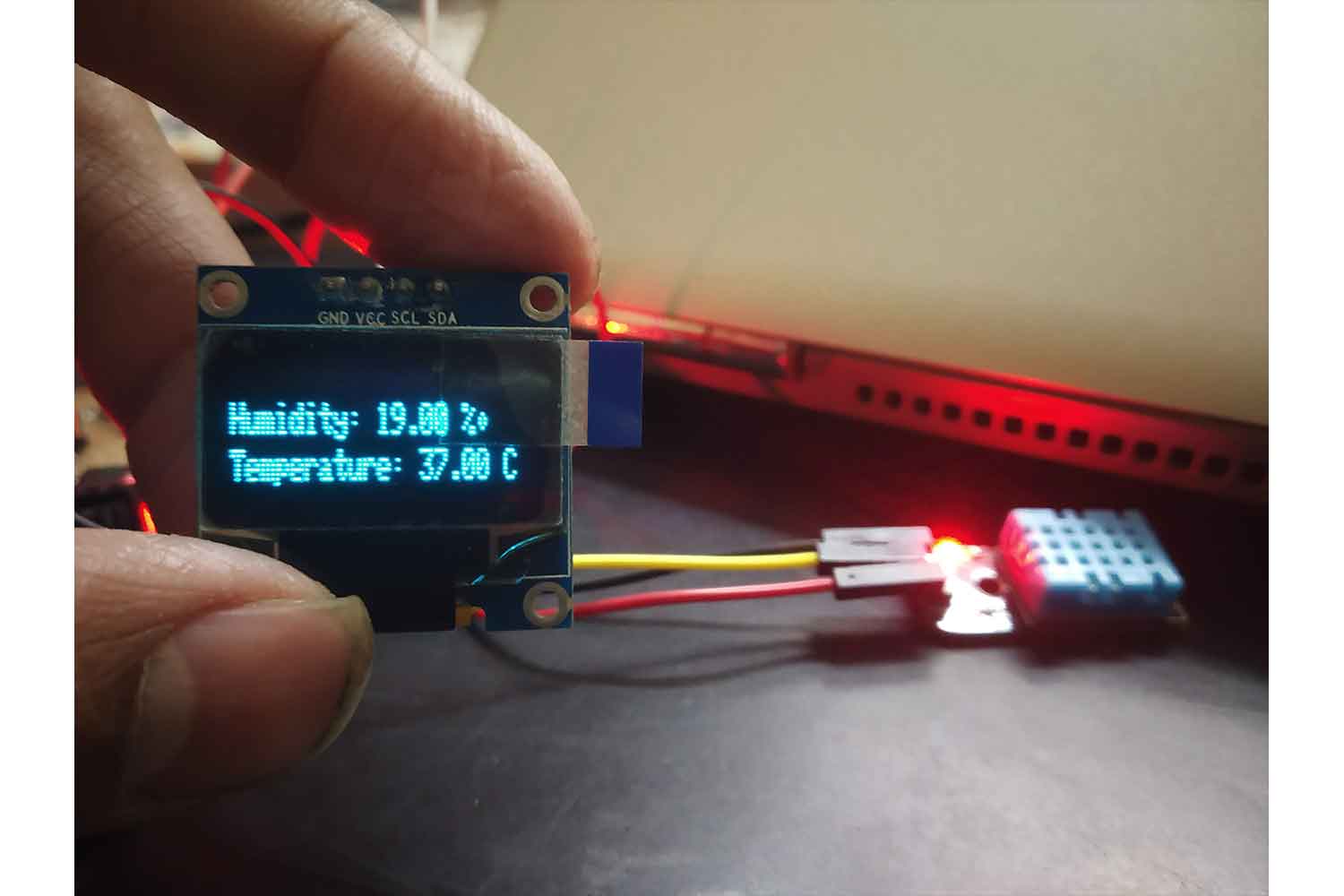

Output

Below I am trying to increase the humidity with a wet Handkerchief, see Below in video!

