Magical Revolving Lantern

When millennium-old tradition meets digital manufacturing.

Project Overview: Perfect fusion of traditional aesthetics and modern technology

Project Origins

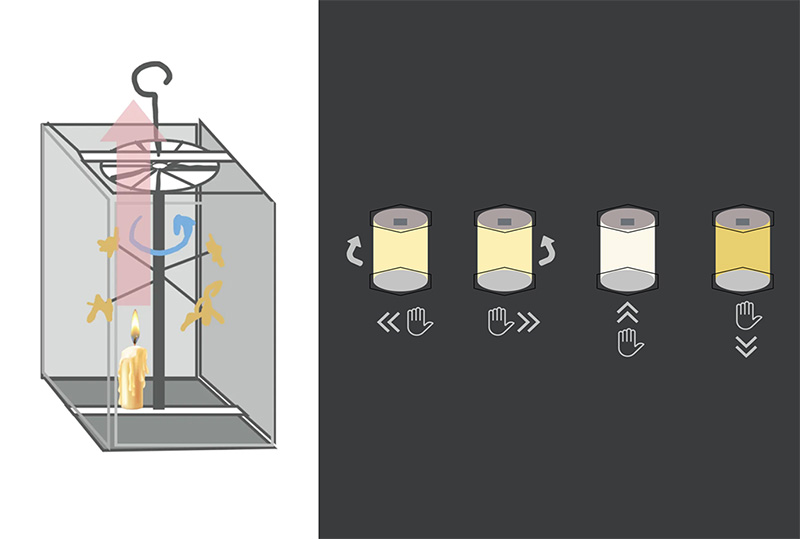

Do you remember the first time you saw a revolving lantern as a child? With flickering candlelight, paper-cut shadows danced gracefully on the lantern cover, as if they had come to life. This ancient toy, dating back to the Han Dynasty, used the simplest physical principle—rising hot air—to create poetic visual experiences.

But as a "digital craftsman" who has been working in Fab Lab for 18 weeks, I couldn't help but wonder: what sparks would fly if this thousand-year-old ancient lamp were given wings of modern technology?

Thus, the Magical Revolving Lantern was born.

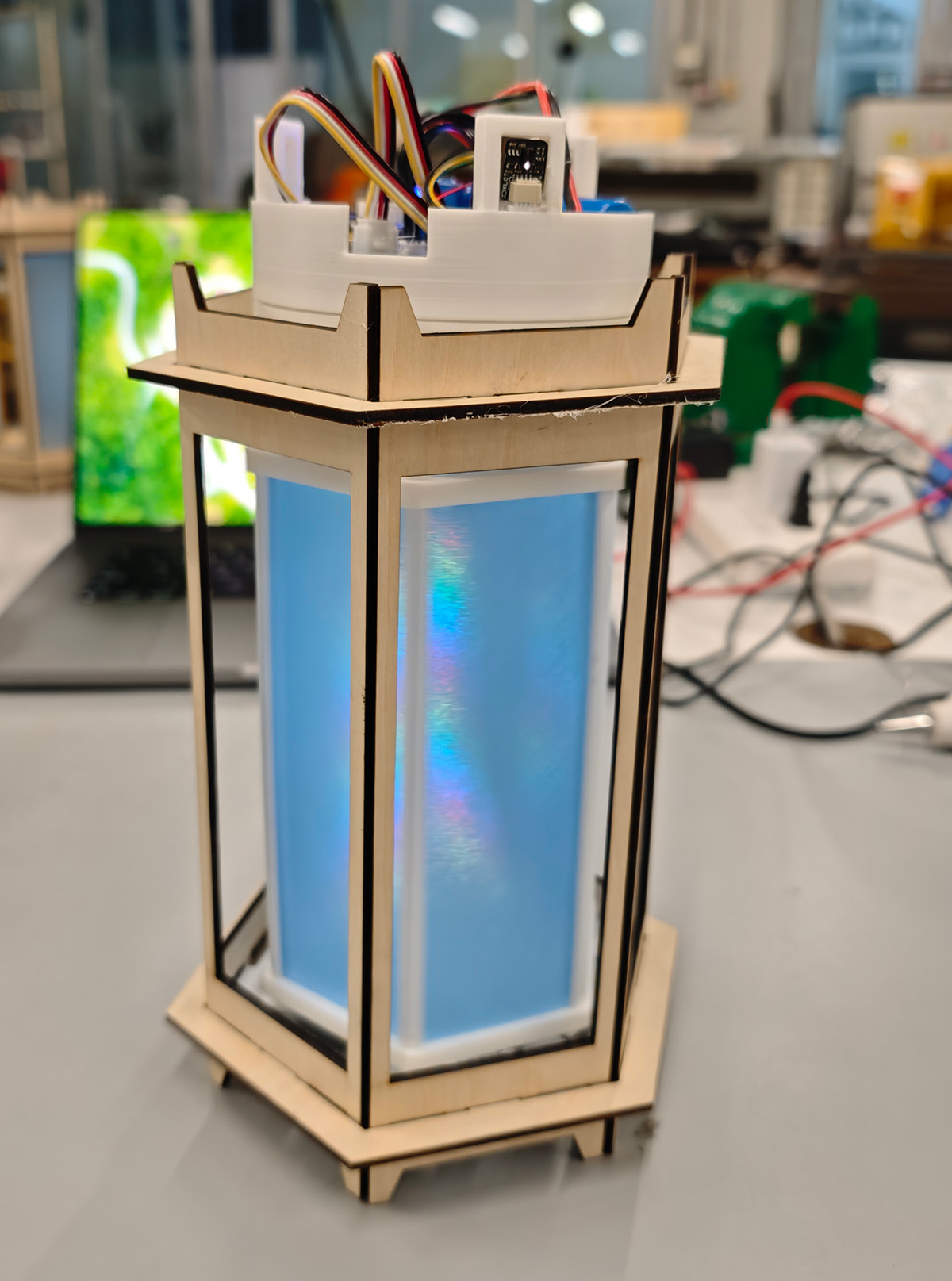

Left: Poetry of traditional revolving lantern; Right: Technological aesthetics of the Magical Revolving Lantern

What Exactly Is It?

Simply put, it's a smart lantern that can "read minds."

Core Features Overview

🎯Precise Rotation Control: Say goodbye to uncontrollable hot air flows, use stepper motors to achieve precise speed control. Want to meditate slowly or party at a fast pace? A gesture does it all.

🌈Programmable Light Magic: 28 WS2812B RGB LEDs arranged in two rows, 360° illumination with no dead angles. From warm candlelight yellow to dreamy rainbow gradients, endless variations at your fingertips.

👋Gesture Recognition: Supports up to three APDS-9960 sensors distributed at 120°, no matter which angle you "interact" with it, it instantly understands your intentions. Up, down, left, right—each gesture has its dedicated light response.

📱Web Remote Control: Phones, computers, tablets—anything that can connect to the internet can control it. During gatherings with friends, everyone can "conduct" the lantern performance together, absolutely becoming the center of attention.

🔗Multi-device Synchronization: Based on MQTT protocol, multiple Magical Revolving Lanterns can form a "lantern array" with synchronized changes—quite a spectacular sight.

Feature Demo: Gesture control, Web interface, synchronization effects

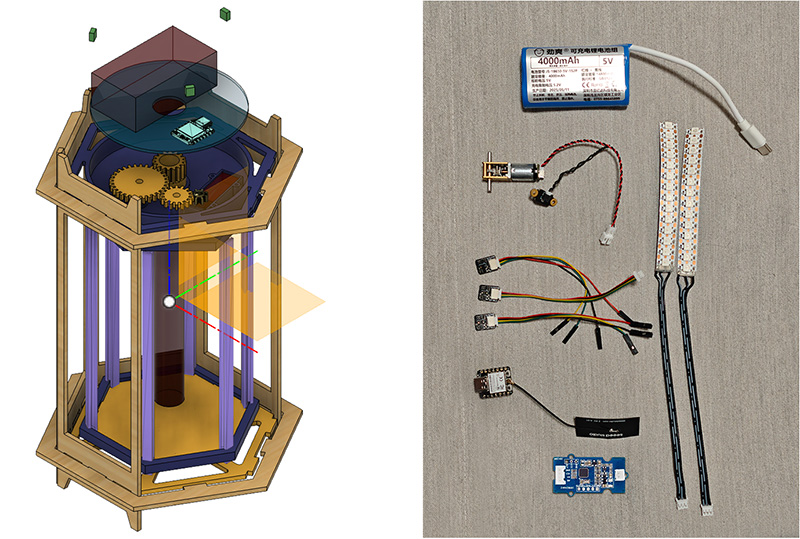

Structural Design

Physical Structure Design

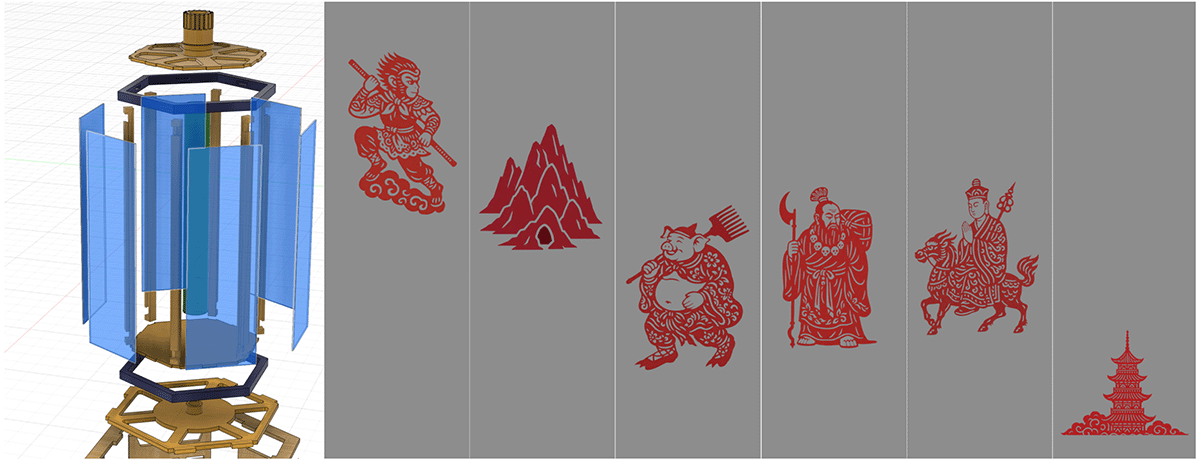

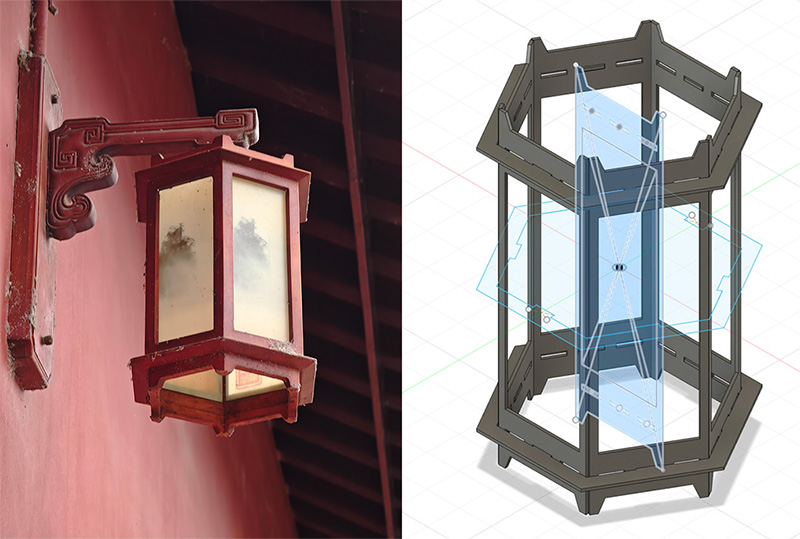

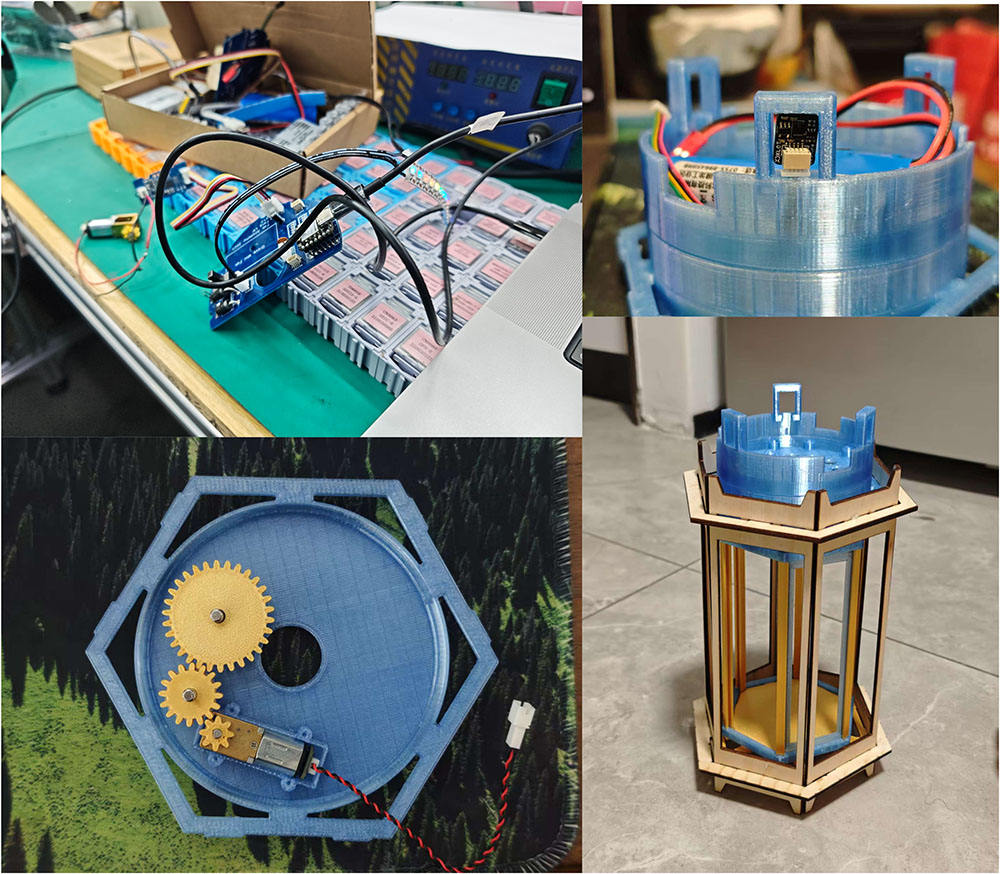

The lantern structure took up a lot of time, as the lantern needs an external frame, an internal rotating structure, and gear mechanisms driven by motors. Integrating these systems together took considerable time.

I used Fusion 360 to design the entire lantern structure, including complex gear systems and assembly design:

- Design file download: https://a360.co/43zU9ao

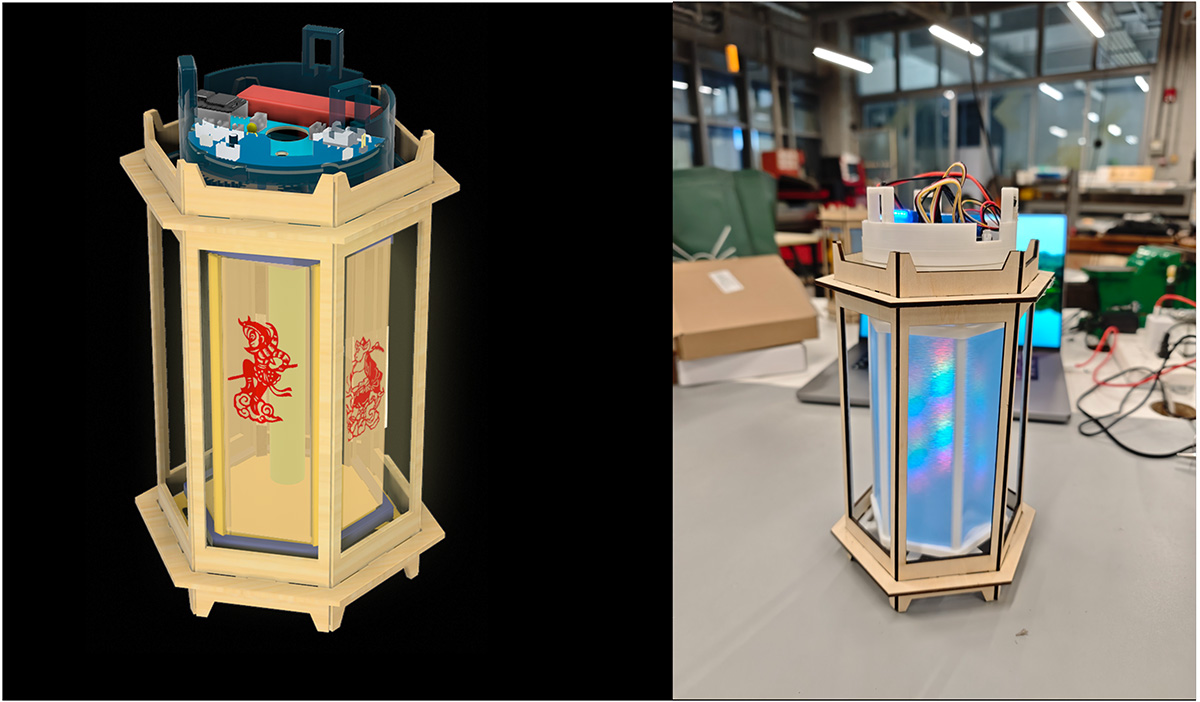

The rendered effect based on the design file is shown below:

Final design version rendering, designed in Fusion 360

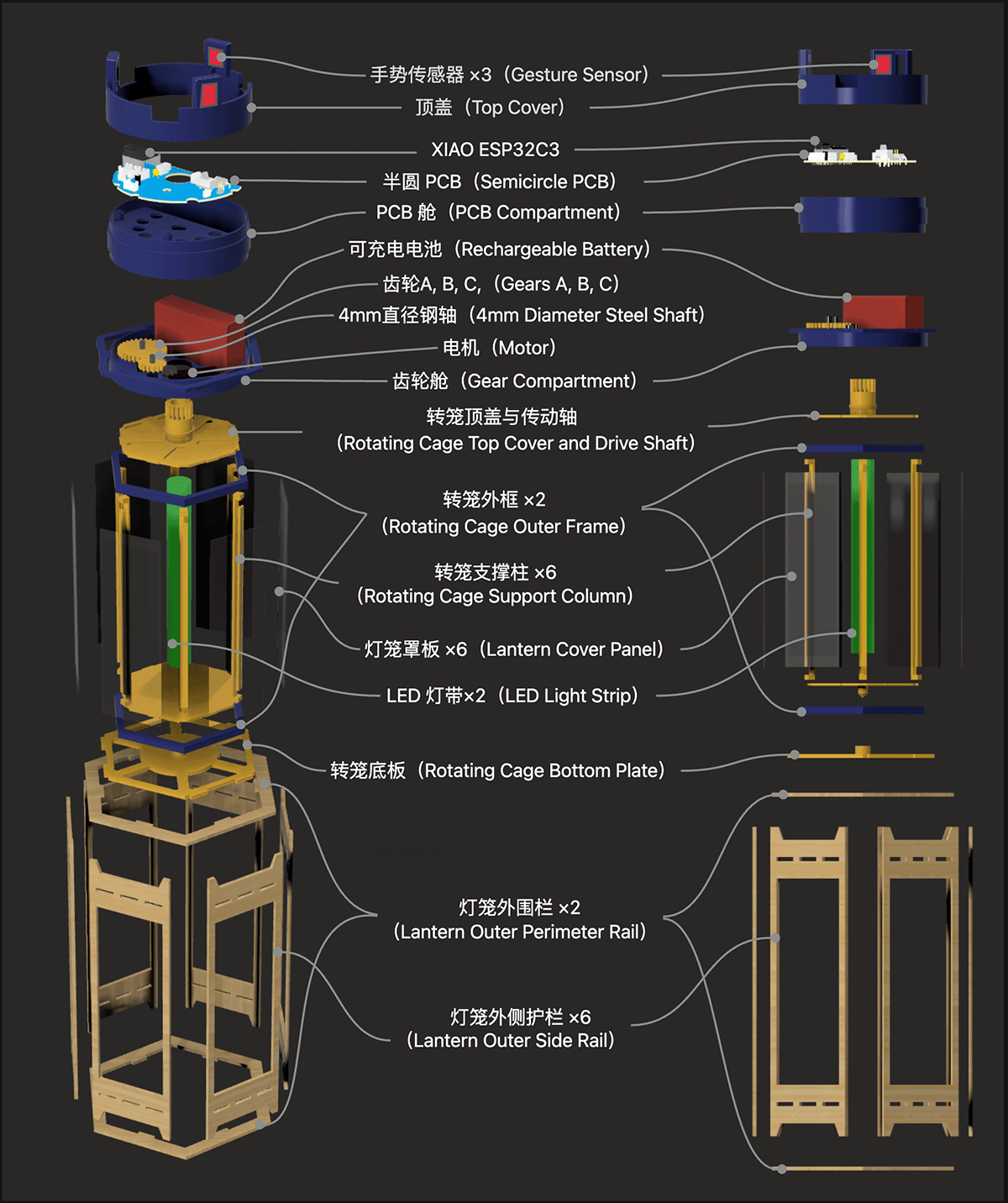

Then I copied a file in Fusion and expanded all structural components as shown in the figure below:

Expanding all components in Fusion 360 and rendering to get the illustration, then I numbered all the structural component files that need to be manufactured

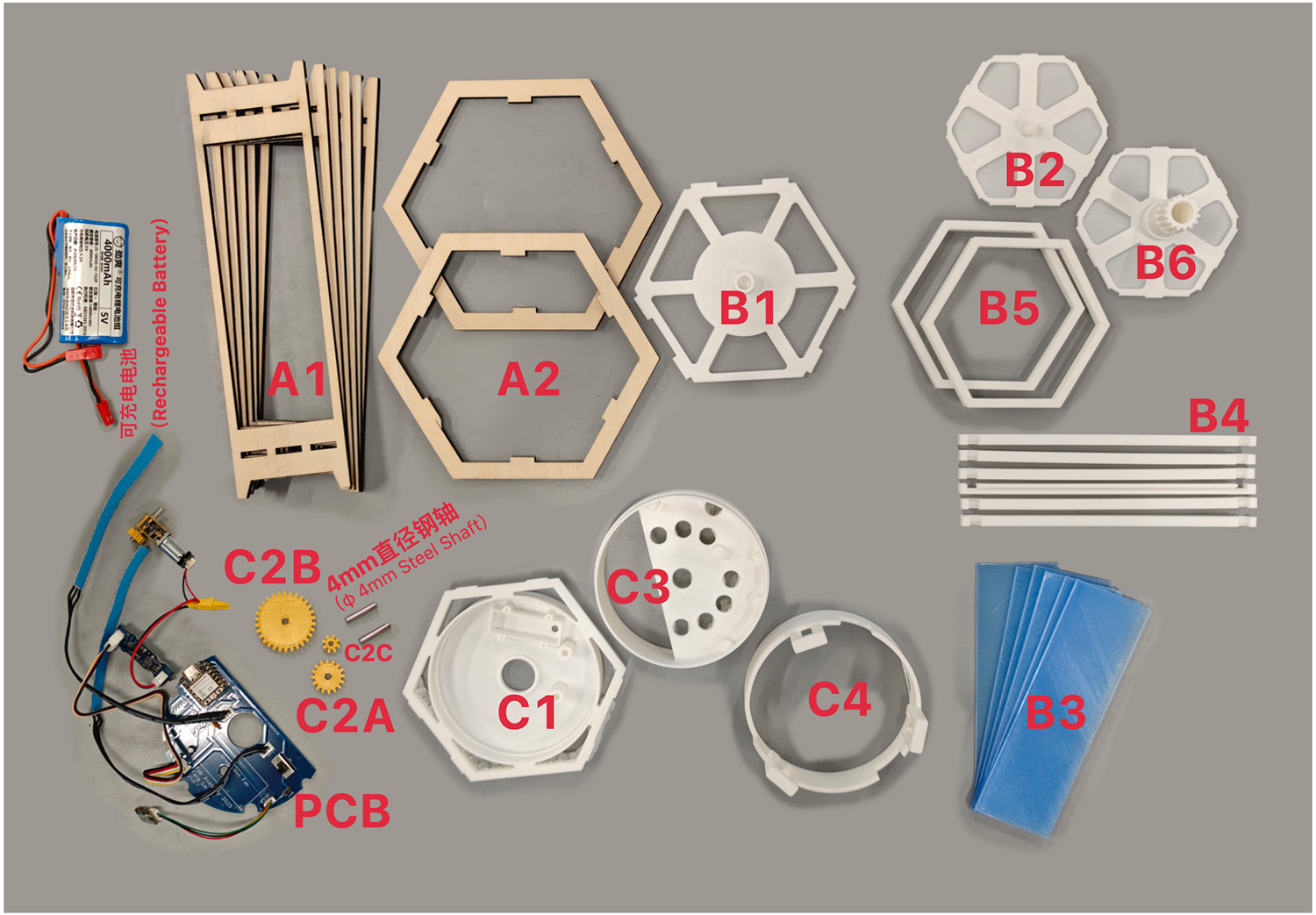

Structural Component List

| Component No. | Part Name | Quantity | Function Description | Manufacturing Method | Material |

|---|---|---|---|---|---|

| Gesture Sensor | 3 | Supports installation of up to 3 gesture sensors to sense gestures from various directions, directly controlling lighting effects and motor rotation | Purchase | ||

| C4 | Top Cover | 1 | Cylindrical, located at the very top of the lantern, with 3 gesture sensor brackets distributed at 120 degrees, nested and fixed with PCB compartment | 3D Printing | PLC/PETG |

| XIAO ESP32C3 | 1 | System core controller | Purchase | ||

| Semicircle PCB | 1 | Electronic hardware development board, positioned in PCB compartment through positioning fixing holes | Milling/JLC Production | Copper Clad Board/FR4 | |

| C3 | PCB Compartment | 1 | Cylindrical structure carrying PCB board, nested and fixed with gear compartment | 3D Printing | PLC/PETG |

