Assignment

Design and produce something with a digital fabrication process

(incorporating computer-aided design and manufacturing) not covered

in another assignment, documenting the requirements that your

assignment meets, and including everything necessary to reproduce

it. Possibilities include (but are not limited to) composites, textiles,

biotechnology, robotics, folding, and cooking.

For this week assignment I will choose the Composite and will make the Lighting cover of my final project

Introduction

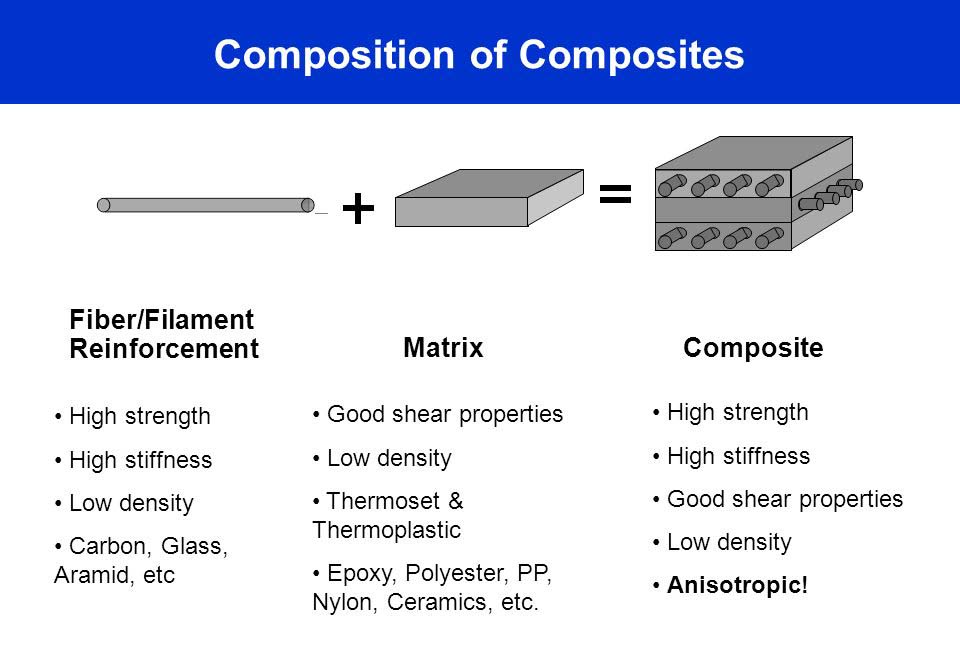

What is composite?

A composite material is composed of at least two materials, which combine to give properties superior to those of the individual constituents.

The fibre reinforced polymer (FRP) composites, usually with carbon, glass, aramid, polymer or natural fibres embedded in a polymer matrix. Other matrix materials can be used and composites may also contain fillers or nano-materials such as graphene.

The many component materials and different processes that can be used make composites extremely versatile and efficient. They typically result in lighter, stronger, more durable solutions compared to traditional materials.

