This is my way at the Fab Academy, trying to do almost anything

"I do not think there is any thrill that can go through the human heart like that felt by the inventor as he sees some creation of the brain unfolding to success... such emotions make a man forget food, sleep, friends, love, everything."

Nikola Tesla

My name is Alex Tocagon. I'm from Ecuador. I am 28 years old I am indigenous to the Kayambi culture. I am the second of 5 brothers. I graduated from the University in the career of Mechatronics, since I was a child I liked to discover, create and understand technology. What is behind a small toy? I know I have a lot to learn and also many things to share, that's why I'm at the Fab Academy.

Build a personal site describing you and your final project.

Upload to the class file. Work with a git tutorial

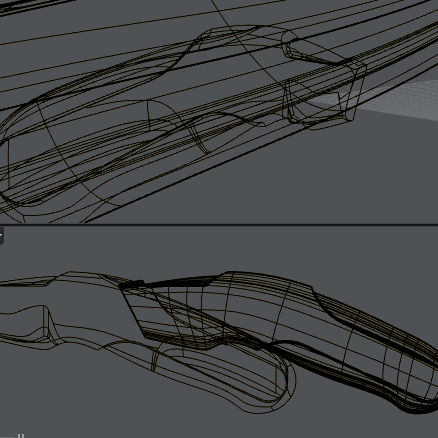

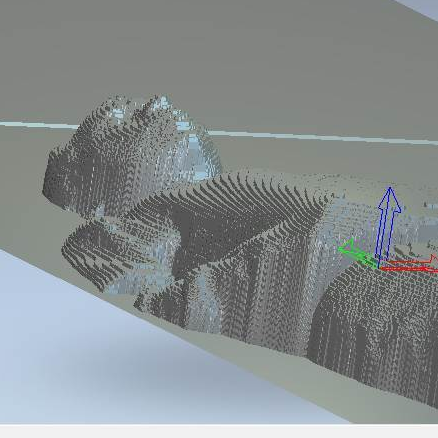

Model (draw, render, animate, simulate, ...) a possible final project, and post it on your class page with original 2D and 3D files.

Evaluate and select 2D and 3D software

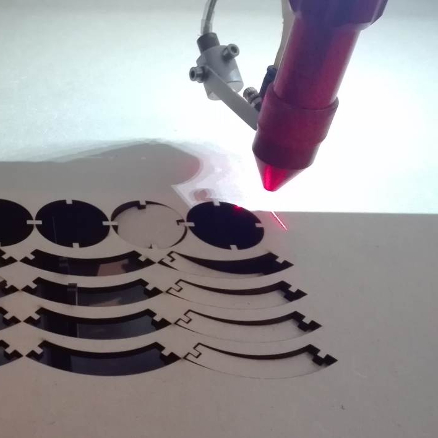

Characterize your lasercutter, making lasercutter test part(s), making test part(s) that vary cutting settings and dimensions(group project)

Cut something on the vinylcutter

Design, make, and document a parametric press-fit construction kit, accounting for the lasercutter kerf, which can be assembled in multiple ways

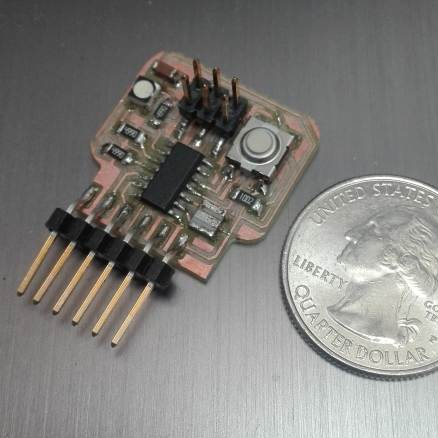

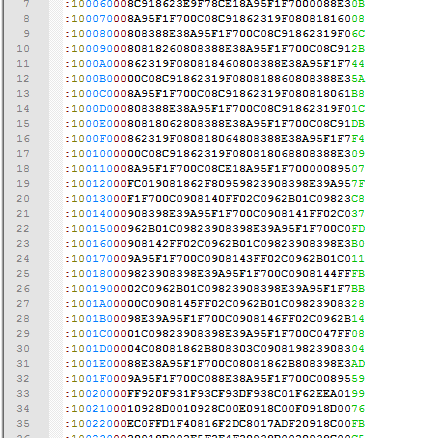

Characterize the specifications of your PCB production process

Make an in-circuit programmer by milling the PCB (program it, so that you can use it to program your board in Electronics Design week, and in other weeks)

Optionally, trying other processes.

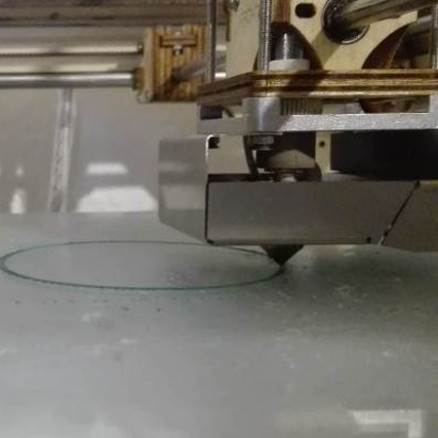

Test the design rules for your 3D printer(s)

Design and 3D print an object (small, few cm) that could not be made subtractively

3D scan an object (and optionally print it)

Use the test equipment in your lab to observe the operation of a microcontroller circuit board