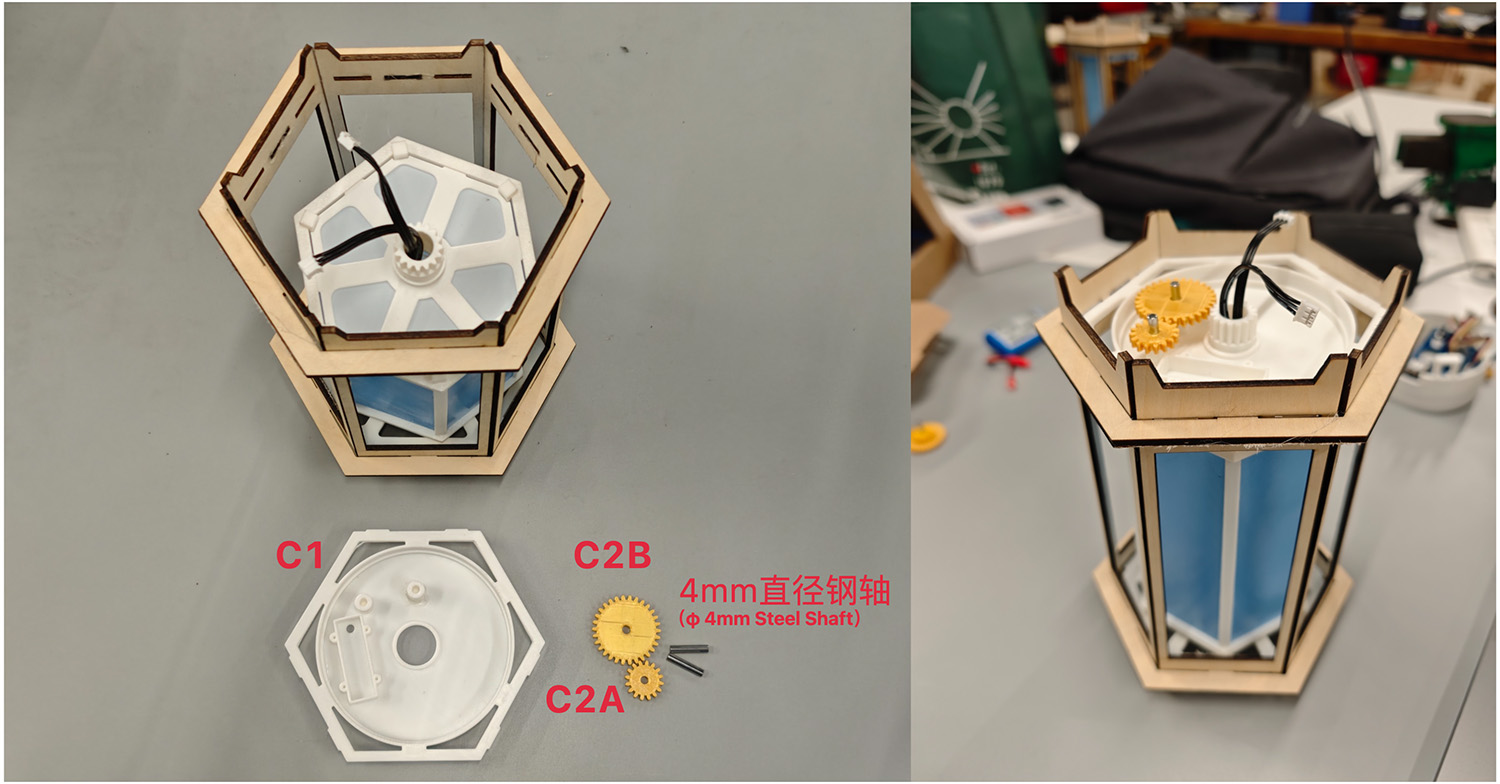

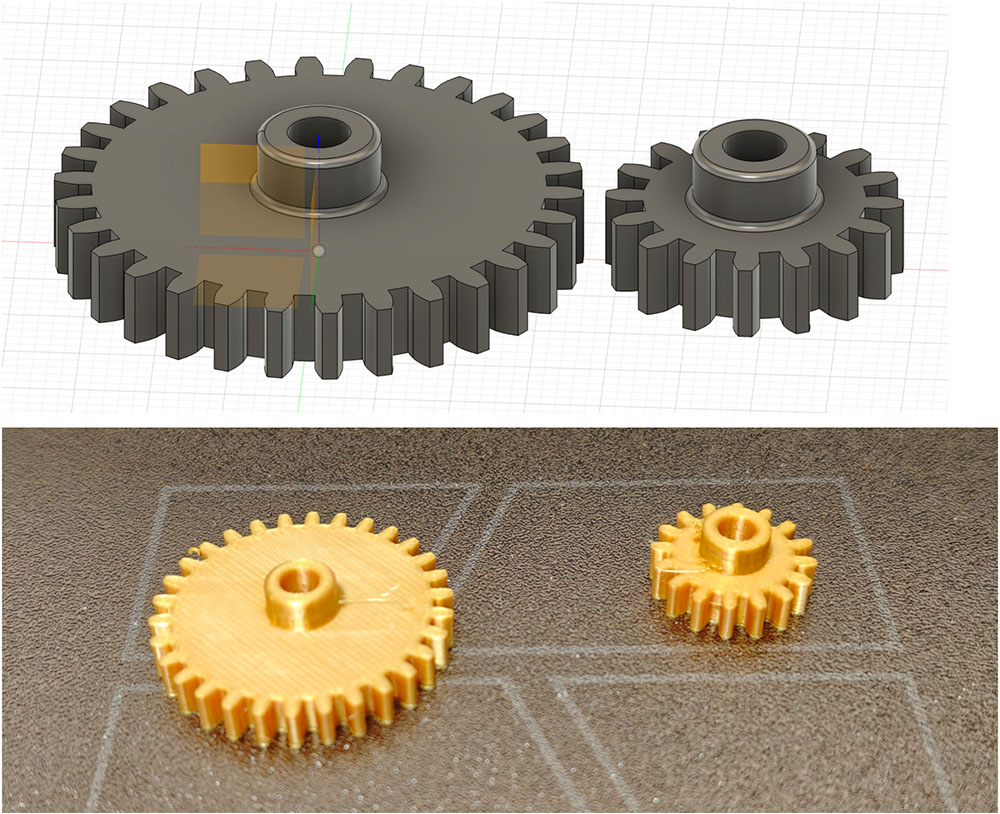

| C2A | Gear A m1.1x16 | 1 | Module 1.1mm, 16 teeth, bore diameter 4.25mm, fixed by 4mm steel shaft; Gear B drives rotating cage shaft gear through Gear A | 3D Printing | PLC |

| C2B | Gear B m1.1x30 | 1 | Module 1.1mm, 30 teeth, bore diameter 4.25mm, fixed by 4mm steel shaft; Gear C drives Gear A through Gear B | 3D Printing | PLC |

| C2C | Gear C m1.1x8 | 1 | Module 1.1mm, 8 teeth, connected to motor shaft, motor rotation also drives Gear C | 3D Printing | PLC |

| 4mm Diameter Steel Shaft | 2 | Supporting gears | Purchase | ||

| Motor | 1 | Drives gear group, then drives lantern rotating cage | Purchase | ||

| Rechargeable Battery | 1 | Powers the system | Purchase | ||

| C1 | Gear Compartment | 1 | Supports 3 gears, contains motor box and battery compartment; center has round hole for lantern rotating shaft gear to pass through and connect with gears inside gear compartment; fixed with outer rail through slot holes | 3D Printing | PLC/PETG |

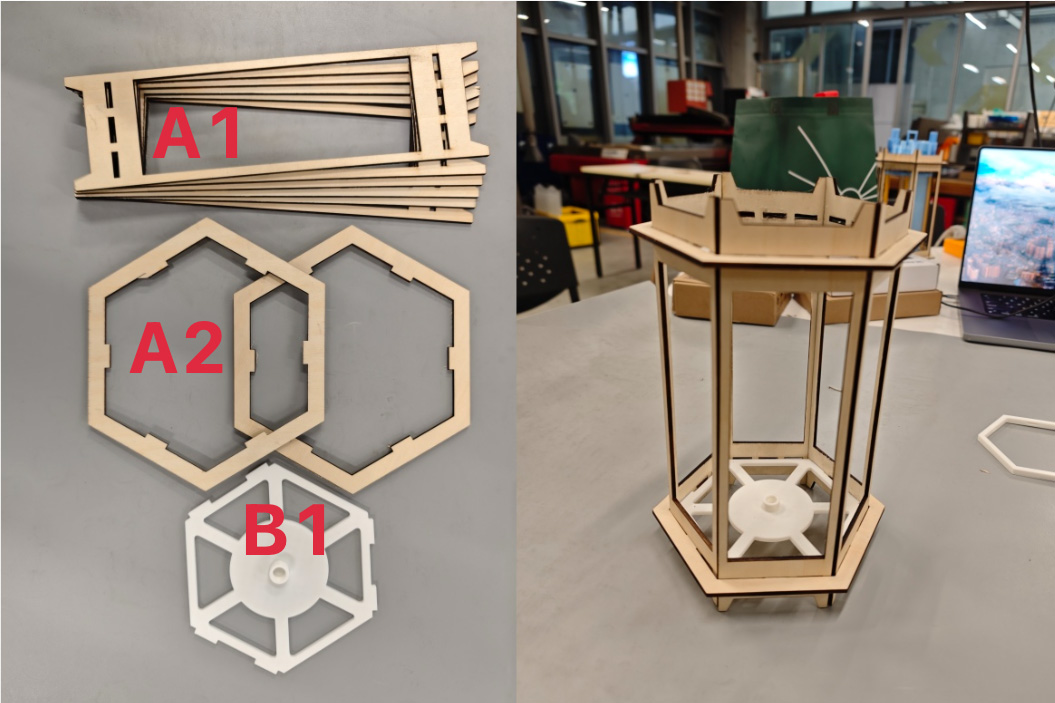

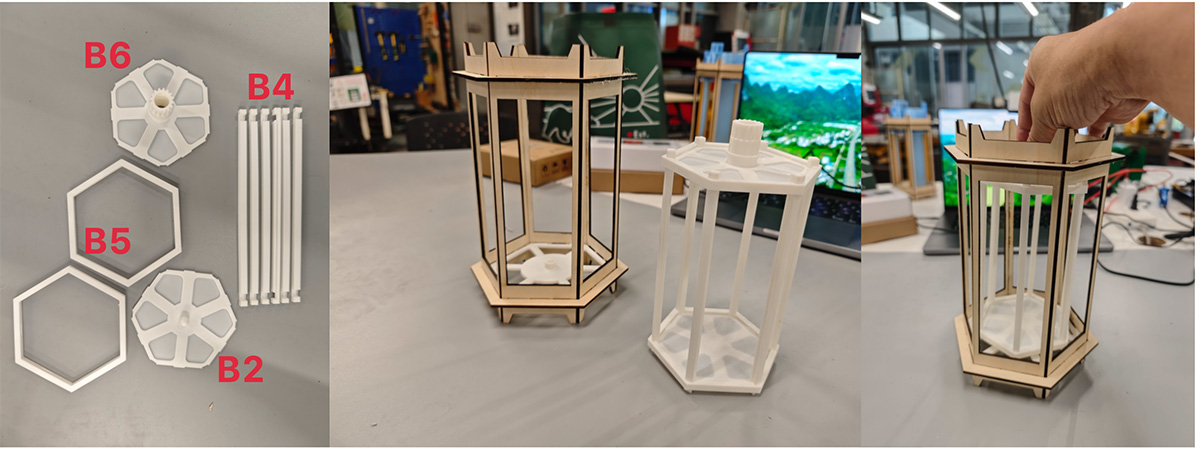

| B6 | Rotating Cage Top Cover and Drive Shaft | 1 | Top cover central shaft with gear, driven by Gear A in gear compartment to rotate entire rotating cage | 3D Printing | PLC |

| B5 | Rotating Cage Outer Frame | 2 | Top and bottom of rotating cage each have one, fixing rotating cage top cover, bottom cover and 6 rotating cage support columns | 3D Printing | PLC/PETG |

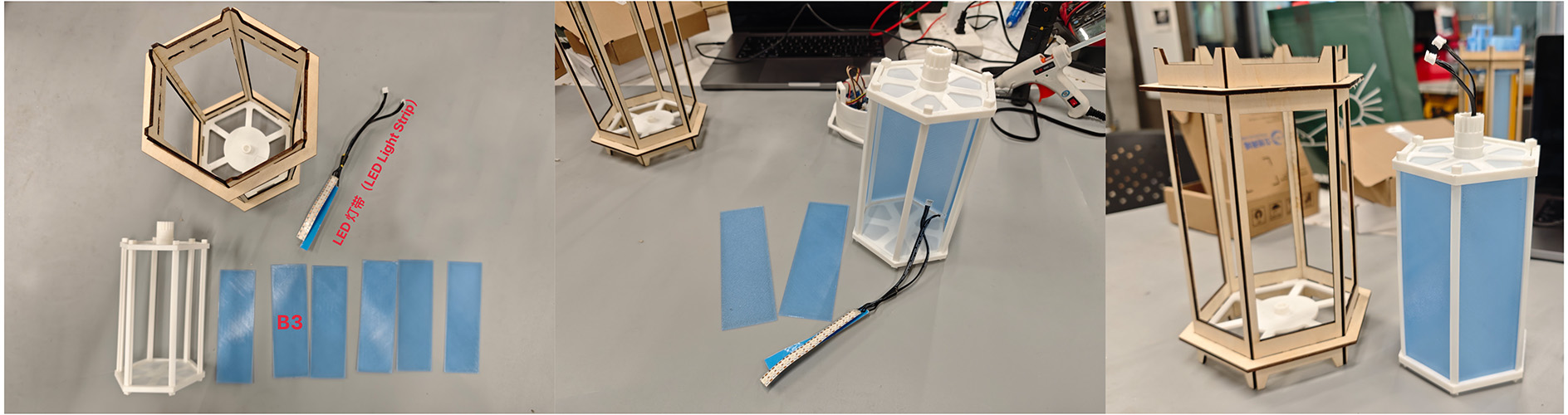

| LED Light Strip | 2 | Each light strip consists of 14 RGB LEDs | Purchase | ||

| B4 | Rotating Cage Support Column | 6 | Supports rotating cage and fixes lantern cover panels | 3D Printing | PLC |

| B3 | Lantern Cover Panel | 6 | 1mm thick semi-thin panels, 6 panels can have vinyl-cut sticker patterns, customizable DIY according to preferred themes | 3D Printing | PLC/PETG |

| B2 | Rotating Cage Bottom Plate | 1 | Bottom has a conical protrusion that can be placed in cylindrical constraint of lower support base | 3D Printing | PLC |

| B1 | Bottom Bracket of the Cage | 1 | Top has cylindrical fixing hole, fixed with outer rail through slot holes | 3D Printing | PLC |

| A1 | Lantern Outer Side Rail | 6 | Obtained by laser cutting | Laser Cutting | 3mm Wood Board |

| A2 | Lantern Outer Perimeter Rail | 2 | Top and bottom 2 pieces constrain lantern outer side rails | Laser Cutting | 3mm Wood Board |

Component Manufacturing

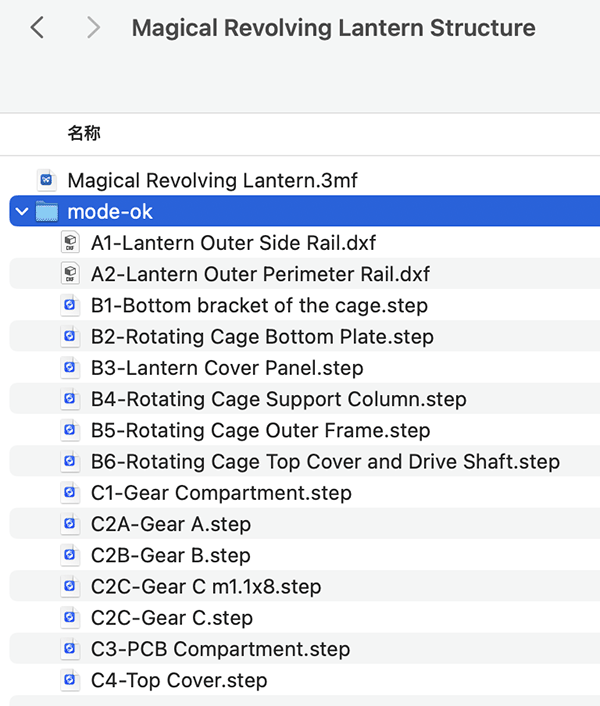

Manufacturing File Export

According to the numbering, I exported all files needed for manufacturing the structural parts, with the directory structure as follows.

All component files needed for the structural part

Download structure file archive: Magical Revolving Lantern Structure.zip

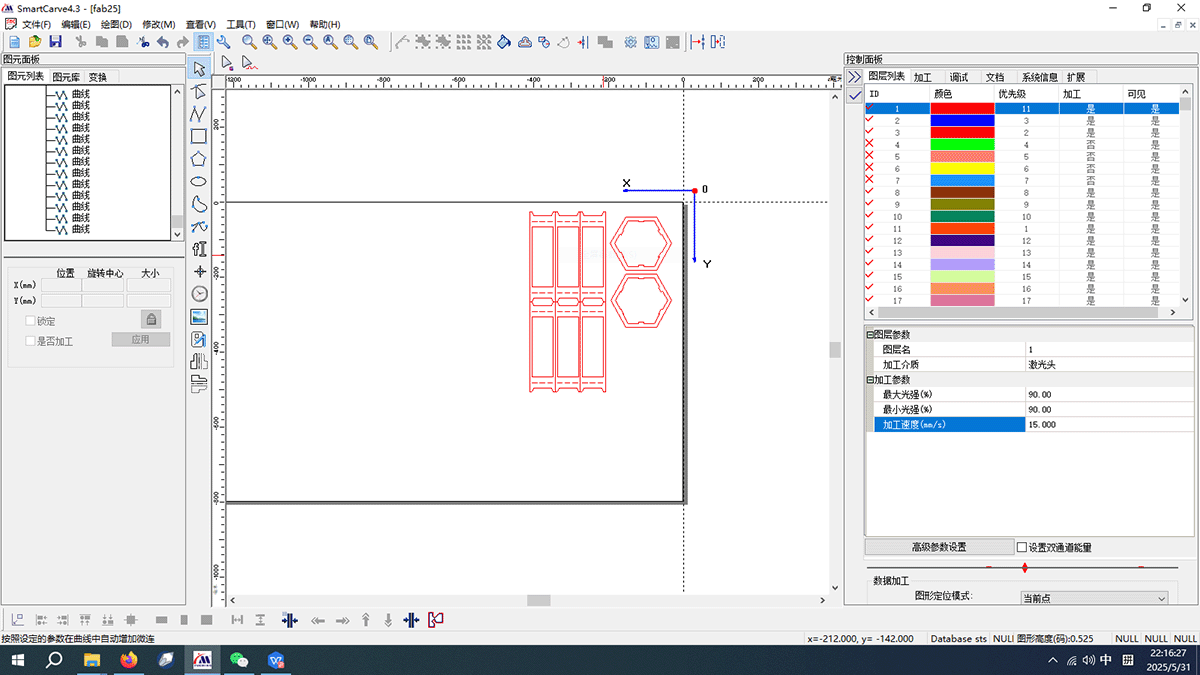

A1-A2 Laser Cutting

Import A1-Lantern Outer Side Rail.dxf (clone to 6 pieces) and A2-Lantern Outer Perimeter Rail.dxf (clone to 2 pieces) into laser cutting software. For 3mm basswood board, I set 90% laser intensity and processing speed of 15m/s.

Import A1 and A2 files into laser cutting machine software, clone required quantities, adjust laser energy and speed

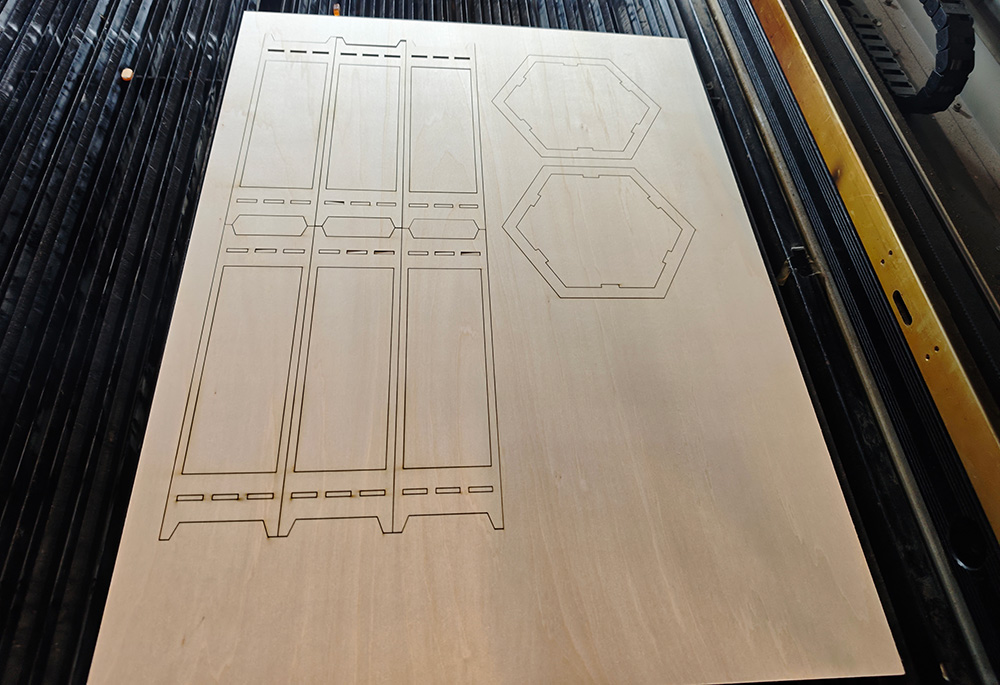

Then proceed with cutting.

