Week 02 — Computer-Aided Design¶

Focus this week¶

I have some experience in Fusion 360, but this week I want to: - learn Joints and Motion tools (to test ideas for my final project).

Tools I used¶

- Fusion 360 (joints, motion, assembly tests)

- OpenSCAD (parametric / code-based modeling)

Part A — Fusion 360 (Linear Actuator, Joints & Motion)¶

Goal¶

For my final project I plan to use linear actuators, so this week I focused on: - building a simple linear actuator model - understanding how linear motion is defined in Fusion 360 - testing motion limits and constraints

Initial actuator test (components vs bodies)¶

First, I built a simple two-part model that connects and moves relative to each other.

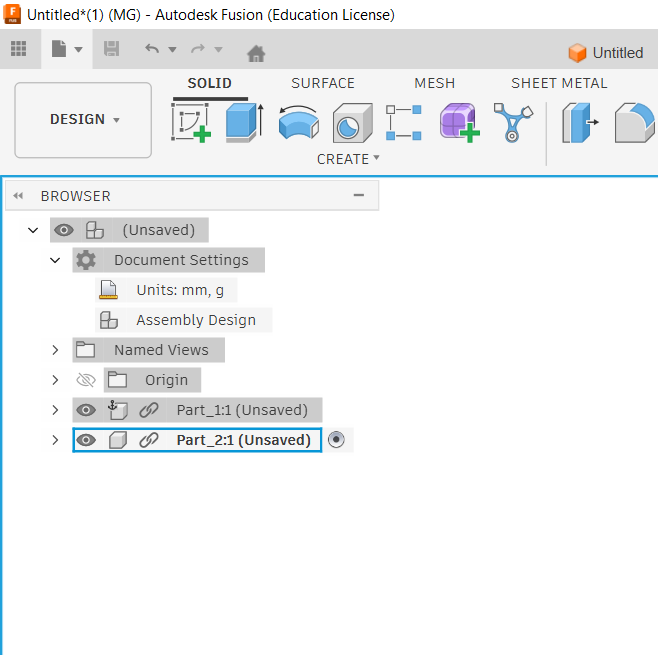

Instead of modeling everything as bodies, I created separate components.

Using components is necessary because joints only work between components, not bodies.

