Wk20. Project Development

Assignment: Complete your final project, tracking your progress:

- What tasks have been completed, and what tasks remain?

- What has worked? what hasn’t?

- What questions need to be resolved?

- What will happen when?

- What have you learned?

The Final Push

That moment has arrived. Panic. Stress. Rush. That time where schedules fly out the window, and we frantically scramble to machine our last bits and pieces and piece together out final project.

To mitigate this chaos I took advantage of a couple of hours this week to do a little bit of admin, regather my thoughts and make a list of what I needed to complete my final project. While you will see most of my progress documented on the project development page, I will outline my organising here.

Tasks remaining

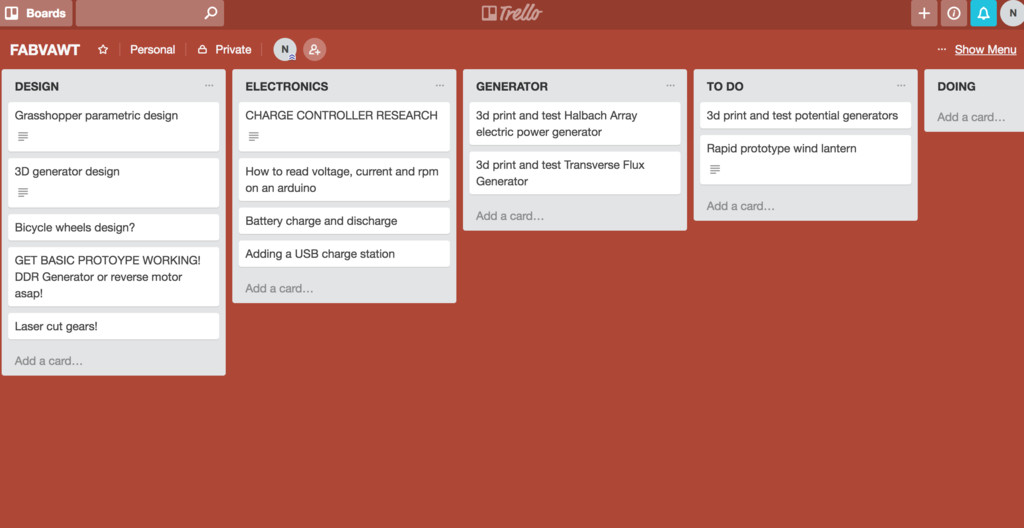

While I had earlier been reliant on Trello to organise my final project task, and I found this platform highly useful, I sort of lost touch with my task management here somewhere around machine week. Here is the last update.

