After I wrote the text using fusion 360 I made extrude then I went to the CAM process in fusion, then I used 2D pocket, the material that I want to mill is cupper so in order to mill the material I have to know the speeds limits or the recomended speeds.... to calculate the speeds for the bit that I want to use which is 3/32" flat 2 flutes carbide endmill

I have the table below

for copper the SFM (V) is 900 so if we calculate the RPM depending on V we get:

RPM= (12*V)/(3.14*Diameter of the tool) //D=3/32 and V=350-900 so we get RPM of aproximatelly 11000-36000rpm .. in order to calculate the feed rate we use this equation :

Feed= RPM*numberof flutes*chip load..... Feed=(11000-36000)*2*.001= (10-72) inch/min

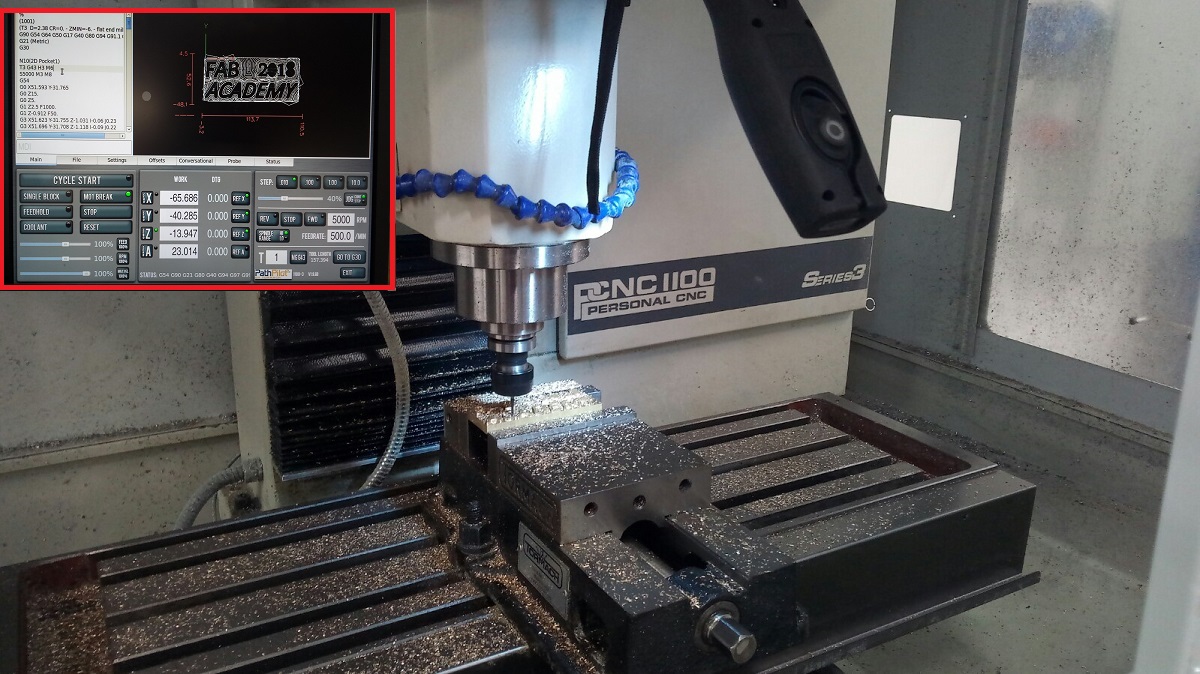

I used the maximum RPM of 5000 and feed rate of 34in/min = 800mm/min

And this is the generated tool path

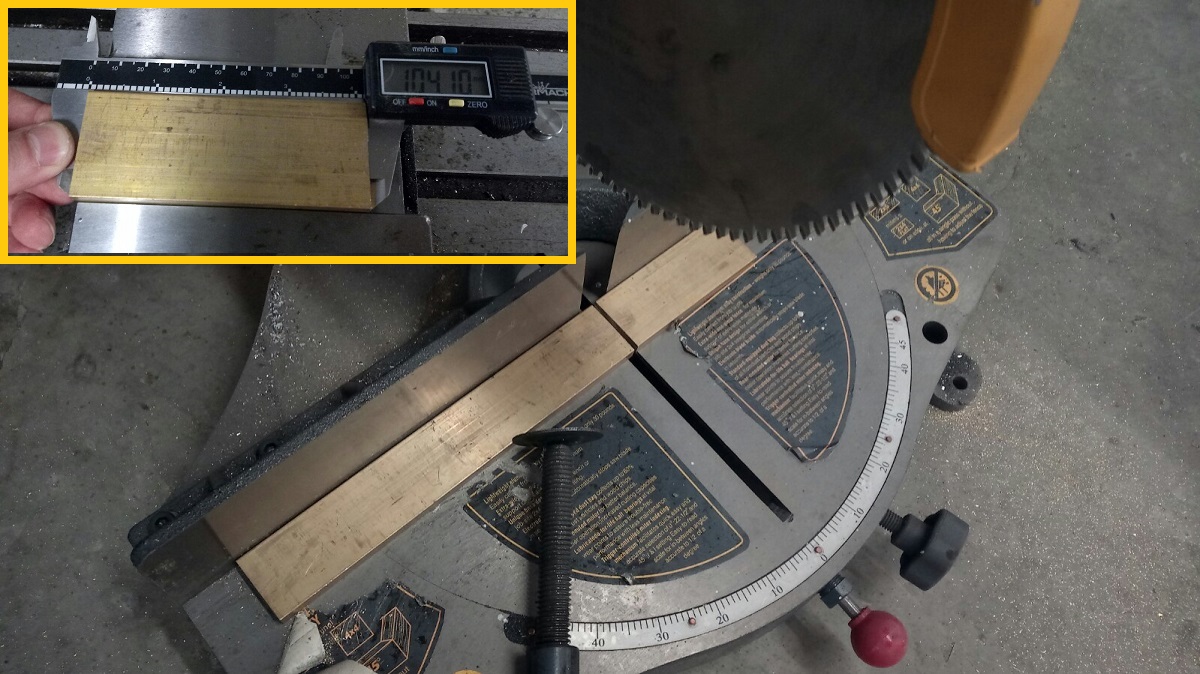

then I used a manual saw to cut the raw material as the same as the dimension of my design 104mm*40mm

After I put the work piece in the machine holder and I set the x and y zero and z axis zero and then si started the milling operation

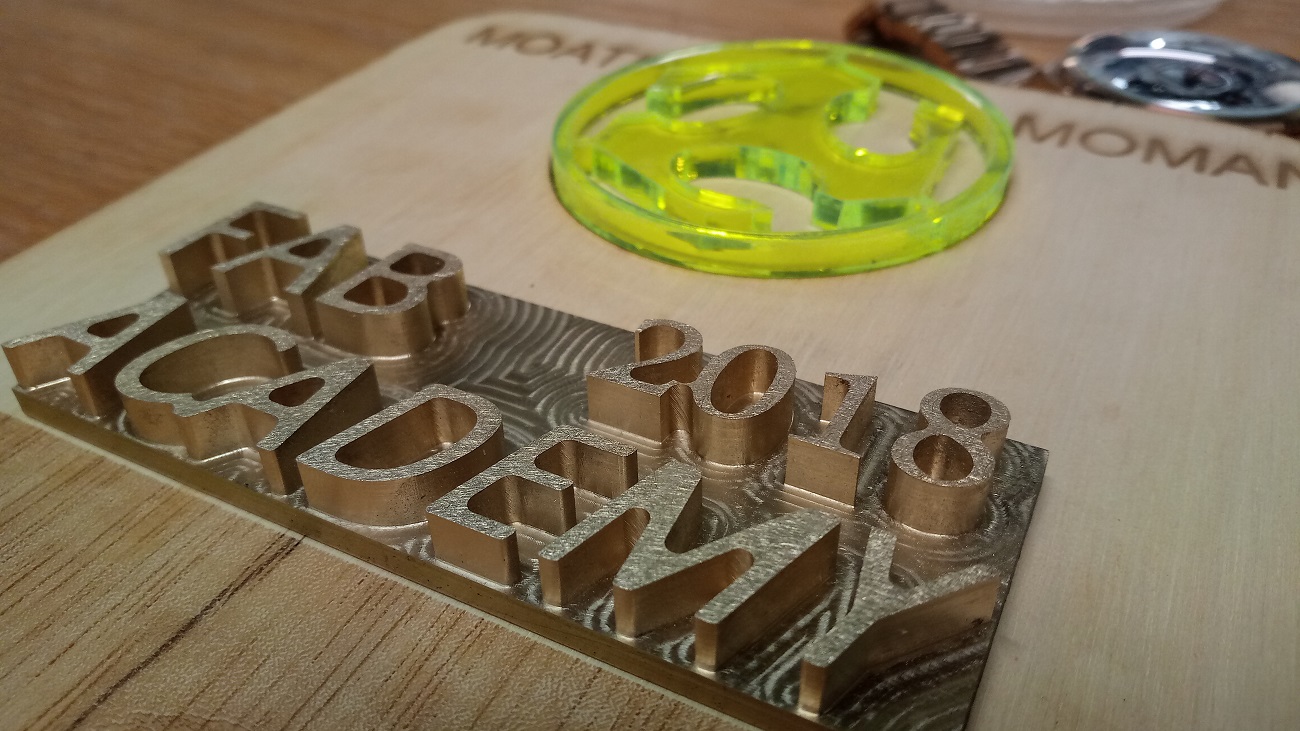

And this is the final workpiece :D

After I have finished the milling its the time to start working on laser cutter but first I need the design so I used SolidWorks to design the fab academy logo, so I made a sketch from a picture of the logo then I saved it as DXF because after I want to make the logo of fab academy of acrylic then I want to make the top and buttom for the graduation book from plywood, at the top plate of the plywood I want also to make engraving of a picture by the laser, so lets start with the logo ..