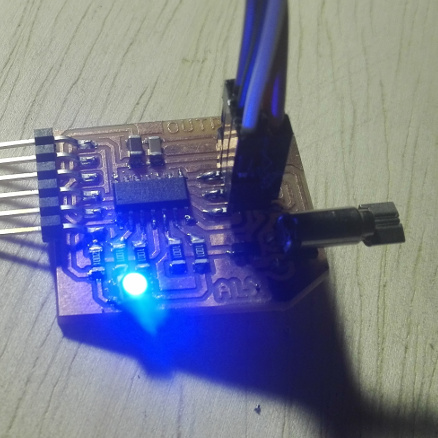

Redraw the echo hello-world board,add (at least) a button and LED (with current-limiting resistor),check the design rules, make it, and test it

Extra credit: simulate its operation and render it

Test runout, alignment, speeds, feeds, and toolpaths for your machine

Make something big

Read a microcontroller data sheet

With as many different programming languages and programming environments as possible

Compare the performance and development workflows for other architectures

Review the safety data sheets for each of your molding and casting materials, then make and compare test casts with each of them

Design a 3D mold around the stock and tooling that you'll be using, machine it, and use it to cast parts

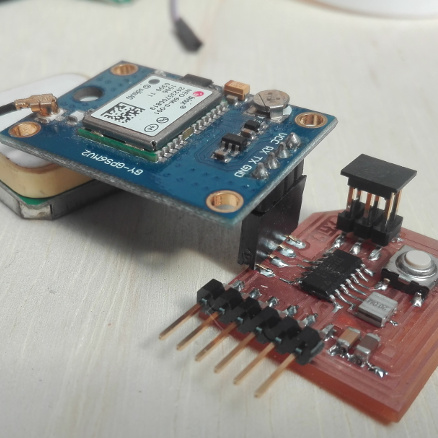

Measure something: add a sensor to a microcontroller board that you have designed and read it

Measure the analog levels and digital signals in an input device

Add an output device to a microcontroller board you've designed, and program it to do something

Measure the power consumption of an output device

Write an application that interfaces with an input &/or output device that you made

Compare as many tool options as possible

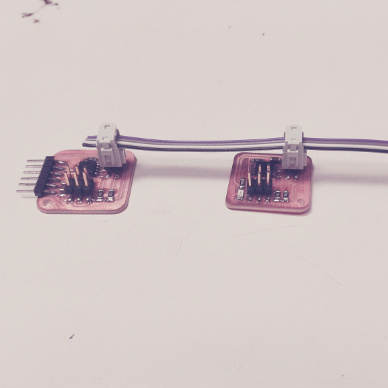

Design and build a wired &/or wireless network connecting at least two processors

Send a message between two projects

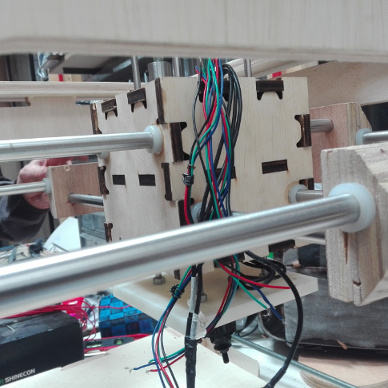

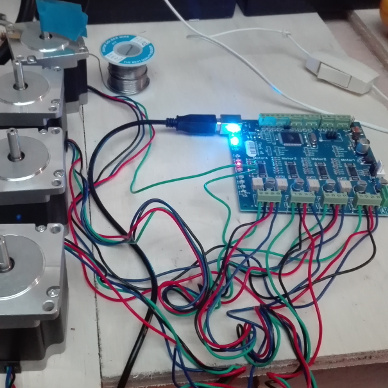

Design a machine that includes mechanism+actuation+automation

Build the mechanical parts and operate it manually

Document the group project and your individual contribution

Actuate and automate your machine.

Document the group project and your individual contribution.

Design and produce something with a digital fabrication process (incorporating computer-aided design and manufacturing) not covered in another assignment, documenting the requirements that your assignment meets, and including everything necessary to reproduce it. Possibilities include (but are not limited to) composites, textiles, biotechnology, robotics, and cooking.

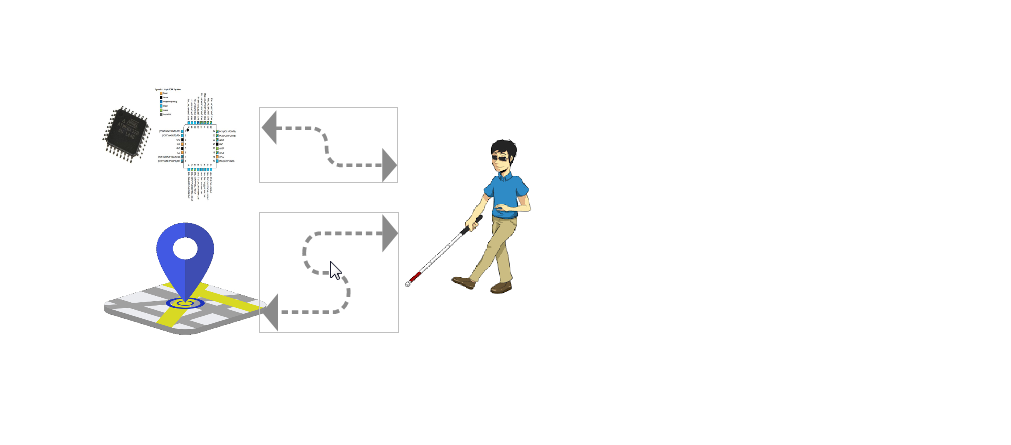

Propose a final project that integrates the range of units covered.

Develop a plan for dissemination of your final project

prepare a summary slide (presentation.png, 1280x1024) and video clip (presentation.mp4, 1080p HTML5, ~minute, ~10 MB) in your root directory