A1-A2 cutting completed

B1-C4 3D Printing

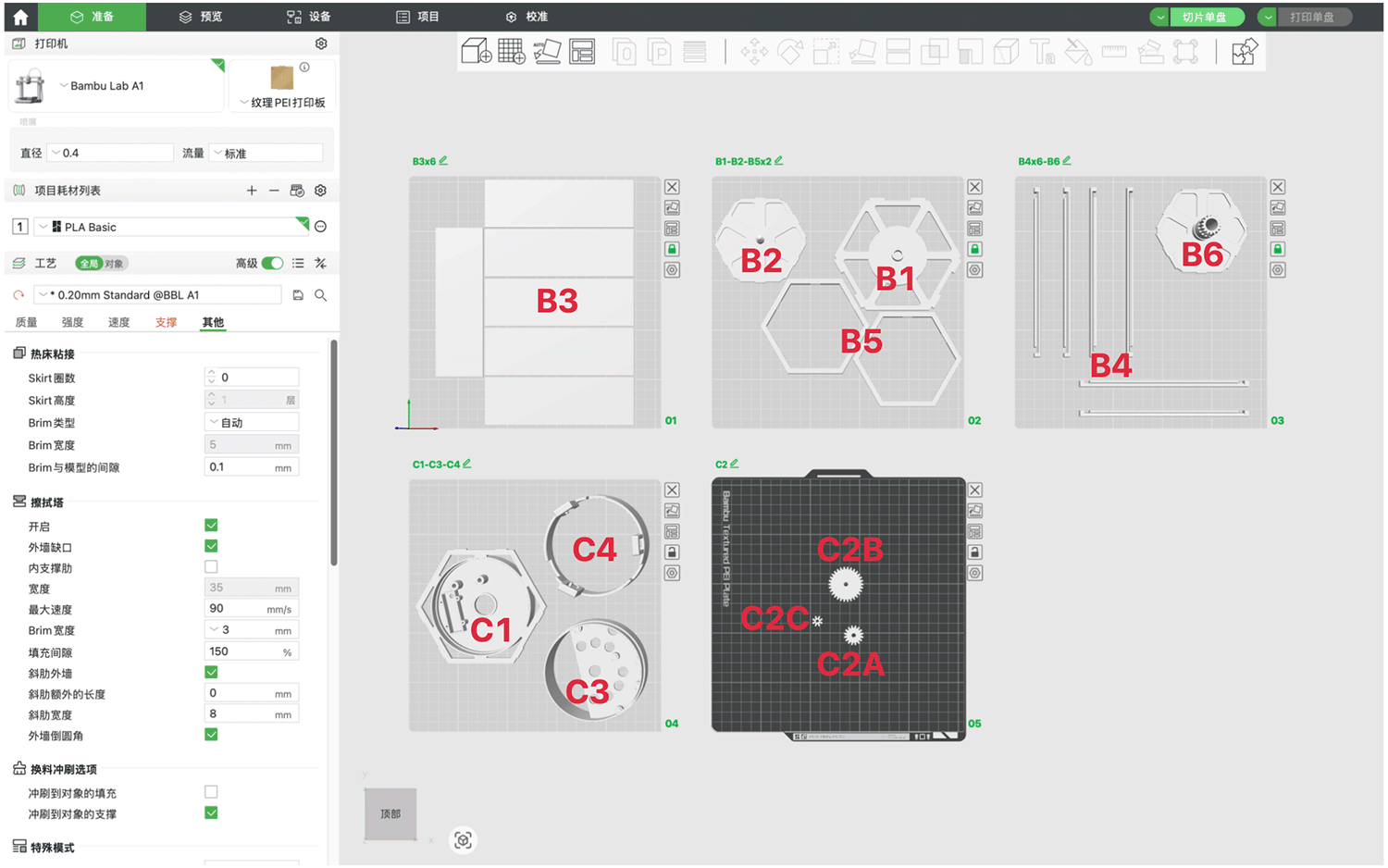

There's a Magical Revolving Lantern.3mf file in the archive, which is a Bambu printer project archive. When opened, you can see the plate distribution effects of all 3D printed parts, convenient for slicing and printing plate by plate.

Bambu printer project multi-plate archive

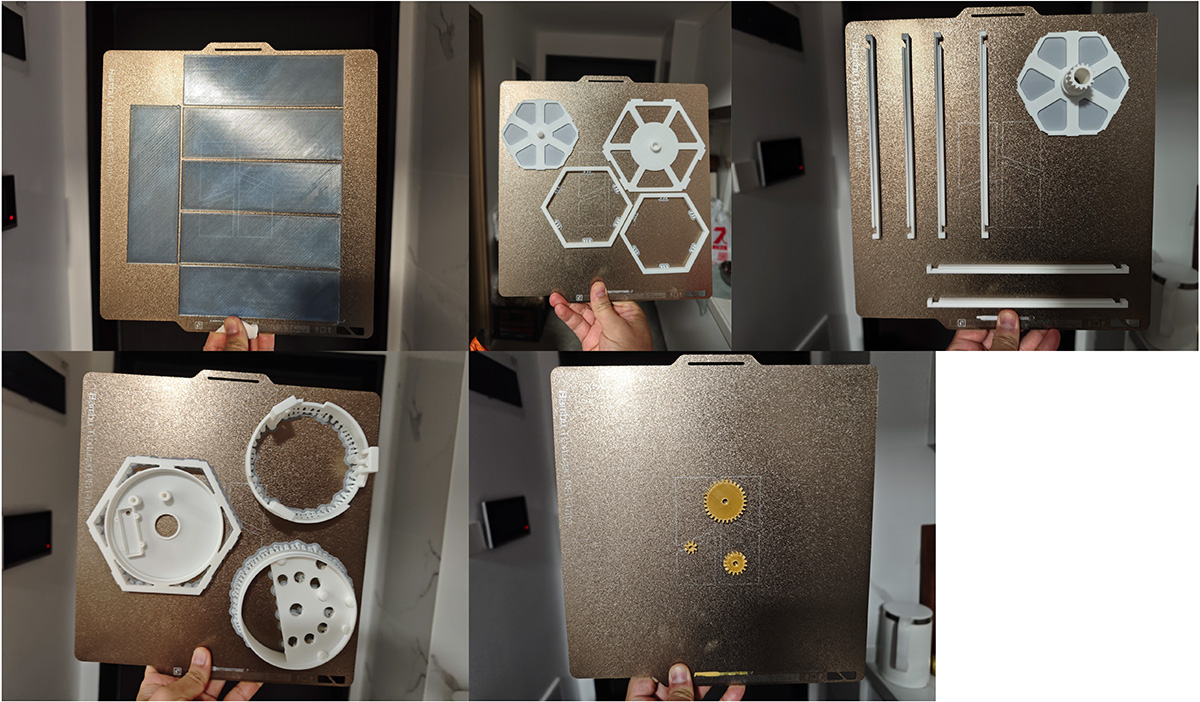

Printing plate by plate, using Bambu LAB A1 printer, I printed all components plate by plate. For B3 lantern cover panels, I used translucent PETE material. For gears, to distinguish them from the gear compartment, I used golden PLA Silk material. Everything else was white PLA material.

Using Bambu LAB A1 printer, printed all components plate by plate

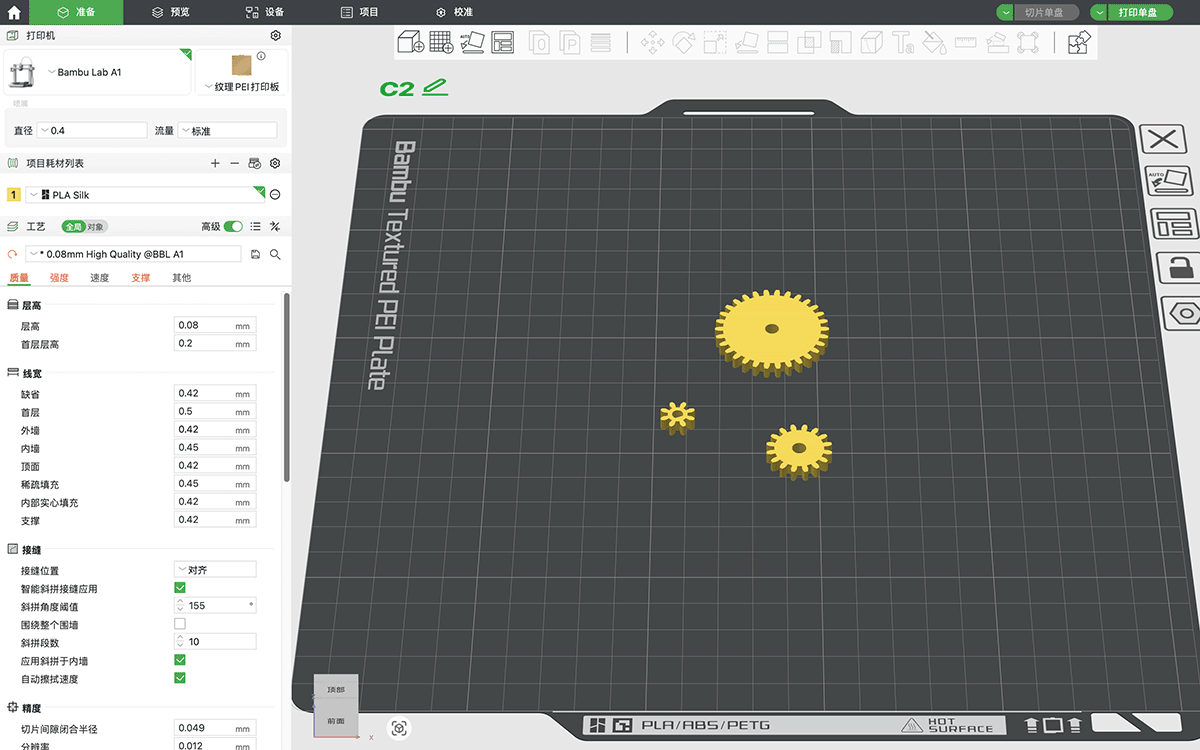

When printing gears, it's best to use highest quality printing (0.08mm High Quality). I tried it and found that the default 0.2mm makes the holes in the middle of gears smaller, unable to rotate when fitted on 4mm steel shafts.

When printing gears, recommend selecting highest quality

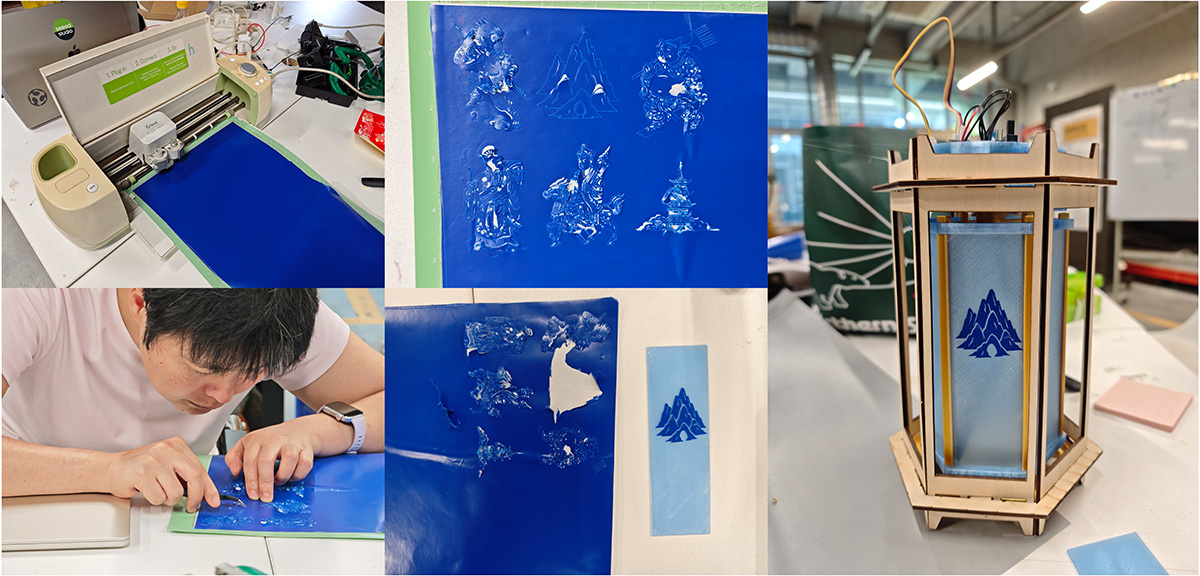

Lantern Rotating Cage Cover Sticker Design

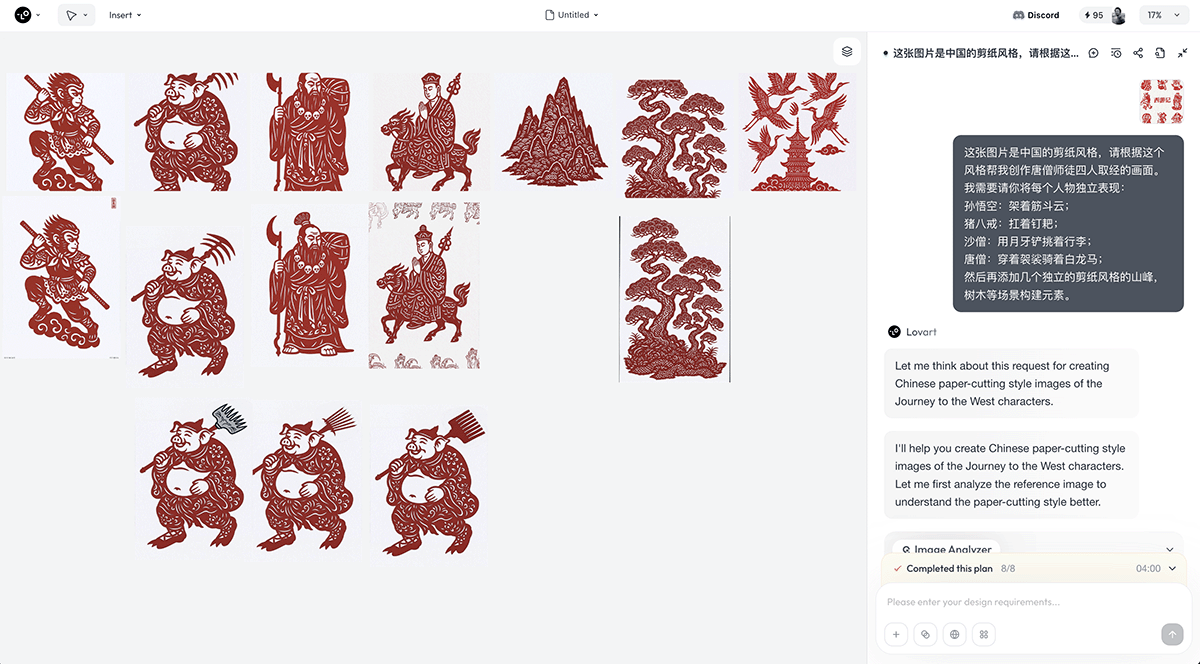

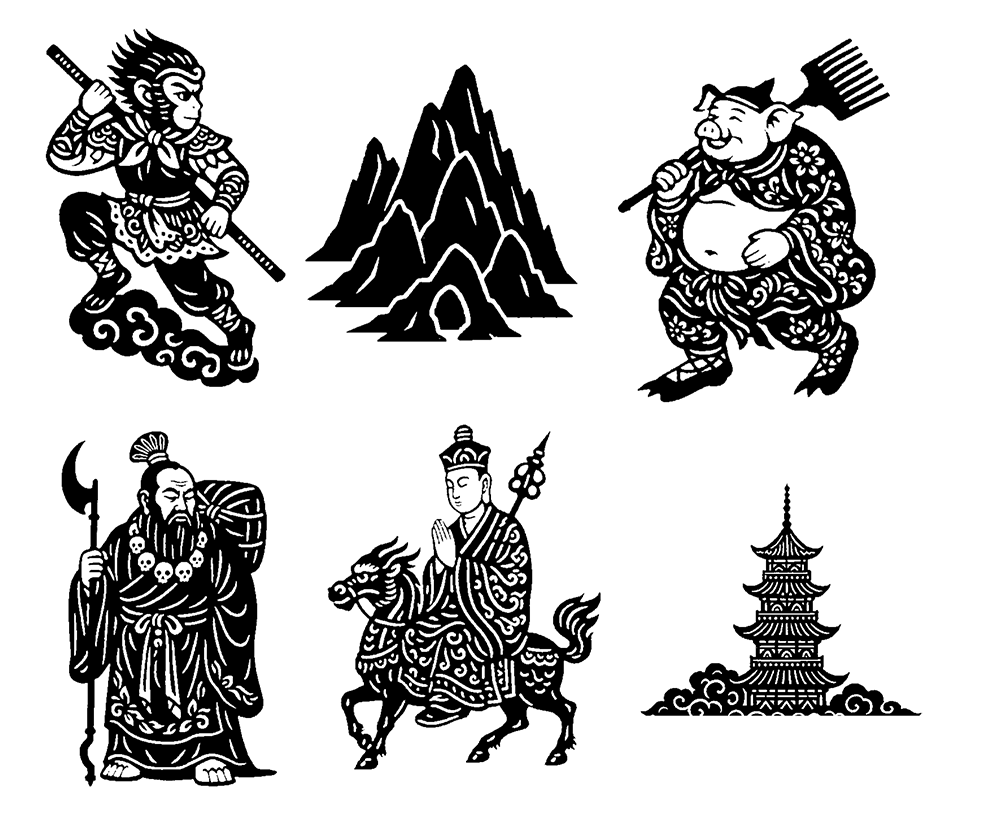

For the lantern rotating cage covers, I used light blue translucent PETG material for printing, with 1mm thickness. Single piece dimensions are 48×151 mm, with a total of 6 pieces. I wanted to use vinyl cutting for some Chinese-style paper-cut patterns to stick on the lantern cover surface.

So I tried using the online tool https://www.lovart.ai/, through prompts and Chinese paper-cut reference images, I made requests. After several rounds of communication, I got the Journey to the West paper-cut style patterns I needed.

The online tool https://www.lovart.ai/ can generate series of high-quality Journey to the West paper-cut illustrations through the paper-cut reference images I provided and prompts

Then I planned the required patterns according to the dimensions of the 6 rotating cage lantern covers, as shown in the figure below.

Readjusted the size of AI-generated paper-cut patterns to fit the size of rotating cage cover panels

Obtained the patterns needed for the vinyl cutting machine, as shown in the figure below.

Patterns needed for vinyl cutting machine

Electronic Hardware Design

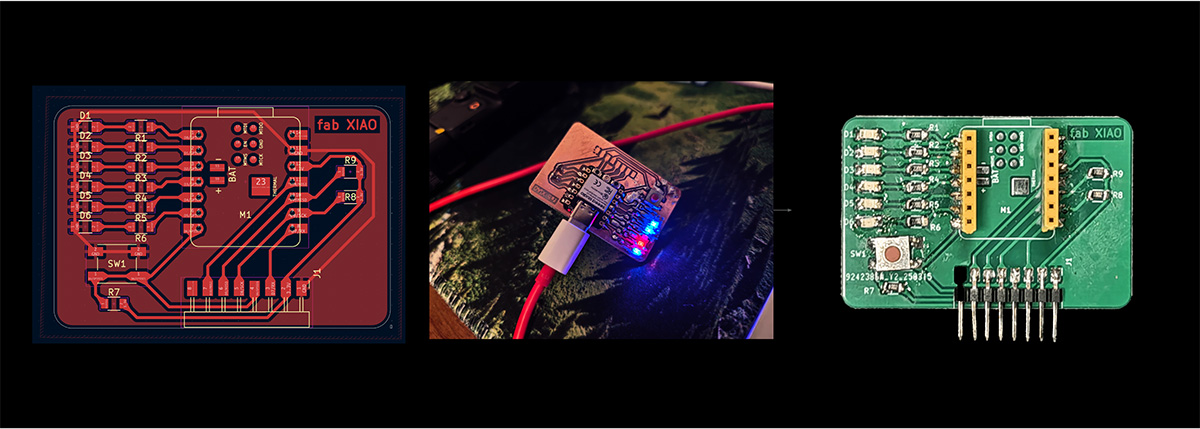

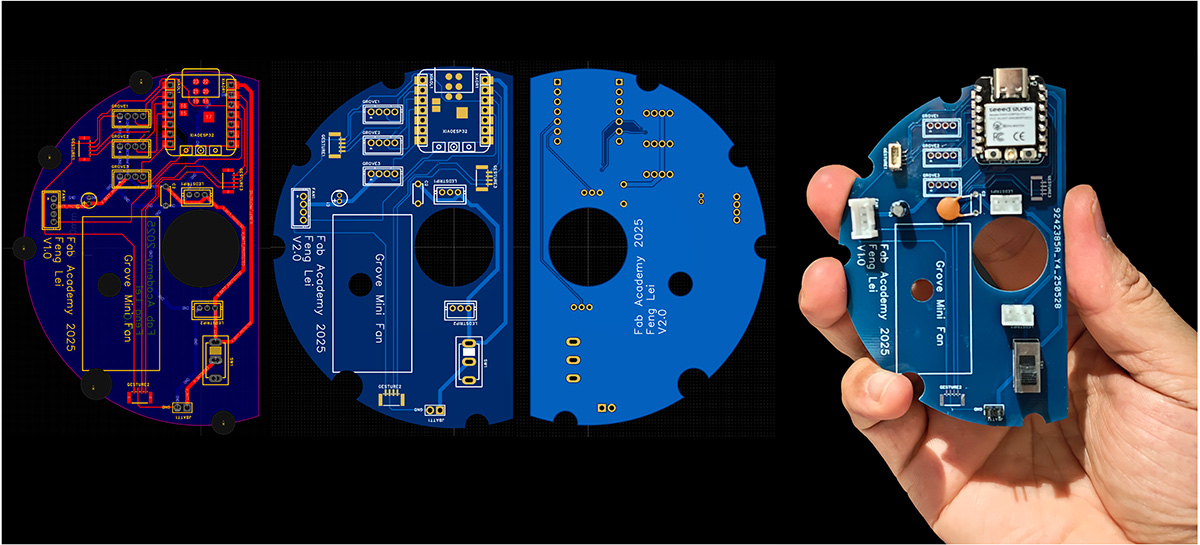

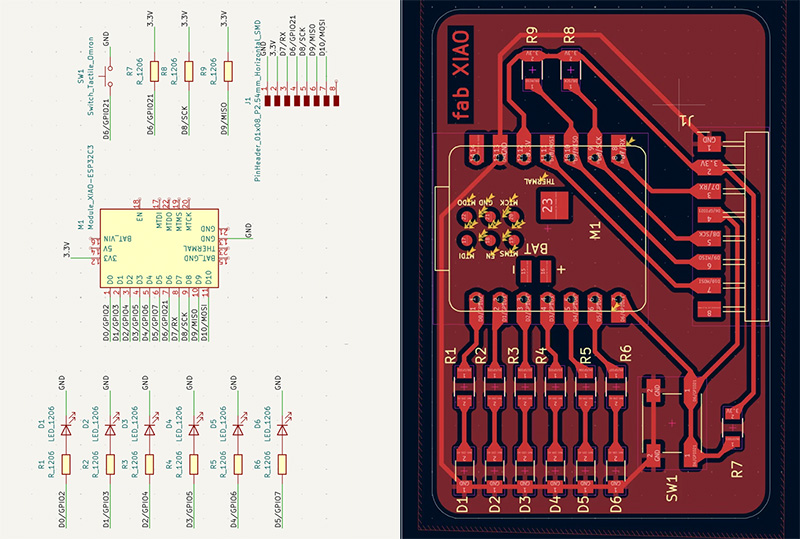

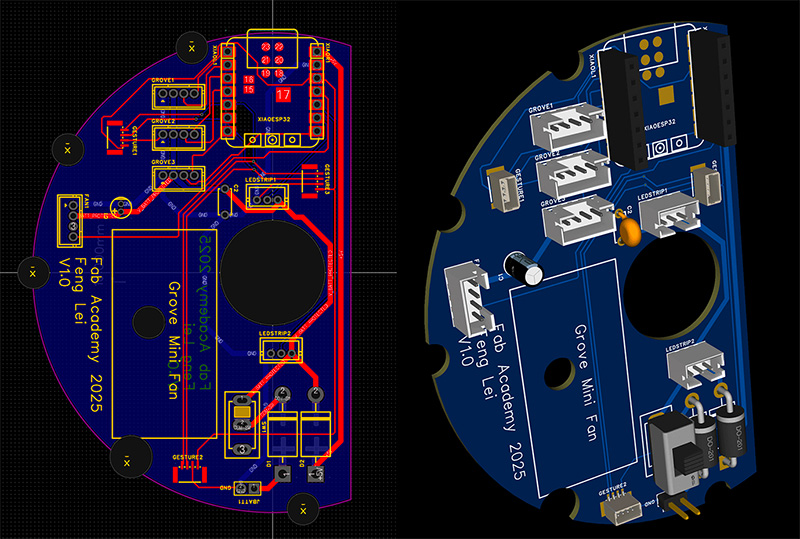

The PCB of the Magical Revolving Lantern went through 4 major iterations.

Version 1: Weekly Course Electronic Project Verification

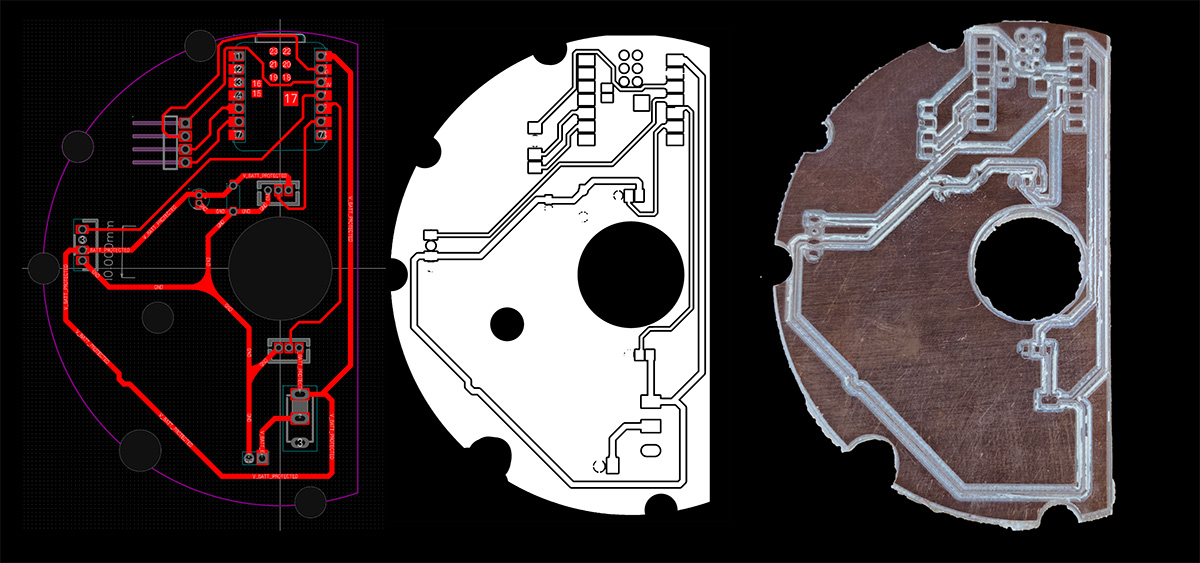

In my Fab Academy course weekly projects, I designed an initial version PCB with KiCad and tried both CNC cutting and commercial manufacturing (JLC production). These 2 boards from the first generation helped me complete various electronic projects in the first 15 weeks, verifying various electronic functions required for the lantern.

