Laser Cutting¶

The design of the calibrating SVG, characteristics, safety instructions and and how to operate the laser cutter was done as part of the group assignment and can be read in labs page here

In this document I describe the steps of the construction kit I designed.

Apparently I missed the note that one should not use Inkscpape’s clone tool to the parametric design because “it is not a real parametric software.” 😬

In any case, that was precisely what I used and it worked quite well for my objective. In the future I plan to use “real” parametric design in a tool like FreeCAD.

Here’s the process:

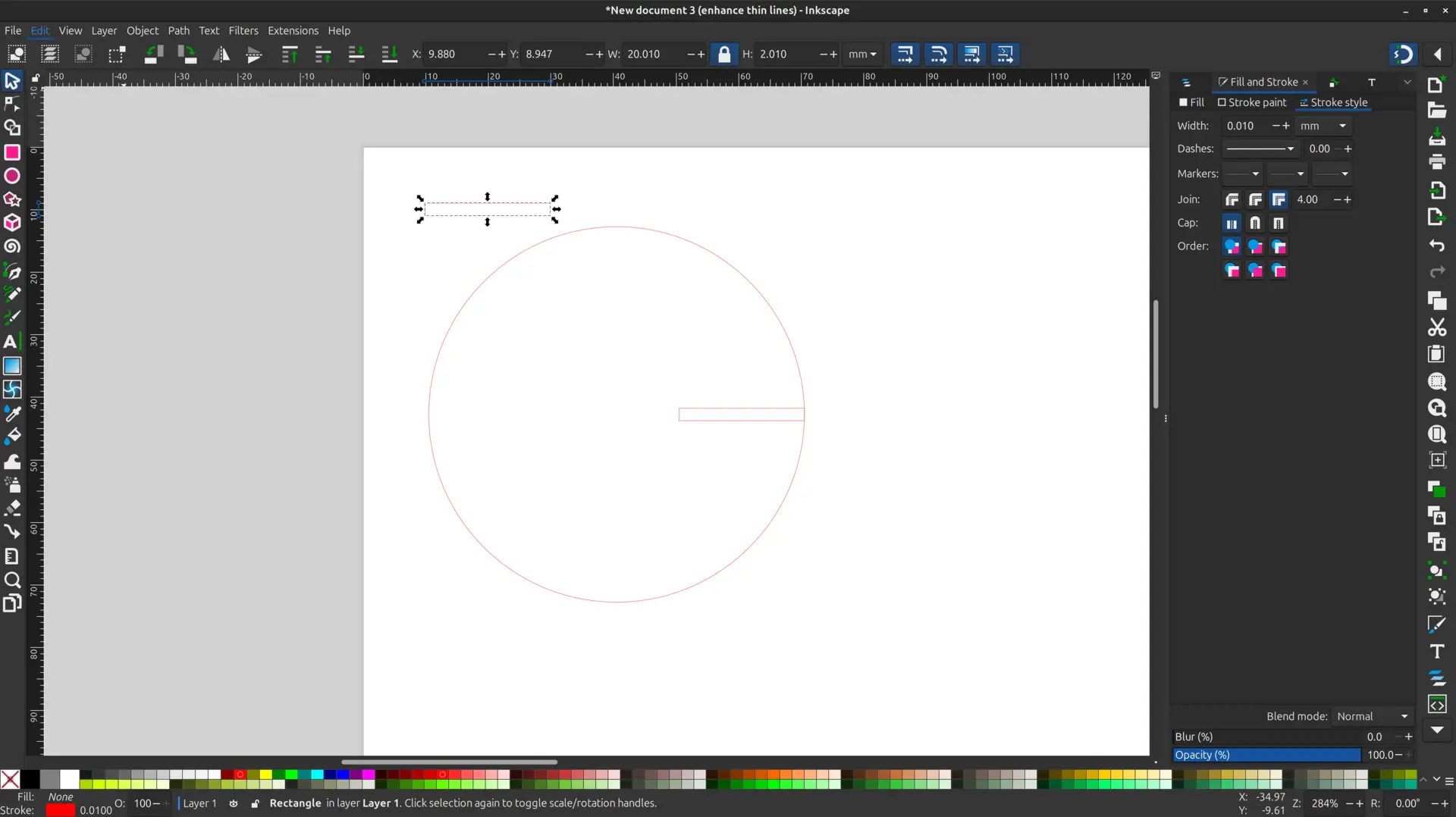

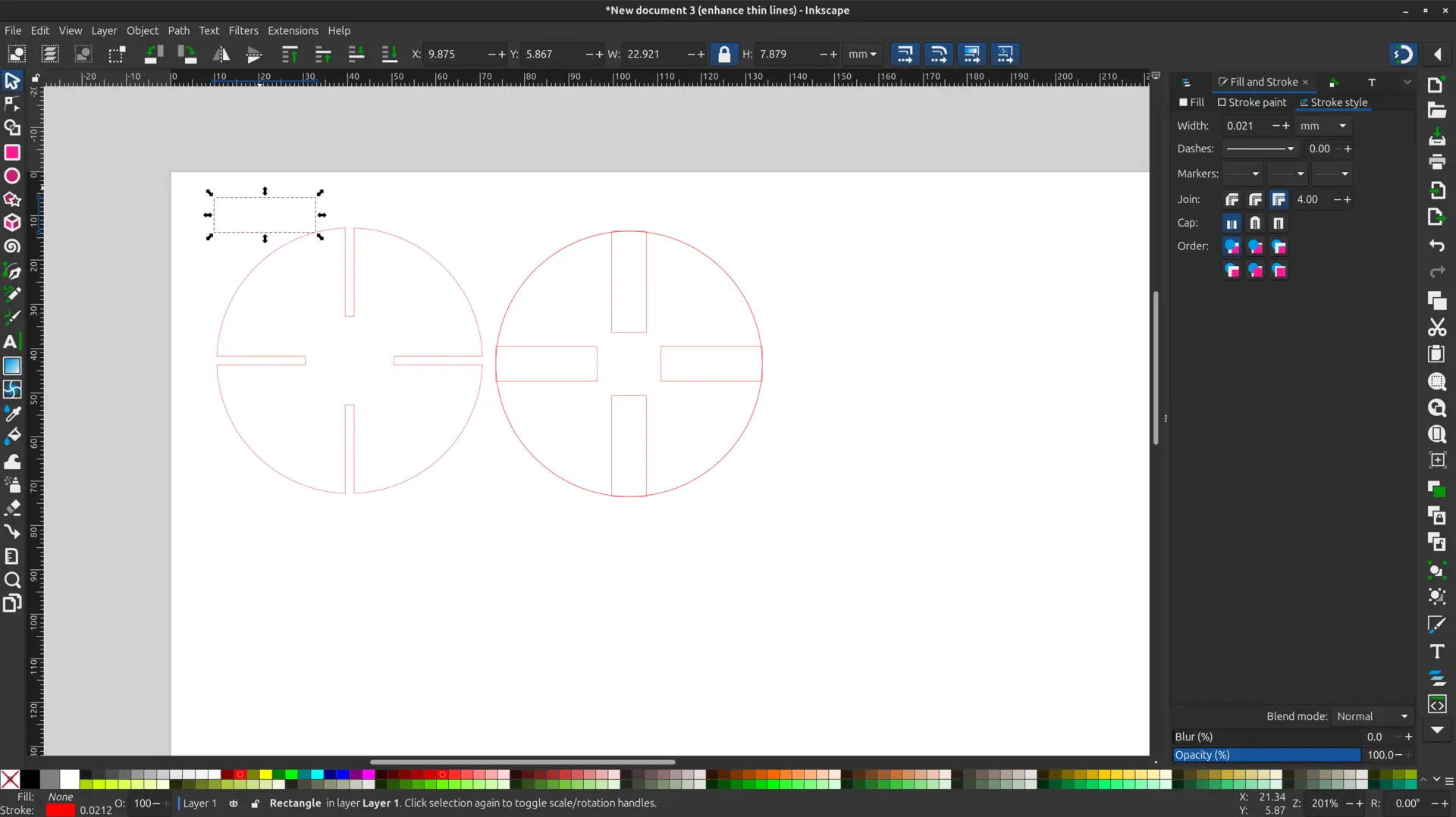

I designed a rectangle and circle.

