Week 03 — Computer-Controlled Cutting¶

Assignment requirements (Fab Academy)¶

Group - Do lab safety training - Characterize laser cutter: focus, power, speed, rate, kerf, joint clearance & joint types

Individual - Cut something on the vinyl cutter - Design + laser-cut a parametric construction kit (account for kerf)

Tools & Machines¶

- CAD: (RDWorks / Fusion / Illustrator)

- Laser cutter: RW-1390 C02

- Vinyl cutter: Mimaki CG-FXII

Group assignment — Laser cutter characterization¶

1) Safety Training¶

Before operating the laser cutter, we follow strict safety rules in our lab to prevent fire hazards, toxic fumes, and equipment damage.

🔥 1. Never Leave the Laser Unattended¶

The laser cutter must never be left unattended while operating.

Even if the cutting job takes a long time, we stay in the same room and continuously monitor the process.

Laser cutting plywood or cardboard can ignite unexpectedly. Immediate reaction is critical to prevent fire.

🌲 2. Extra Care with Plywood and Cardboard¶

When cutting plywood or cardboard, we take additional precautions because:

- These materials are highly flammable

- Glue layers in plywood can ignite

- Cardboard can burn quickly if power/speed settings are incorrect

We carefully monitor flame formation and are ready to stop the machine immediately if necessary.

🌬 3. Industrial Ventilation System¶

Our lab uses an extra industrial ventilation module.

- The exhaust duct extends above the building roof

- This prevents smoke from spreading inside the building

- It protects other workers and nearby animals from harmful fumes

Proper ventilation is essential because laser cutting produces smoke and fine particles.

💧 4. Water Cooling / Chiller System Check¶

Before every cutting session, we:

- Check the water cooling (chiller) system

- Confirm water circulation is working

- Ensure the temperature is within a safe operating range

Laser tubes can overheat and be permanently damaged if cooling fails.

🛑 5. Additional Safety Measures¶

- Never cut PVC or unknown plastics (to avoid toxic chlorine gas)

- Keep a fire extinguisher accessible

- Clean the cutting bed before operation

- Turn on air assist during cutting

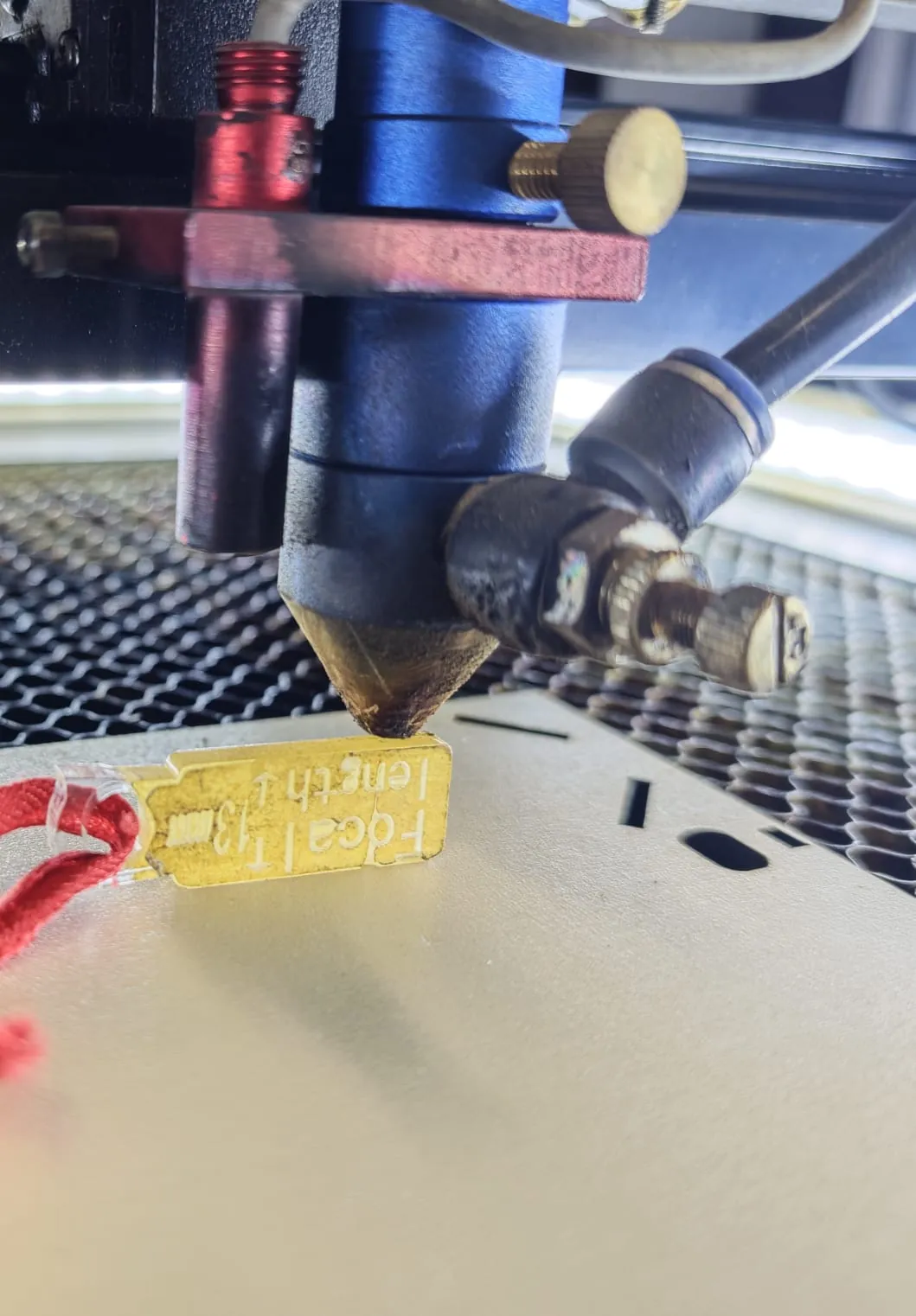

2) Focus Adjustment Test¶

To achieve accurate cutting results, correct laser focus is essential.

To adjust the focus height, I used a small focus test pattern.

I gradually adjusted the Z height until the cut line became the thinnest and cleanest.

Correct focus produces: - Minimal burn marks - Sharp cut edges - Smallest kerf width

The best focus height was determined visually by comparing the cut quality.