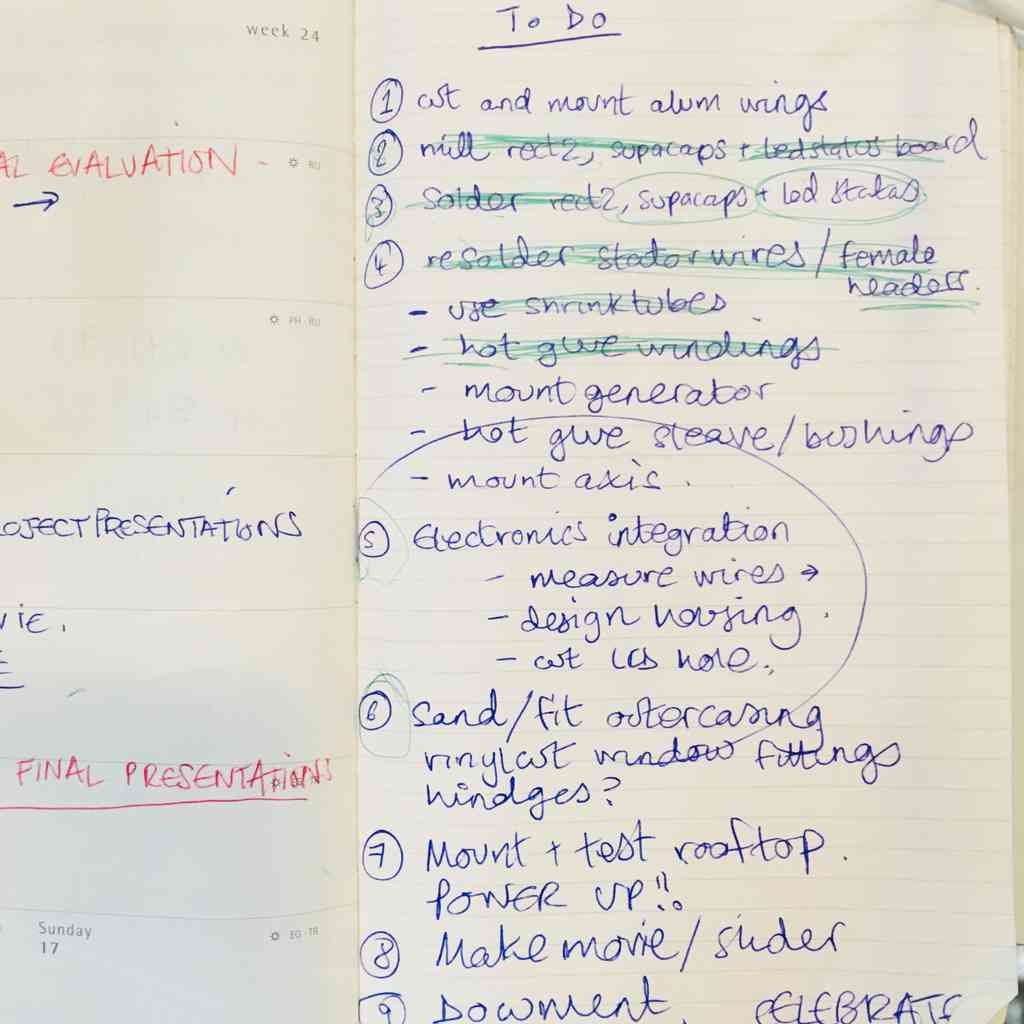

Since then, my digital fabrication organisation has taken a rebelliously analogue turn. My agenda has since become my life saviour. While I have always tried to maintain the concept of spiral development, focusing on small manageable tasks and then slowly improving. I did this with the first prototype, and then the second iteration of the 3d printed generator for example.

However maintaining a strict supply-side time management has been more challenging. With the pressure of the last two weeks I have had to concentrate on completing the essentials of my turbine and generator. I have done this by maintaining detailed To Do Lists which I have attempted to complete in order of most time consuming (usually machine dependent) tasks first. These look like so:

What works and what doesn’t

Basically in this week I was able to complete the project to comprise both the turbine, the generator, power control/conversion and input/output that I had originally planned.

I faced the inevitable irony of trying to test my turbine on a day when there was barely a gust of wind. It became evident that my turbine was not going to spin anywhere beyond the 300 RPM mark with the wind that day. This is not going to power much.

Here it is getting the best of lazy breeze:

BOM

- 12mm precision steel rod (850mm) - (€15)

- Thrust bearings, shaft collars and sleeve bearings (€12).

- 15mm Plywood x 2,400mm x 1,200mm sheet (€35)

- 5mm White Acrylic Sheet 1000mm x 250mm (€13)

- 0.5 mm aluminium flashing 1000x1000mm (€18)

- 3D printing PLA generator (1kg 1.5mm spool = €20)

- 2x 100x40x37mm High Density Polyurethane Foam (100mmx600mmx2000mm = €98.95)

- Burlap fabric composite and epoxy (€3/m)

- 60-100 turns of 0.2mm gage insulated copper wire (€8/kg)

- Step up DC to DC step up converter (€1.5)

All of these materials bar the step-up module, the aluminium flashing and my bearings were scavenged and up-cycled in the lab. In total, out of pocket this project cost me €35.

Testing

So basically, it was up to me to create the windy conditions to be able to generate the power I was needing to power my electronics. Here is the complete system mounted. The caveat here is that I had to spin this for quite a while to trickle charge my supercaps enough to power the display, LED and tachometer. However, as a proof of concept and for demonstration purposes it works.

Project development

Moving forward, I’d like to spend some more time to develop this project. Not only exhaustively testing the current model in real and simulated conditions, but designing a robust methodology for testing turbines and generators in the lab. There are a few other things on both the software and hardware side that I could improve.

- Creating a low RPM threshold which will not flash the LED at every rotation and turn off the LCD backlight (which currently chews a lot of power).

- Improving the housing with more durable fastening and hinges. For now I used remaining cuts from my aluminium flashing to fasten the composite housing to the base.

- While the wings turn very smoothly and the design catches the wind perfectly even in a slow breeze, their size was limited by the size of the Trotec 400 laser cutter which I used to cut my wing vanes. These could be much bigger and made out of a much more mechanically resilient material.

- Adding Lipo battery bank and MPPT charge control.

- Adding a wireless communication device.

What have I learnt

This project has really been a crash course in wind power and electronics. Considerable time and research have been dedicated to researching this subject since week 3 FabAcademy. I have attempted to the best of my ability to document in my learning by doing as I go along. But here I list what I have most got out of this project:

- How to design, 3d print and wire a small generator.

- How to generate current using electromagnetic induction.

- How to convert AC to DC power.

- Some general ideas about the mechanics turbines and the physics of wind.

- How to test for power using multimeter and oscilloscope.

- How to ride sines waves.

- The pros and cons of molding n casting, composites and 3dprinting.

- Spiral development and electronic rapid prototyping using open source tools and techniques. Learning by failing, often and better.

- Last but not least, I know now that it is both possible and useful to power micro controller devices and sensors using wind energy generated by a simple turbine.