After the logo I designed the top plate

And the buttom plate

Now I saved them as DXF then I went to CorelDraw

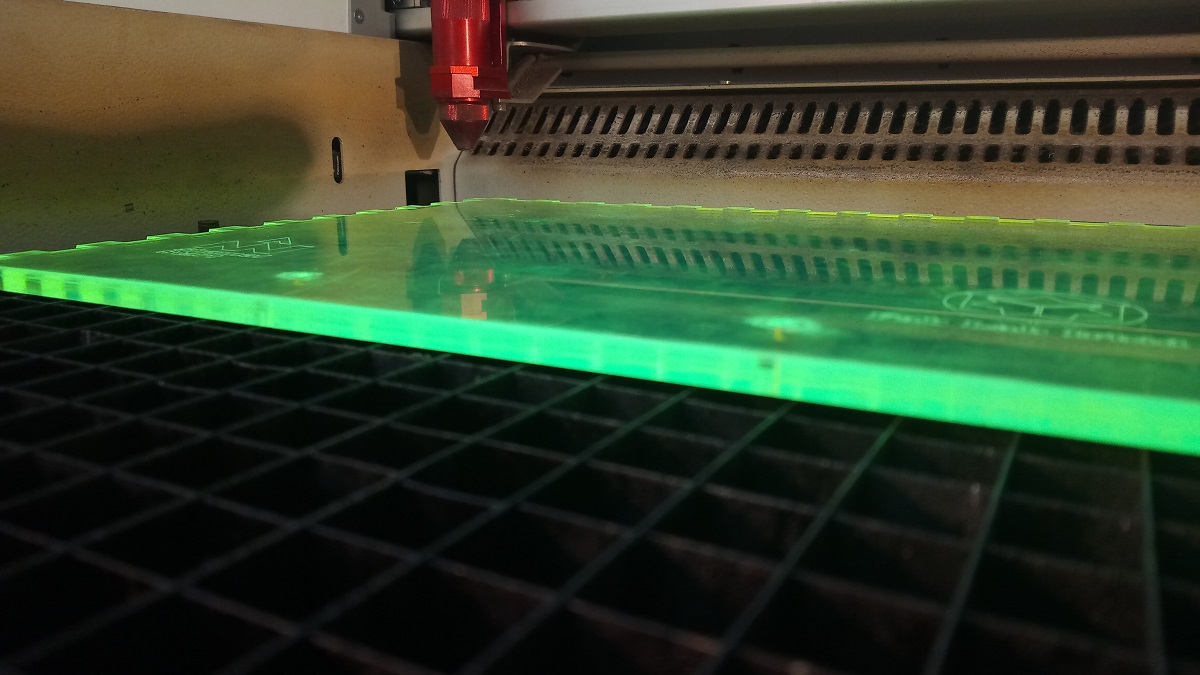

in order to set the color RGB 255,0,0 which mean full red color, and then print the job to trotec engraver machine

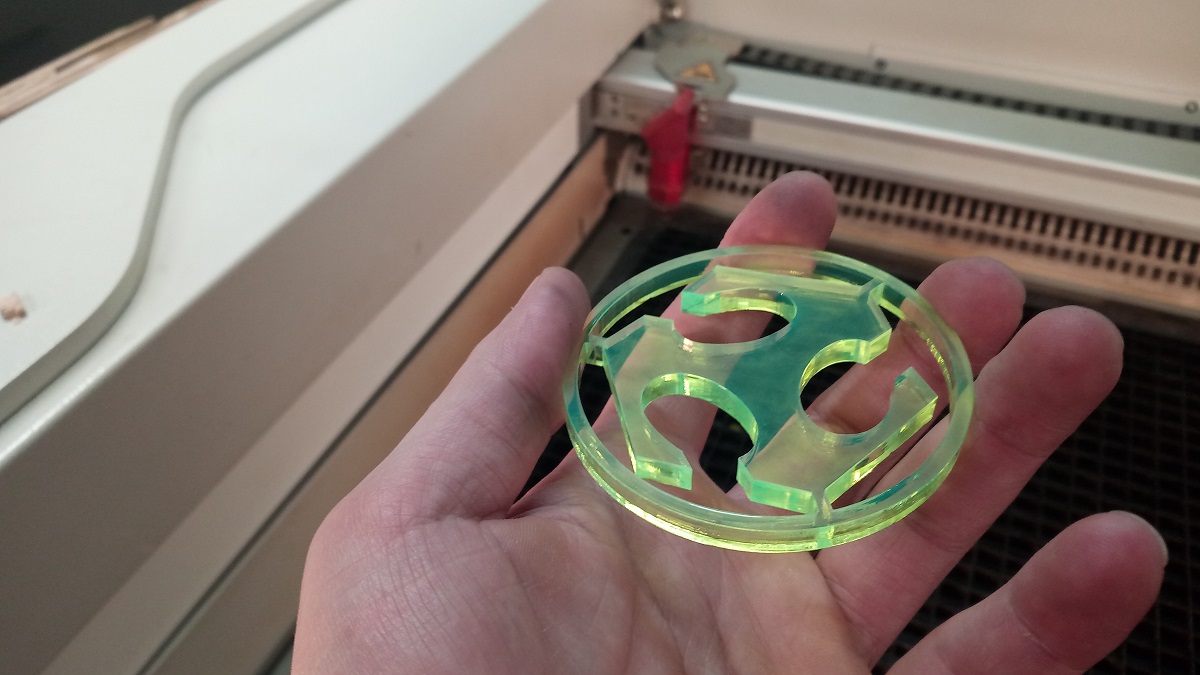

The raw material is green transparant acrylic of thickness 6mm so I used the following cutting variables in laser :

Power 100%

Velocity 0.4

frequency 55000

and the final result was pretty good!

Now I will cut the top plate of the plywood but before I want to add some edits like engraving a picture on the wood, to do that I chose A good picture and I make the color of it black and white/ stucki.

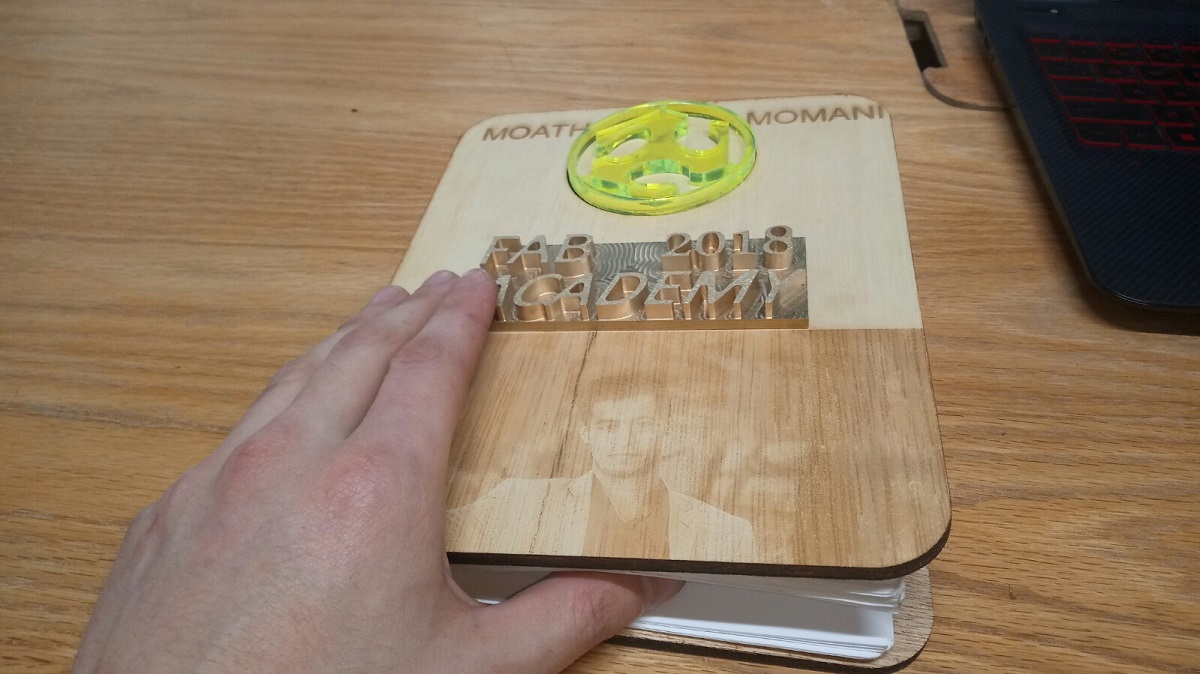

then I added the picture to the wood plate desing and also I put a circle to replace it with the acrylic one.