Generation 1 PCB designed for Magical Revolving Lantern. To facilitate light effect testing, I placed the LED array diameter on the PCB and tried both CNC milling and commercial manufacturing

Version 2: Milled Semicircular PCB

The entire PCB of the Magical Revolving Lantern began to be planned as circular to fit exactly on top of the gear compartment, but this left insufficient space for the battery, so according to the structure, I adopted a semicircular ring PCB integrated design to make room for the battery.

From Version 2, I started trying EasyEDA, feeling that its library is much richer and convenient for manufacturing. I first designed a milled PCB aiming for basic functional verification, but found that wiring was troublesome.

Version 2 PCB schematic

Version 2: Left is the milled PCB design from EasyEDA, middle is PNG converted from nc file for circuit cutting output by CNC, right is the milled PCB

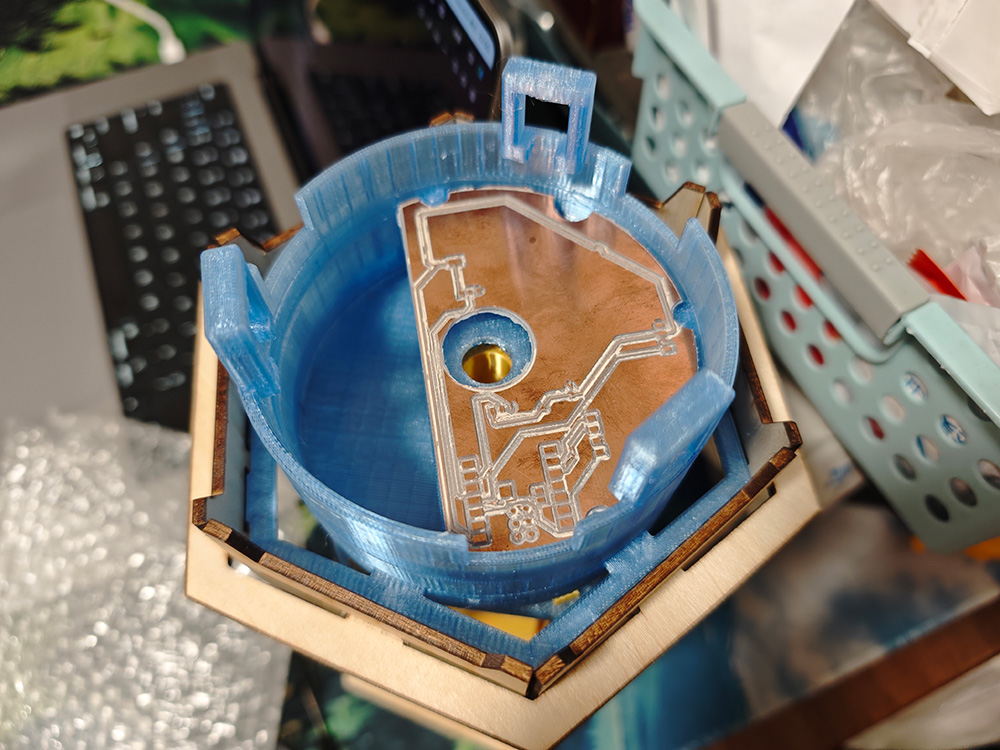

Testing the size of the milled PCB, it fits well with the PCB compartment.

Testing Version 2 milled PCB dimensions

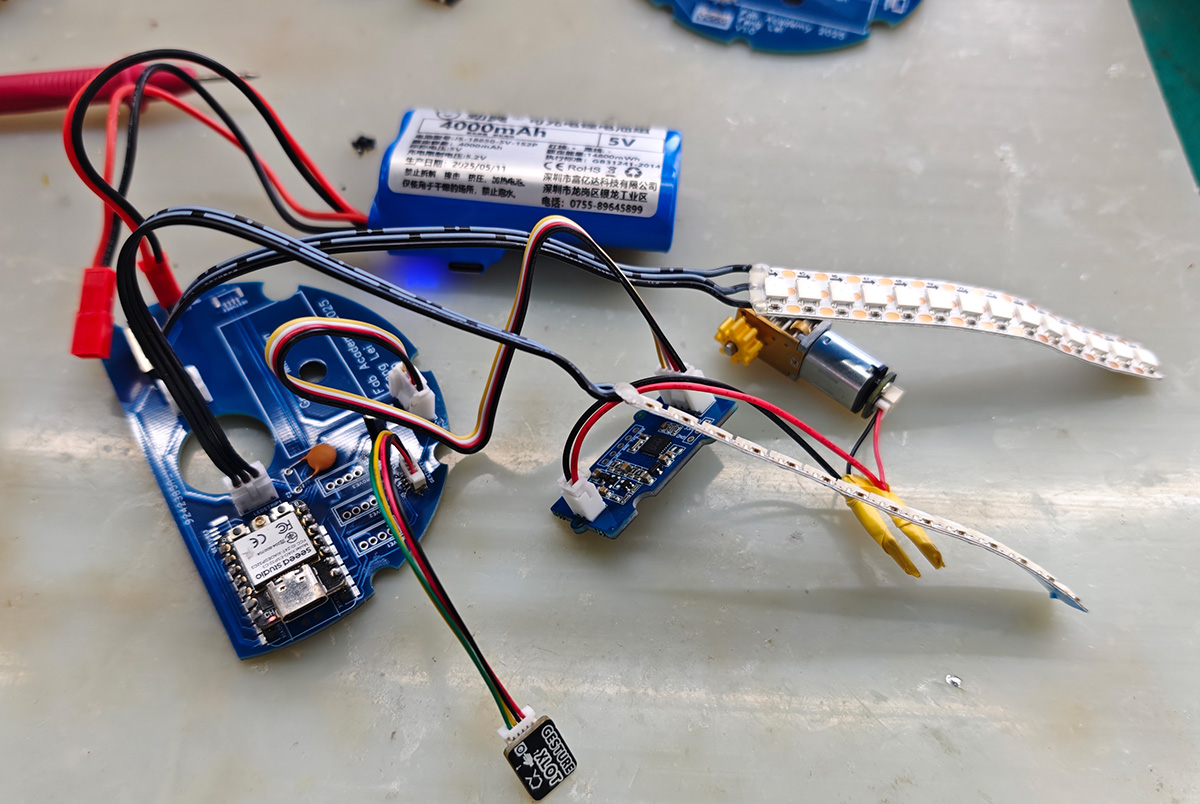

I used this PCB to initially verify XIAO ESP32 C3, battery, switch, motor, LED strips and gesture sensors, but the main problem was that wiring was complex and not very stable.

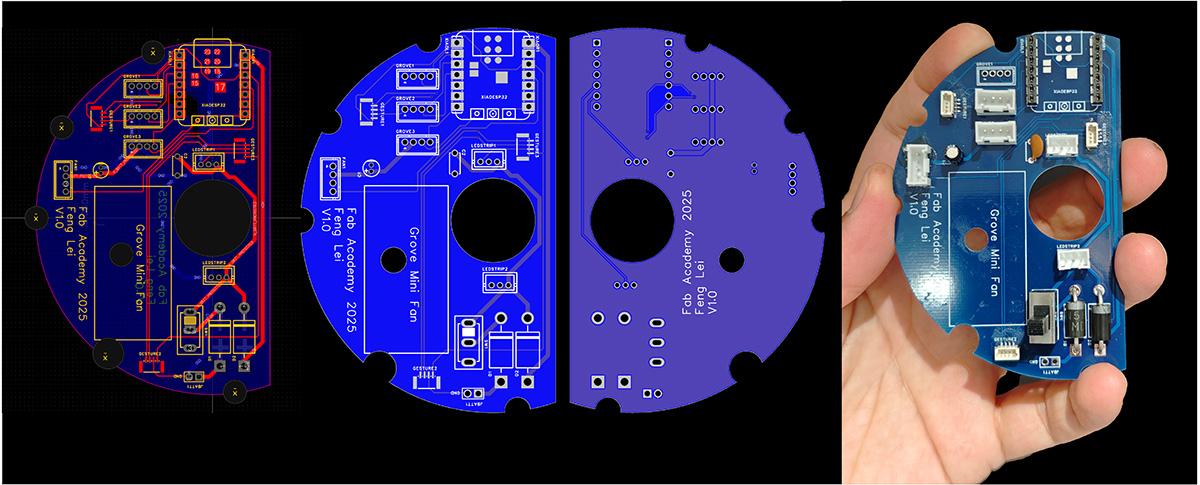

Version 3: Double-sided PCB Attempt - Various Failure Lessons

Version 2 attempted more complex PCB design (I wrote this process into Week 17 individual assignment), including double-sided and adding wire-to-board connector support. Because the board was quite complex, I had it manufactured through JLC. The board came out beautifully, and I confidently soldered all components.

The soldered board looked great, but reality was that this version's new design had many bugs, causing this board to be completely scrapped. Main problems included:

- Incorrect spacing of XIAO dual-row pin sockets (about 3mm too wide), preventing XIAO from fitting into sockets;

- Reversed wire order for LED strips, gesture sensors and motor connector interfaces, causing all wire orders to be reversed when plugged in;

- AI-suggested Schottky diodes cause voltage drop, preventing battery power supply to XIAO;

I addressed these issues and modified the PCB design a third time.

Version 4: Double-sided PCB Revision Attempt - Finally Successful

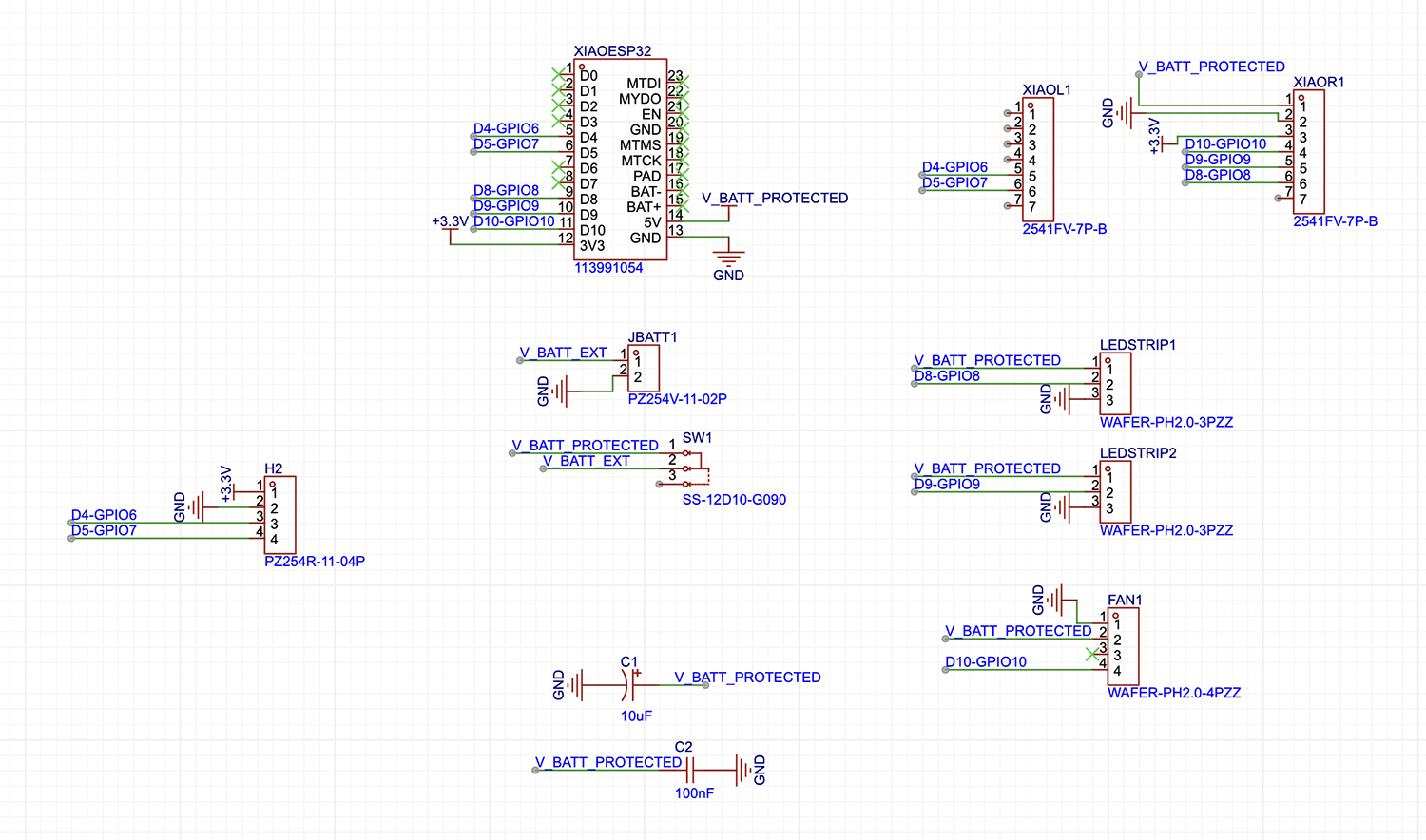

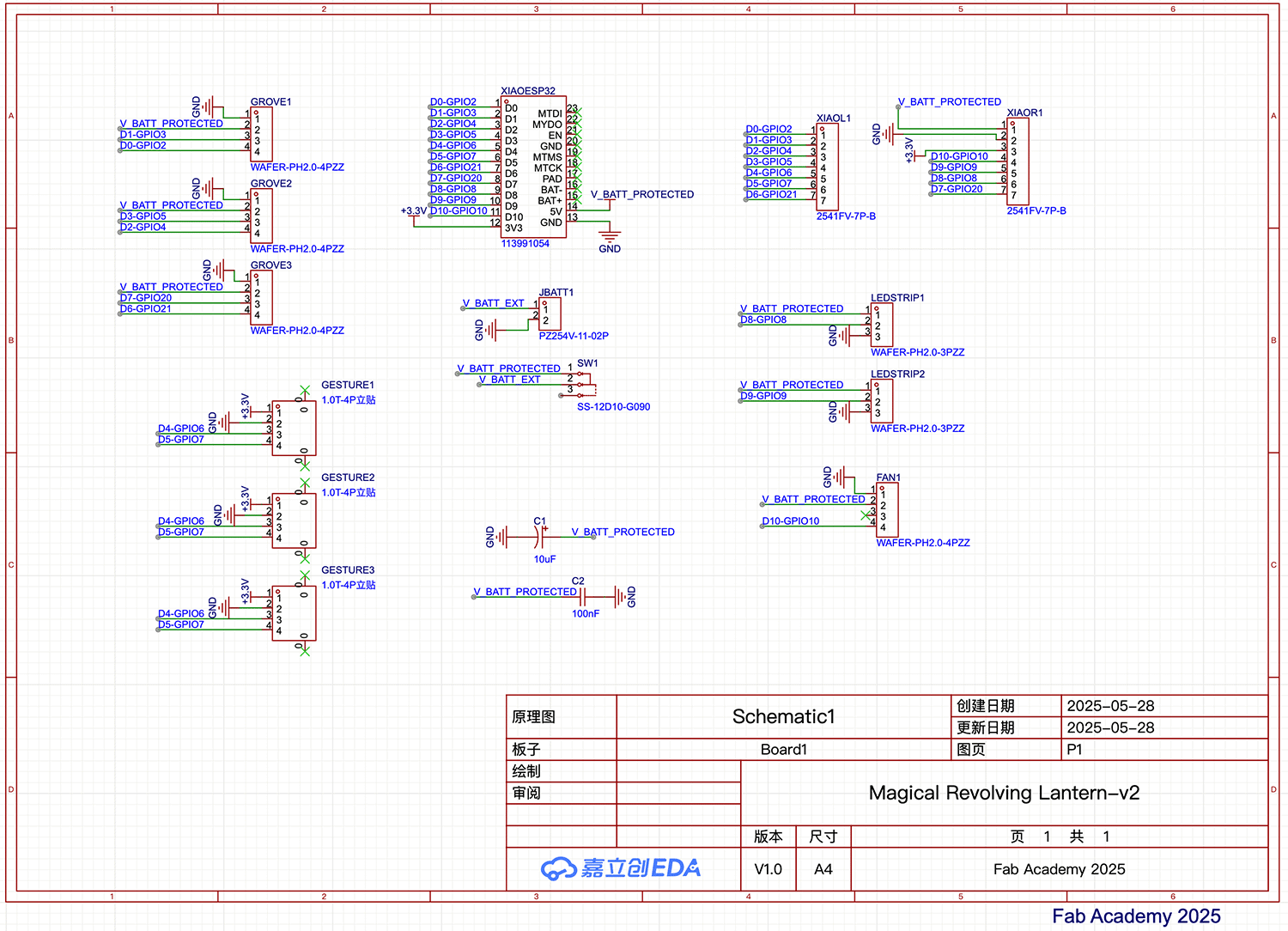

Addressing the problems encountered in actual soldering and testing of the PCB designed and manufactured in Week 17, I made a round of improvements. The final completed circuit schematic is shown below.

Version 4 PCB design circuit schematic

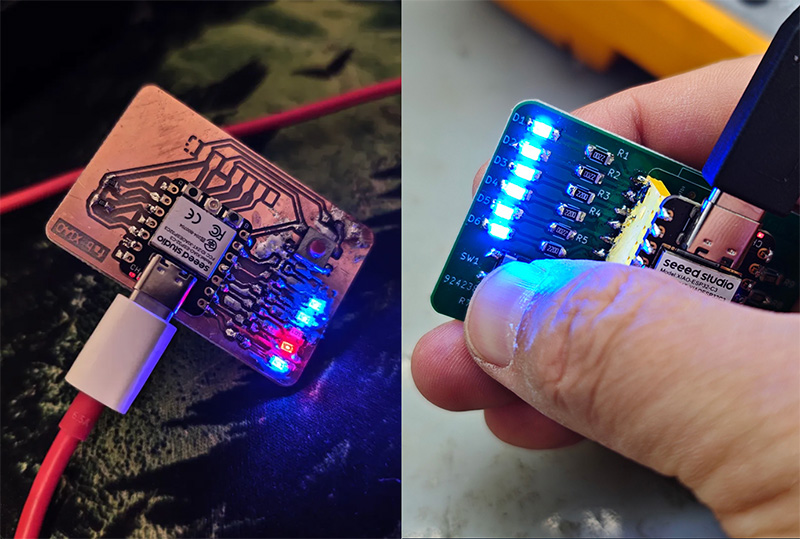

In EasyEDA, I readjusted components and wiring according to the schematic and remanufactured it. This time the component soldering and testing went very smoothly.

Using EasyEDA for routing and displaying 3D effects

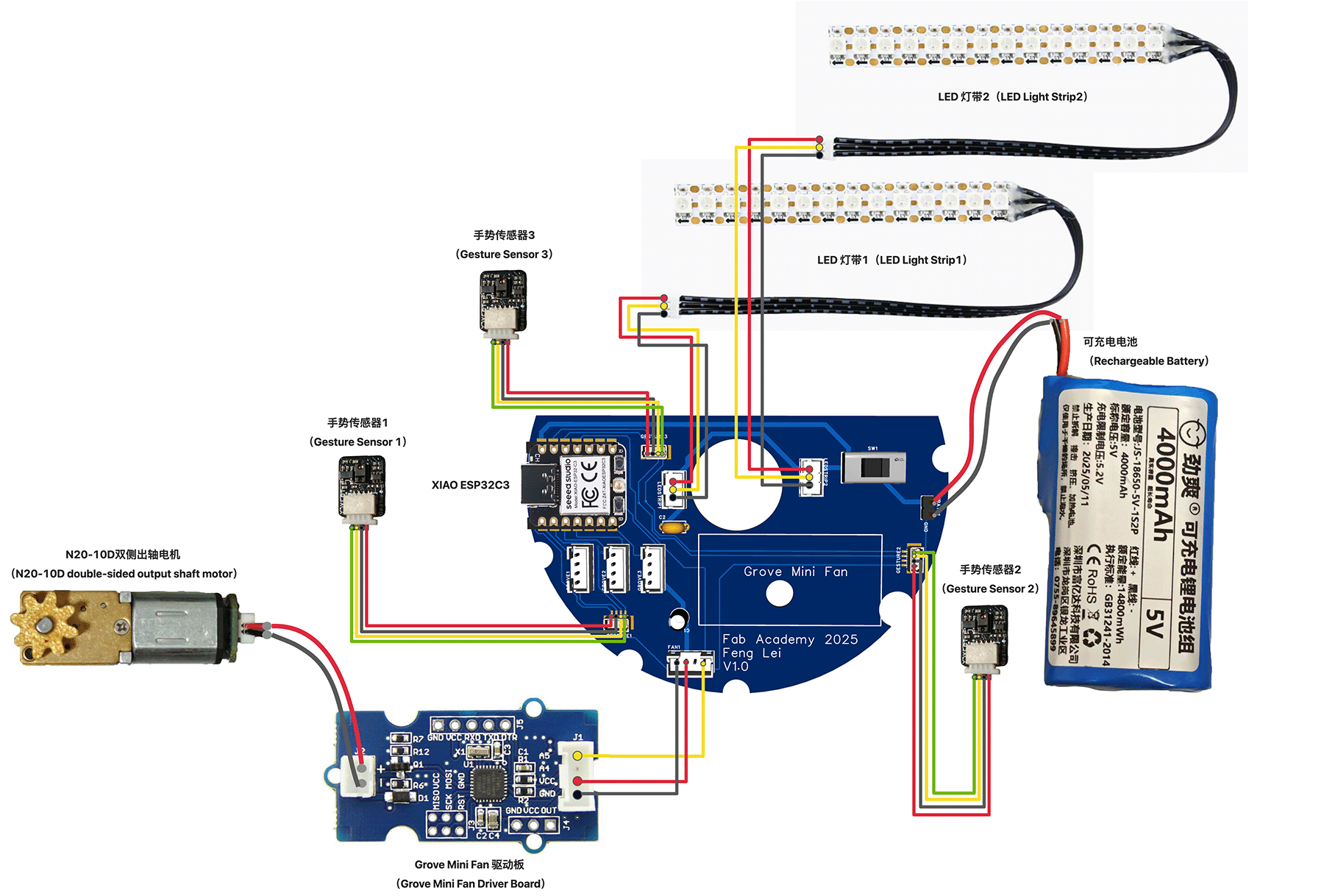

The final module connection diagram is shown below:

Electronic hardware connection diagram used by the lantern

Control Core: XIAO ESP32C3 I chose this little guy for three reasons: compact size, built-in WiFi, Arduino compatibility. On a coin-sized PCB, it serves as the brain of the entire system.

Sensing System: Three-Eye Detective Three APDS-9960 sensors distributed at 120°, theoretically covering all directions on the horizontal plane. Each sensor can not only recognize gestures but also detect distance and ambient light intensity, leaving expansion space for future intelligence.

Actuator: Gear Transmission + LED Array The mechanical part uses a precisely calculated gear system with optimized transmission ratio, ensuring sufficient torque while controlling speed within reasonable range. The LED part consists of 2 light strips (each strip has 14 RGB LEDs), creating rich light and shadow effects.

Testing Version 4 PCB to ensure all connected devices work properly.