Create components

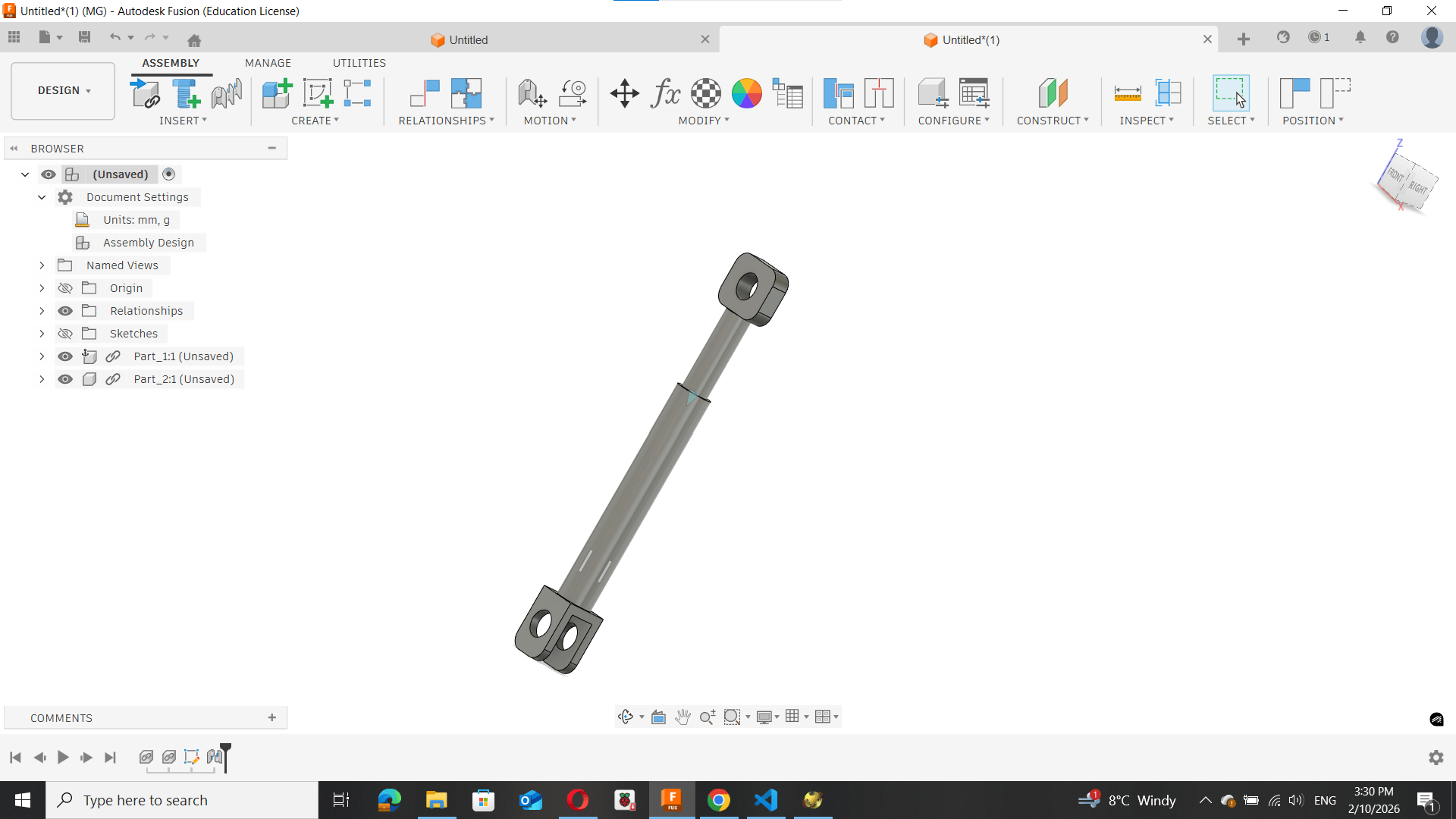

Simple component connection test¶