For the plywood of 6mm thickness I used the following cutting variables

Power 100%

Velocity 0.6

frequency 2000

and the final result was pretty good!

and this is my final fab academy book :D

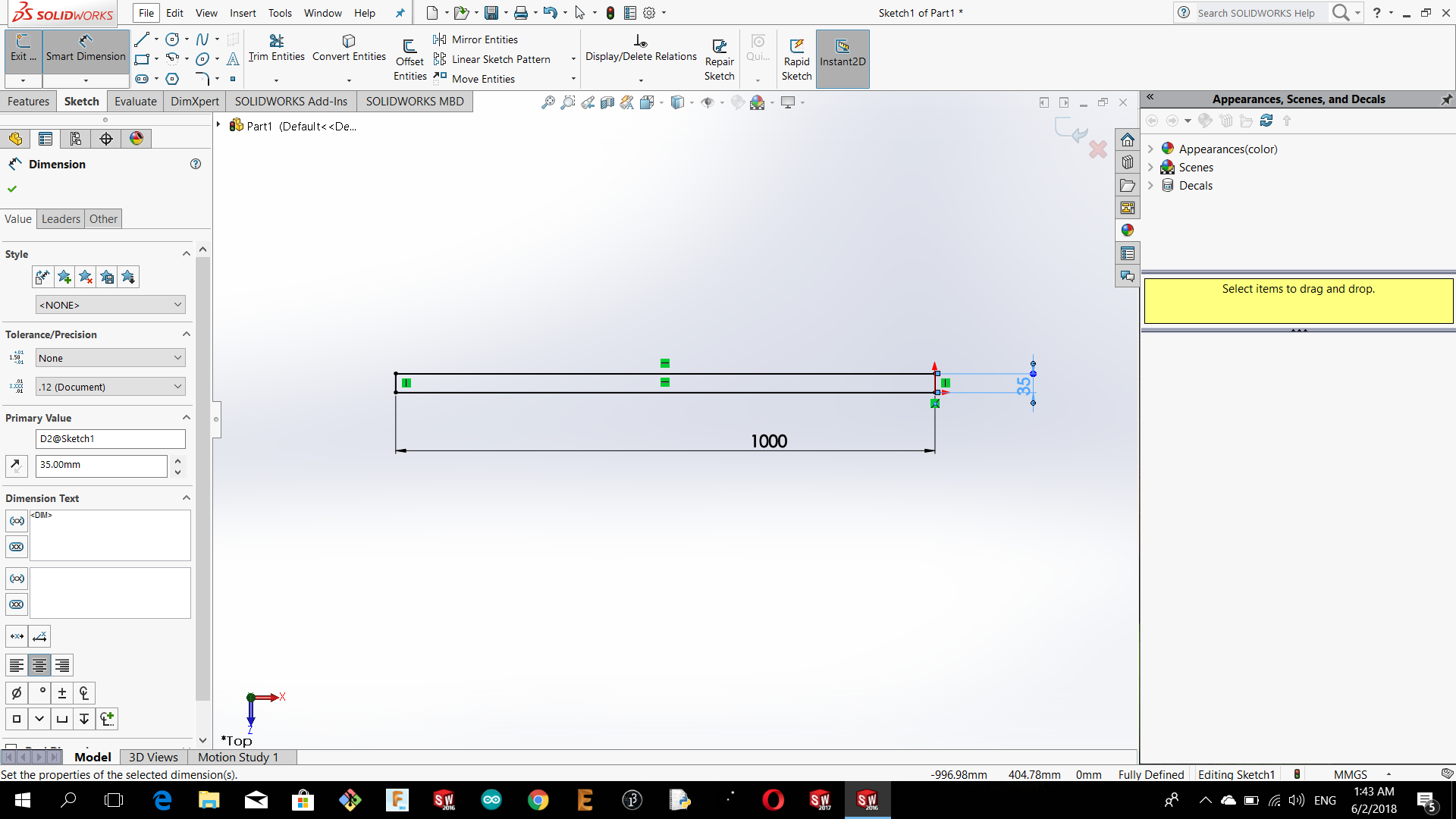

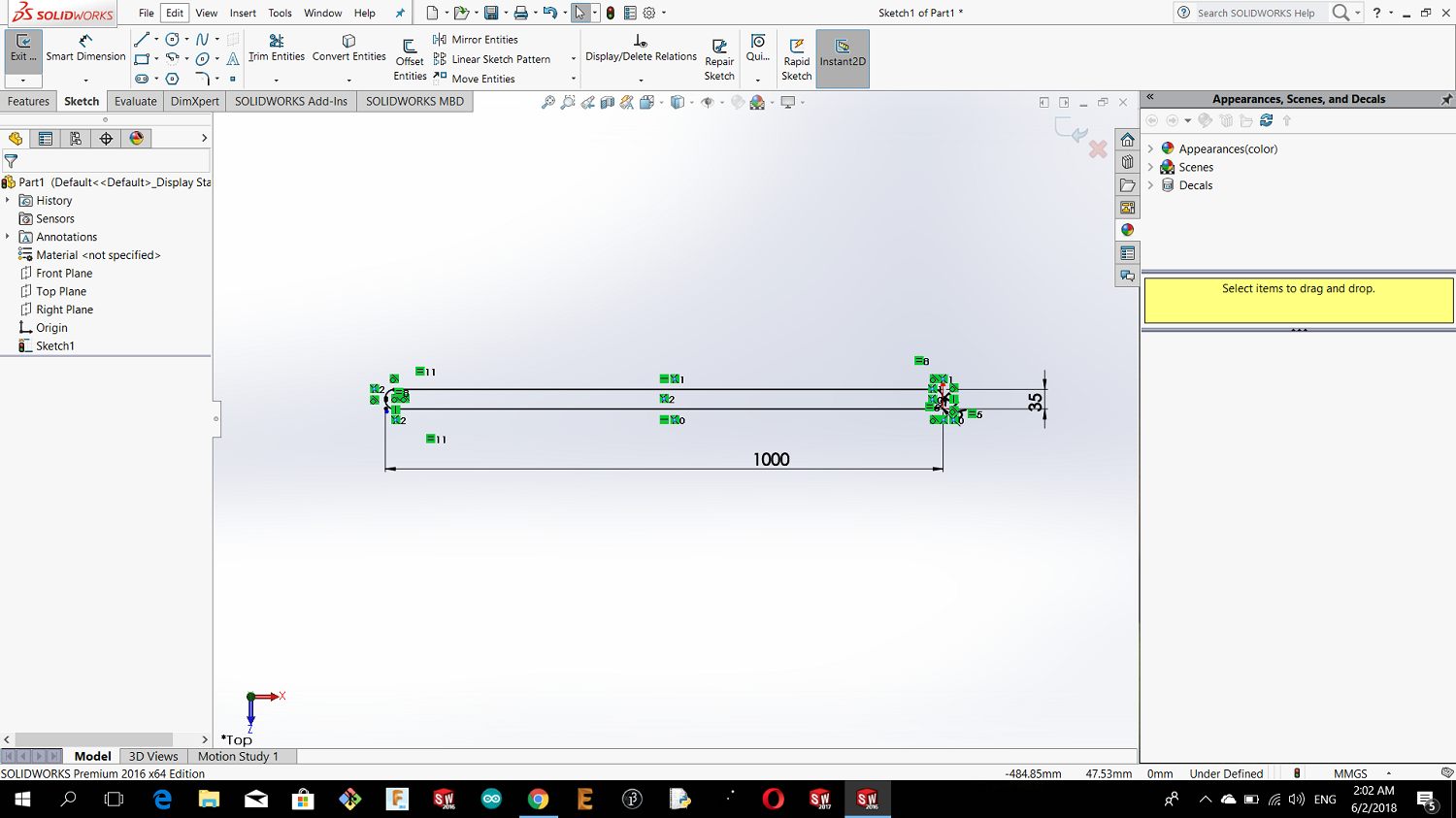

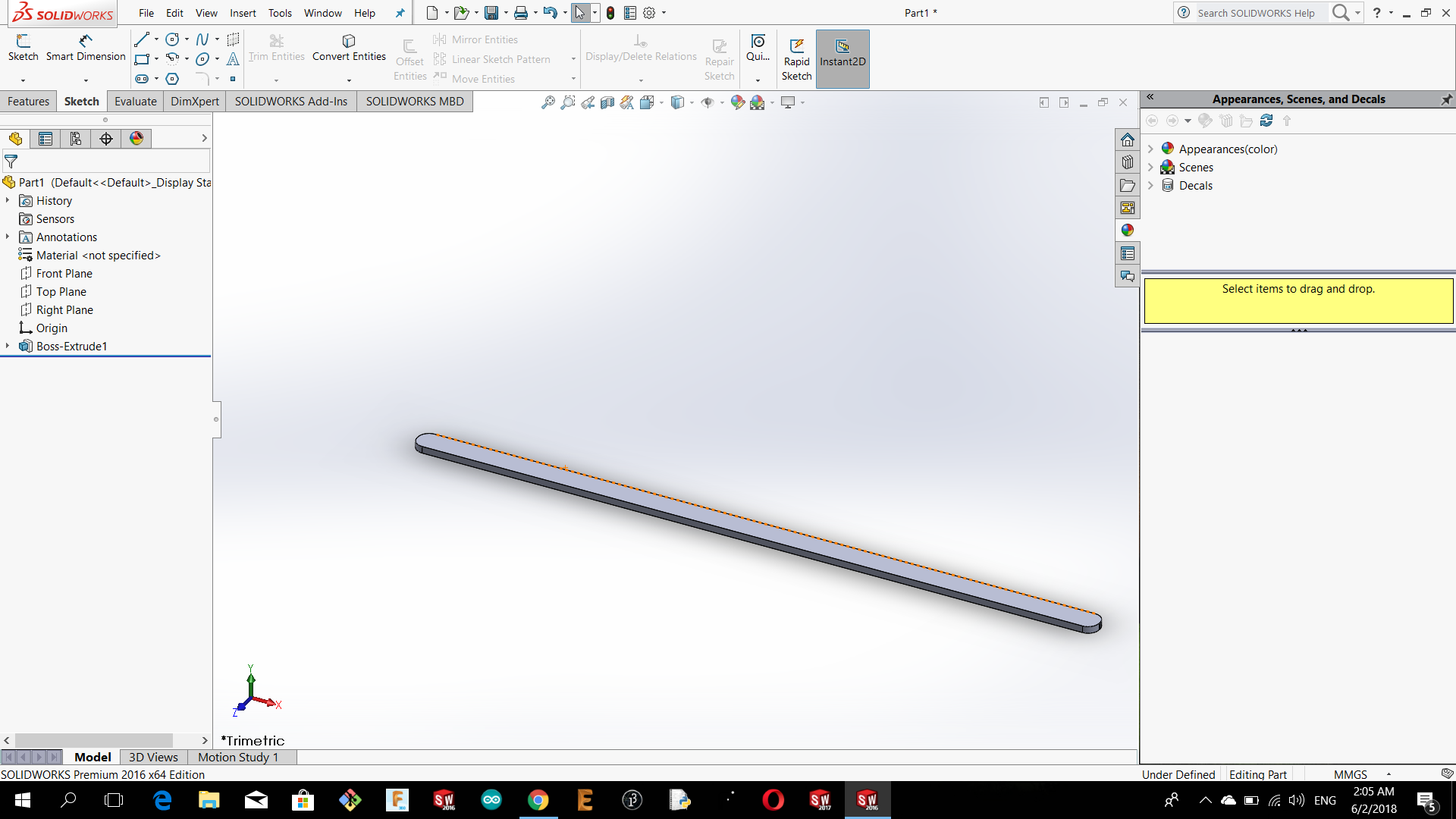

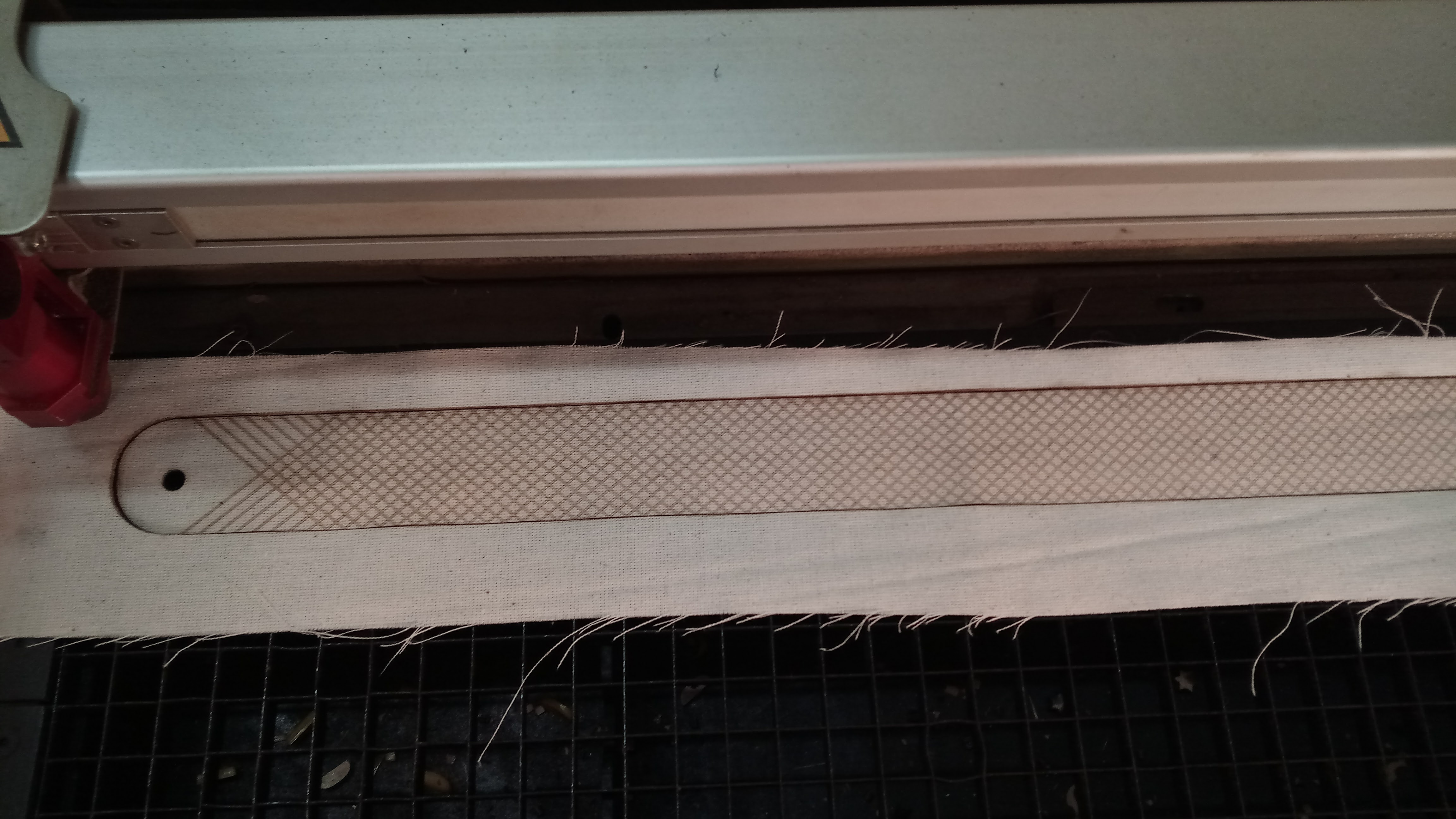