I used the Edit -> Clone -> Create clone tool to make a clone of the rectangle and aligned it with outer edge of the circle.

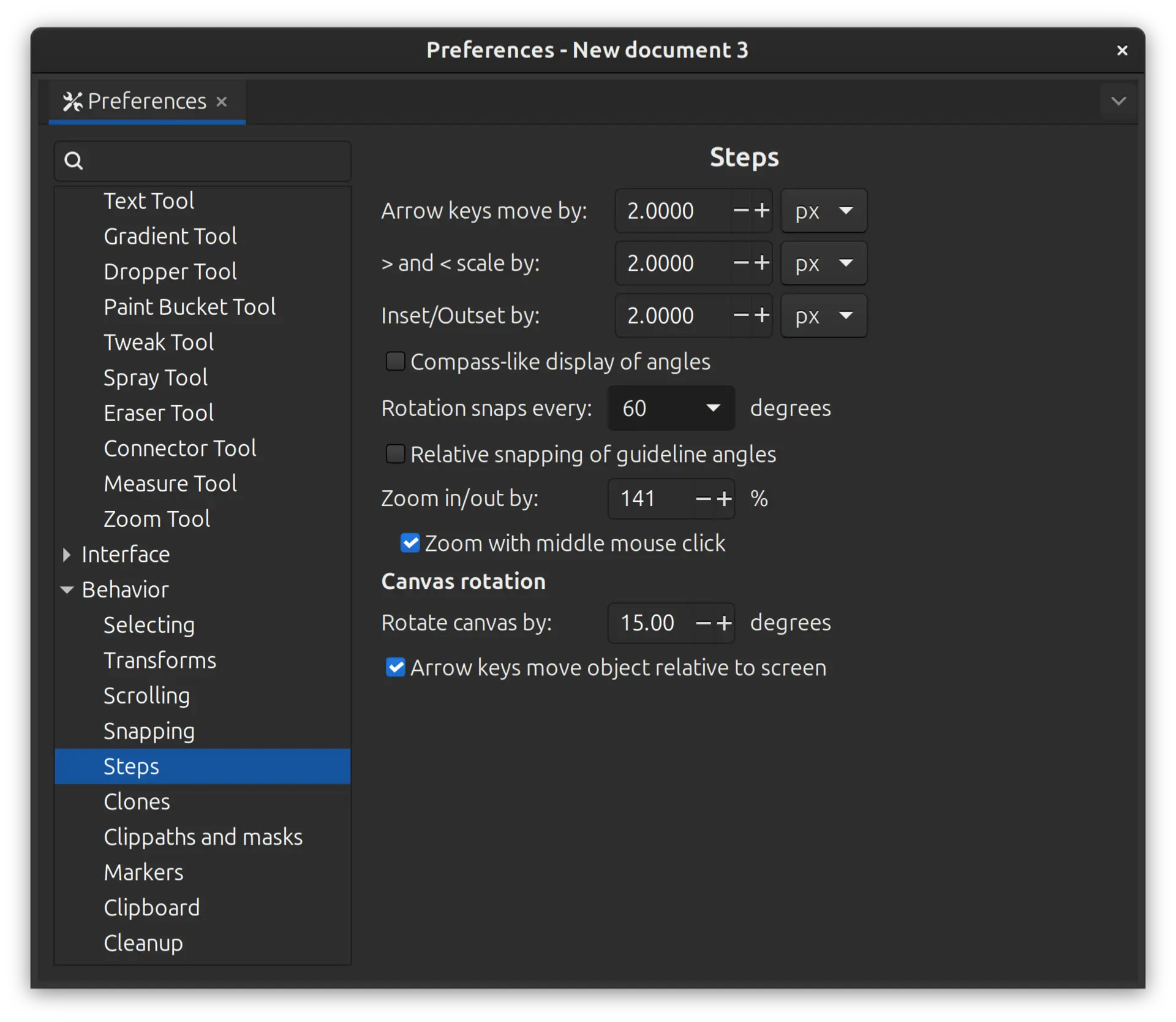

I then went into Edit -> Preferences -> Behavior -> Steps and changed the setting for Rotation snaps every __ degrees and changed it to the desired angle