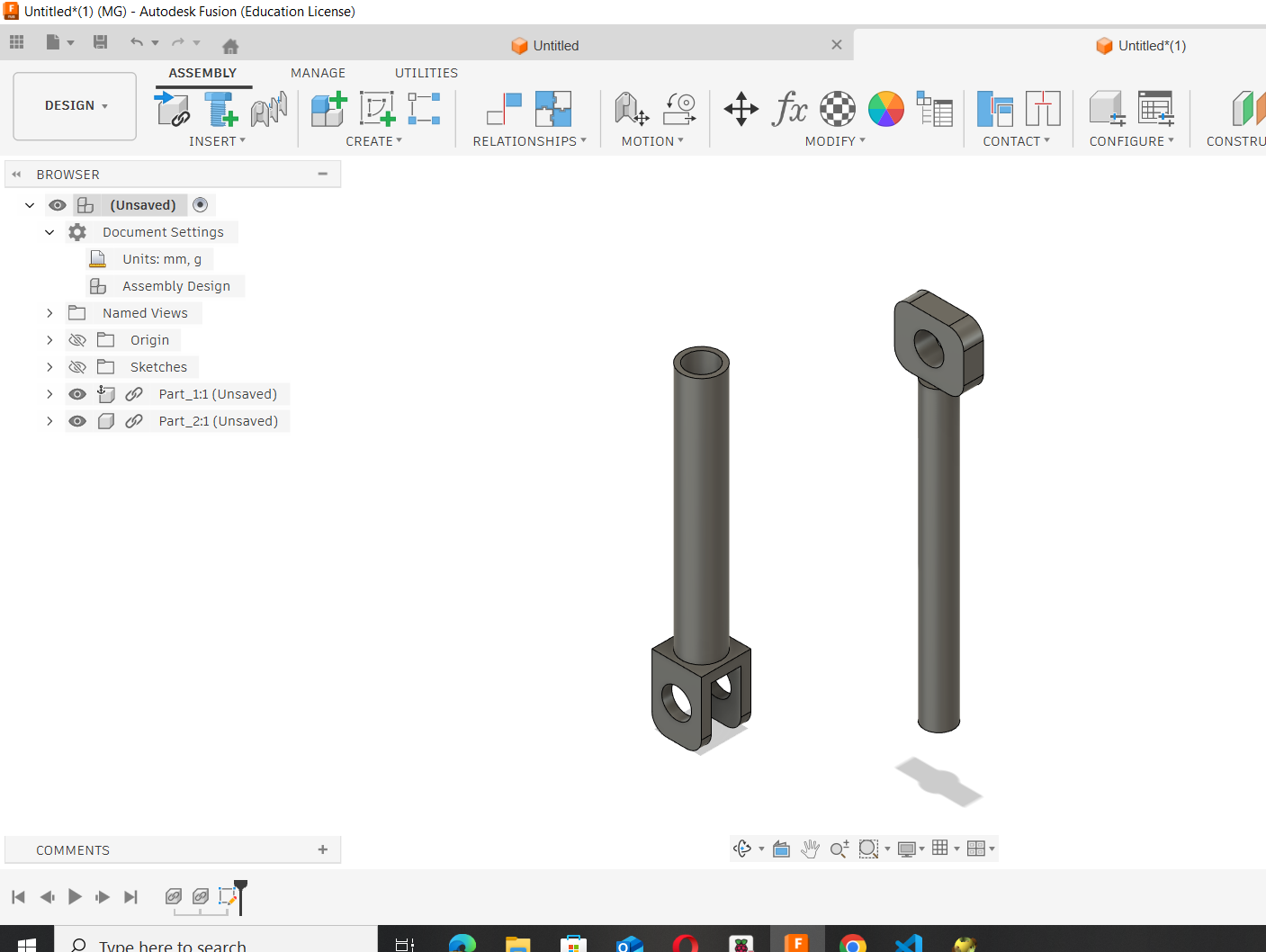

After that, I built two simple components designed to join and interact with each other.