Now I'm going to make a belt from fabric then I want to engrave on it using laser, first I start the design using solid works by 2d sketch to make a rectangle as the following dimension

Then I made a fillet

Then extrude

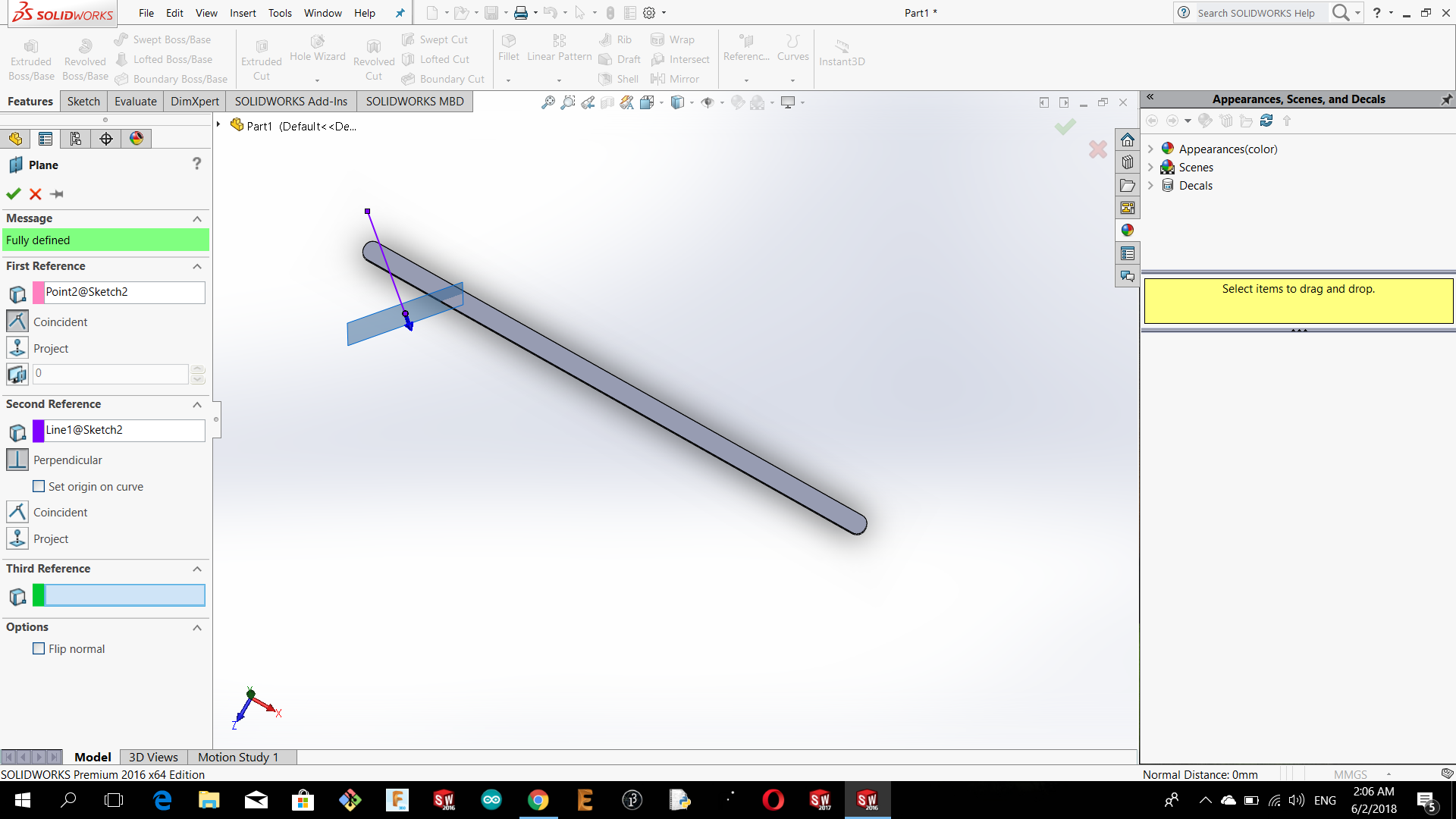

After, I made a line and a new plane perpendicular on it in order to sketch a triangle