Version 4 PCB testing successful

Assembly Process

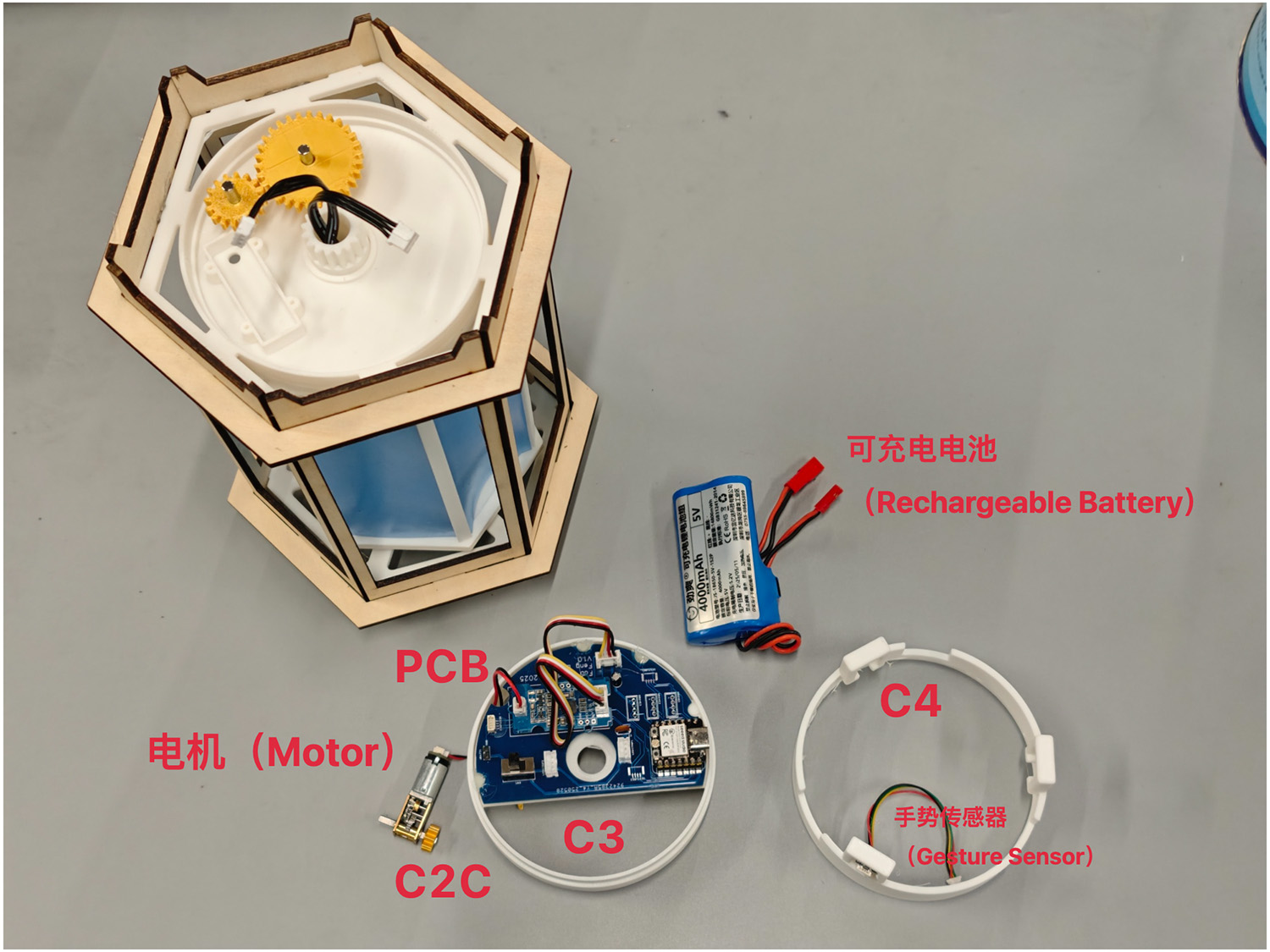

With structural components and PCB ready, we can proceed with assembly. Below are all the parts and components of a Magical Revolving Lantern.

All parts and components of the Magical Revolving Lantern

Assembling Outer Frame Structure A1, A2 and B1

When assembling A1 and A2, you can use a hot glue gun for initial fixing (small amount only, to prevent A1 from falling during inversion). Once assembly is complete, the entire structure becomes very tight and solid. Note that B1 has a cylindrical protrusion that must face upward.

First assemble laser-cut wooden boards A1 and A2, then embed B1 into bottom slots, noting that B1's cylindrical groove should face upward

Assembling Lantern Rotating Cage

This step requires patience. Note that B2 needs the conical rotating shaft face downward so the bottom conical shaft of the rotating cage can be placed into B1's cylindrical groove. The assembled rotating cage is shown below. You can try placing the assembled rotating cage into the outer frame assembled in step 1, ensuring the bottom cone of the rotating cage fits into the lower base's cylindrical groove, allowing easy hand rotation of the rotating cage.

Assemble B2, B4, B5 and B6 to get a solid rotating cage, can be placed into the outer frame assembled in step 1 for testing

Adding Cover Panels and Placing LED Light Strips to Rotating Cage

Carefully embed the rotating cage cover panels (B3) into the grooves on the sides of the rotating cage support columns. When 2 panels remain, remember to thread the thinner plug end of the LED strips from inside through the shaft hole of B6 at the top of the rotating cage, then seal the last two cover panels.

Install lantern cover panels (B3), remember when 2 panels remain, thread the LED strip connectors through the shaft hole of B6 at the top of the rotating cage, then install the remaining 2 panels to seal the lantern

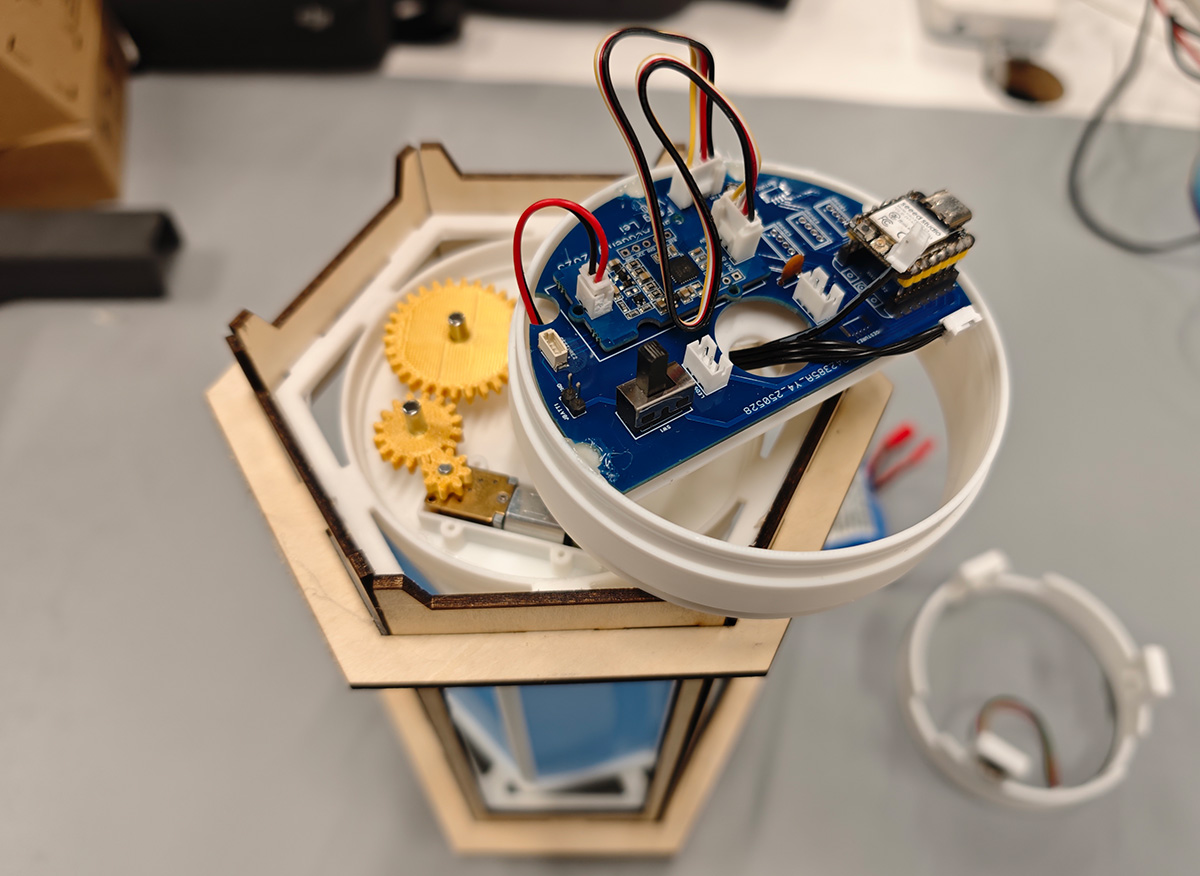

Assembling Gear Compartment (C1) and C2A & C2B Gears

Insert 4mm diameter steel shafts into the 2 shaft holes of B3, and place C2A and C2B gears respectively, then place B3 into the revolving lantern structure, let the rotating cage's geared shaft pass through B3's center hole. Push B3 down into the wooden lantern frame's slots, and the rotating cage truly becomes stable. At this point, you can manually rotate the rotating cage's central shaft gear, and you should see the rotating cage rotate very flexibly while driving C2A and C2B gears to rotate.

Insert 4mm diameter steel shafts into the 2 shaft seats of gear compartment (C1), then place gear C2B (the largest one, positioned close to the rotating cage central shaft gear) and C2A on the steel shafts. Push C1 down along the wooden frame, letting the rotating cage's geared central shaft pass through C1's center hole, then get caught by the wooden side rail slots

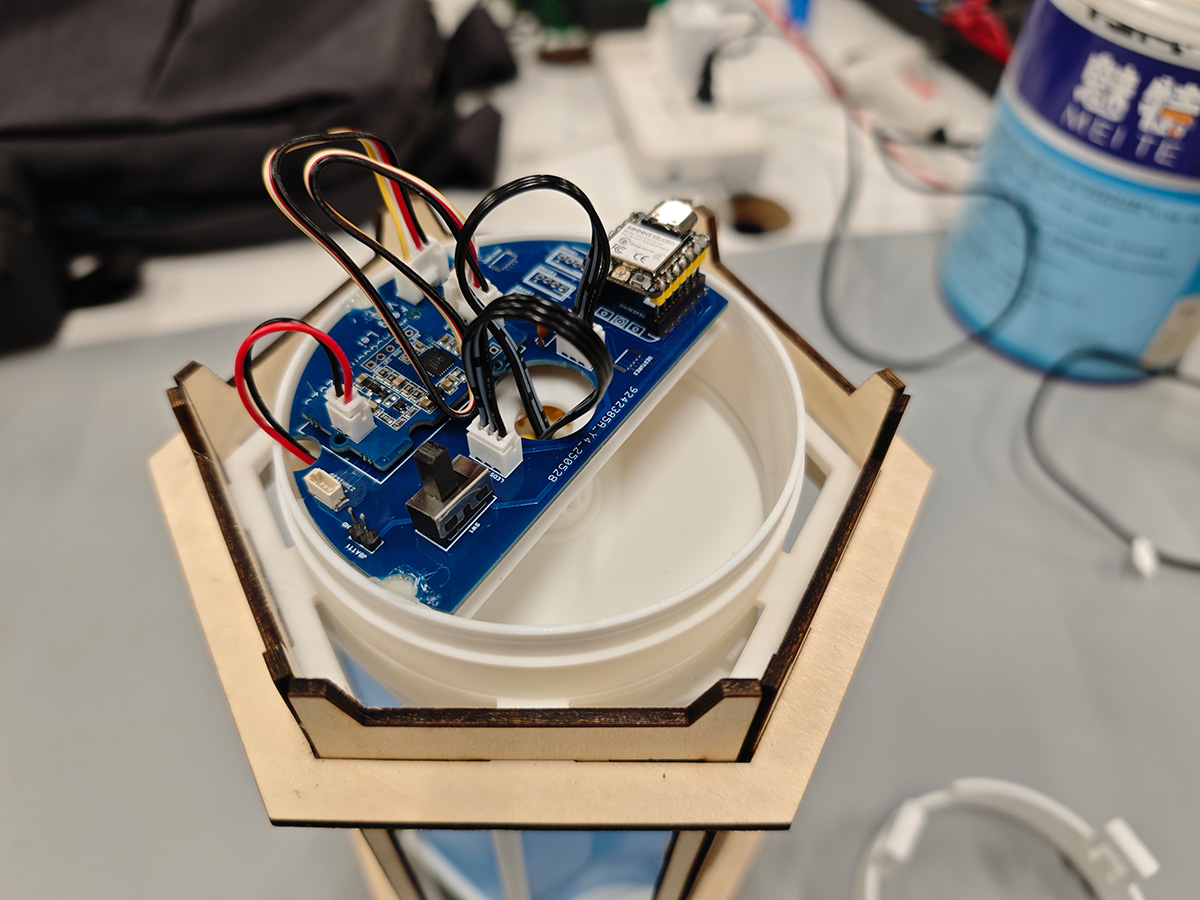

Integrating PCB Compartment and Top Cover

First place the PCB along the positioning holes in the PCB compartment (C3), can use hot glue gun to fix the PCB, then also fix the Grove Mini FAN control board on the PCB, and connect the PCB and control board with Grove wire. The 2P motor wire from one end of the control board can pass through the hole on the side of the PCB, connecting to the motor. Then fix the head of 1 gesture sensor on the bracket reserved in C4 with hot glue gun, noting that the sensor probe faces outward.

Place the PCB board in PCB compartment (C3), connect the motor control board, the 2P motor wire from one end of the control board can pass through the hole on the side of the PCB; fix the head of 1 gesture sensor on the bracket reserved in C4 with hot glue gun

Install C2C gear on the motor shaft and place in the battery compartment.

First place the motor in the battery compartment

Before installing the PCB compartment, remember to connect the motor's 2P power wire.

Connect the motor 2P wire first, then install the PCB compartment

Carefully insert the PCB compartment on top of the gear compartment, then connect the 2 LED strip connectors.

Install PCB compartment and plug in LED strip connectors

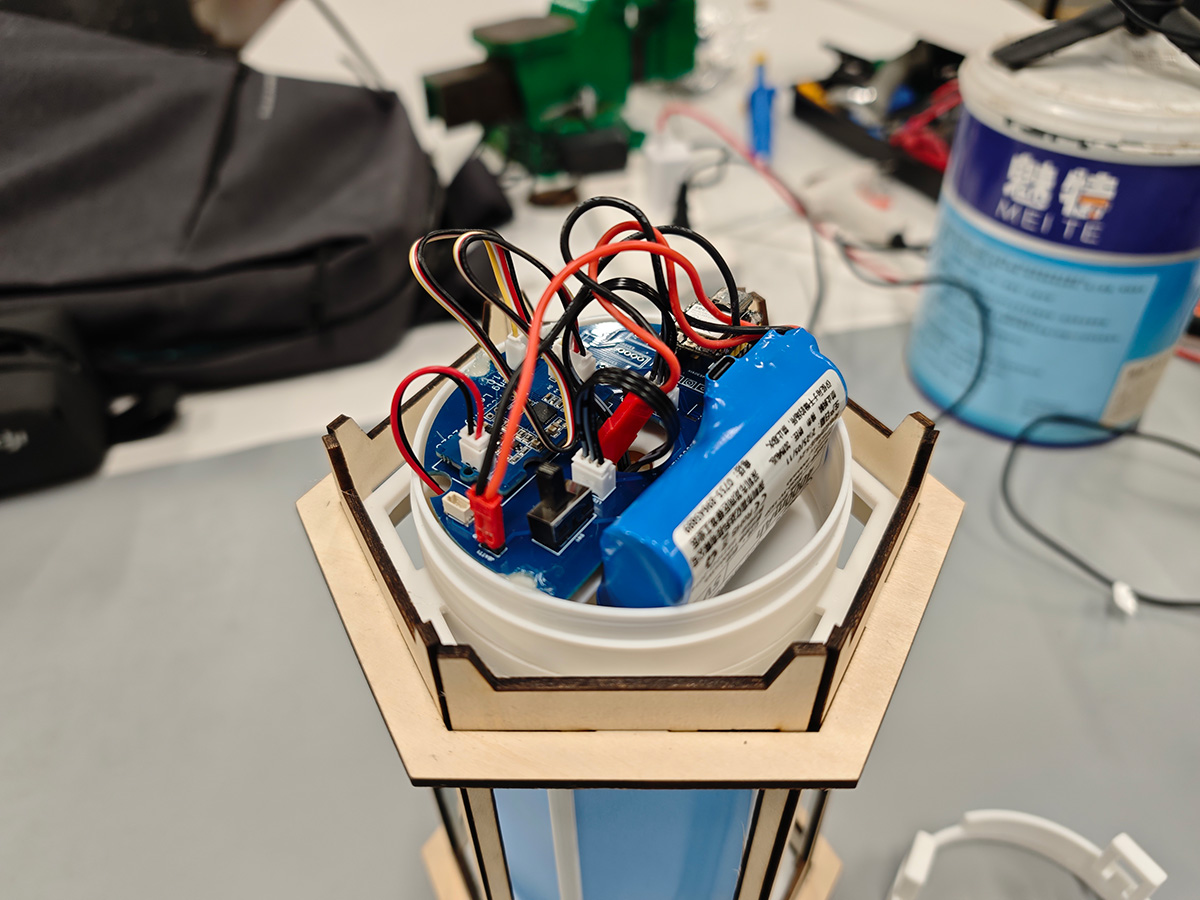

Insert the battery and connect the battery to the PCB socket, being careful not to reverse the red and black wires.

Connect battery

Finally, connect the gesture sensor connector to the PCB socket, then plug in the top cover, turn on the switch, now the motor, light strips and gesture sensors all work.

Vinyl Sticker Cutting and Installation

The printed stickers, with my wife's help, completed the transfer of 1 pattern. The finally cut stickers were applied to the rotating cage cover panels.

Used vinyl cutting machine to cut paper-cut style stickers, then with wife's help transferred them to the rotating cage cover panels

Interaction Design

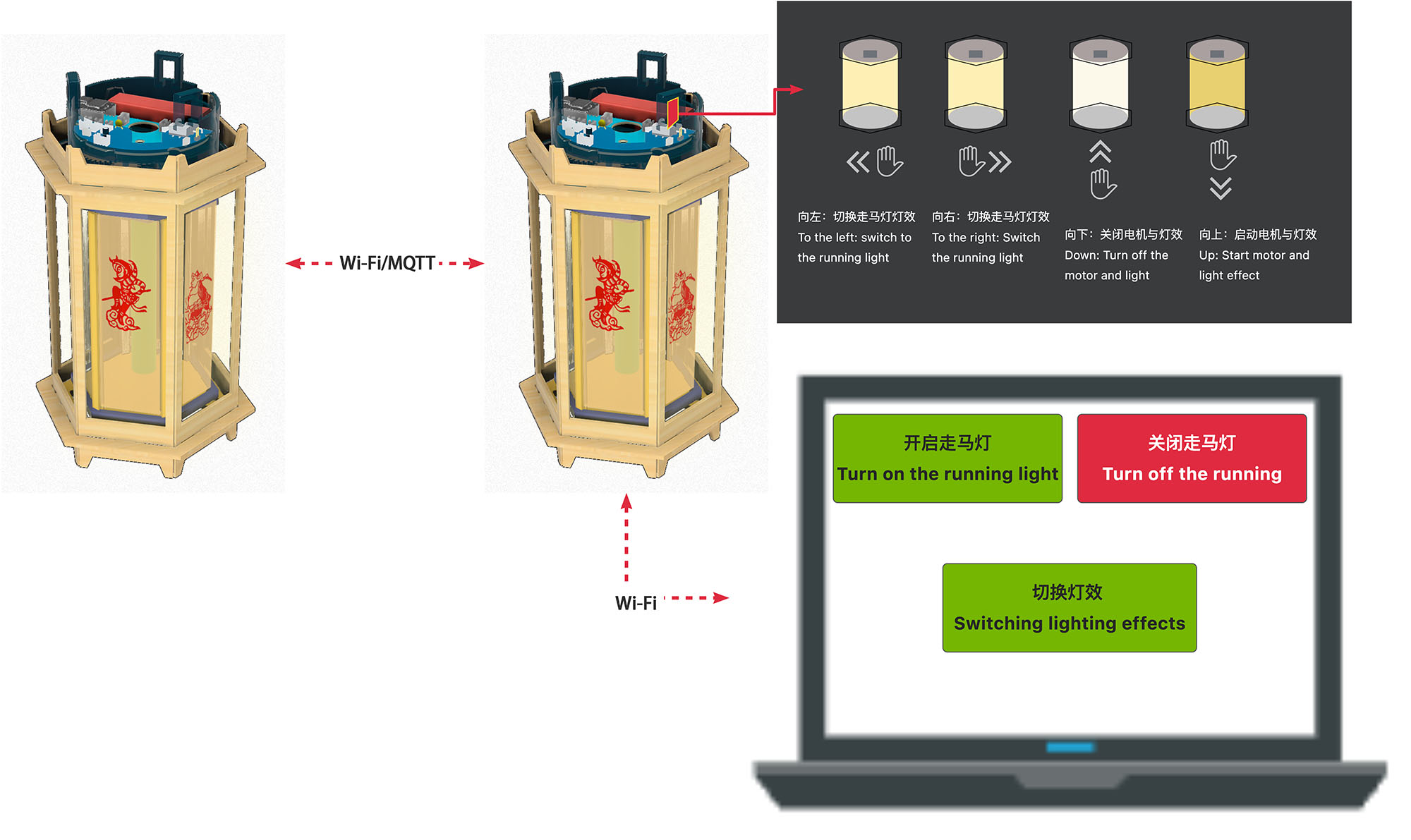

This part has been verified and tested in previous courses. Control of the revolving lantern is through 3 methods:

- Lantern gesture sensors

- Web control via Wi-Fi

- Multiple lanterns can automatically synchronize via Wi-Fi/MQTT

Lantern can be controlled in 3 ways

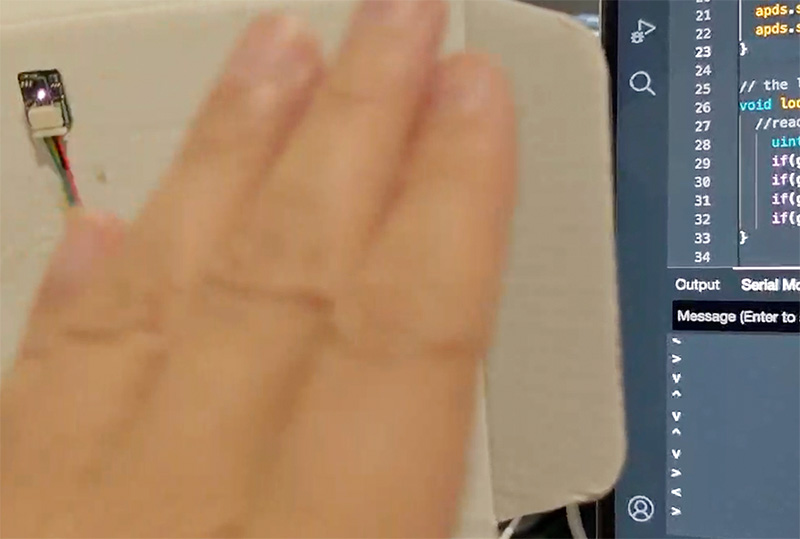

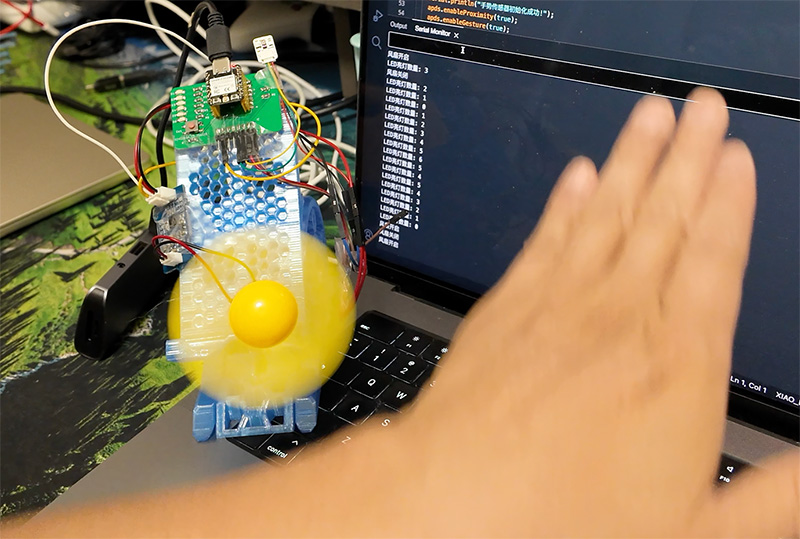

Gesture Sensor Control

I integrated ultra-mini APDS-9960 gesture sensors, related programs have been verified in Week 9 assignment. Here I adjusted the gesture control functions:

- Left/Right gestures: Switch between multiple lighting effect modes (traditional revolving lantern, flame effect, rainbow rotation, breathing sync, meteor chase, festival celebration)

- Up gesture: Turn on revolving lantern (simultaneously start motor and lighting effects)

- Down gesture: Turn off revolving lantern (stop motor and lighting effects)

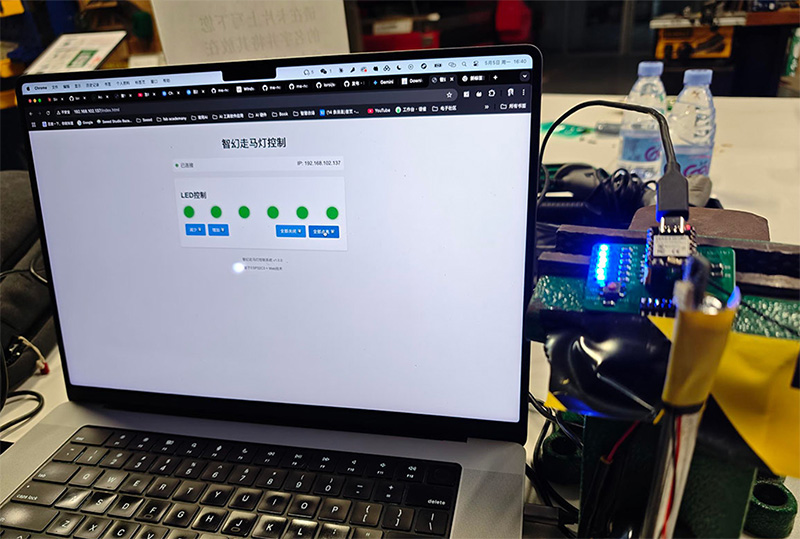

Web Control via Wi-Fi

Related programs have been verified in Week 15 individual assignment. For Web control in the Final Project, I plan to place 3 buttons:

- Switch lighting effects

- Turn on revolving lantern

- Turn off revolving lantern

Multiple Lanterns Can Automatically Synchronize via Wi-Fi/MQTT

Related programs have been verified in Week 11 individual assignment. Multiple lanterns will automatically synchronize via Wi-Fi using MQTT protocol.