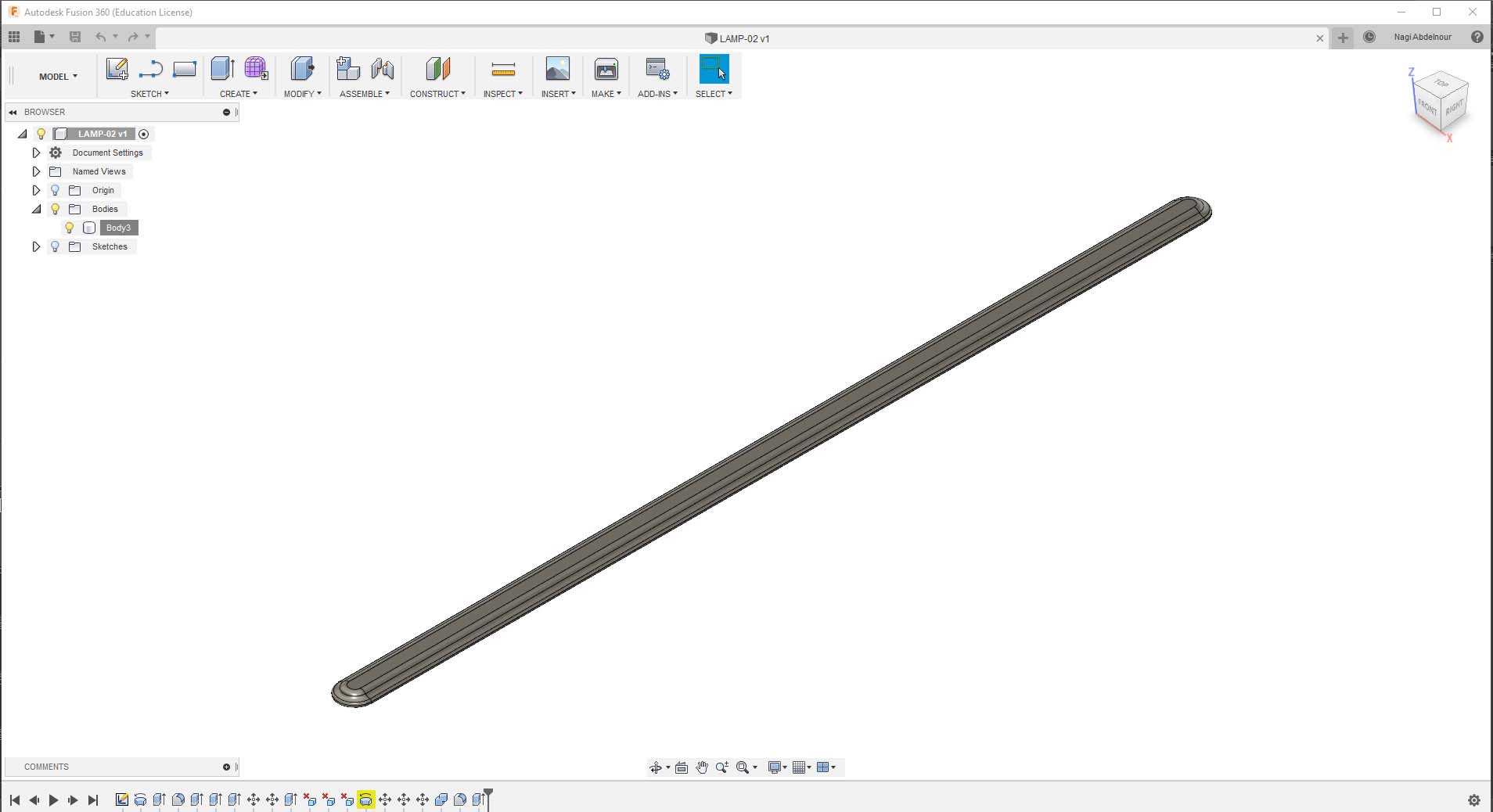

The Design

I will use Fusion software to design and 3D model my object

Then I will save it as STL in order to mill it on the CNC machine

Click Here to download the STL file.