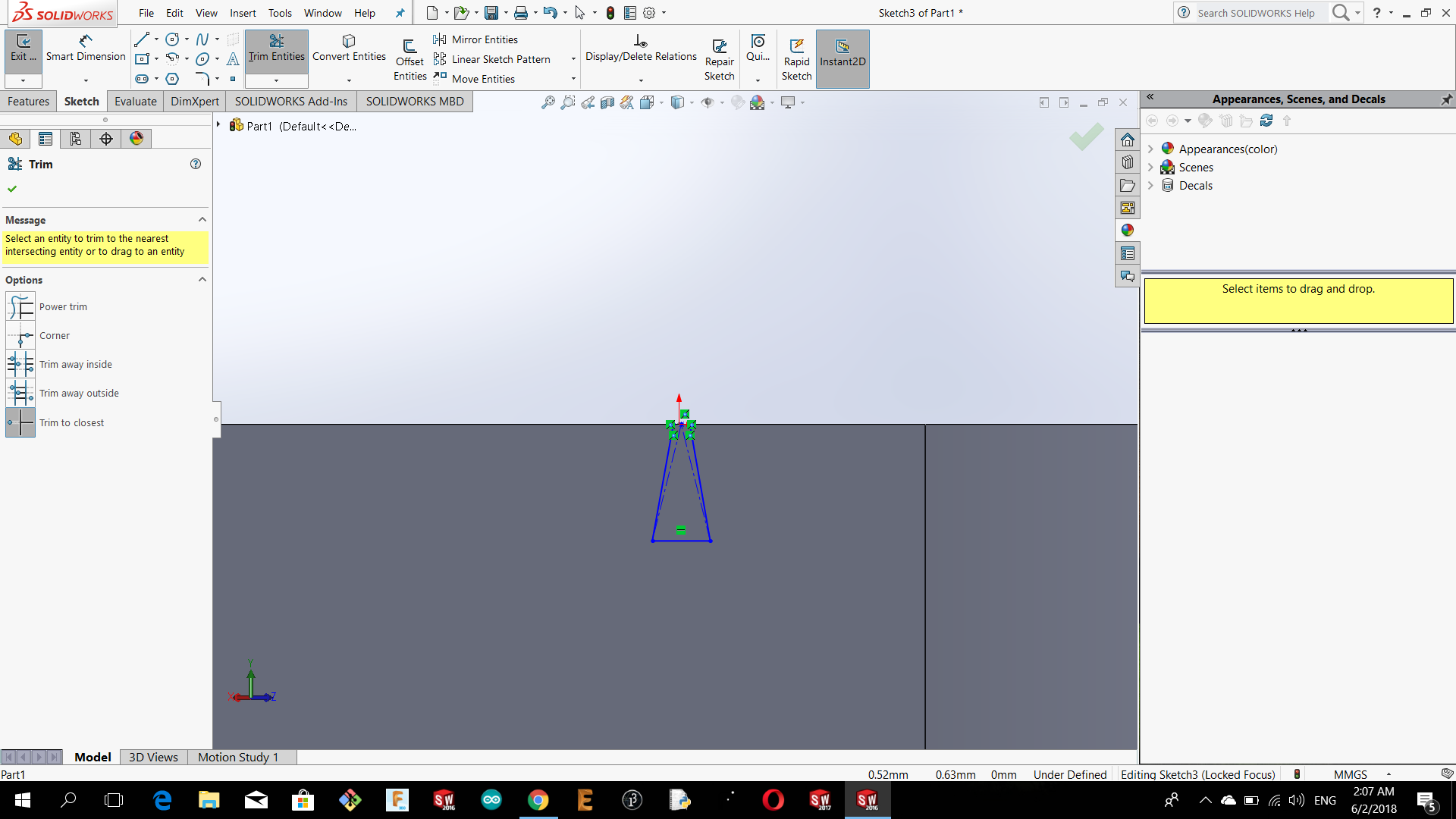

Then, I draw this sketch in the new plane

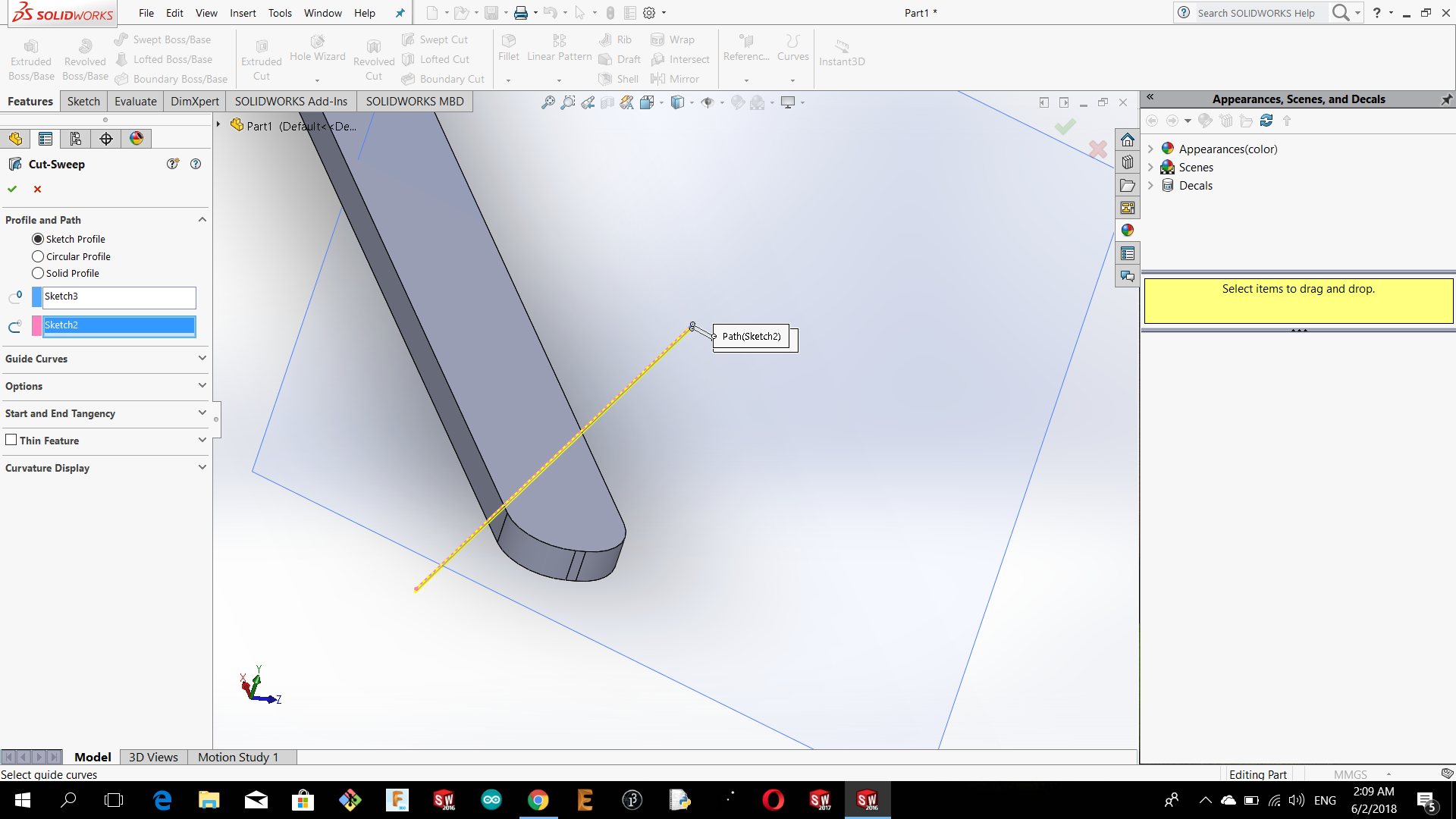

Here I made a sweep cut

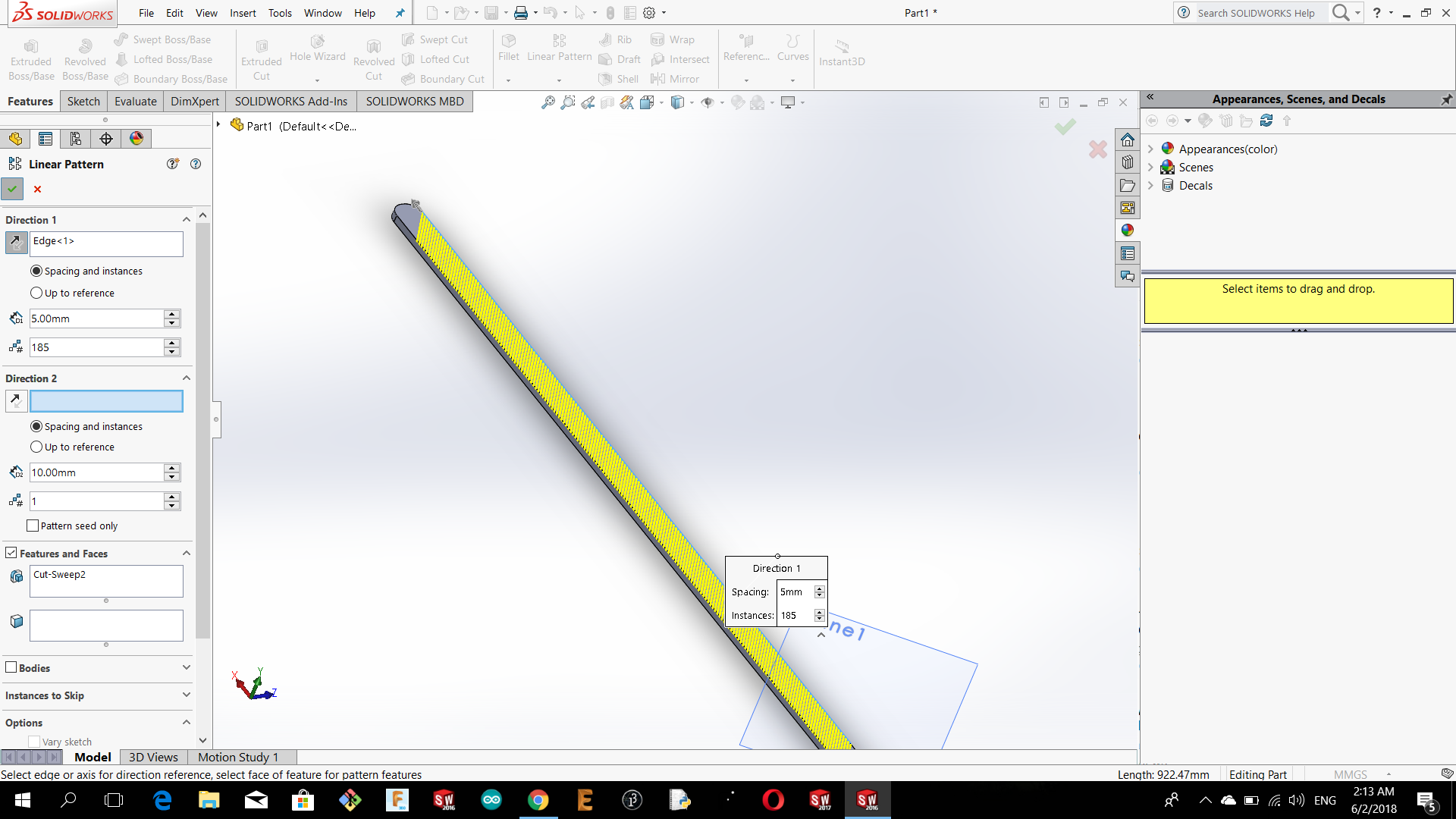