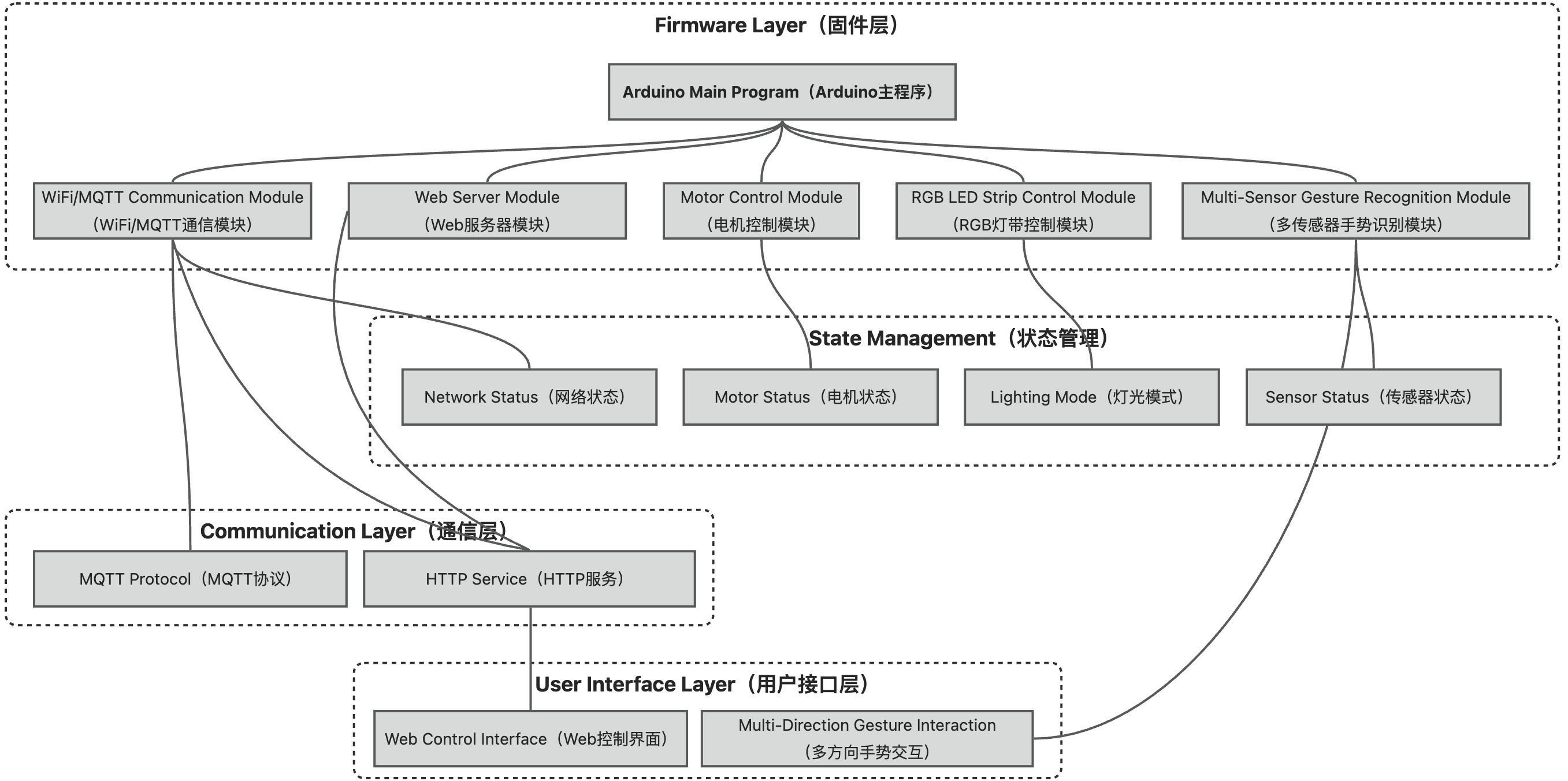

Software Architecture

The software part adopts a multi-task concurrent architecture design, fully utilizing the dual-core advantages of ESP32C3.

Software Architecture: Multi-task concurrent processing diagram

Gesture Recognition Algorithm: Not simple direction judgment, but composite gesture recognition based on timing analysis. For example, "circle drawing" gesture triggers rainbow mode, "upward push" gesture gradually increases brightness.

LED Control Strategy: Implements smooth color transition algorithms, avoiding abrupt jumps. Also supports multiple preset modes: breathing light, flowing light, strobe, gradient, etc.

Communication Protocol Design: Combines WiFi and ESP-NOW communication methods. Daily control uses WiFi (stable, long distance), group synchronization uses ESP-NOW (low latency, no router needed).

Staged Testing Programs

Special Note: All programs in this project were written by Claude Sonnet 4. The AI generated the code based on other relevant course assignment documents and requirements I provided, which were then tested and improved upon.

Motor Switch Test Program

Initially only connecting the motor and testing if the motor can work normally, test program as follows:

#define MOTOR_PIN 10

void setup() {

Serial.begin(115200);

delay(2000);

Serial.println("Basic Motor Test - ON/OFF only");

pinMode(MOTOR_PIN, OUTPUT);

digitalWrite(MOTOR_PIN, LOW);

}

void loop() {

Serial.println("Motor ON");

digitalWrite(MOTOR_PIN, HIGH);

delay(3000);

Serial.println("Motor OFF");

digitalWrite(MOTOR_PIN, LOW);

delay(3000);

}LED Light Effect Test

Then only connecting 1 LED light (GPIO9), testing light effect control program as follows:

#include <Adafruit_NeoPixel.h>

#define PIN 9 // Changed to GPIO 9

#define MAX_LED 14

Adafruit_NeoPixel strip = Adafruit_NeoPixel(MAX_LED, PIN, NEO_GRB + NEO_KHZ800);

void setup() {

Serial.begin(115200);

delay(2000);

Serial.println("Testing GPIO 9...");

strip.begin();

strip.setBrightness(20);

// Stable initialization

strip.clear();

strip.show();

delay(100);

strip.clear();

strip.show();

delay(100);

}

void loop() {

// Simple red green blue test

Serial.println("RED");

for(int i = 0; i < MAX_LED; i++) {

strip.setPixelColor(i, strip.Color(50, 0, 0));

}

strip.show();

delay(1000);

Serial.println("GREEN");

for(int i = 0; i < MAX_LED; i++) {

strip.setPixelColor(i, strip.Color(0, 50, 0));

}

strip.show();

delay(1000);

Serial.println("BLUE");

for(int i = 0; i < MAX_LED; i++) {

strip.setPixelColor(i, strip.Color(0, 0, 50));

}

strip.show();

delay(1000);

Serial.println("OFF");

strip.clear();

strip.show();

delay(1000);

}LED Light Effects and Motor Program

After multiple debugging and revisions, completed the test program for motor and 2 LEDs working synchronously:

#include <Adafruit_NeoPixel.h>

// Hardware definitions

#define LED_PIN_1 9 // GPIO9 controls first LED strip

#define LED_PIN_2 8 // GPIO8 controls second LED strip

#define MOTOR_PIN 10 // GPIO10 controls motor

#define MAX_LED 14 // 14 LEDs

// Dual LED strip initialization

Adafruit_NeoPixel strip1 = Adafruit_NeoPixel(MAX_LED, LED_PIN_1, NEO_GRB + NEO_KHZ800);

Adafruit_NeoPixel strip2 = Adafruit_NeoPixel(MAX_LED, LED_PIN_2, NEO_GRB + NEO_KHZ800);

// PWM parameters

const int PWM_FREQ = 5000;

const int PWM_RESOLUTION = 8;

// Color definitions (low brightness)

#define RED strip1.Color(50, 0, 0)

#define GREEN strip1.Color(0, 50, 0)

#define BLUE strip1.Color(0, 0, 50)

#define YELLOW strip1.Color(50, 50, 0)

#define PURPLE strip1.Color(50, 0, 50)

#define CYAN strip1.Color(0, 50, 50)

#define WHITE strip1.Color(30, 30, 30)

#define ORANGE strip1.Color(60, 20, 0)

#define OFF strip1.Color(0, 0, 0)

// Current mode

int currentMode = 0;

const int TOTAL_MODES = 6;

// Helper function: Set both LED strips' pixel colors simultaneously

void setDualPixelColor(int pixel, uint32_t color) {

strip1.setPixelColor(pixel, color);

strip2.setPixelColor(pixel, color);

}

// Helper function: Display both LED strips simultaneously

void showDualStrips() {

strip1.show();

strip2.show();

}

// Helper function: Clear both LED strips simultaneously

void clearDualStrips() {

strip1.clear();

strip2.clear();

}

// Helper function: Create color (compatible with both strips)

uint32_t createColor(int r, int g, int b) {

return strip1.Color(r, g, b);

}

void setup() {

Serial.begin(115200);

delay(2000);

Serial.println("=== Magical Revolving Lantern Dual LED Version Startup ===");

Serial.println("Smart Lantern - Dual LED & Motor Integration");

// Initialize both LED strips

strip1.begin();

strip1.setBrightness(20);

strip1.clear();

strip1.show();

strip2.begin();

strip2.setBrightness(20);

strip2.clear();

strip2.show();

delay(100);

clearDualStrips();

showDualStrips();

// Initialize motor PWM

ledcAttach(MOTOR_PIN, PWM_FREQ, PWM_RESOLUTION);

ledcWrite(MOTOR_PIN, 0);

// Startup animation

startupSequence();

Serial.println("\nDual LED system ready! Starting effect operations...\n");

}

void loop() {

switch(currentMode) {

case 0:

Serial.println("Mode 1: Traditional Lantern (Dual LED)");

traditionalLanternMode();

break;

case 1:

Serial.println("Mode 2: Fire Effect (Dual LED)");

fireMode();

break;

case 2:

Serial.println("Mode 3: Rainbow Spin (Dual LED)");

rainbowSpinMode();

break;

case 3:

Serial.println("Mode 4: Breathing Sync (Dual LED)");

breathingSyncMode();

break;

case 4:

Serial.println("Mode 5: Meteor Chase (Dual LED)");

meteorChaseMode();

break;

case 5:

Serial.println("Mode 6: Festival Mode (Dual LED)");

festivalMode();

break;

}

// Switch to next mode

currentMode = (currentMode + 1) % TOTAL_MODES;

// Inter-mode transition

transitionEffect();

}

// Startup animation

void startupSequence() {

Serial.println("Startup sequence - Dual LED sync...");

// Motor slow startup

for(int speed = 0; speed <= 100; speed += 5) {

ledcWrite(MOTOR_PIN, speed);

delay(30);

}

// Both LED strips light up one by one synchronously

for(int i = 0; i < MAX_LED; i++) {

setDualPixelColor(i, WHITE);

showDualStrips();

delay(50);

}

delay(500);

// Turn off all

clearDualStrips();

showDualStrips();

ledcWrite(MOTOR_PIN, 0);

delay(500);

}

// Mode 1: Traditional lantern effect

void traditionalLanternMode() {

uint32_t colors[] = {RED, ORANGE, YELLOW, GREEN, CYAN, BLUE};

int numColors = 6;

// Motor medium speed rotation

ledcWrite(MOTOR_PIN, 120);

// Run for 30 seconds

unsigned long startTime = millis();

int offset = 0;

while(millis() - startTime < 30000) {

// Dual LED color flow

for(int i = 0; i < MAX_LED; i++) {

int colorIndex = (i + offset) % numColors;

setDualPixelColor(i, colors[colorIndex]);

}

showDualStrips();

offset++;

delay(200); // Match motor speed

}

// Gradually stop

for(int speed = 120; speed >= 0; speed -= 5) {

ledcWrite(MOTOR_PIN, speed);

delay(50);

}

}

// Mode 2: Fire effect

void fireMode() {

// Motor slow rotation, simulating flame flickering

ledcWrite(MOTOR_PIN, 80);

unsigned long startTime = millis();

while(millis() - startTime < 30000) {

// Flame flicker effect

for(int i = 0; i < MAX_LED; i++) {

int flicker = random(20, 80);

int r = flicker;

int g = flicker * 0.3;

int b = 0;

setDualPixelColor(i, createColor(r, g, b));

}

showDualStrips();

// Motor speed random variation

int motorSpeed = 60 + random(-20, 20);

ledcWrite(MOTOR_PIN, motorSpeed);

delay(50);

}

ledcWrite(MOTOR_PIN, 0);

}

// Mode 3: Rainbow spin

void rainbowSpinMode() {

unsigned long startTime = millis();

int colorOffset = 0;

int loopCount = 0;

while(millis() - startTime < 30000) {

// Dual LED rainbow display - using simple RGB cycle

for(int i = 0; i < MAX_LED; i++) {

// Create rainbow effect

int phase = ((i * 255 / MAX_LED) + (colorOffset * 10)) % 255;

int r = 0, g = 0, b = 0;

if(phase < 85) {

// Red to green

r = (255 - phase * 3) / 5; // Directly divide by 5 to reduce brightness

g = (phase * 3) / 5;

b = 0;

} else if(phase < 170) {

// Green to blue

phase -= 85;

r = 0;

g = (255 - phase * 3) / 5;

b = (phase * 3) / 5;

} else {

// Blue to red

phase -= 170;

r = (phase * 3) / 5;

g = 0;

b = (255 - phase * 3) / 5;

}

setDualPixelColor(i, createColor(r, g, b));

}

showDualStrips();

// Motor speed varies with rainbow

int motorSpeed = 120; // Fixed speed

ledcWrite(MOTOR_PIN, motorSpeed);

colorOffset = (colorOffset + 1) % 26; // Cycle range

delay(100); // Delay

// Debug output

loopCount++;

if(loopCount % 10 == 0) {

Serial.print(".");

}

}

ledcWrite(MOTOR_PIN, 0);

}

// Mode 4: Breathing sync

void breathingSyncMode() {

unsigned long startTime = millis();

while(millis() - startTime < 30000) {

// Breathing cycle

// Brighten + accelerate

for(int level = 0; level <= 100; level += 2) {

// Dual LED brightness

int brightness = level / 2;

for(int i = 0; i < MAX_LED; i++) {

setDualPixelColor(i, createColor(brightness, brightness/2, 0));

}

showDualStrips();

// Motor speed

ledcWrite(MOTOR_PIN, 50 + level);

delay(30);

}

// Dim + decelerate

for(int level = 100; level >= 0; level -= 2) {

// Dual LED brightness

int brightness = level / 2;

for(int i = 0; i < MAX_LED; i++) {

setDualPixelColor(i, createColor(brightness, brightness/2, 0));

}

showDualStrips();

// Motor speed

ledcWrite(MOTOR_PIN, 50 + level);

delay(30);

}

}

ledcWrite(MOTOR_PIN, 0);

}

// Mode 5: Meteor chase

void meteorChaseMode() {

// Motor fast rotation

ledcWrite(MOTOR_PIN, 180);

unsigned long startTime = millis();

int position = 0;

while(millis() - startTime < 30000) {

clearDualStrips();

// Main meteor

setDualPixelColor(position, WHITE);

// Trail

if(position > 0) {

setDualPixelColor((position - 1) % MAX_LED, createColor(20, 20, 20));

}

if(position > 1) {

setDualPixelColor((position - 2) % MAX_LED, createColor(10, 10, 10));

}

if(position > 2) {

setDualPixelColor((position - 3) % MAX_LED, createColor(5, 5, 5));

}

showDualStrips();

position = (position + 1) % MAX_LED;

delay(50);

}

// Decelerate stop

for(int speed = 180; speed >= 0; speed -= 5) {

ledcWrite(MOTOR_PIN, speed);

delay(30);

}

}

// Mode 6: Festival celebration

void festivalMode() {

uint32_t festiveColors[] = {RED, GREEN, YELLOW, BLUE, PURPLE};

// Motor medium speed rotation

ledcWrite(MOTOR_PIN, 130);

unsigned long startTime = millis();

while(millis() - startTime < 30000) {

// Random flashing

for(int i = 0; i < MAX_LED; i++) {

if(random(10) > 7) { // 30% chance to flash

setDualPixelColor(i, festiveColors[random(5)]);

} else {

setDualPixelColor(i, OFF);

}

}

showDualStrips();

// Occasional motor speed change

if(random(100) > 90) {

ledcWrite(MOTOR_PIN, 100 + random(60));

}

delay(100);

}

ledcWrite(MOTOR_PIN, 0);

}

// Inter-mode transition effect

void transitionEffect() {

Serial.println("Mode switching - Dual LED sync...");

// Stop motor

ledcWrite(MOTOR_PIN, 0);

// Gradually dim all LEDs

for(int brightness = 20; brightness >= 0; brightness--) {

for(int i = 0; i < MAX_LED; i++) {

setDualPixelColor(i, createColor(brightness, brightness, brightness));

}

showDualStrips();

delay(50);

}

clearDualStrips();

showDualStrips();

delay(1000);

}Adding Multi-Gesture Sensor Test Program

#include <Adafruit_NeoPixel.h>

#include <Wire.h>

#include "XLOT_APDS9960AD.h"

// Hardware definitions

#define LED_PIN_1 9 // GPIO9 controls first LED strip

#define LED_PIN_2 8 // GPIO8 controls second LED strip

#define MOTOR_PIN 10 // GPIO10 controls motor

#define MAX_LED 14 // 14 LEDs

// I2C pin definitions (for gesture sensors)

#define SDA_PIN 6 // GPIO6 (D4) - I2C data line

#define SCL_PIN 7 // GPIO7 (D5) - I2C clock line

// Dual LED strip initialization

Adafruit_NeoPixel strip1 = Adafruit_NeoPixel(MAX_LED, LED_PIN_1, NEO_GRB + NEO_KHZ800);

Adafruit_NeoPixel strip2 = Adafruit_NeoPixel(MAX_LED, LED_PIN_2, NEO_GRB + NEO_KHZ800);

// Gesture sensor initialization

XLOT_APDS9960AD apds;

// PWM parameters

const int PWM_FREQ = 5000;

const int PWM_RESOLUTION = 8;

// Color definitions (low brightness)

#define RED strip1.Color(50, 0, 0)

#define GREEN strip1.Color(0, 50, 0)

#define BLUE strip1.Color(0, 0, 50)

#define YELLOW strip1.Color(50, 50, 0)

#define PURPLE strip1.Color(50, 0, 50)

#define CYAN strip1.Color(0, 50, 50)

#define WHITE strip1.Color(30, 30, 30)

#define ORANGE strip1.Color(60, 20, 0)

#define OFF strip1.Color(0, 0, 0)

// System state control

bool lanternOn = false; // Lantern on/off state

int currentMode = 0; // Current light effect mode

const int TOTAL_MODES = 6; // Total number of modes

int currentBrightness = 20; // Current brightness

// Mode control variables

unsigned long modeStartTime = 0; // Mode start time

int modeOffset = 0; // Mode internal offset

// Gesture control debounce

unsigned long lastGestureTime = 0;

const unsigned long GESTURE_DELAY = 800; // Gesture interval 800ms

// Mode name array (for debug output)

const char* modeNames[TOTAL_MODES] = {

"Traditional Lantern",

"Fire Effect",

"Rainbow Spin",

"Breathing Sync",

"Meteor Chase",

"Festival Mode"

};

// Helper function: Set both LED strips' pixel colors simultaneously

void setDualPixelColor(int pixel, uint32_t color) {

strip1.setPixelColor(pixel, color);

strip2.setPixelColor(pixel, color);

}

// Helper function: Display both LED strips simultaneously

void showDualStrips() {

strip1.show();

strip2.show();

}

// Helper function: Clear both LED strips simultaneously

void clearDualStrips() {

strip1.clear();

strip2.clear();

}

// Helper function: Create color (compatible with both strips)

uint32_t createColor(int r, int g, int b) {

return strip1.Color(r, g, b);

}

// Gesture handling function

void handleGestures() {

uint8_t gesture = apds.readGesture();

if (gesture != 0) {

// Gesture debounce processing

if (millis() - lastGestureTime < GESTURE_DELAY) {

return;

}

lastGestureTime = millis();

switch (gesture) {

case APDS9960_LEFT:

Serial.println("🔄 Gesture: ← (Switch to previous mode)");

switchMode(-1);

break;

case APDS9960_RIGHT:

Serial.println("🔄 Gesture: → (Switch to next mode)");

switchMode(1);

break;

case APDS9960_UP:

Serial.println("🔆 Gesture: ↑ (Turn on lantern)");

turnOnLantern();

break;

case APDS9960_DOWN:

Serial.println("🔅 Gesture: ↓ (Turn off lantern)");

turnOffLantern();

break;

}

}

}

// Mode switching function

void switchMode(int direction) {

// Can only switch modes when lantern is on

if (!lanternOn) {

Serial.println(" ⚠️ Lantern not on, please swipe up first to turn on");

return;

}

// Calculate new mode

currentMode += direction;

if (currentMode < 0) {

currentMode = TOTAL_MODES - 1;

} else if (currentMode >= TOTAL_MODES) {

currentMode = 0;

}

// Reset mode time and offset

modeStartTime = millis();

modeOffset = 0;

Serial.print(" ✅ Switched to mode ");

Serial.print(currentMode + 1);

Serial.print(": ");

Serial.println(modeNames[currentMode]);

// Show mode switch indicator

showModeIndicator();

}

// Turn on lantern

void turnOnLantern() {

if (lanternOn) {

Serial.println(" ℹ️ Lantern already on");

return;

}

lanternOn = true;

modeStartTime = millis();

modeOffset = 0;

Serial.println(" ✅ Lantern turned on");

Serial.print(" 🎨 Current mode: ");

Serial.println(modeNames[currentMode]);

// Show startup animation

showStartupAnimation();

}

// Turn off lantern

void turnOffLantern() {

if (!lanternOn) {

Serial.println(" ℹ️ Lantern already off");

return;

}

lanternOn = false;

Serial.println(" ✅ Lantern turned off");

// Show shutdown animation

showShutdownAnimation();

// Stop motor and clear LEDs

ledcWrite(MOTOR_PIN, 0);

clearDualStrips();

showDualStrips();

}

// Show mode switch indicator

void showModeIndicator() {

clearDualStrips();

// Show different colors based on mode

uint32_t indicatorColor;

switch(currentMode) {

case 0: indicatorColor = ORANGE; break; // Traditional lantern - orange

case 1: indicatorColor = RED; break; // Fire effect - red

case 2: indicatorColor = createColor(25, 25, 25); break; // Rainbow spin - white

case 3: indicatorColor = YELLOW; break; // Breathing sync - yellow

case 4: indicatorColor = CYAN; break; // Meteor chase - cyan

case 5: indicatorColor = PURPLE; break; // Festival mode - purple

}

// Show LED quantity corresponding to mode number

for (int i = 0; i <= currentMode; i++) {

setDualPixelColor(i, indicatorColor);

}

showDualStrips();

delay(800);

clearDualStrips();

showDualStrips();

delay(200);

}

// Show startup animation

void showStartupAnimation() {

Serial.println(" 🎬 Playing startup animation...");

// LEDs spread out from center

for (int i = 0; i < MAX_LED; i++) {

setDualPixelColor(i, GREEN);

showDualStrips();

delay(80);

}

delay(300);