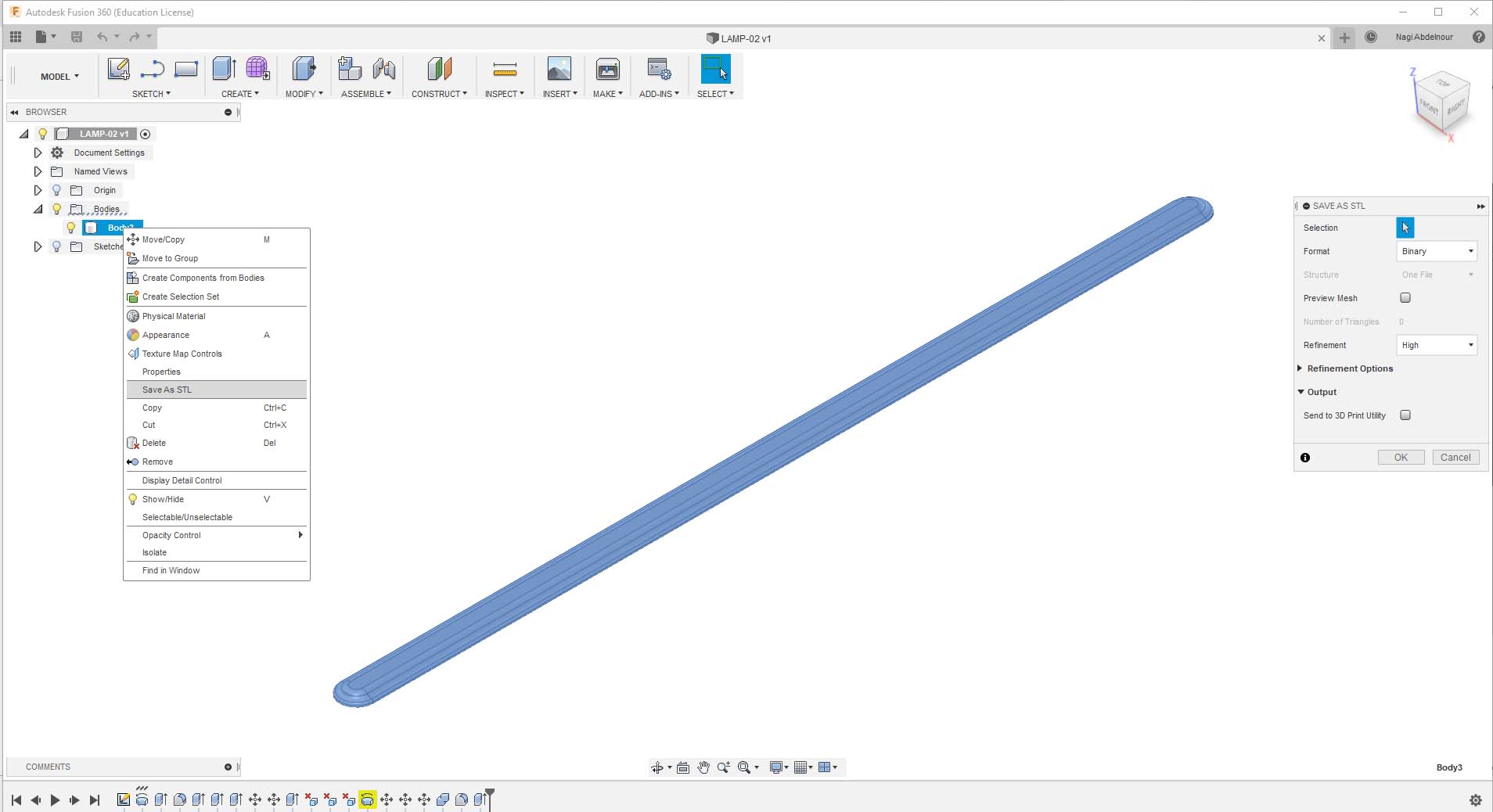

The Execution of the mold

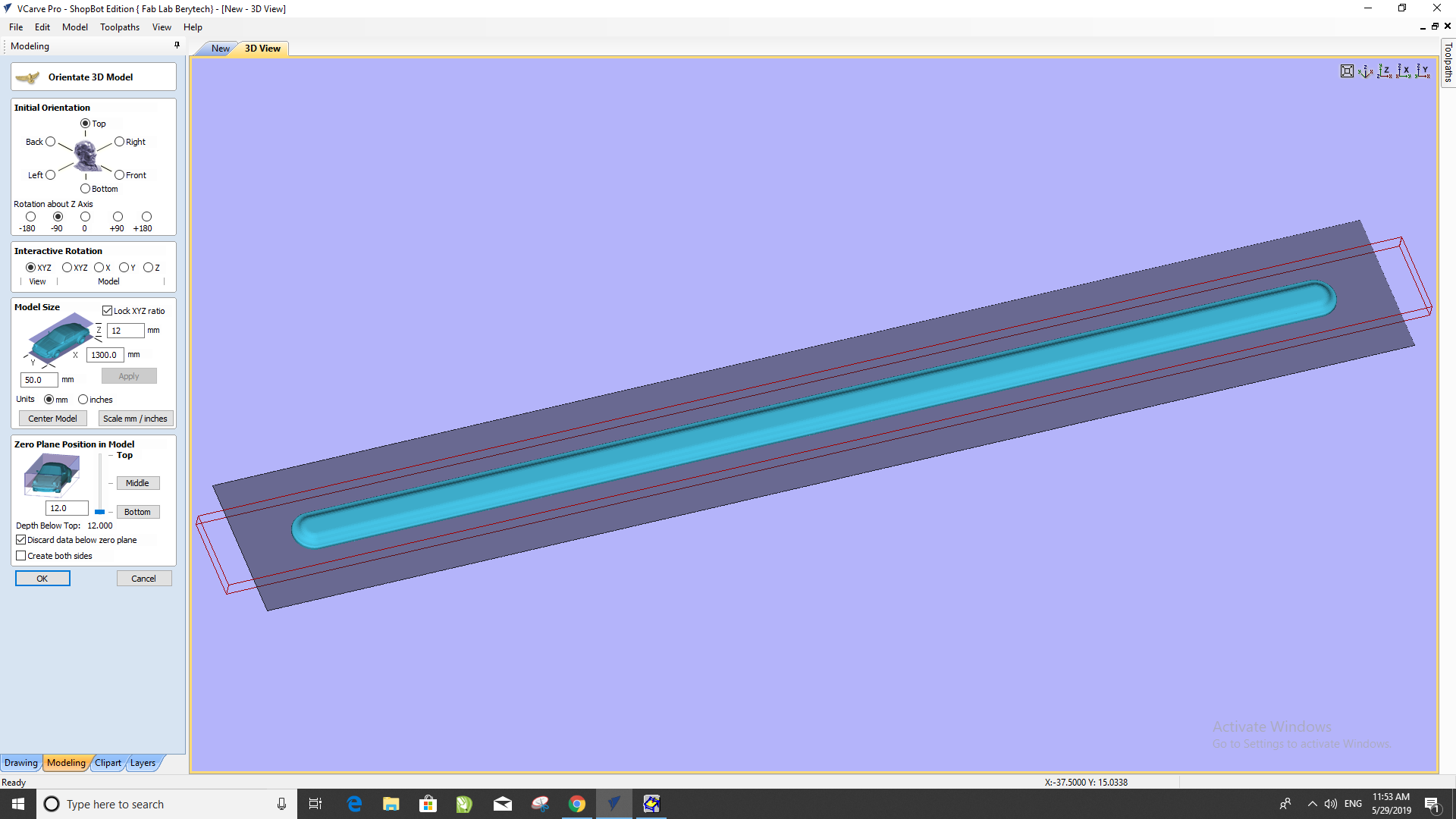

The STL file is opened on Vcarve software in order to mill it on the ShopBot cnc machine

Click Here to download the g-code files.

