This year I looked out the old files for the Vcarve and the dxf files for the item however I had extreme problems getting any of them to read, I tried a couple of packages, without any luck . Hence a redraw was required and since I was going to have to redraw this I decided to move away from the rectangular shaping that I had used in the previous design and make more use of the facilities a cnc router would allow me and added a lot more curves.

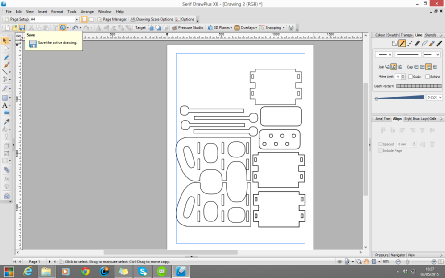

I was able to draw out my shape using Serif Drawplus which is now able to cope with a 2400 x 1200 page.

Having drawn the shape in serif Drawplus I was then able to save this as a dxf file.

Having the dxf file allowed me to import this to the Vcarve software that the Maklab use (as we do not as yet have our own shopbot).

Within vcare we were able to add on some of the additional items such as dog bones and tags

Dog bones are a trick that allows the router to complete internal corners to be used by rectangular items in assembly. Under normal circumstances the corner of an internal space can only have corners equal to the radius of the cutter. With V carve it was possible to select the corners and the software automatically added in the extra shaping.

Short tags were also added such that when machining the outside of a shape that shape was not free to move on the bed allowing for additional work to be completed. Even though the user chose the order that the toolpaths were cut this was a good additional feature. The tags would be cut but left as thing joining pieces.

The final model was then sanded and assembled such that it could be varnished

The material used was OSB which created problems over its inconsistent thickness..