// Motor slow startup

for (int speed = 0; speed <= 120; speed += 10) {

ledcWrite(MOTOR_PIN, speed);

delay(50);

}

clearDualStrips();

showDualStrips();

}

// Show shutdown animation

void showShutdownAnimation() {

Serial.println(" 🎬 Playing shutdown animation...");

// Motor gradual stop

int currentSpeed = 120;

while (currentSpeed > 0) {

ledcWrite(MOTOR_PIN, currentSpeed);

currentSpeed -= 10;

delay(100);

}

ledcWrite(MOTOR_PIN, 0);

// LEDs turn off from outside to inside

for (int i = MAX_LED - 1; i >= 0; i--) {

setDualPixelColor(i, OFF);

showDualStrips();

delay(80);

}

}

// Run current mode light effects

void runCurrentMode() {

if (!lanternOn) {

return; // Don't run any effects when lantern is off

}

switch(currentMode) {

case 0:

traditionalLanternMode();

break;

case 1:

fireMode();

break;

case 2:

rainbowSpinMode();

break;

case 3:

breathingSyncMode();

break;

case 4:

meteorChaseMode();

break;

case 5:

festivalMode();

break;

}

}

// Mode 1: Traditional lantern effect

void traditionalLanternMode() {

uint32_t colors[] = {RED, ORANGE, YELLOW, GREEN, CYAN, BLUE};

int numColors = 6;

// Motor medium speed rotation

ledcWrite(MOTOR_PIN, 120);

// Dual LED color flow

for(int i = 0; i < MAX_LED; i++) {

int colorIndex = (i + modeOffset) % numColors;

setDualPixelColor(i, colors[colorIndex]);

}

showDualStrips();

// Update offset every 200ms

if (millis() - modeStartTime > (modeOffset + 1) * 200) {

modeOffset++;

}

}

// Mode 2: Fire effect

void fireMode() {

// Motor slow rotation, simulating flame flickering

int motorSpeed = 80 + random(-15, 15);

ledcWrite(MOTOR_PIN, motorSpeed);

// Flame flicker effect

for(int i = 0; i < MAX_LED; i++) {

int flicker = random(20, 80);

int r = flicker;

int g = flicker * 0.3;

int b = 0;

setDualPixelColor(i, createColor(r, g, b));

}

showDualStrips();

}

// Mode 3: Rainbow spin

void rainbowSpinMode() {

// Motor fixed speed

ledcWrite(MOTOR_PIN, 120);

// Dual LED rainbow display

for(int i = 0; i < MAX_LED; i++) {

int phase = ((i * 255 / MAX_LED) + (modeOffset * 10)) % 255;

int r = 0, g = 0, b = 0;

if(phase < 85) {

r = (255 - phase * 3) / 5;

g = (phase * 3) / 5;

b = 0;

} else if(phase < 170) {

phase -= 85;

r = 0;

g = (255 - phase * 3) / 5;

b = (phase * 3) / 5;

} else {

phase -= 170;

r = (phase * 3) / 5;

g = 0;

b = (255 - phase * 3) / 5;

}

setDualPixelColor(i, createColor(r, g, b));

}

showDualStrips();

// Update offset every 100ms

if (millis() - modeStartTime > (modeOffset + 1) * 100) {

modeOffset++;

if (modeOffset > 25) modeOffset = 0;

}

}

// Mode 4: Breathing sync

void breathingSyncMode() {

// Calculate breathing cycle

unsigned long cycleTime = (millis() - modeStartTime) % 4000; // 4 second cycle

int breathLevel = 0;

if (cycleTime < 2000) {

// Brightening process

breathLevel = map(cycleTime, 0, 2000, 0, 100);

} else {

// Dimming process

breathLevel = map(cycleTime, 2000, 4000, 100, 0);

}

// Dual LED brightness

int brightness = breathLevel / 2;

for(int i = 0; i < MAX_LED; i++) {

setDualPixelColor(i, createColor(brightness, brightness/2, 0));

}

showDualStrips();

// Motor speed varies with breathing

ledcWrite(MOTOR_PIN, 50 + breathLevel);

}

// Mode 5: Meteor chase

void meteorChaseMode() {

// Motor fast rotation

ledcWrite(MOTOR_PIN, 180);

// Calculate meteor position

int position = (modeOffset) % MAX_LED;

clearDualStrips();

// Main meteor

setDualPixelColor(position, WHITE);

// Trail

for (int i = 1; i <= 3; i++) {

int tailPos = (position - i + MAX_LED) % MAX_LED;

int brightness = 30 - (i * 8);

if (brightness > 0) {

setDualPixelColor(tailPos, createColor(brightness, brightness, brightness));

}

}

showDualStrips();

// Update position every 50ms

if (millis() - modeStartTime > (modeOffset + 1) * 50) {

modeOffset++;

}

}

// Mode 6: Festival celebration

void festivalMode() {

uint32_t festiveColors[] = {RED, GREEN, YELLOW, BLUE, PURPLE};

// Motor medium speed rotation

ledcWrite(MOTOR_PIN, 130);

// Random flashing

for(int i = 0; i < MAX_LED; i++) {

if(random(10) > 7) { // 30% chance to flash

setDualPixelColor(i, festiveColors[random(5)]);

} else {

setDualPixelColor(i, OFF);

}

}

showDualStrips();

// Occasional motor speed change

if(random(100) > 95) {

ledcWrite(MOTOR_PIN, 100 + random(60));

}

}

void setup() {

Serial.begin(115200);

delay(2000);

Serial.println("=== Magical Revolving Lantern Gesture Control System Startup ===");

Serial.println("Smart Lantern - Gesture Control System");

// Initialize I2C bus (for gesture sensors)

Wire.begin(SDA_PIN, SCL_PIN);

// Initialize gesture sensor

if(!apds.begin()){

Serial.println("❌ Gesture sensor initialization failed! Please check wiring.");

Serial.println(" Running in non-gesture control mode...");

} else {

Serial.println("✅ Gesture sensor initialization successful!");

// Configure gesture sensor

apds.enableProximity(true);

apds.enableGesture(true);

apds.setProxGain(APDS9960_PGAIN_8X);

apds.setGestureGain(APDS9960_PGAIN_8X);

apds.setGestureGain(APDS9960_AGAIN_64X);

apds.setGestureGain(APDS9960_GGAIN_8);

}

// Initialize both LED strips

strip1.begin();

strip1.setBrightness(currentBrightness);

strip1.clear();

strip1.show();

strip2.begin();

strip2.setBrightness(currentBrightness);

strip2.clear();

strip2.show();

// Initialize motor PWM

ledcAttach(MOTOR_PIN, PWM_FREQ, PWM_RESOLUTION);

ledcWrite(MOTOR_PIN, 0);

Serial.println("\n🎮 Gesture control instructions:");

Serial.println(" ↑ : Turn on lantern");

Serial.println(" ↓ : Turn off lantern");

Serial.println(" ← : Switch to previous light effect mode");

Serial.println(" → : Switch to next light effect mode");

Serial.println("\n💡 System ready, waiting for gesture control...");

// Show ready indicator

for(int i = 0; i < 3; i++) {

setDualPixelColor(0, GREEN);

showDualStrips();

delay(200);

clearDualStrips();

showDualStrips();

delay(200);

}

}

void loop() {

// Detect gestures

handleGestures();

// Run current mode (only when on)

runCurrentMode();

// Short delay

delay(50);

}Now gestures, light strips and motor all respond.

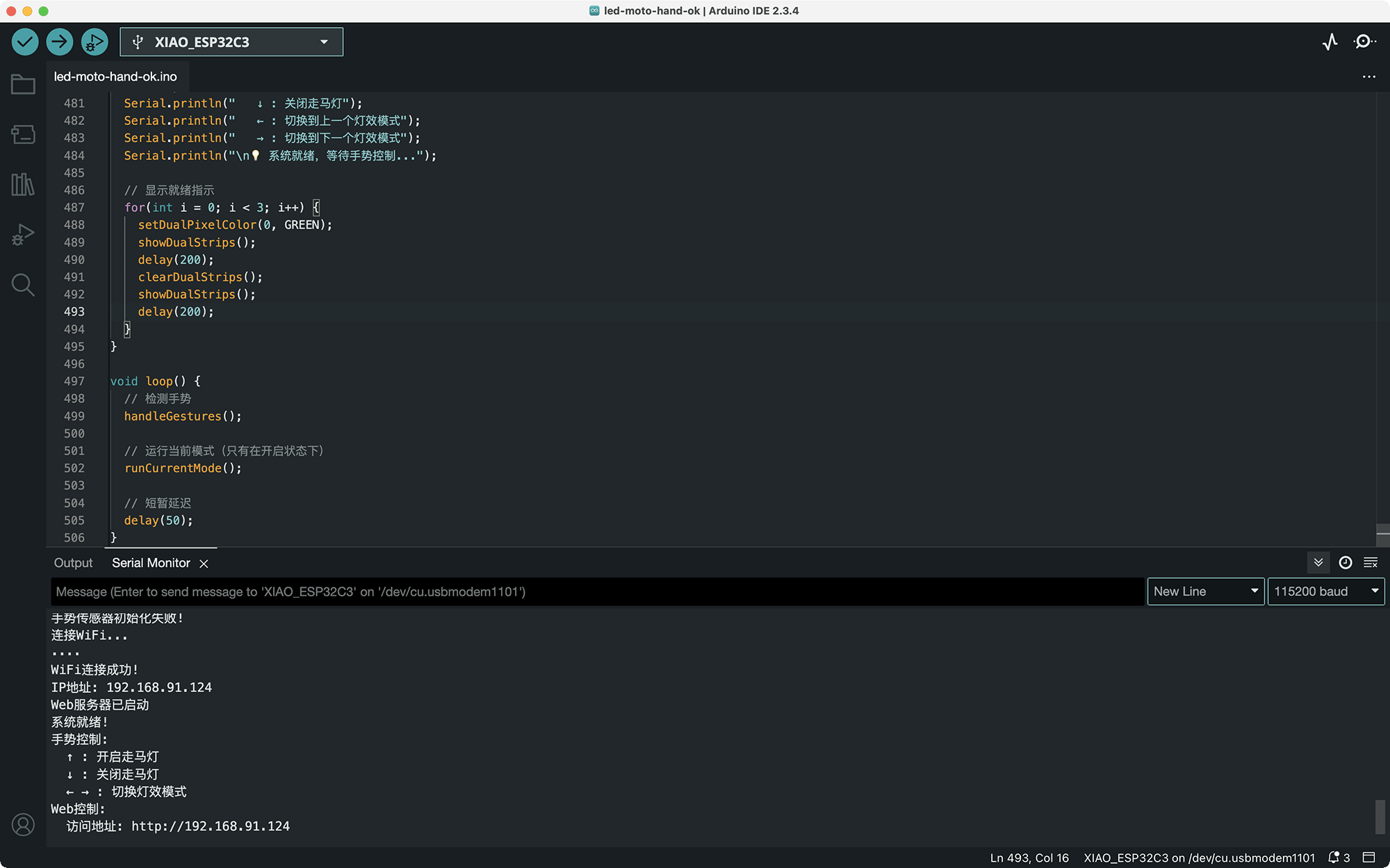

Adding Web Module Test Program

- Web Interface Features

Modern design: gradient backgrounds, frosted glass effects, shadow animations.

Responsive layout: perfect display on phones, tablets and computers.

Real-time status display: current on/off status and mode names.

Three core buttons:

🔆 Turn on lantern

🔅 Turn off lantern

🎨 Switch light effects

- API Interfaces

GET /api/status: Get current status (on/off status, mode information).

POST /api/control: Send control commands (on/off/switch).

- Smart Interaction

Status sync: Web interface automatically updates status every 3 seconds.

Operation feedback: Every operation has success/failure prompts.

Prevent misoperation: Cannot switch modes when off (consistent with gestures and web).

🔧 Usage

Modify WiFi information:

const char* ssid = "YourWiFiName"; // Change to your WiFi name

const char* password = "YourWiFiPassword"; // Change to your WiFi passwordAfter uploading program:

Serial monitor will display IP address

Use browser to access that IP address to see control interface

Dual control:

Gesture control: up to turn on, down to turn off, left/right to switch modes

Web control: click buttons to achieve same functions

#include <Adafruit_NeoPixel.h>

#include <Wire.h>

#include <WiFi.h>

#include <AsyncTCP.h>

#include <ESPAsyncWebServer.h>

#include <ArduinoJson.h>

#include "XLOT_APDS9960AD.h"

// WiFi settings - Please modify to your WiFi information

const char* ssid = "YourWiFiName";

const char* password = "YourWiFiPassword";

// Web server

AsyncWebServer server(80);

// Hardware definitions

#define LED_PIN_1 9 // GPIO9 controls first LED strip

#define LED_PIN_2 8 // GPIO8 controls second LED strip

#define MOTOR_PIN 10 // GPIO10 controls motor

#define MAX_LED 14 // 14 LEDs

// I2C pin definitions

#define SDA_PIN 6 // GPIO6 - I2C data line

#define SCL_PIN 7 // GPIO7 - I2C clock line

// LED strips

Adafruit_NeoPixel strip1 = Adafruit_NeoPixel(MAX_LED, LED_PIN_1, NEO_GRB + NEO_KHZ800);

Adafruit_NeoPixel strip2 = Adafruit_NeoPixel(MAX_LED, LED_PIN_2, NEO_GRB + NEO_KHZ800);

// Gesture sensor

XLOT_APDS9960AD apds;

// PWM parameters

const int PWM_FREQ = 5000;

const int PWM_RESOLUTION = 8;

// System state

bool lanternOn = false;

int currentMode = 0;

const int TOTAL_MODES = 6;

int currentBrightness = 20;

// Gesture control debounce

unsigned long lastGestureTime = 0;

const unsigned long GESTURE_DELAY = 800;

// Mode names

const char* modeNames[TOTAL_MODES] = {

"Traditional Lantern", "Fire Effect", "Rainbow Spin",

"Breathing Sync", "Meteor Chase", "Festival Mode"

};

// Mode control variables

unsigned long modeStartTime = 0;

int modeOffset = 0;

// Helper functions

void setDualPixelColor(int pixel, uint32_t color) {

strip1.setPixelColor(pixel, color);

strip2.setPixelColor(pixel, color);

}

void showDualStrips() {

strip1.show();

strip2.show();

}

void clearDualStrips() {

strip1.clear();

strip2.clear();

}

uint32_t createColor(int r, int g, int b) {

return strip1.Color(r, g, b);

}

// This function is not needed in current program as we use LED strips instead of individual LEDs

// void updateLEDs() {

// // This function is for individual LED control, current program uses LED strips

// }

// WiFi connection

void connectToWiFi() {

Serial.println("Connecting WiFi...");

WiFi.begin(ssid, password);

int retries = 0;

while (WiFi.status() != WL_CONNECTED && retries < 20) {

delay(500);

Serial.print(".");

retries++;

}

if (WiFi.status() == WL_CONNECTED) {

Serial.println("");

Serial.println("WiFi connected successfully!");

Serial.print("IP address: ");

Serial.println(WiFi.localIP());

} else {

Serial.println("");

Serial.println("WiFi connection failed!");

}

}

// Web server setup

void setupWebServer() {

// Homepage

server.on("/", HTTP_GET, [](AsyncWebServerRequest *request) {

String html = "<!DOCTYPE html><html><head><meta charset='UTF-8'>";

html += "<title>Magical Revolving Lantern Control</title>";

html += "<style>body{font-family:Arial;text-align:center;background:#667eea;color:white;padding:20px}";

html += ".container{background:rgba(255,255,255,0.1);padding:30px;border-radius:15px;max-width:400px;margin:0 auto}";

html += "button{width:100%;padding:15px;margin:10px 0;border:none;border-radius:10px;font-size:16px;cursor:pointer}";

html += ".btn-on{background:#4CAF50;color:white}";

html += ".btn-off{background:#f44336;color:white}";

html += ".btn-switch{background:#2196F3;color:white}";

html += ".status{background:rgba(255,255,255,0.2);padding:10px;border-radius:8px;margin:20px 0}";

html += "</style></head><body>";

html += "<div class='container'>";

html += "<h1>Magical Revolving Lantern</h1>";

html += "<div class='status'>";

html += "<p>Status: <span id='status'>Loading</span></p>";

html += "<p>Mode: <span id='mode'>Loading</span></p>";

html += "</div>";

html += "<button class='btn-on' onclick='sendCmd(\"on\")'>Turn On Lantern</button>";

html += "<button class='btn-off' onclick='sendCmd(\"off\")'>Turn Off Lantern</button>";

html += "<button class='btn-switch' onclick='sendCmd(\"switch\")'>Switch Light Effect</button>";

html += "</div>";

html += "<script>";

html += "var modes=['Traditional Lantern','Fire Effect','Rainbow Spin','Breathing Sync','Meteor Chase','Festival Mode'];";

html += "function updateStatus(){";

html += "fetch('/api/status').then(r=>r.json()).then(d=>{";

html += "document.getElementById('status').innerText=d.on?'On':'Off';";

html += "document.getElementById('mode').innerText=modes[d.mode]||'Unknown';";

html += "}).catch(e=>document.getElementById('status').innerText='Connection Failed');}";

html += "function sendCmd(cmd){";

html += "fetch('/api/control',{method:'POST',headers:{'Content-Type':'application/x-www-form-urlencoded'},";

html += "body:'command='+cmd}).then(r=>r.json()).then(d=>{";

html += "if(d.success)setTimeout(updateStatus,200);else alert('Operation failed:'+d.message);";

html += "}).catch(e=>alert('Network error'));}";

html += "updateStatus();setInterval(updateStatus,3000);";

html += "</script></body></html>";

request->send(200, "text/html", html);

});

// API: Get status

server.on("/api/status", HTTP_GET, [](AsyncWebServerRequest *request) {

DynamicJsonDocument doc(128);

doc["on"] = lanternOn;

doc["mode"] = currentMode;

String response;

serializeJson(doc, response);

request->send(200, "application/json", response);

});

// API: Control commands

server.on("/api/control", HTTP_POST, [](AsyncWebServerRequest *request) {

DynamicJsonDocument responseDoc(128);

responseDoc["success"] = false;

responseDoc["message"] = "Invalid request";

if (request->hasParam("command", true)) {

String command = request->getParam("command", true)->value();

if (command == "on") {

if (!lanternOn) {

turnOnLantern();

responseDoc["success"] = true;

responseDoc["message"] = "Lantern turned on";

} else {

responseDoc["message"] = "Lantern already on";

}

}

else if (command == "off") {

if (lanternOn) {

turnOffLantern();

responseDoc["success"] = true;

responseDoc["message"] = "Lantern turned off";

} else {

responseDoc["message"] = "Lantern already off";

}

}

else if (command == "switch") {

if (lanternOn) {

switchMode(1);

responseDoc["success"] = true;

responseDoc["message"] = String("Switched to: ") + modeNames[currentMode];

} else {

responseDoc["message"] = "Please turn on lantern first";

}

}

}

String response;

serializeJson(responseDoc, response);

request->send(200, "application/json", response);

});

server.begin();

Serial.println("Web server started");

}

// Gesture handling

void handleGestures() {

uint8_t gesture = apds.readGesture();

if (gesture != 0) {

if (millis() - lastGestureTime < GESTURE_DELAY) {

return;

}

lastGestureTime = millis();

switch (gesture) {

case APDS9960_LEFT:

Serial.println("Gesture: ← (Previous mode)");

switchMode(-1);

break;

case APDS9960_RIGHT:

Serial.println("Gesture: → (Next mode)");

switchMode(1);

break;

case APDS9960_UP:

Serial.println("Gesture: ↑ (Turn on lantern)");

turnOnLantern();

break;

case APDS9960_DOWN:

Serial.println("Gesture: ↓ (Turn off lantern)");

turnOffLantern();

break;

}

}

}

// Switch mode

void switchMode(int direction) {

if (!lanternOn) {

Serial.println("Lantern not on, please swipe up first to turn on");

return;

}

currentMode += direction;

if (currentMode < 0) {

currentMode = TOTAL_MODES - 1;

} else if (currentMode >= TOTAL_MODES) {

currentMode = 0;

}

modeStartTime = millis();

modeOffset = 0;

Serial.print("Switched to mode: ");

Serial.println(modeNames[currentMode]);

showModeIndicator();

}

// Turn on lantern

void turnOnLantern() {

if (lanternOn) {

Serial.println("Lantern already on");

return;

}

lanternOn = true;

modeStartTime = millis();

modeOffset = 0;

Serial.println("Lantern turned on");

Serial.print("Current mode: ");

Serial.println(modeNames[currentMode]);

showStartupAnimation();

}

// Turn off lantern

void turnOffLantern() {

if (!lanternOn) {

Serial.println("Lantern already off");

return;

}

lanternOn = false;

Serial.println("Lantern turned off");

showShutdownAnimation();

ledcWrite(MOTOR_PIN, 0);

clearDualStrips();

showDualStrips();

}

// Show mode indicator

void showModeIndicator() {

clearDualStrips();

uint32_t indicatorColor;

switch(currentMode) {

case 0: indicatorColor = createColor(60, 20, 0); break; // Orange

case 1: indicatorColor = createColor(50, 0, 0); break; // Red

case 2: indicatorColor = createColor(25, 25, 25); break; // White

case 3: indicatorColor = createColor(50, 50, 0); break; // Yellow

case 4: indicatorColor = createColor(0, 50, 50); break; // Cyan

case 5: indicatorColor = createColor(50, 0, 50); break; // Purple

}

for (int i = 0; i <= currentMode; i++) {

setDualPixelColor(i, indicatorColor);

}

showDualStrips();

delay(800);

clearDualStrips();

showDualStrips();

delay(200);

}

// Startup animation

void showStartupAnimation() {

Serial.println("Playing startup animation...");

for (int i = 0; i < MAX_LED; i++) {

setDualPixelColor(i, createColor(0, 50, 0));

showDualStrips();

delay(80);

}

delay(300);

for (int speed = 0; speed <= 120; speed += 10) {

ledcWrite(MOTOR_PIN, speed);

delay(50);

}

clearDualStrips();

showDualStrips();

}

// Shutdown animation

void showShutdownAnimation() {

Serial.println("Playing shutdown animation...");

int currentSpeed = 120;

while (currentSpeed > 0) {

ledcWrite(MOTOR_PIN, currentSpeed);

currentSpeed -= 10;

delay(100);

}

ledcWrite(MOTOR_PIN, 0);

for (int i = MAX_LED - 1; i >= 0; i--) {

setDualPixelColor(i, createColor(0, 0, 0));

showDualStrips();

delay(80);

}

}

// Run current mode

void runCurrentMode() {

if (!lanternOn) {

return;

}

switch(currentMode) {

case 0:

traditionalLanternMode();

break;

case 1:

fireMode();

break;

case 2:

rainbowSpinMode();

break;

case 3:

breathingSyncMode();

break;

case 4:

meteorChaseMode();

break;

case 5:

festivalMode();

break;

}

}

// Mode 1: Traditional lantern

void traditionalLanternMode() {

uint32_t colors[] = {

createColor(50, 0, 0), // Red

createColor(60, 20, 0), // Orange

createColor(50, 50, 0), // Yellow

createColor(0, 50, 0), // Green

createColor(0, 50, 50), // Cyan

createColor(0, 0, 50) // Blue

};

int numColors = 6;

ledcWrite(MOTOR_PIN, 120);

for(int i = 0; i < MAX_LED; i++) {

int colorIndex = (i + modeOffset) % numColors;

setDualPixelColor(i, colors[colorIndex]);

}

showDualStrips();

if (millis() - modeStartTime > (modeOffset + 1) * 200) {

modeOffset++;

}

}

// Mode 2: Fire effect

void fireMode() {

int motorSpeed = 80 + random(-15, 15);

ledcWrite(MOTOR_PIN, motorSpeed);

for(int i = 0; i < MAX_LED; i++) {

int flicker = random(20, 80);

int r = flicker;

int g = flicker * 0.3;

int b = 0;

setDualPixelColor(i, createColor(r, g, b));

}

showDualStrips();

}

// Mode 3: Rainbow spin

void rainbowSpinMode() {

ledcWrite(MOTOR_PIN, 120);

for(int i = 0; i < MAX_LED; i++) {

int phase = ((i * 255 / MAX_LED) + (modeOffset * 10)) % 255;

int r = 0, g = 0, b = 0;

if(phase < 85) {

r = (255 - phase * 3) / 5;

g = (phase * 3) / 5;

b = 0;

} else if(phase < 170) {

phase -= 85;

r = 0;

g = (255 - phase * 3) / 5;

b = (phase * 3) / 5;

} else {

phase -= 170;

r = (phase * 3) / 5;

g = 0;

b = (255 - phase * 3) / 5;

}

setDualPixelColor(i, createColor(r, g, b));

}

showDualStrips();

if (millis() - modeStartTime > (modeOffset + 1) * 100) {

modeOffset++;

if (modeOffset > 25) modeOffset = 0;