Servo motor with the Joystick

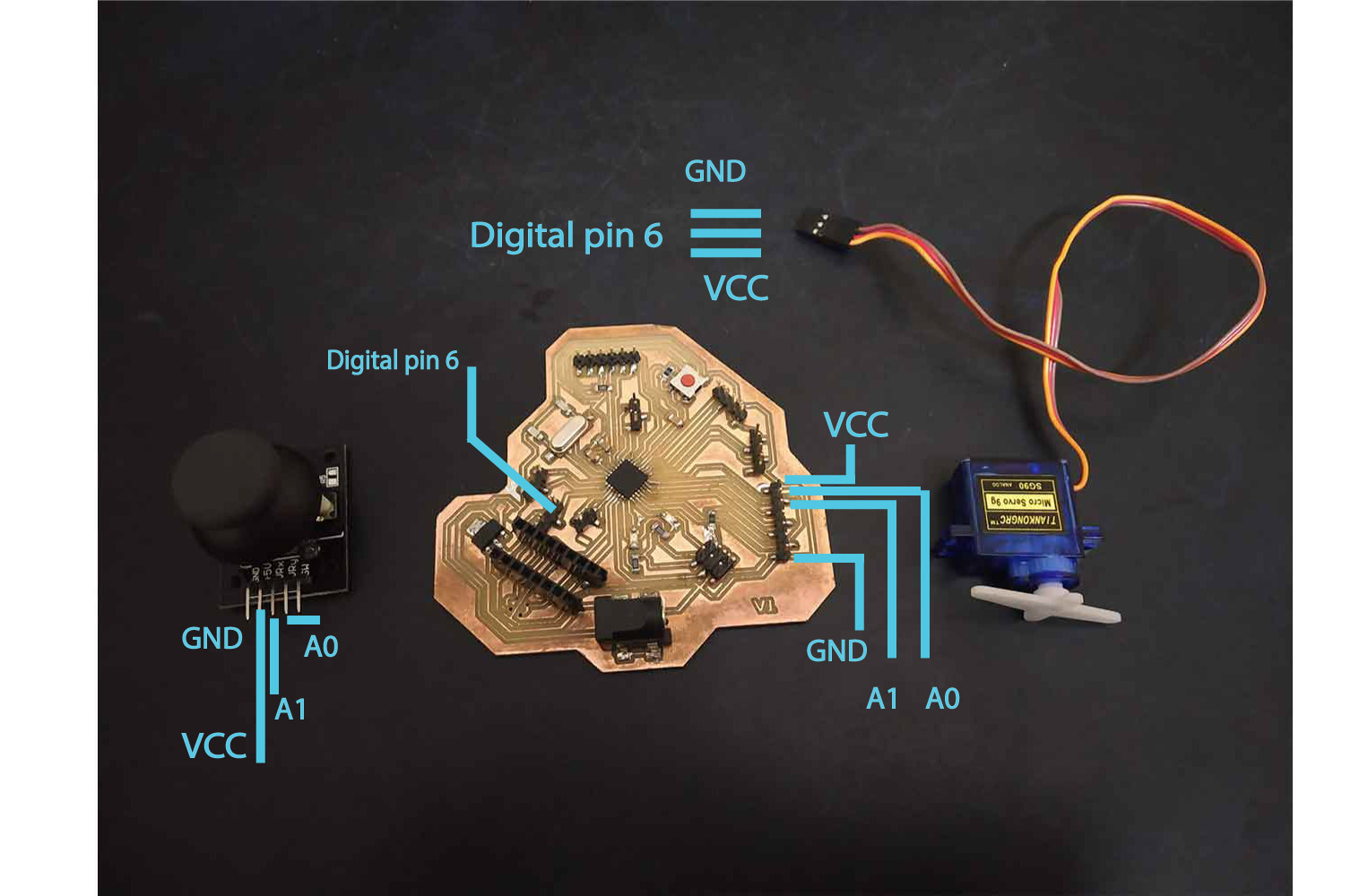

Then I tried to run Micro-servo with joystick module!Setup

Joystick connected to (A1,A0) // Vrx, Vry

servo pin 6

Code

II explained code in the comments, I thought it would be a more efficient way, for simplicity copy code in Arduino and read, it will be more clear there.

Don’t forget to add a library of servo below.

#include <Servo.h>

// including servo library

Servo servo1;

// define servo name

// initialize variables and define pins

int x_pos;

int y_pos;

// Define pin for servo, define PWM pins

int servo1_pin = 6;

int initial_position = 90; // defined initial position, wanted to rotate both side

// set initial numbers

int xPosition = 0;

int yPosition = 0;

int SW_state = 0;

int mapX = 0;

int mapY = 0;

int VRx = A1;

int VRy = A0;

int SW = 8;

void setup ( ) {

Serial.begin (9600); // defining the input and output pins

servo1.attach (servo1_pin );

servo1.write (initial_position);;

pinMode(VRx, INPUT);

pinMode(VRy, INPUT);

pinMode(SW, INPUT_PULLUP);

}

void loop ( ) {

// cod is reading joystick x and y axis readings

xPosition = analogRead(VRx);

yPosition = analogRead(VRy);

SW_state = digitalRead(SW);

// printing on serial monitor

Serial.print("X: ");

Serial.print(mapX);

Serial.print(" | Y: ");

Serial.print(mapY);

Serial.print(" | Button: ");

Serial.println(SW_state);

delay(100);

x_pos = analogRead (xPosition); // reading position for servo control

// below code dividing the values in two segments, (0,300) and (700,1023).

// first part, lets say it is for rotation servo anti-clockwise code

/* Below if position comes below 300 */

if (x_pos < 300){

if (initial_position < 10) {

} // first it will check it is below 10 or what, if it is it will do nothing and forward the loop

else{

/* else it will decrease the data by 10, and new servo position will be available, this position values

will be added or decrease depends on the readings

*/

initial_position = initial_position - 10;

servo1.write ( initial_position );

delay (120); }

}

// second segment if values are greater then the 700, it will run servo to rotate oposite side

if (x_pos > 700){

if (initial_position > 980)

{

}

else{

initial_position = initial_position + 10; // it will just increase the values

servo1.write ( initial_position );

delay (120);

}

}

// same things for y

if (y_pos < 300){

if (initial_position < 10) {

}

else{ initial_position = initial_position - 10;

servo1.write ( initial_position );

delay (120); }

}

if (y_pos > 700){

if (initial_position > 180)

{

}

else{

initial_position = initial_position + 10;

servo1.write ( initial_position );

delay (120);

}

}

}

video

Group work

in group work, we have to measure the power consumption of any output component possible. we measured Power Consumption for a BLDC motor. In this group work, we don’t need to divide specific tasks! we did it together so.

Check group website for more information.

- For lower speed around 12, power consumption was 2.54 w (0.212 A on 12 v )

- For highest speed around 140, power consumption was 8.412 w (0.701 A on 12v)

Conclusion

This week made input week complete, learned I could use an input device to get different types of outputs.