Here I made a linear pattern on x direction

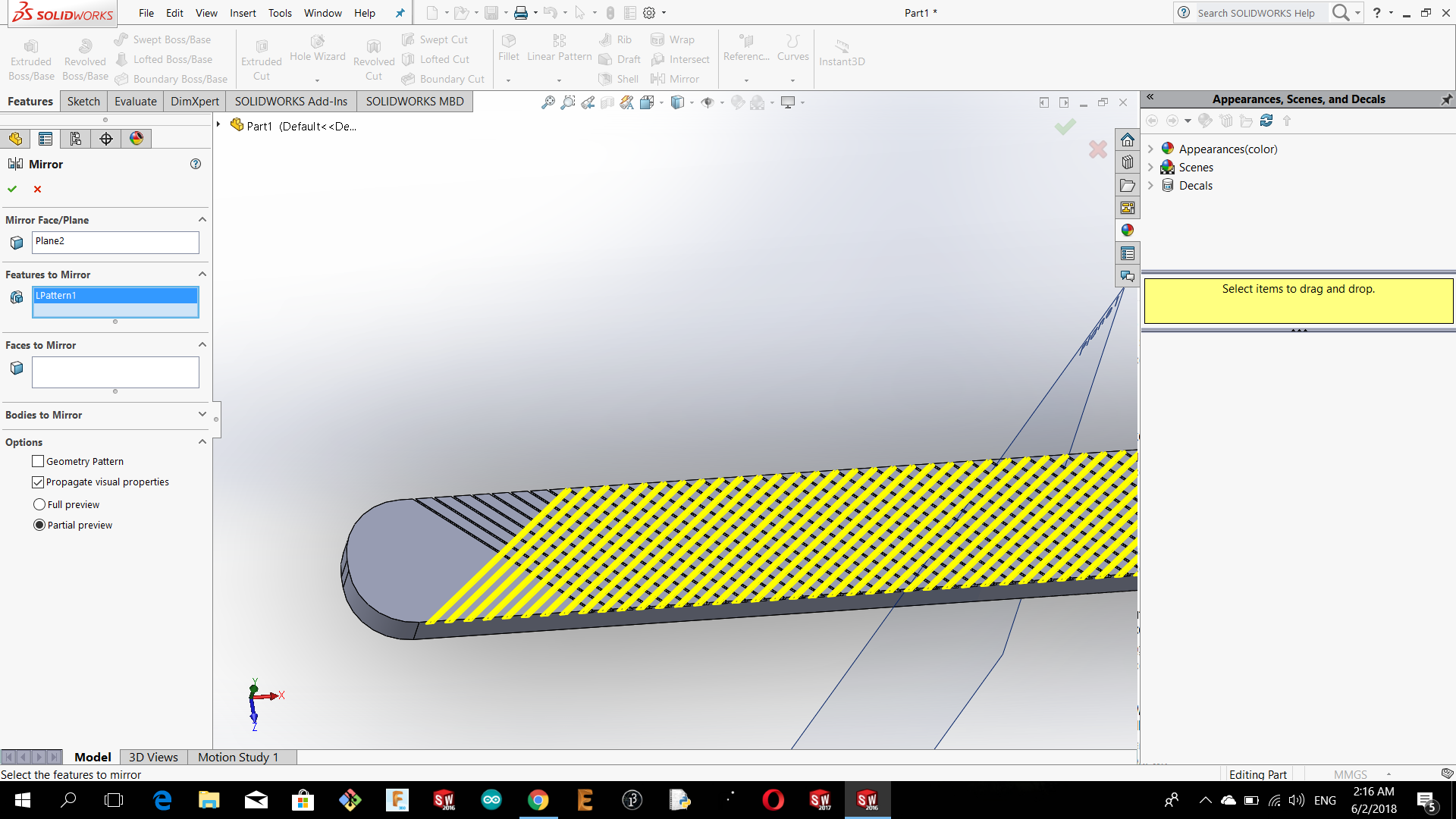

Now I made a perpendicular plane in the center of the model then I made mirror about it in order to make the knurling