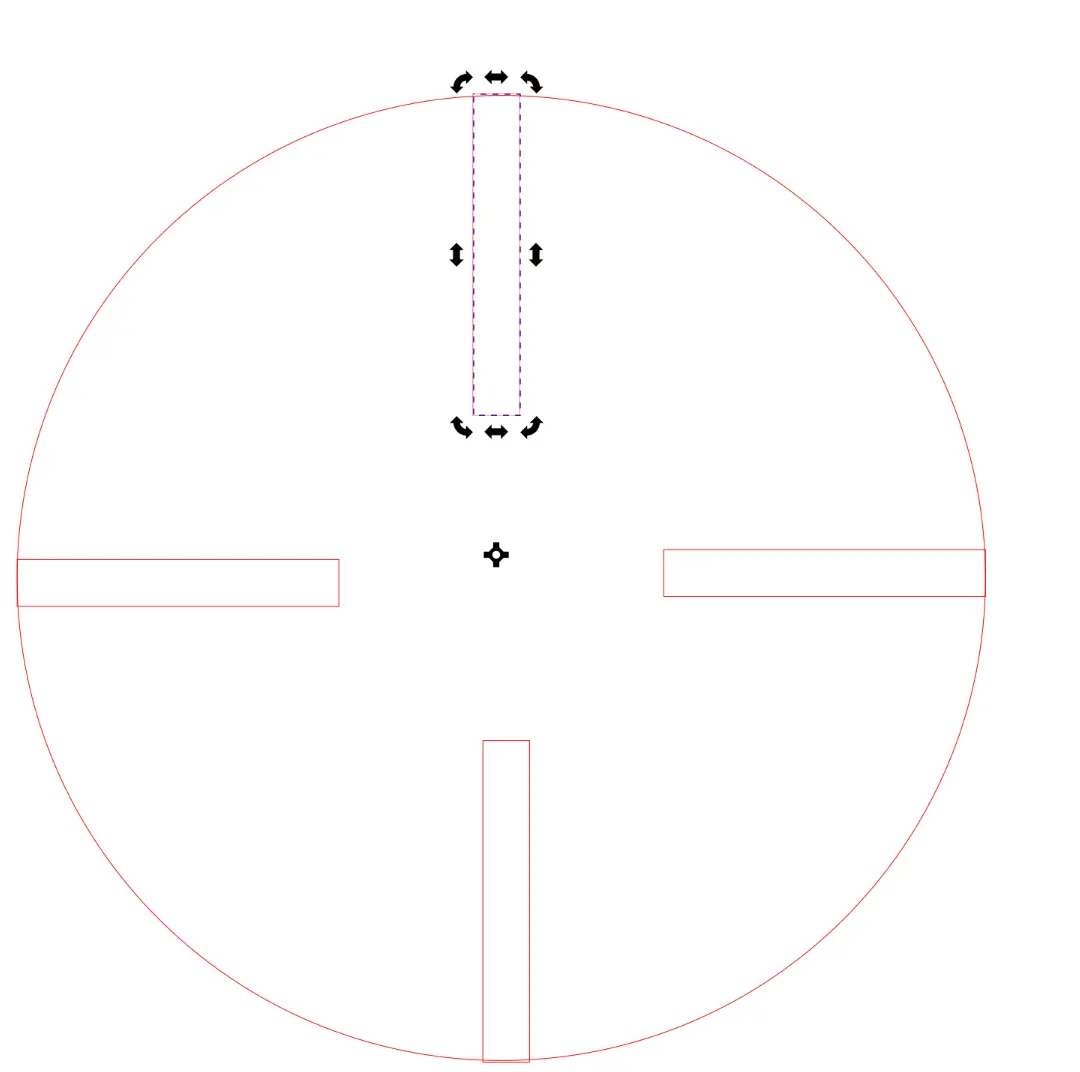

I cloned the object again, and double clicked the cloned object, and shifted the rotation point to match the circle center. While holding down the control key (to snap) I rotated the cloned object, which snaps to the previously defined angles, and repeated the process to have a complete object