2 simple part

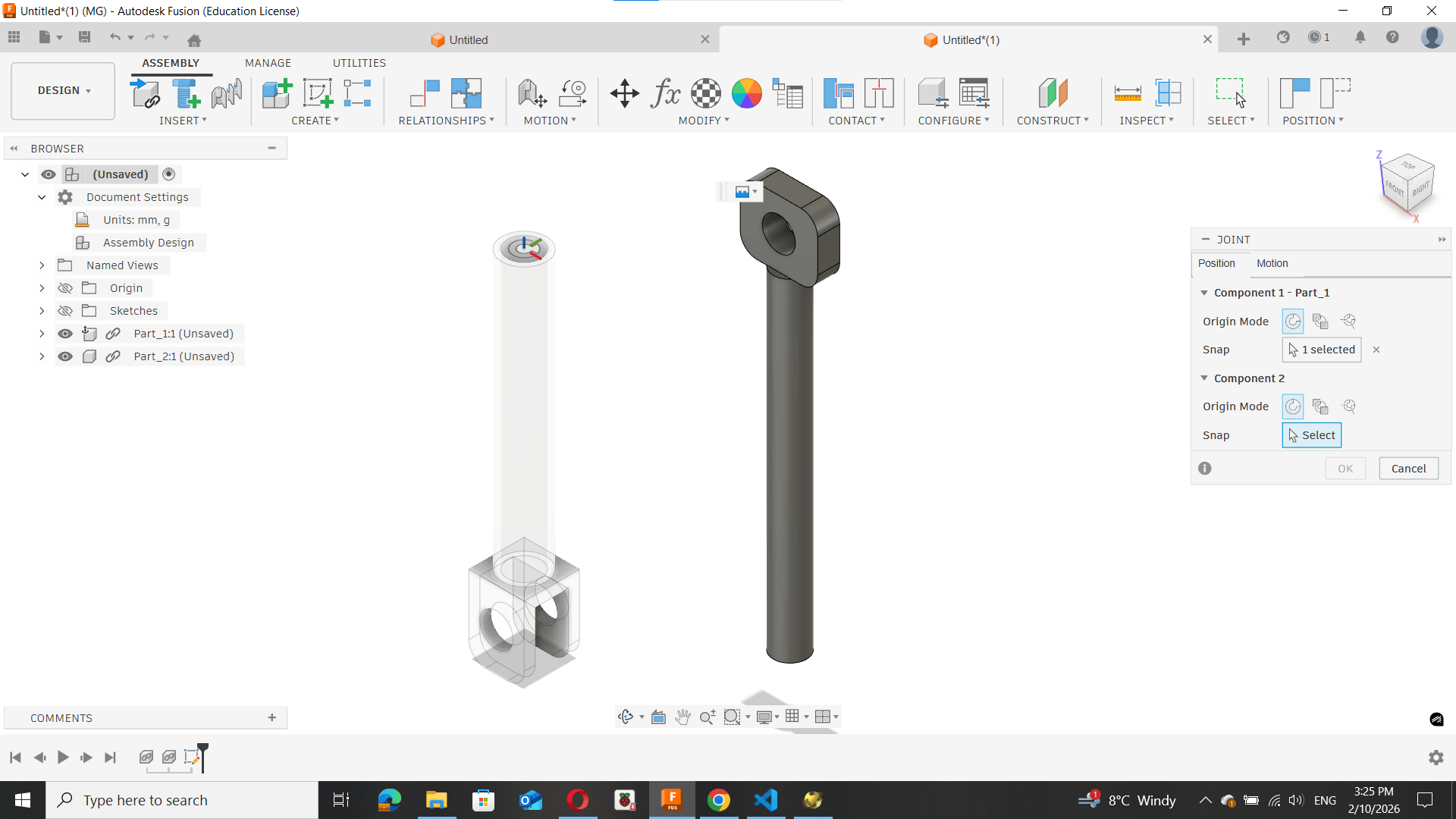

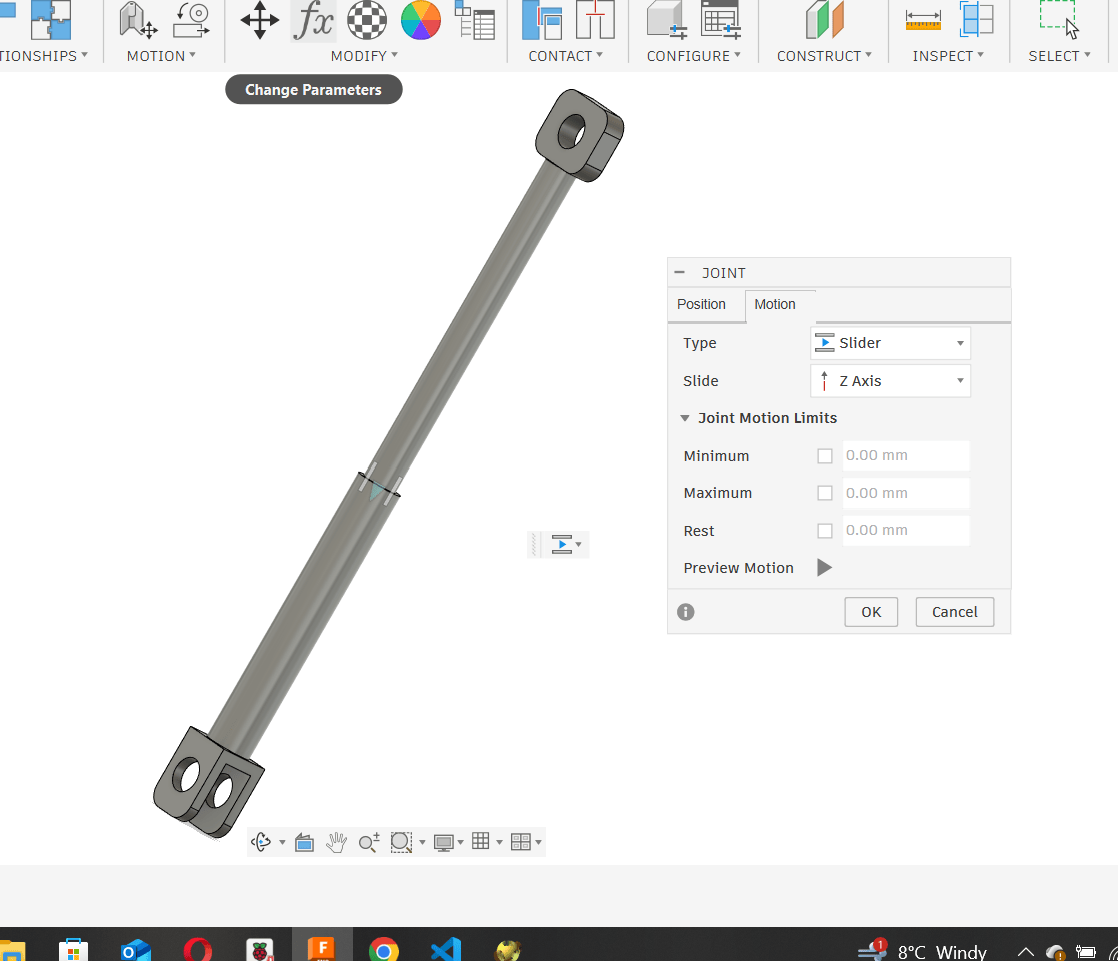

Next, I used the Joint function in Fusion 360 to connect the components.