}

}

// Mode 4: Breathing sync

void breathingSyncMode() {

unsigned long cycleTime = (millis() - modeStartTime) % 4000;

int breathLevel = 0;

if (cycleTime < 2000) {

breathLevel = map(cycleTime, 0, 2000, 0, 100);

} else {

breathLevel = map(cycleTime, 2000, 4000, 100, 0);

}

int brightness = breathLevel / 2;

for(int i = 0; i < MAX_LED; i++) {

setDualPixelColor(i, createColor(brightness, brightness/2, 0));

}

showDualStrips();

ledcWrite(MOTOR_PIN, 50 + breathLevel);

}

// Mode 5: Meteor chase

void meteorChaseMode() {

ledcWrite(MOTOR_PIN, 180);

int position = (modeOffset) % MAX_LED;

clearDualStrips();

setDualPixelColor(position, createColor(30, 30, 30));

for (int i = 1; i <= 3; i++) {

int tailPos = (position - i + MAX_LED) % MAX_LED;

int brightness = 30 - (i * 8);

if (brightness > 0) {

setDualPixelColor(tailPos, createColor(brightness, brightness, brightness));

}

}

showDualStrips();

if (millis() - modeStartTime > (modeOffset + 1) * 50) {

modeOffset++;

}

}

// Mode 6: Festival celebration

void festivalMode() {

uint32_t festiveColors[] = {

createColor(50, 0, 0), // Red

createColor(0, 50, 0), // Green

createColor(50, 50, 0), // Yellow

createColor(0, 0, 50), // Blue

createColor(50, 0, 50) // Purple

};

ledcWrite(MOTOR_PIN, 130);

for(int i = 0; i < MAX_LED; i++) {

if(random(10) > 7) {

setDualPixelColor(i, festiveColors[random(5)]);

} else {

setDualPixelColor(i, createColor(0, 0, 0));

}

}

showDualStrips();

if(random(100) > 95) {

ledcWrite(MOTOR_PIN, 100 + random(60));

}

}

void setup() {

Serial.begin(115200);

delay(2000);

Serial.println("=== Magical Revolving Lantern Gesture+Web Control System Startup ===");

// Initialize I2C

Wire.begin(SDA_PIN, SCL_PIN);

// Initialize gesture sensor

if(!apds.begin()){

Serial.println("Gesture sensor initialization failed!");

} else {

Serial.println("Gesture sensor initialization successful!");

apds.enableProximity(true);

apds.enableGesture(true);

apds.setProxGain(APDS9960_PGAIN_8X);

apds.setGestureGain(APDS9960_PGAIN_8X);

apds.setGestureGain(APDS9960_AGAIN_64X);

apds.setGestureGain(APDS9960_GGAIN_8);

}

// Initialize LEDs

strip1.begin();

strip1.setBrightness(currentBrightness);

strip1.clear();

strip1.show();

strip2.begin();

strip2.setBrightness(currentBrightness);

strip2.clear();

strip2.show();

// Initialize motor

ledcAttach(MOTOR_PIN, PWM_FREQ, PWM_RESOLUTION);

ledcWrite(MOTOR_PIN, 0);

// Connect WiFi

connectToWiFi();

// Setup web server

if (WiFi.status() == WL_CONNECTED) {

setupWebServer();

}

Serial.println("System ready!");

Serial.println("Gesture control:");

Serial.println(" ↑ : Turn on lantern");

Serial.println(" ↓ : Turn off lantern");

Serial.println(" ← → : Switch light effect modes");

if (WiFi.status() == WL_CONNECTED) {

Serial.println("Web control:");

Serial.print(" Access URL: http://");

Serial.println(WiFi.localIP());

}

}

void loop() {

// Detect gestures

handleGestures();

// Run current mode

runCurrentMode();

// Check WiFi connection

if (WiFi.status() != WL_CONNECTED) {

Serial.println("WiFi connection lost, attempting reconnection...");

WiFi.reconnect();

}

delay(50);

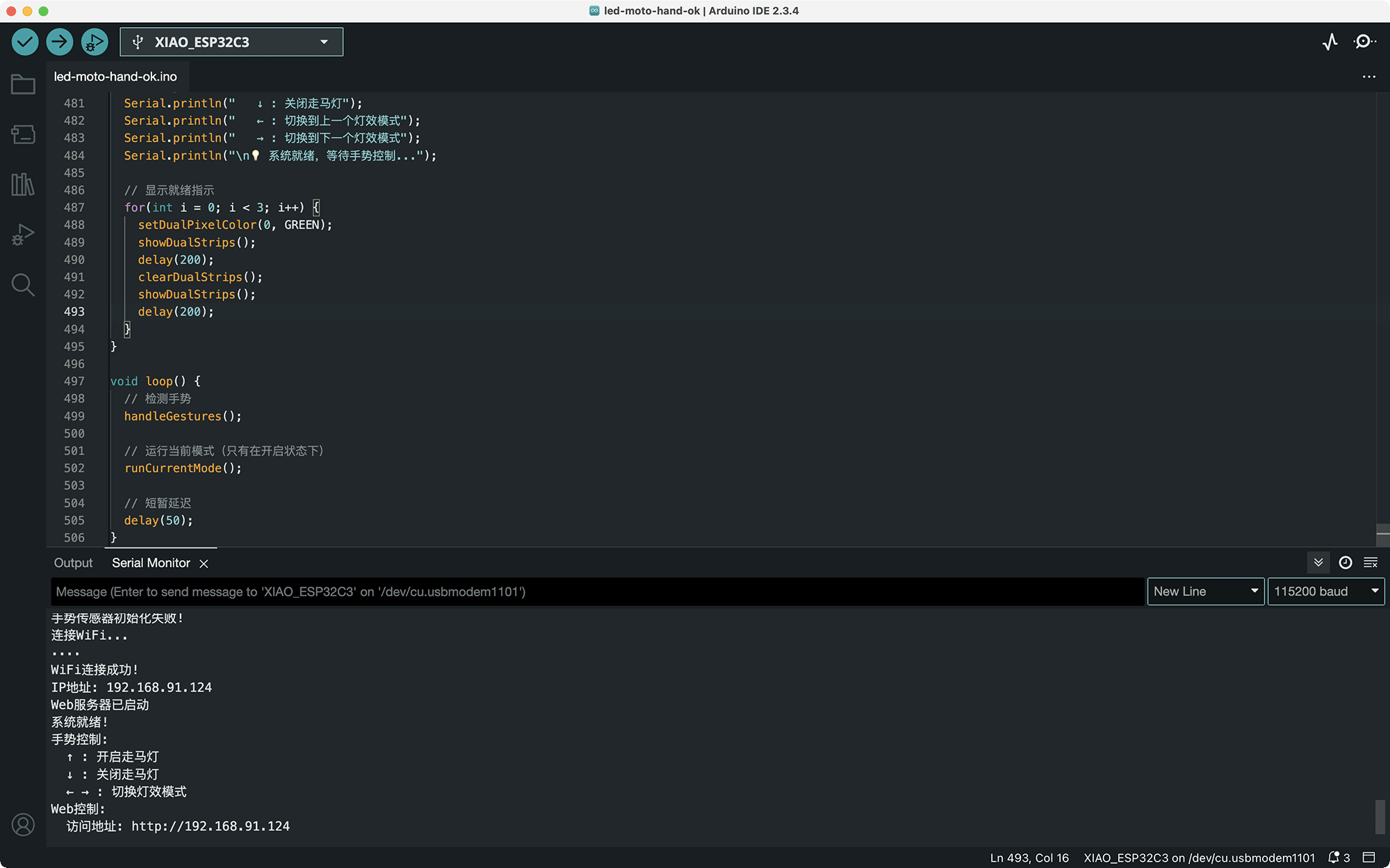

}Successfully compiled and uploaded. In the serial monitor, you can see the IP address provided by XIAO ESP32C3 as shown below. If you need Web control, access: http://192.168.91.124. Note that to access this IP address, your phone or computer needs to use the same Wi-Fi as XIAO ESP32C3.

After successful program compilation and upload, it will show the IP address available in Web mode

I connected my PC to the same Wi-Fi as XIAO and then used browser to access http://192.168.91.124

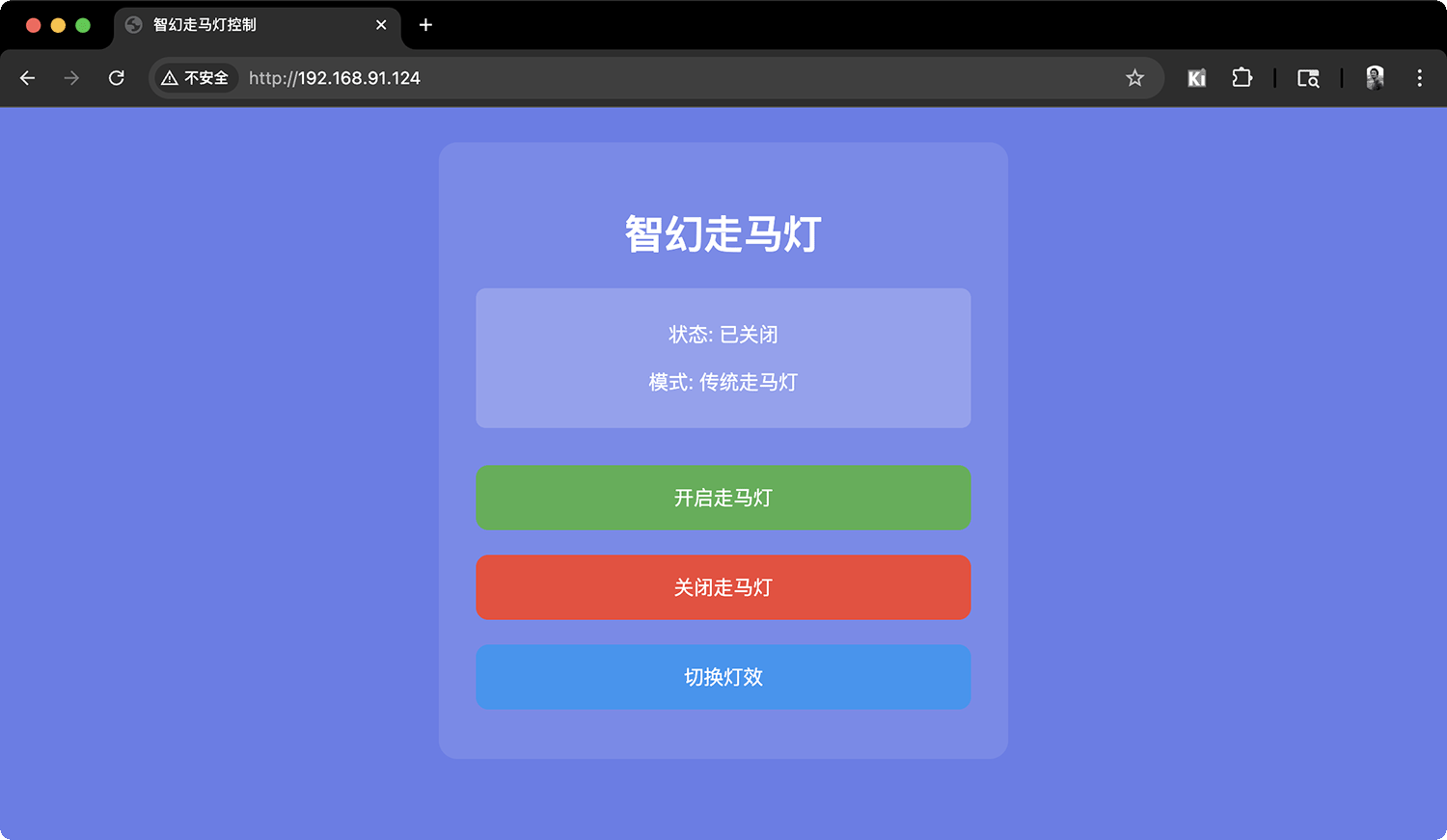

Final Version Program: Gesture+Web+MQTT Sync

Complete Feature List

✅ Gesture Control

- Four-direction gesture recognition (up, down, left, right)

- Multi-retry initialization mechanism

- Time-division detection to avoid resource conflicts

✅ Web Control Interface

- Modern responsive design

- Real-time status display

- Three control buttons + sync switch

✅ MQTT Multi-device Synchronization

- Automatic device discovery

- Real-time status synchronization

- Anti-loop message mechanism

✅ Six Light Effect Modes

- Traditional lantern

- Fire effect

- Rainbow spin

- Breathing sync

- Meteor chase

- Festival celebration

#include <Adafruit_NeoPixel.h>

#include <Wire.h>

#include <WiFi.h>

#include <AsyncTCP.h>

#include <ESPAsyncWebServer.h>

#include <ArduinoJson.h>

#include <PubSubClient.h>

#include "XLOT_APDS9960AD.h"

// WiFi settings - Please modify to your WiFi information

const char* ssid = "xiao";

const char* password = "12345678";

// MQTT settings

const char* mqtt_broker = "broker.hivemq.com";

const int mqtt_port = 1883;

const char* mqtt_topic_command = "smart_lantern/command";

const char* mqtt_topic_status = "smart_lantern/status";

const char* mqtt_topic_heartbeat = "smart_lantern/heartbeat";

// Web server and MQTT client

AsyncWebServer server(80);

WiFiClient espClient;

PubSubClient mqttClient(espClient);

// Hardware definitions

#define LED_PIN_1 9 // GPIO9 controls first LED strip

#define LED_PIN_2 8 // GPIO8 controls second LED strip

#define MOTOR_PIN 10 // GPIO10 controls motor

#define MAX_LED 14 // 14 LEDs

// I2C pin definitions

#define SDA_PIN 6 // GPIO6 - I2C data line

#define SCL_PIN 7 // GPIO7 - I2C clock line

// LED strips

Adafruit_NeoPixel strip1 = Adafruit_NeoPixel(MAX_LED, LED_PIN_1, NEO_GRB + NEO_KHZ800);

Adafruit_NeoPixel strip2 = Adafruit_NeoPixel(MAX_LED, LED_PIN_2, NEO_GRB + NEO_KHZ800);

// Gesture sensor

XLOT_APDS9960AD apds;

// PWM parameters

const int PWM_FREQ = 5000;

const int PWM_RESOLUTION = 8;

// System state

bool lanternOn = false;

int currentMode = 0;

const int TOTAL_MODES = 6;

int currentBrightness = 20;

bool gestureEnabled = false;

// Device unique identifier

String deviceId;

bool syncEnabled = true;

// Task time management

unsigned long lastGestureCheck = 0;

unsigned long lastMqttCheck = 0;

unsigned long lastHeartbeat = 0;

unsigned long lastMqttAttempt = 0;

// Task interval control

const unsigned long GESTURE_CHECK_INTERVAL = 50; // Check gestures every 50ms

const unsigned long MQTT_CHECK_INTERVAL = 100; // Check MQTT every 100ms

const unsigned long HEARTBEAT_INTERVAL = 30000; // 30 second heartbeat

const unsigned long MQTT_RETRY_INTERVAL = 5000; // 5 second reconnection interval

// Gesture control debounce

unsigned long lastGestureTime = 0;

const unsigned long GESTURE_DELAY = 800;

// Mode names

const char* modeNames[TOTAL_MODES] = {

"Traditional Lantern", "Fire Effect", "Rainbow Spin",

"Breathing Sync", "Meteor Chase", "Festival Mode"

};

// Mode control variables

unsigned long modeStartTime = 0;

int modeOffset = 0;

// Initialize device ID

void initDeviceId() {

uint64_t chipId = ESP.getEfuseMac();

char deviceIdBuffer[20];

snprintf(deviceIdBuffer, sizeof(deviceIdBuffer), "Lantern%llX", chipId & 0xFFFFFF);

deviceId = String(deviceIdBuffer);

Serial.print("Device ID: ");

Serial.println(deviceId);

}

// Helper functions

void setDualPixelColor(int pixel, uint32_t color) {

strip1.setPixelColor(pixel, color);

strip2.setPixelColor(pixel, color);

}

void showDualStrips() {

strip1.show();

strip2.show();

}

void clearDualStrips() {

strip1.clear();

strip2.clear();

}

uint32_t createColor(int r, int g, int b) {

return strip1.Color(r, g, b);

}

// I2C device scanner

void scanI2CDevices() {

Serial.println("\n=== I2C Device Scanner ===");

byte error, address;

int deviceCount = 0;

for(address = 1; address < 127; address++) {

Wire.beginTransmission(address);

error = Wire.endTransmission();

if (error == 0) {

Serial.print("Device found at 0x");

if (address < 16) {

Serial.print("0");

}

Serial.print(address, HEX);

if (address == 0x39) {

Serial.print(" <- APDS-9960 Gesture Sensor!");

}

Serial.println();

deviceCount++;

}

}

if (deviceCount == 0) {

Serial.println("No I2C devices found");

} else {

Serial.print("Found ");

Serial.print(deviceCount);

Serial.println(" I2C device(s)");

}

Serial.println("==========================");

}

// Enhanced gesture sensor initialization

bool initGestureSensor() {

Serial.println("\n=== Enhanced Gesture Sensor Init ===");

// First scan I2C devices

scanI2CDevices();

// Reset I2C bus

Serial.println("Resetting I2C bus...");

Wire.end();

delay(100);

Wire.begin(SDA_PIN, SCL_PIN);

delay(500);

// Multiple initialization attempts, reset before each attempt

for(int attempt = 1; attempt <= 5; attempt++) {

Serial.print("Gesture sensor init attempt ");

Serial.print(attempt);

Serial.print("/5: ");

// Slight delay before each attempt

delay(attempt * 200);

if(apds.begin()) {

Serial.println("SUCCESS!");

// Verify sensor is actually usable

delay(100);

// Configure sensor

Serial.println("Configuring sensor...");

apds.enableProximity(true);

delay(50);

apds.enableGesture(true);

delay(50);

apds.setProxGain(APDS9960_PGAIN_8X);

delay(50);

apds.setGestureGain(APDS9960_PGAIN_8X);

delay(50);

apds.setGestureGain(APDS9960_AGAIN_64X);

delay(50);

apds.setGestureGain(APDS9960_GGAIN_8);

delay(50);

Serial.println("Sensor configured successfully!");

// Test read function

Serial.println("Testing sensor read...");

for(int test = 0; test < 5; test++) {

uint8_t testGesture = apds.readGesture();

delay(100);

}

Serial.println("Sensor test completed!");

return true;

} else {

Serial.println("FAILED");

// Re-scan I2C after failures

if(attempt == 3) {

Serial.println("Re-scanning I2C after failures...");

scanI2CDevices();

}

}

}

Serial.println("All gesture sensor init attempts failed!");

return false;

}

// WiFi connection

void connectToWiFi() {

Serial.println("Connecting to WiFi...");

WiFi.mode(WIFI_STA);

WiFi.begin(ssid, password);

int retries = 0;

while (WiFi.status() != WL_CONNECTED && retries < 20) {

delay(500);

Serial.print(".");

retries++;

}

if (WiFi.status() == WL_CONNECTED) {

Serial.println("");

Serial.println("WiFi connected successfully!");

Serial.print("IP address: ");

Serial.println(WiFi.localIP());

} else {

Serial.println("");

Serial.println("WiFi connection failed!");

}

}

// MQTT connection

void connectToMQTT() {

if (!mqttClient.connected() && WiFi.status() == WL_CONNECTED) {

if (millis() - lastMqttAttempt > MQTT_RETRY_INTERVAL) {

lastMqttAttempt = millis();

if (mqttClient.connect(deviceId.c_str())) {

Serial.println("MQTT connected successfully!");

// Subscribe to topics

mqttClient.subscribe(mqtt_topic_command);

mqttClient.subscribe(mqtt_topic_status);

mqttClient.subscribe(mqtt_topic_heartbeat);

// Send online notification

publishHeartbeat();

publishStatus();

} else {

Serial.print("MQTT connection failed, error code: ");

Serial.println(mqttClient.state());

}

}

}

}

// Publish heartbeat message

void publishHeartbeat() {

if (mqttClient.connected()) {

DynamicJsonDocument doc(256);

doc["deviceId"] = deviceId;

doc["timestamp"] = millis();

doc["ip"] = WiFi.localIP().toString();

doc["status"] = "online";

String message;

serializeJson(doc, message);

mqttClient.publish(mqtt_topic_heartbeat, message.c_str());

}

}

// Publish status message

void publishStatus() {

if (mqttClient.connected()) {

DynamicJsonDocument doc(256);

doc["deviceId"] = deviceId;

doc["lanternOn"] = lanternOn;

doc["currentMode"] = currentMode;

doc["modeName"] = modeNames[currentMode];

doc["timestamp"] = millis();

String message;

serializeJson(doc, message);

mqttClient.publish(mqtt_topic_status, message.c_str());

}

}

// Publish control command

void publishCommand(const String& command, const String& source = "gesture") {

if (mqttClient.connected() && syncEnabled) {

DynamicJsonDocument doc(256);

doc["deviceId"] = deviceId;

doc["command"] = command;

doc["source"] = source;

doc["lanternOn"] = lanternOn;

doc["currentMode"] = currentMode;

doc["timestamp"] = millis();

String message;

serializeJson(doc, message);

bool published = mqttClient.publish(mqtt_topic_command, message.c_str());

if (published) {

Serial.print("Published command: ");

Serial.println(command);

}

}

}

// MQTT message callback

void onMqttMessage(char* topic, byte* payload, unsigned int length) {

String message;

for (int i = 0; i < length; i++) {

message += (char)payload[i];

}

// Parse JSON message

DynamicJsonDocument doc(512);

DeserializationError error = deserializeJson(doc, message);

if (error) {

return; // Silently ignore parsing errors

}

String senderId = doc["deviceId"];

// Ignore messages from self

if (senderId == deviceId) {

return;

}

// Handle different types of messages

String topicStr = String(topic);

if (topicStr == mqtt_topic_command) {

String command = doc["command"];

Serial.print("Received sync command: ");

Serial.print(command);

Serial.print(" (from: ");

Serial.print(senderId);

Serial.println(")");

// Execute sync commands

if (command == "turn_on") {

if (!lanternOn) {

lanternOn = true;

modeStartTime = millis();

modeOffset = 0;

showStartupAnimation();

}

}

else if (command == "turn_off") {

if (lanternOn) {

lanternOn = false;

showShutdownAnimation();

ledcWrite(MOTOR_PIN, 0);

clearDualStrips();

showDualStrips();

}

}

else if (command == "switch_mode") {

if (lanternOn) {

int newMode = doc["currentMode"];

if (newMode >= 0 && newMode < TOTAL_MODES) {

currentMode = newMode;

modeStartTime = millis();

modeOffset = 0;

showModeIndicator();

}

}

}

}

else if (topicStr == mqtt_topic_heartbeat) {

String status = doc["status"];

if (status == "online") {

Serial.print("Device online: ");

Serial.println(senderId);

}

}

}

// Web server setup

void setupWebServer() {

// Homepage

server.on("/", HTTP_GET, [](AsyncWebServerRequest *request) {

String html = "<!DOCTYPE html><html><head><meta charset='UTF-8'>";

html += "<title>Smart Lantern Control</title>";

html += "<style>body{font-family:Arial;text-align:center;background:#667eea;color:white;padding:20px}";

html += ".container{background:rgba(255,255,255,0.1);padding:30px;border-radius:15px;max-width:400px;margin:0 auto}";

html += "button{width:100%;padding:15px;margin:10px 0;border:none;border-radius:10px;font-size:16px;cursor:pointer}";

html += ".btn-on{background:#4CAF50;color:white}";

html += ".btn-off{background:#f44336;color:white}";

html += ".btn-switch{background:#2196F3;color:white}";

html += ".btn-sync{background:#FF9800;color:white}";

html += ".status{background:rgba(255,255,255,0.2);padding:10px;border-radius:8px;margin:20px 0}";

html += "</style></head><body>";

html += "<div class='container'>";

html += "<h1>🏮 Smart Lantern</h1>";

html += "<div class='status'>";

html += "<p>Status: <span id='status'>Loading...</span></p>";

html += "<p>Mode: <span id='mode'>Loading...</span></p>";

html += "<p>Device: <span id='deviceId'>Loading...</span></p>";

html += "<p>MQTT: <span id='mqttStatus'>Loading...</span></p>";

html += "<p>Gesture: <span id='gestureStatus'>Loading...</span></p>";

html += "</div>";

html += "<button class='btn-on' onclick='sendCmd(\"on\")'>🔆 Turn On</button>";

html += "<button class='btn-off' onclick='sendCmd(\"off\")'>🔅 Turn Off</button>";

html += "<button class='btn-switch' onclick='sendCmd(\"switch\")'>🎨 Switch Mode</button>";

html += "<button class='btn-sync' onclick='sendCmd(\"toggle_sync\")'>🔄 Sync: <span id='syncStatus'>Loading...</span></button>";

html += "</div>";

html += "<script>";