I also experimented with one of the shapes to subtract the rectangle from the circle to achieve a clean cut. This can be done by selecting the circle and the rectangle, and then selecting Path -> Difference as seen here:

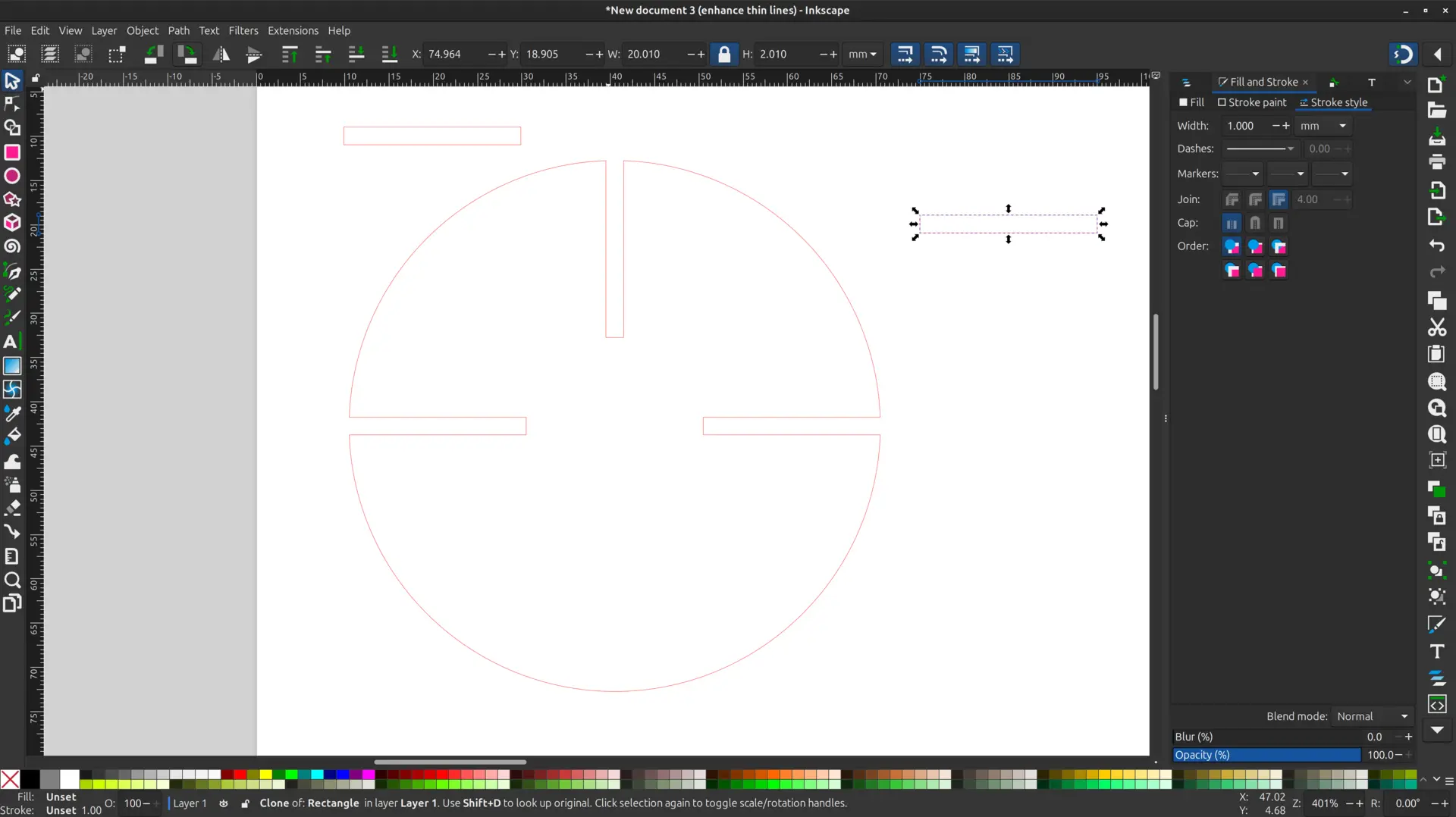

However, when doing so, the cuttings are no longer a clone, and if one changes the size of the original object, the clones changes shapes, but the unified path doesn’t, as seen here:

Here is the final result:

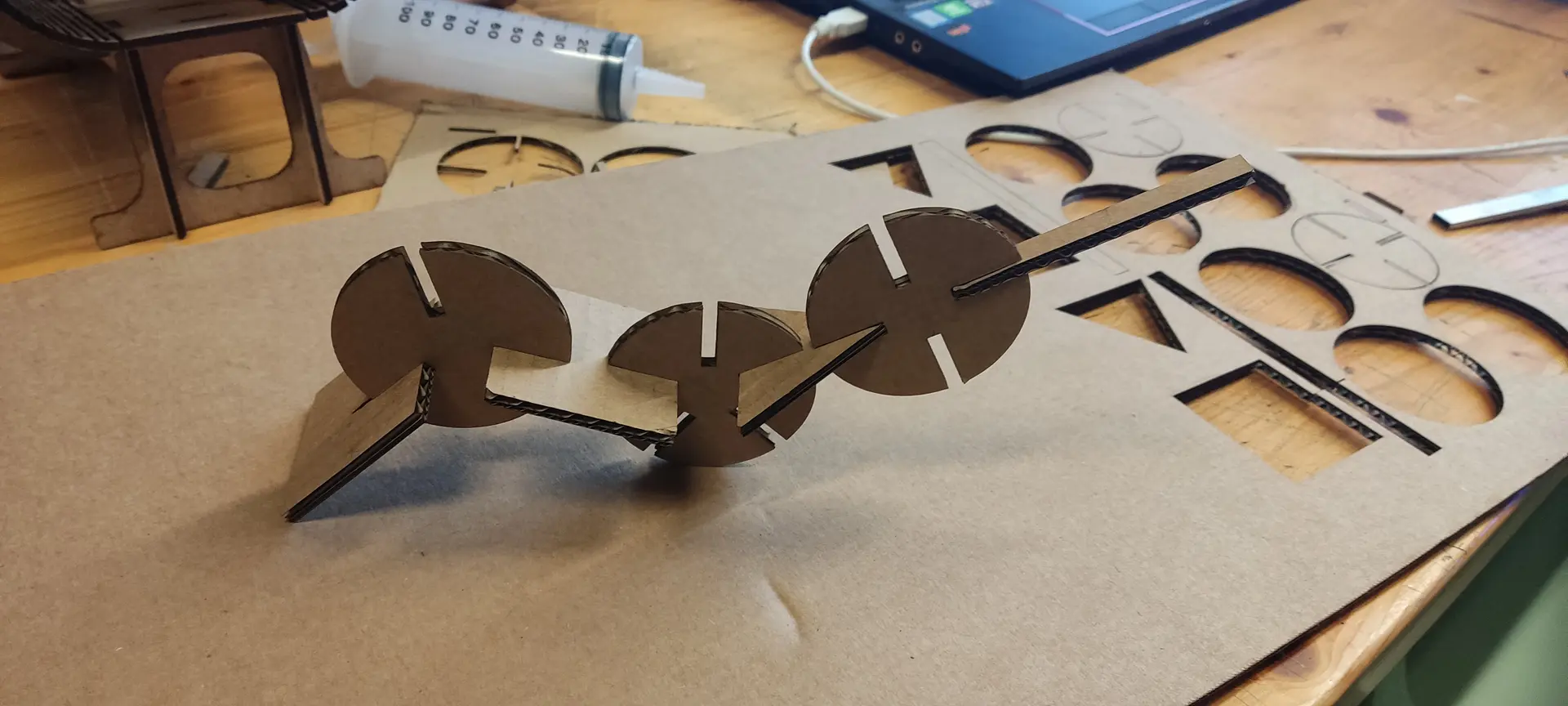

The size of the cutting took into account the Kerf determined in the in the group assignment.

And here’s the end result:

All in all, I learned quite a bit about vector drawing and concepts I didn’t know previously