I selected the two components and defined a linear (slider) joint between them.

This joint allows the components to move only along a single axis, which simulates linear motion similar to a real linear actuator.

Part B — OpenSCAD (Parametric CAD Using Code)¶

Goal¶

After working with Fusion 360 and motion tools, I wanted to try a different CAD approach.

For this purpose, I used OpenSCAD, which is a script-based parametric modeling tool.

The goal was to:

- Understand code-based modeling

- Compare it with traditional sketch-based CAD

- Create a simple parametric mechanical part

- Export fabrication-ready files

Why OpenSCAD?¶

Unlike Fusion 360, OpenSCAD does not use sketches or graphical constraints.

Instead, geometry is defined using code and variables.

This makes it: - Fully parametric - Very precise - Easy to modify dimensions globally

However, it does not support: - Assemblies - Motion simulation - Joints

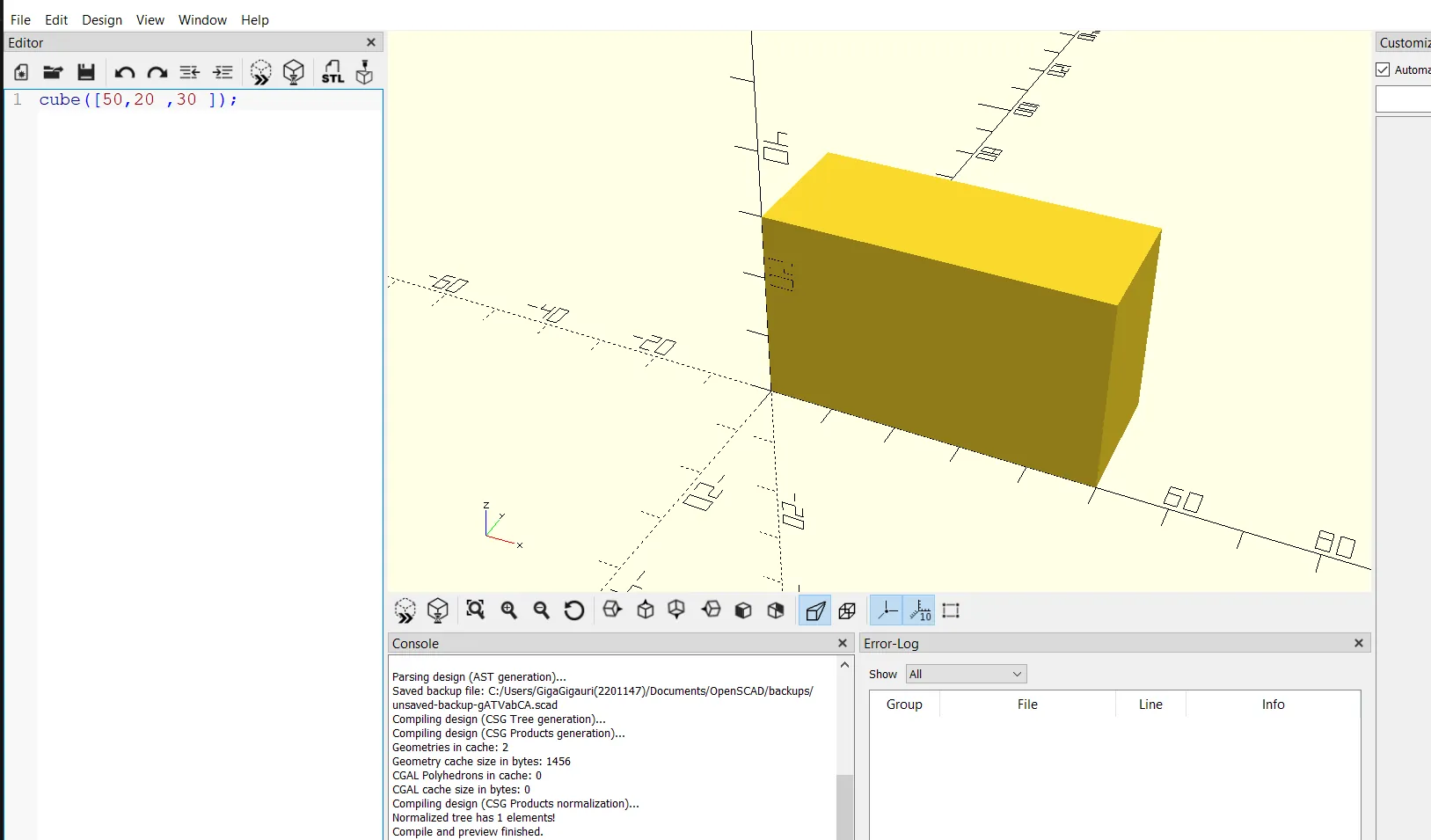

First Parametric Test¶

To understand the workflow, I created a simple parametric mechanical part.

Example structure:¶

length = 60;

width = 20;

height = 10;

cube([length, width, height]);

By changing the values of length, width, or height, the model updates instantly.

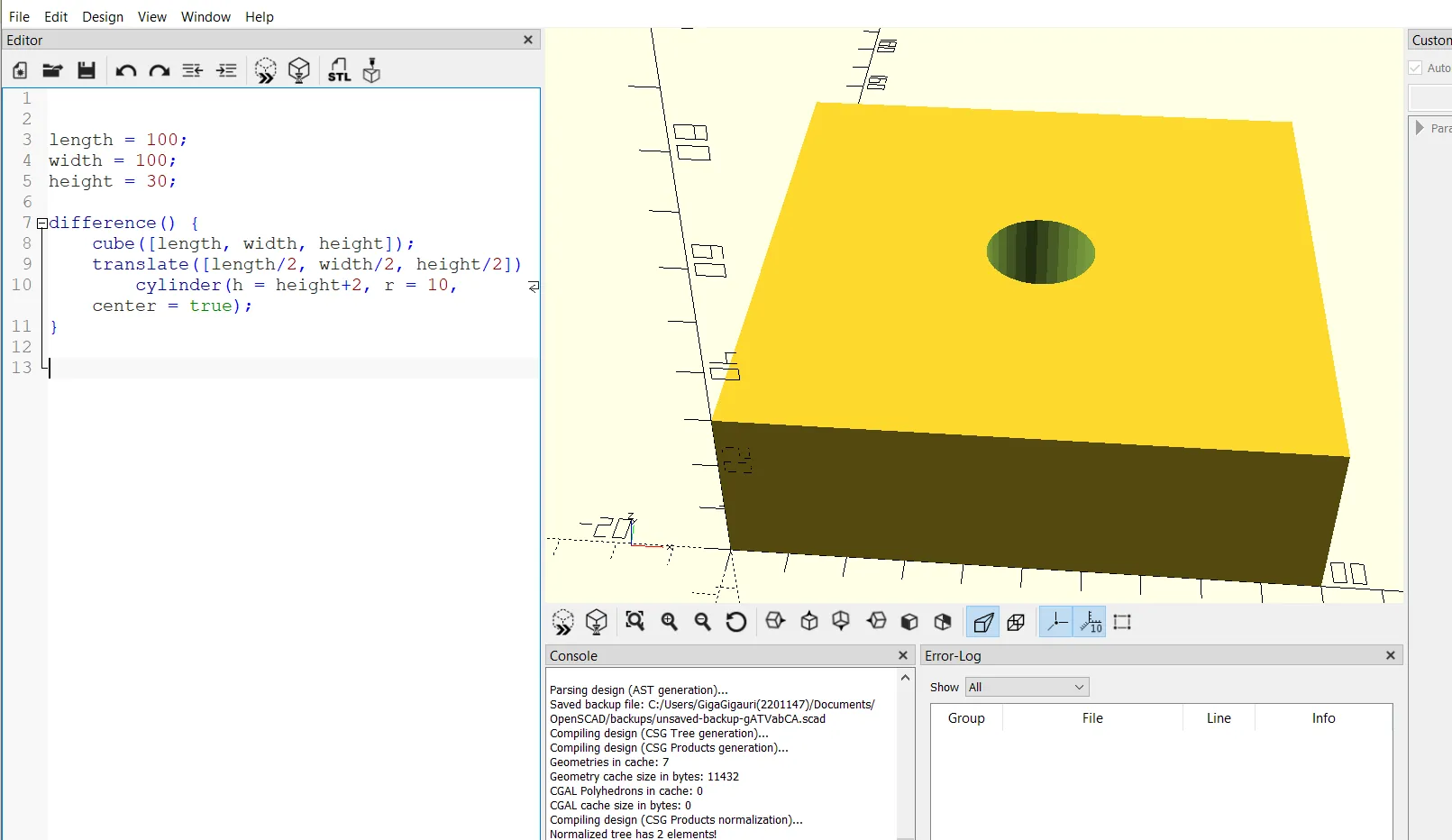

Adding Features¶

Next, I modified the model to include a hole:

¶

¶

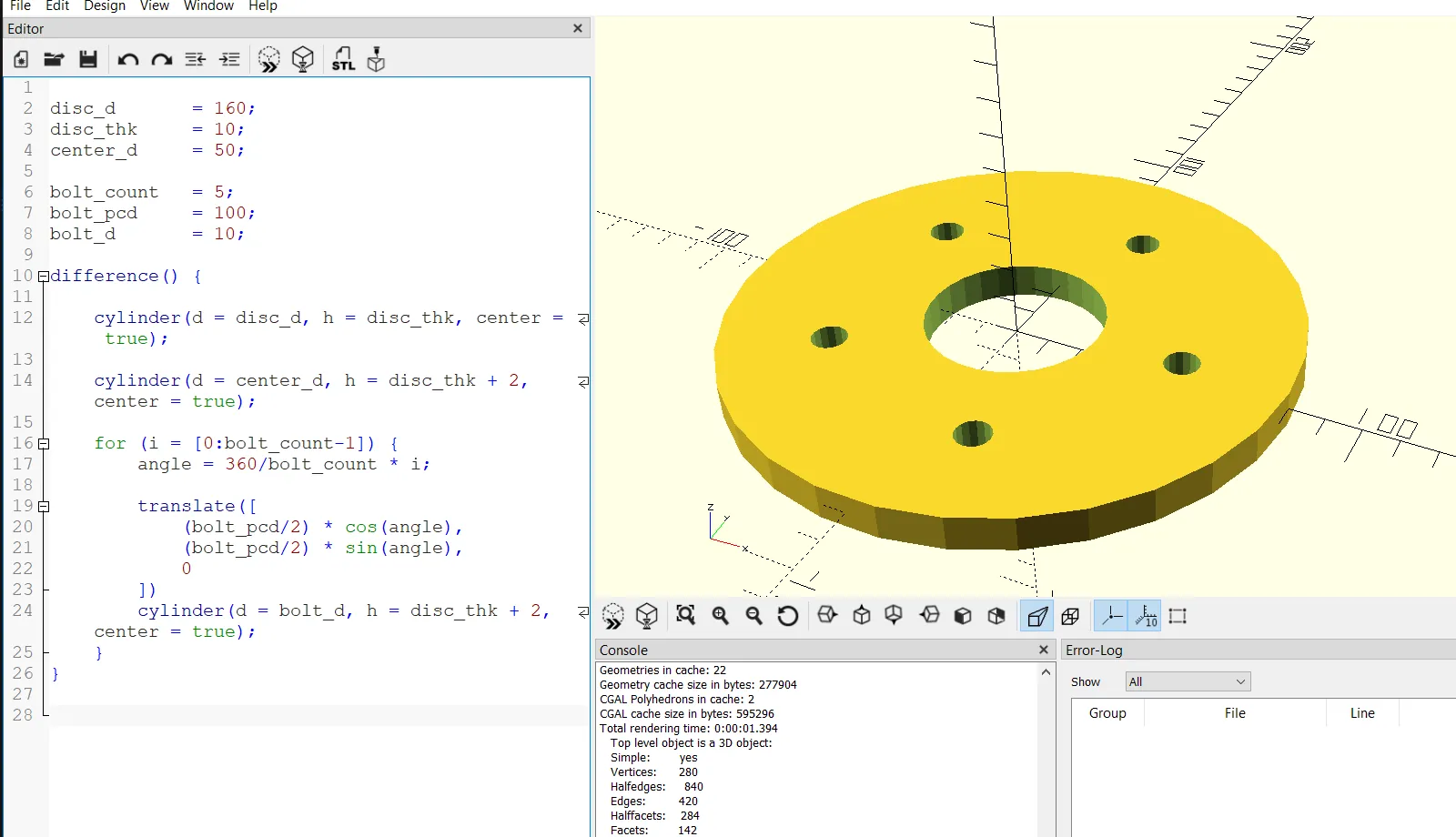

Simple Disc Geometry in OpenSCAD¶

I created a simple parametric disc using OpenSCAD.