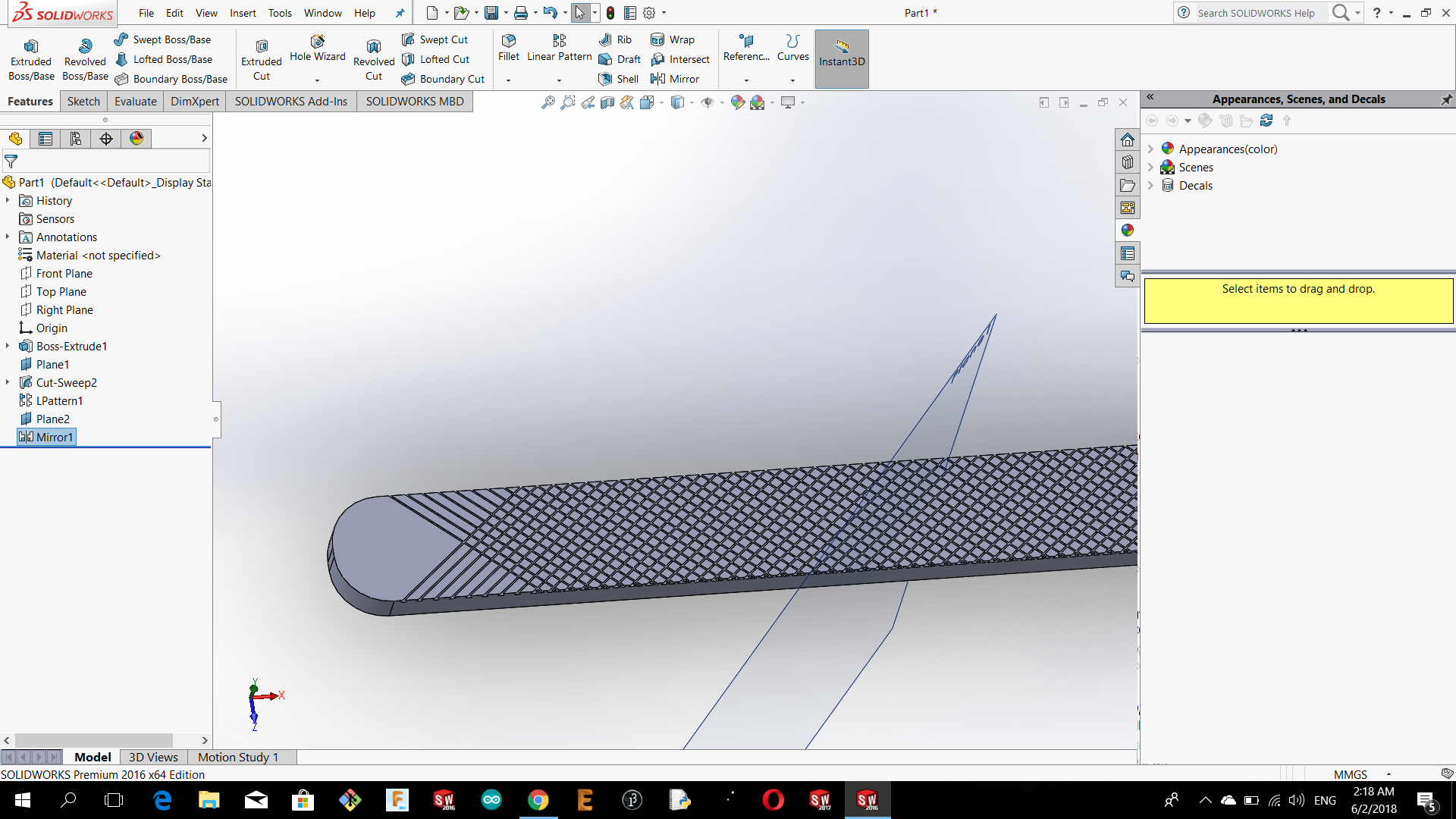

Here is the knurling

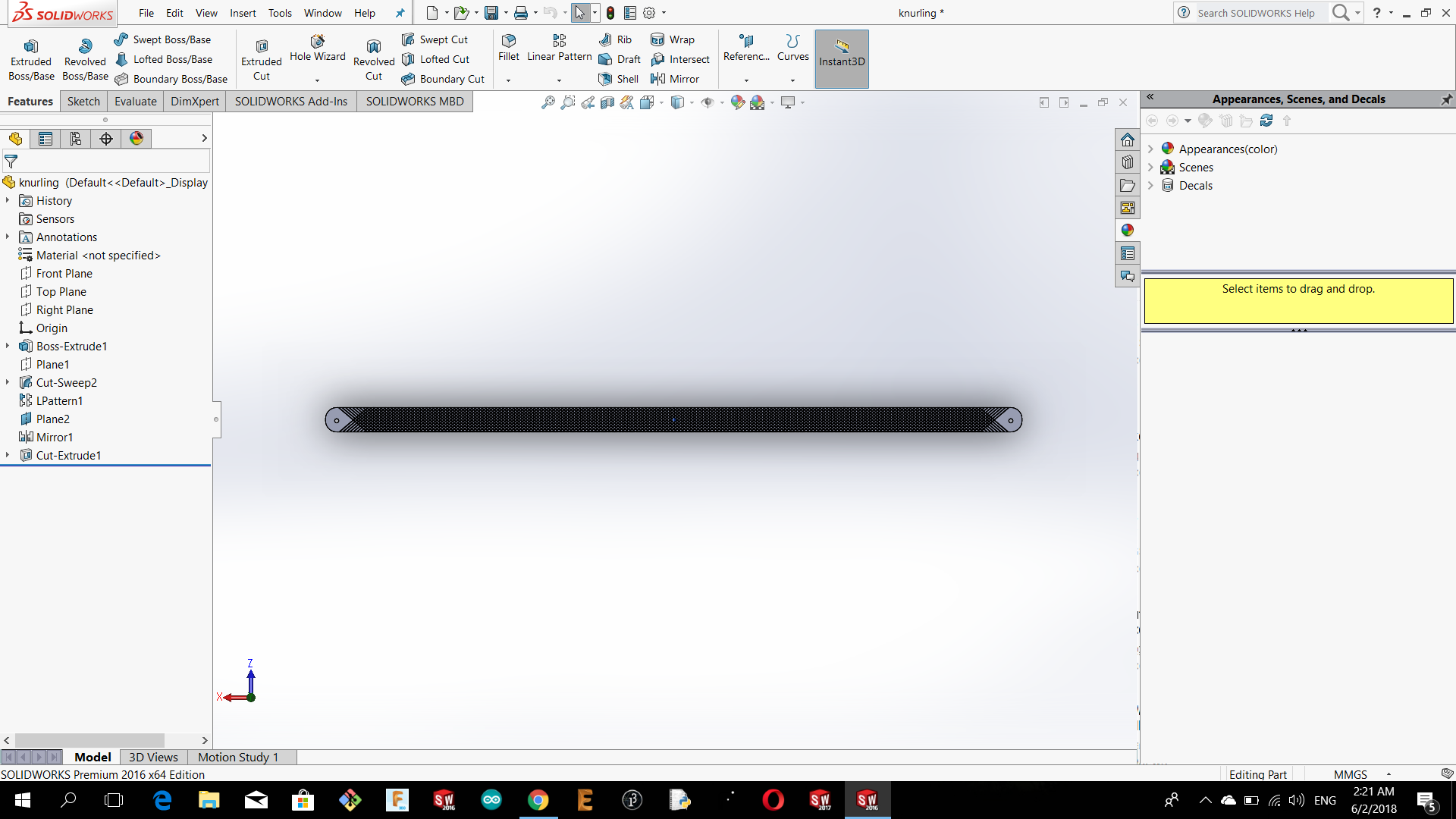

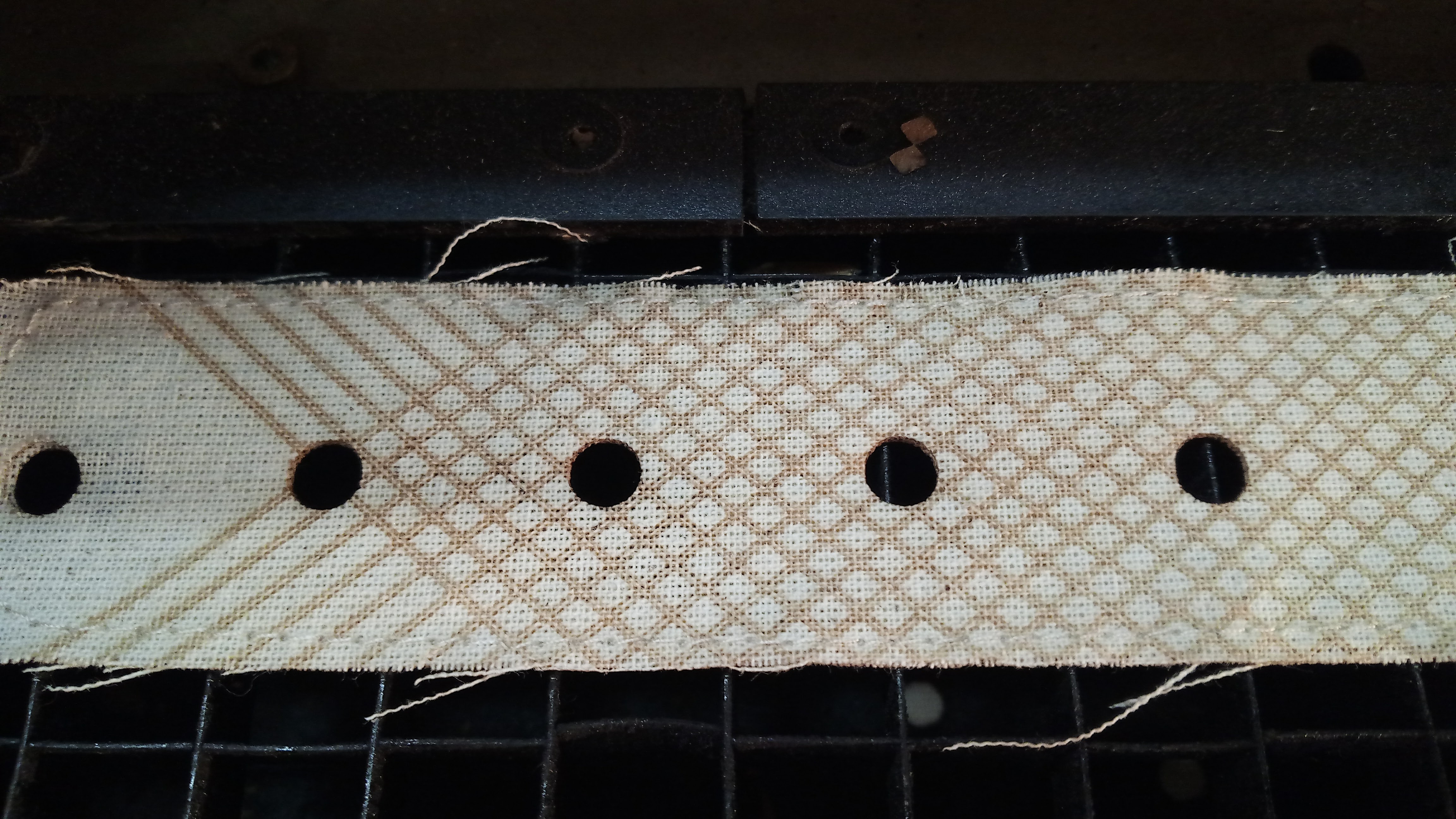

I made some holes as shown and I saved the design as DXF in order to open it on corel draw software

Now I start working on corel draw to change the colors to RGB red for cut and black for engraving