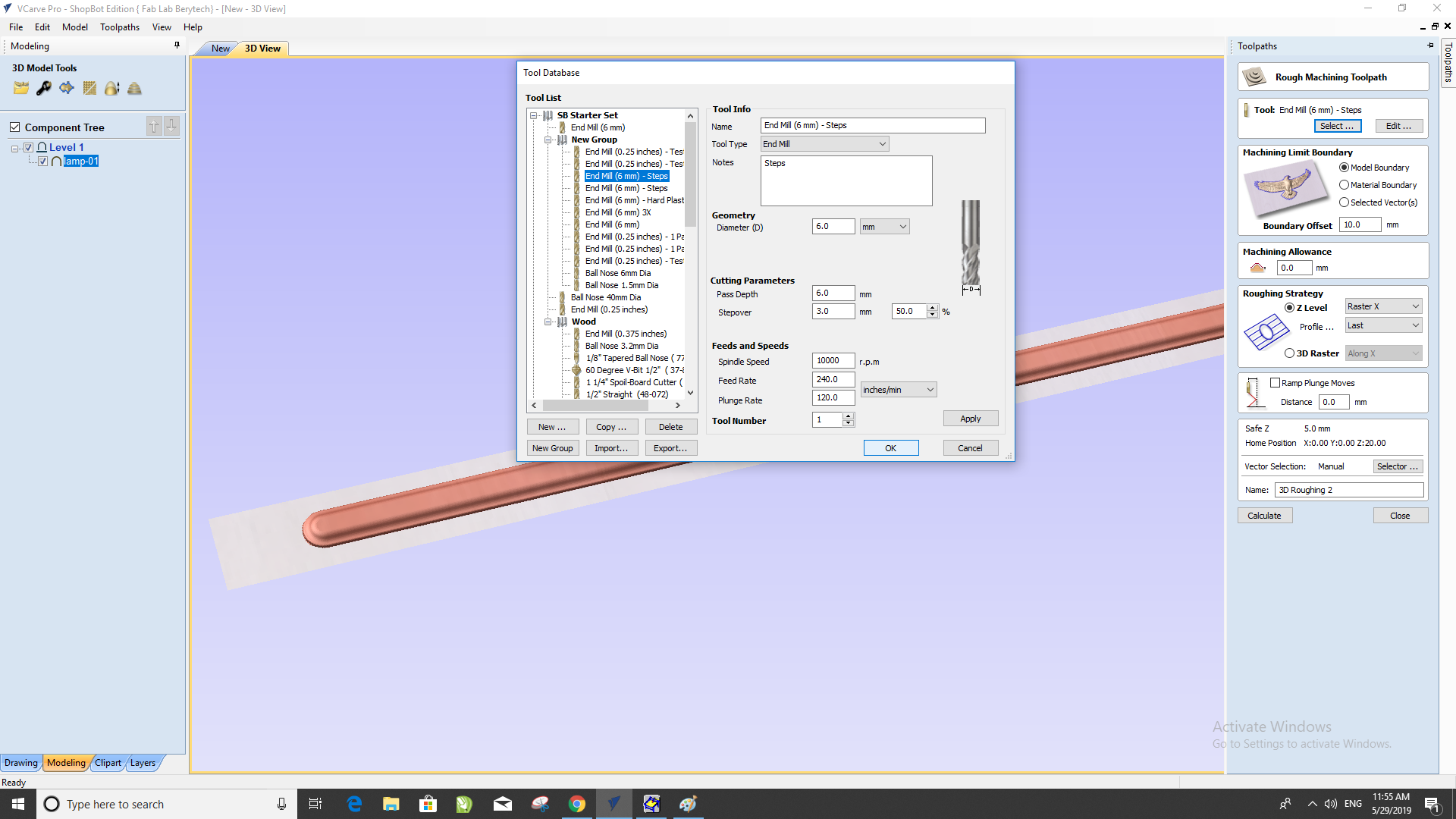

First step I will do the roughing

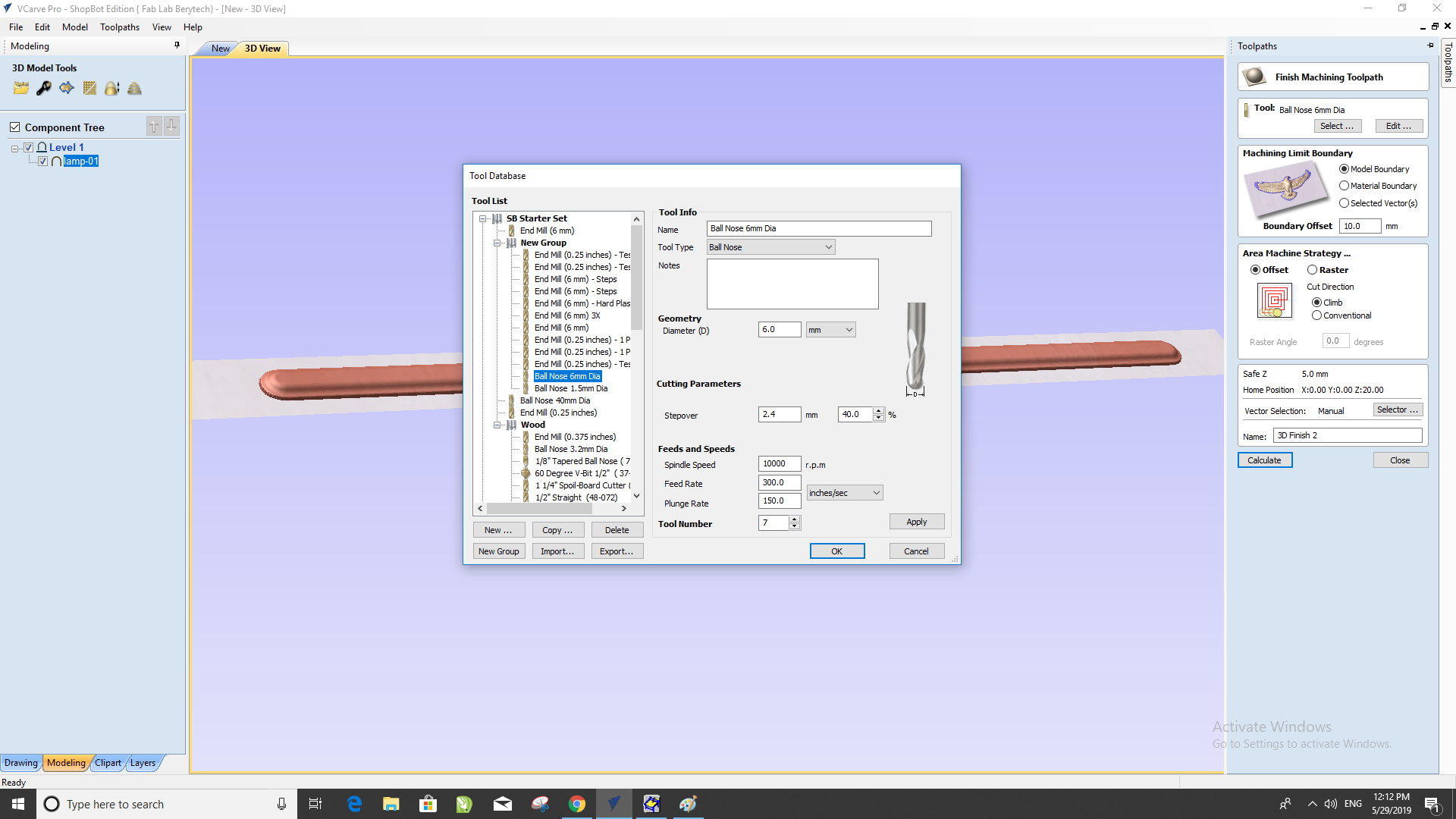

Second step I will do the smoothing with the 6mm

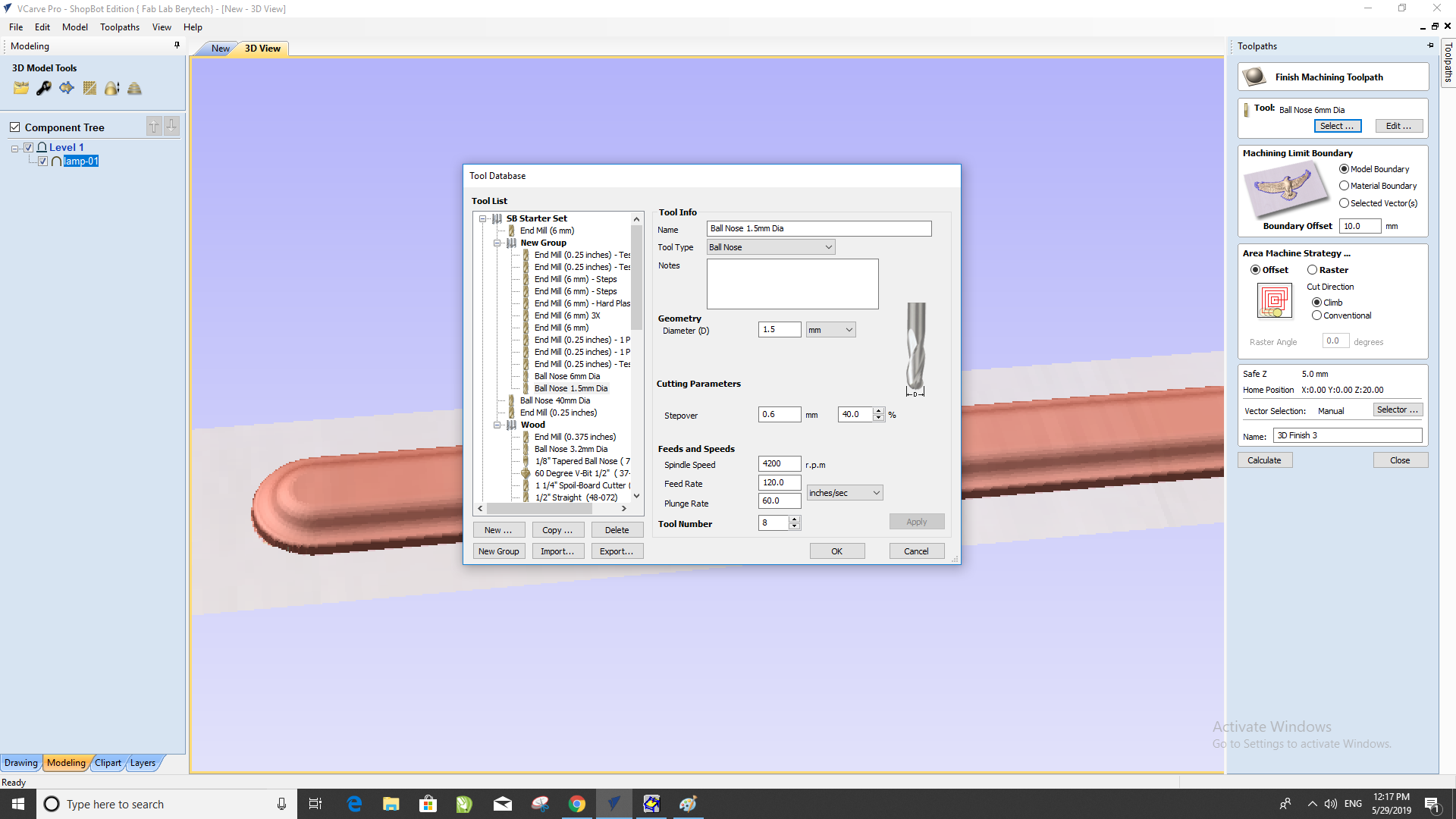

Third step I will do the smoothing with the 1.5mm

And this is the final CNC result

TDS and SDS

Before starting with the resin I had to read the technical data sheet (TDS) and safety data sheet (SDS)of the epoxy resin that i will be using

You can download the data sheet of VIMEPOX BETON-IMP from the following Link

The following is a summary of the Technical Data Sheet.

- Composition: Two-component epoxy system

- Component A: Transparent solvent based epoxy resin

- Component B: Transparent solvent based hardener

- Mixing ratio: A:B = 3.44:1 by weight

- Specific gravity of mixture: (A+B): 0.92 kg/l

