| This week | |

|---|---|

| Presentation mechanical design | http://academy.cba.mit.edu/classes/mechanical_design/index.html |

| video of the review (networking and communications) | http://archive.fabacademy.org/archives/2018/lectures/fab-20180502.html |

| video of the recitation on mods | http://archive.fabacademy.org/archives/2018/lectures/fab-20180507.html |

| Assignment | Used software | Files/Downloads/links |

|---|---|---|

| group assignment | design a machine that includes mechanism+actuation+automation | group page |

| build the mechanical parts and operate it manually | ||

| document the group project and your individual contribution | ||

| slots | FreecAD | slot.fcstd |

| housing | Inkscape | tubeblock+holders_6mm.svg |

tube extractor

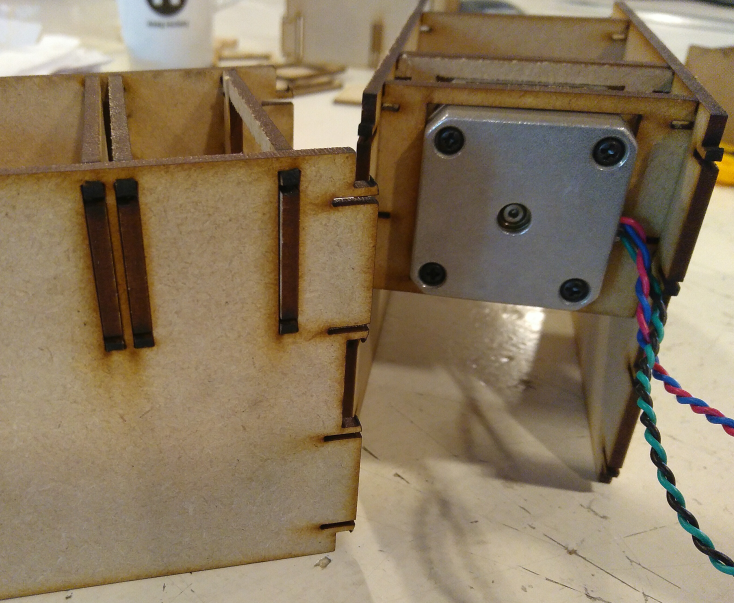

For our machine i designed the tube extractor.

Things i wanted to learn this week:

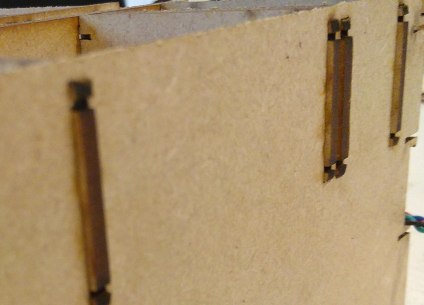

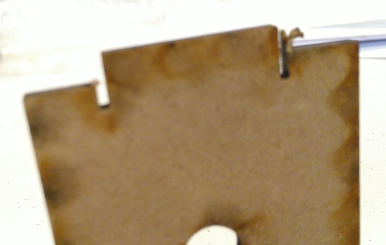

- how to make a presfit with joints

- how to design and redesign fast

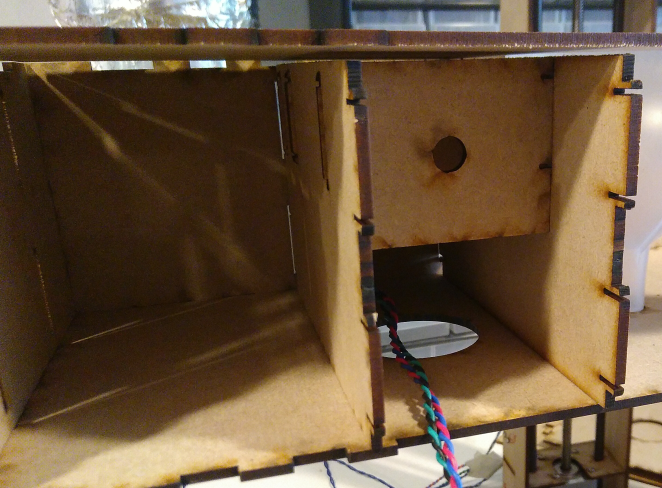

At the end i should have a tube extractor for our machine. And because images say more than words, and because of fun, i will show the final result:

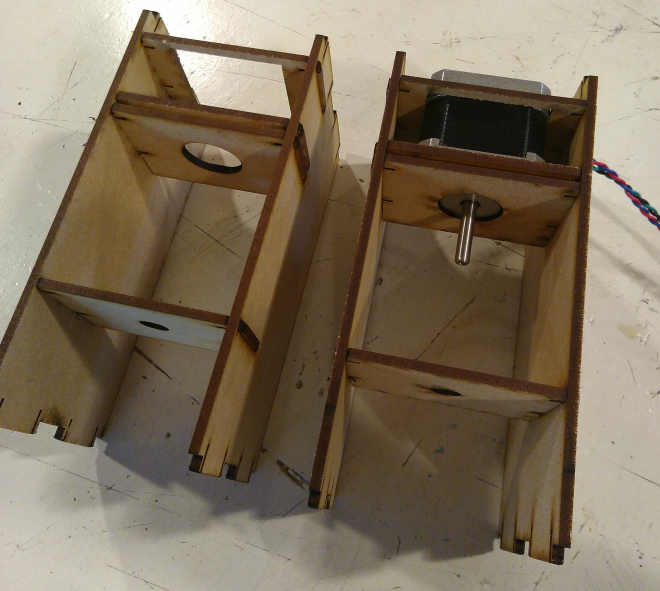

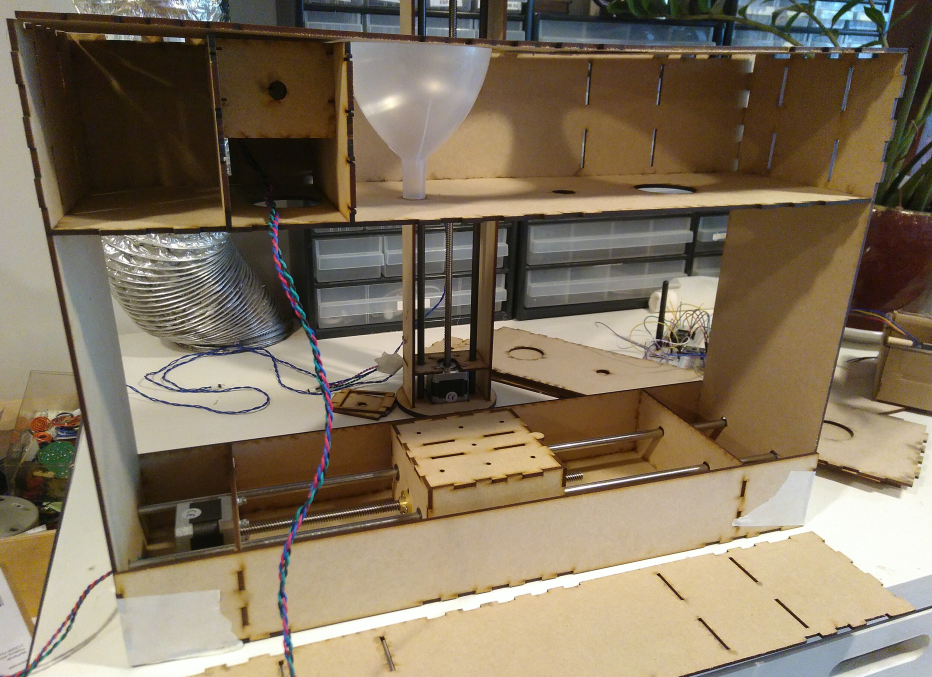

So as you can see, a tube extractor extracts in this case ketchup out of a tube. It’s done by using a steppermotor. The motor rotates half a revolution and so extruding the ketchup out of the tube.

The motor is in a housing i will design this week.

workflow

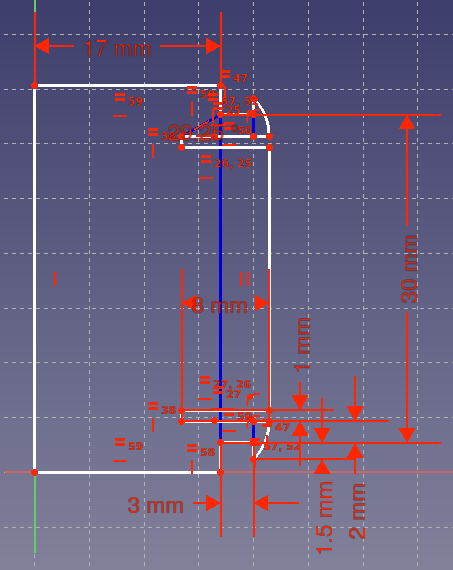

I did the main design in inkscape. The presfit with joint i made in freecad, because it was the most complex part, that i also wanted to make parametric.