I forget to make more holes so I made them here

Here is the fabric belt

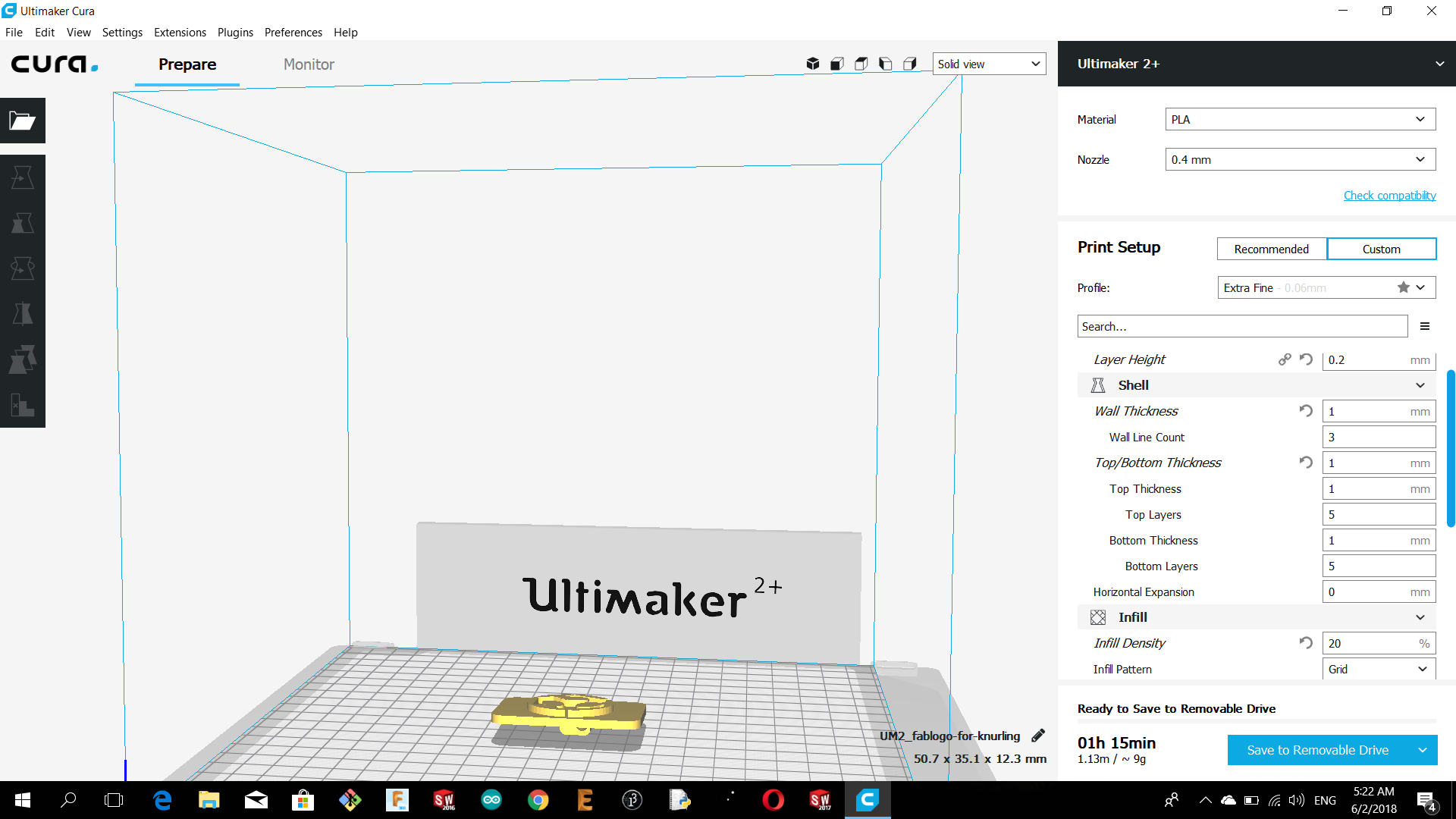

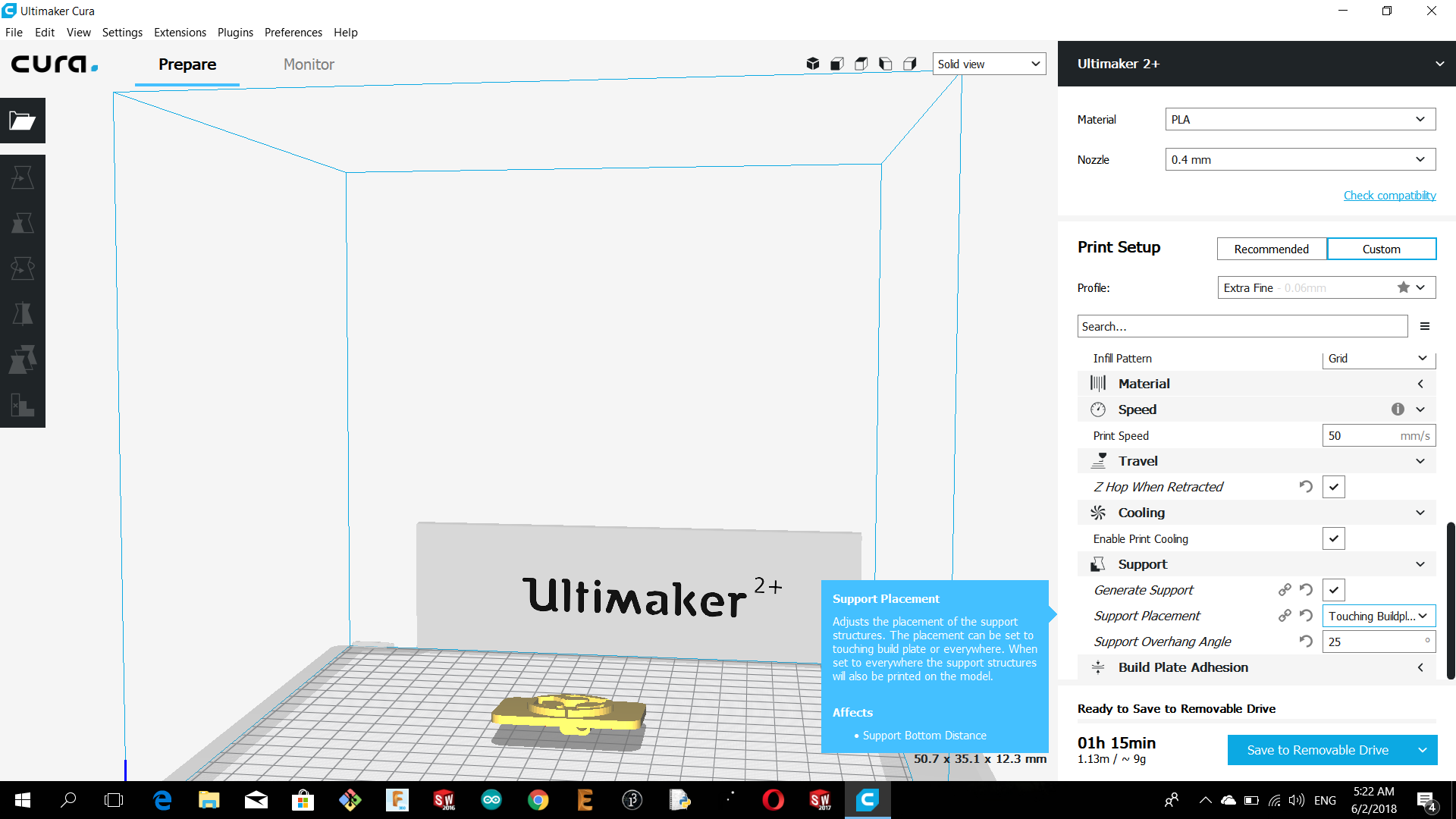

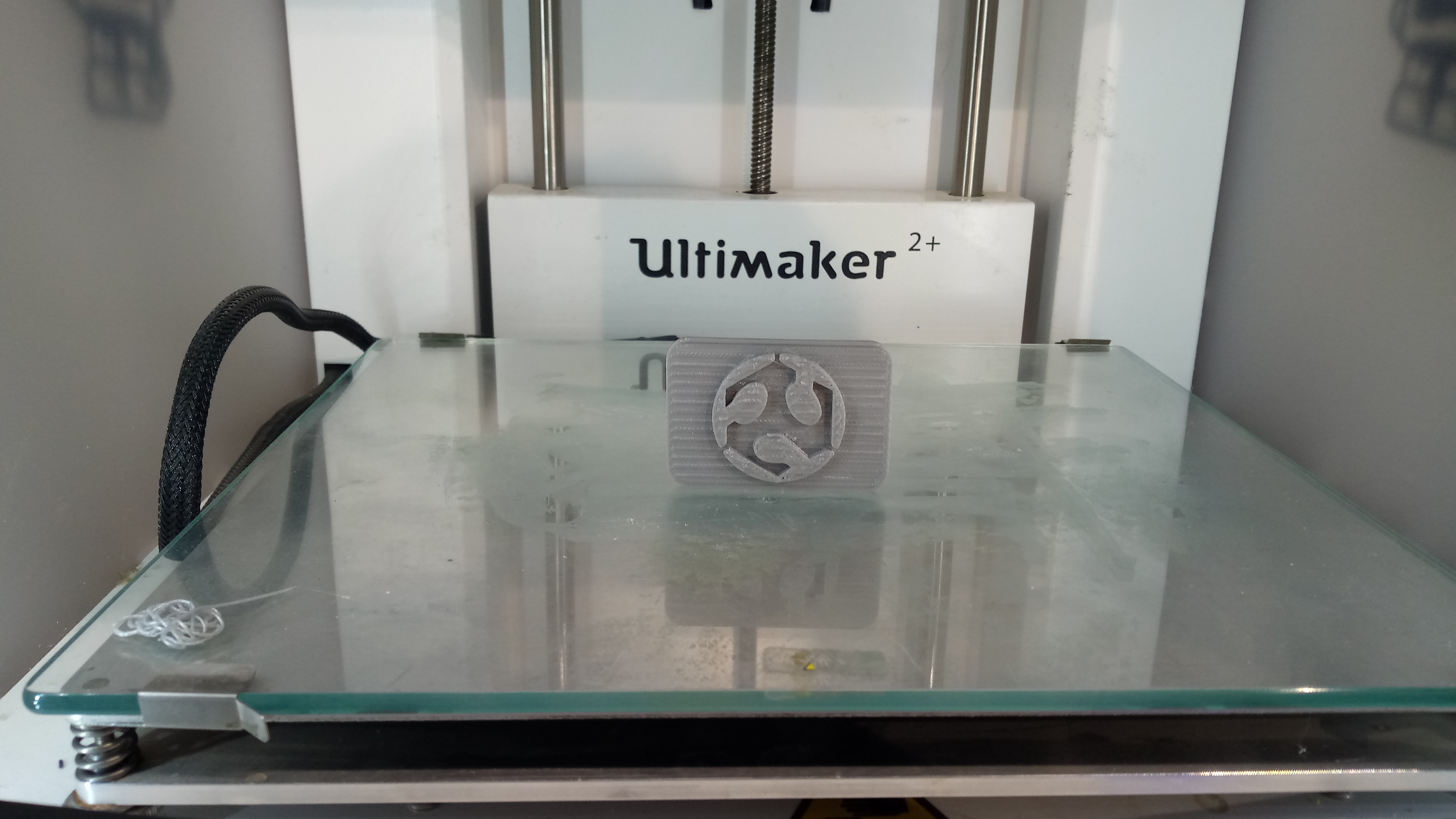

Now I want to make a 3D printed holder for the belt so I make a rectangle and I designed the fab logo on it

With Ultimaker 2+ I used this printing variables

After more than hour I got my pretty printed piece :D

Finallyyyyyyyyyyyyyyyy this is the belt

Download

Fab academy logo DXF and SLD part

Belt with knurling DXF and SLD part

Belt holder STL and SLD part