The model consists of:

- One main cylindrical body (the disc)

- One center hole

- Multiple bolt holes distributed evenly on a circular pattern

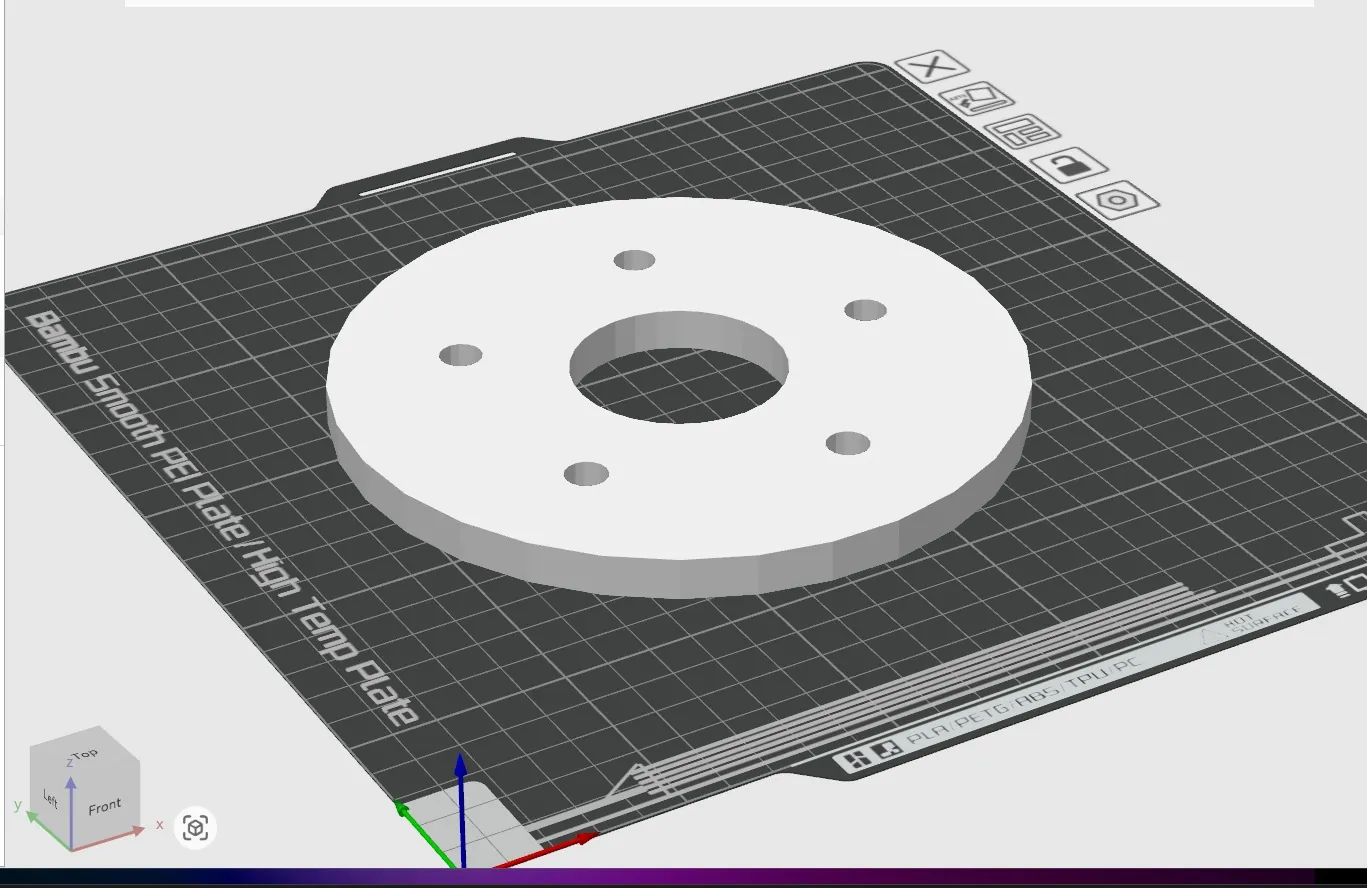

Exporting Files¶

After finishing the model, I exported it as:

- STL

Then I verified the STL in a slicer to confirm:

- Correct scale (mm)

- No geometry errors

- Clean mesh