- Mixture viscosity: 45 mPa.s at 23 degrees celsius.

- Pot lifeL about 10 hours at 20 degrees celsius

- Can be coated: after 10-24 hours(priming)

- Final strengths: After 7 days at 20 degrees celsius

Always use safety products when working with epoxy resin. Always wear gloves, apron, coveralls, boots, chemical goggles.

VIMEPOX BETON-IMP contains solvents. Make sure that the room is well aired when using it. The hardeners used in epoxy systems are corrosive materials and therefore the persons using them must take protective measures:

The following are the safety warning for both material:

- Wear plastic gloves and protective goggles.

- Avoid eye and skin contact.

- If contact of the resin, the hardener or their mixture with the skin occurs, wipe the material away using a napkin and then wash with soap and water (you may add 2% vinegar).

- Use with ventilation. In case of ill effects, remove to fresh air

- In case of contact with the eyes, wash with plenty of water within the first 10-15 minutes and then visit an ophthalmologist.

- VIMEPOX BETON-IMP is absolutely harmless for your health after hardening.

The execution of the composite

Now I will use the mold to cover it with several layers of fiber and resine

First I start by cutting the fiber layers

Than I will cover the mold with grease

Now I will put the fiber than coat it with resine using a brush.

Now that I finished the resin I should put it in a plastic bag and use a vaccum but the problem is that it is too big and the vaccum suction will not press it enough. So the solution was to press it manually

After curing I removed the mold

And this is the result