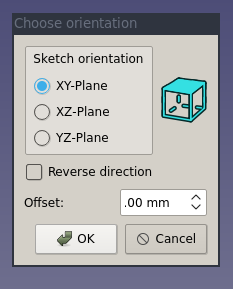

After making the part fully constrained, i had problems exporting it to dxf. The part came out as a flat line. So after some guessing, i figured out it had to do with the orientation of the plane used in freecad. So i had to change planes. It took me a while to figure out where to do it in freecad. It finally found it under parts design menu.

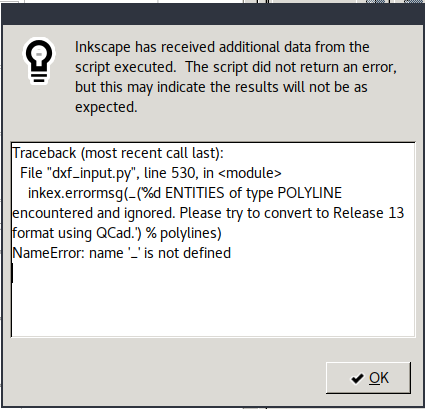

The file was exported to dxf and then imported in inkscape. Inkscape however give an error when importing dxf files from freecad.

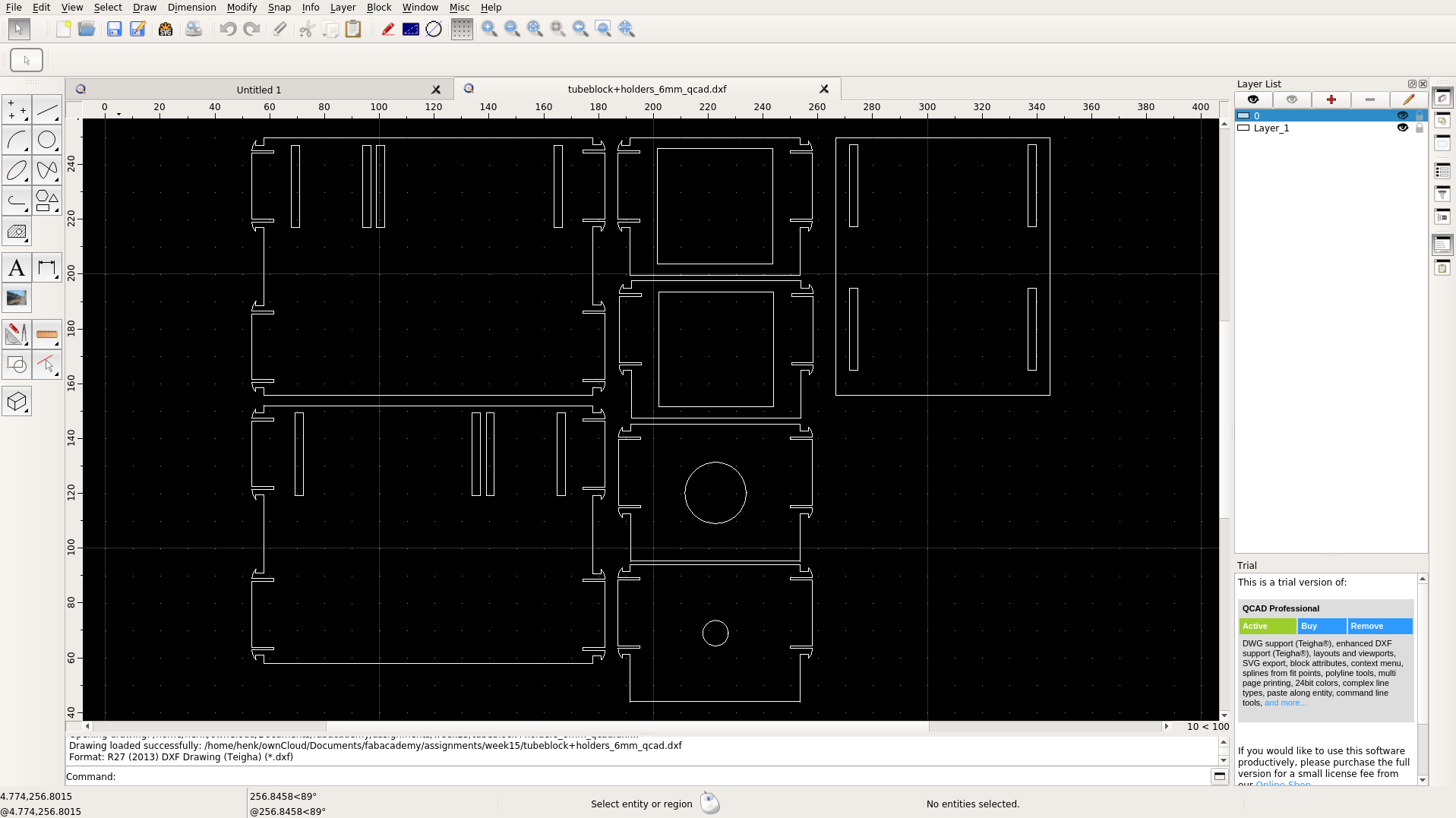

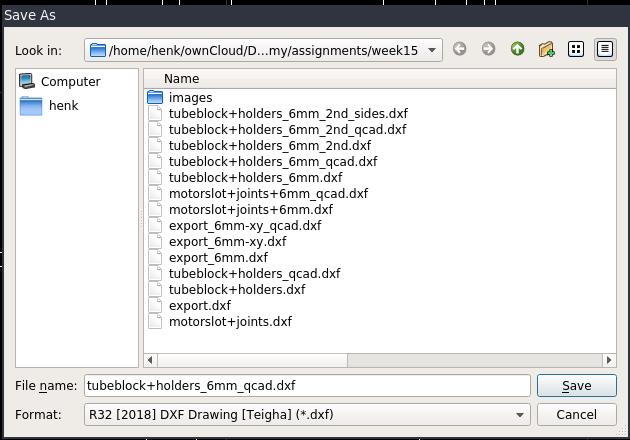

So again I used qcad to open the dxf and save it in another dxf format.

Not listening to errors (who needs them anyway!) i saved the design in DXF R32 format. That on imported fine to inkscape.

The result

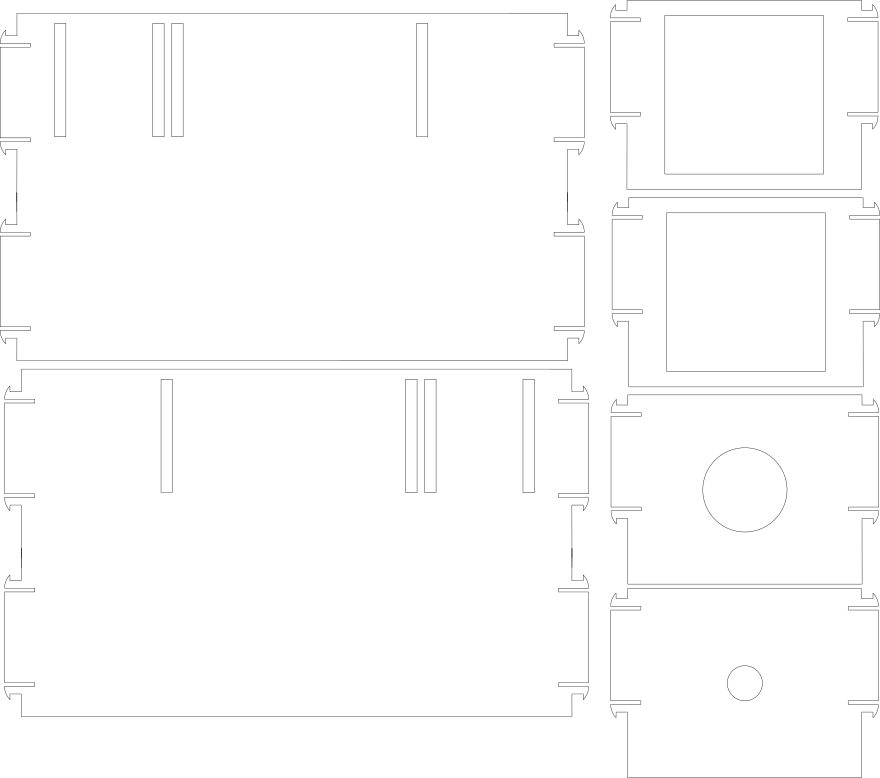

Here is the design i made:

how it looks in our machine

Lessons learned:

- Working fast and exact measurements and placements are not a good combination

- When you have a design in mind it makes sense to think what tools to use. In this case parametric design for the joints in freecad and the final design in inkscape worked really well.

- joint work really well but they have to be strong enough. I first made joints of 1mm thickness but they broke of course.

- As you see next week in the documentation for the machine design week the tube extruder did work, but it could have given better results. Now the rotation of the steppers are used to roll up the tube and thus extruding ketchup. This works because we prepaired the tube a bit, so flatten both sides, actually pre roll them a bit, so the engine did not stall because the tube rolled up differently as we expected. It probably would have been a better idea to pull the tube between 2 bars to get an extrusion. Another idea would have been to use the torque to squeeze out ketchup.