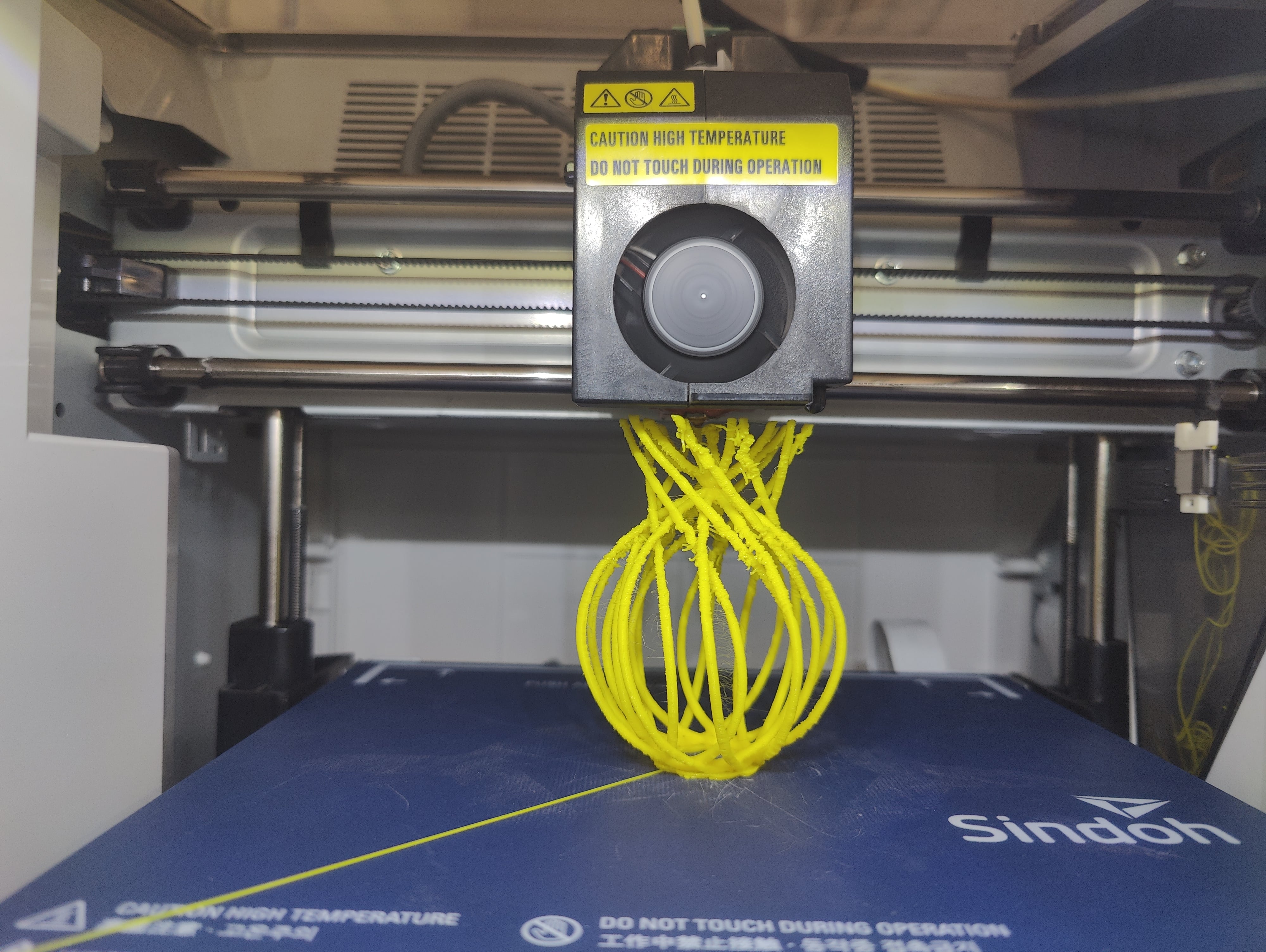

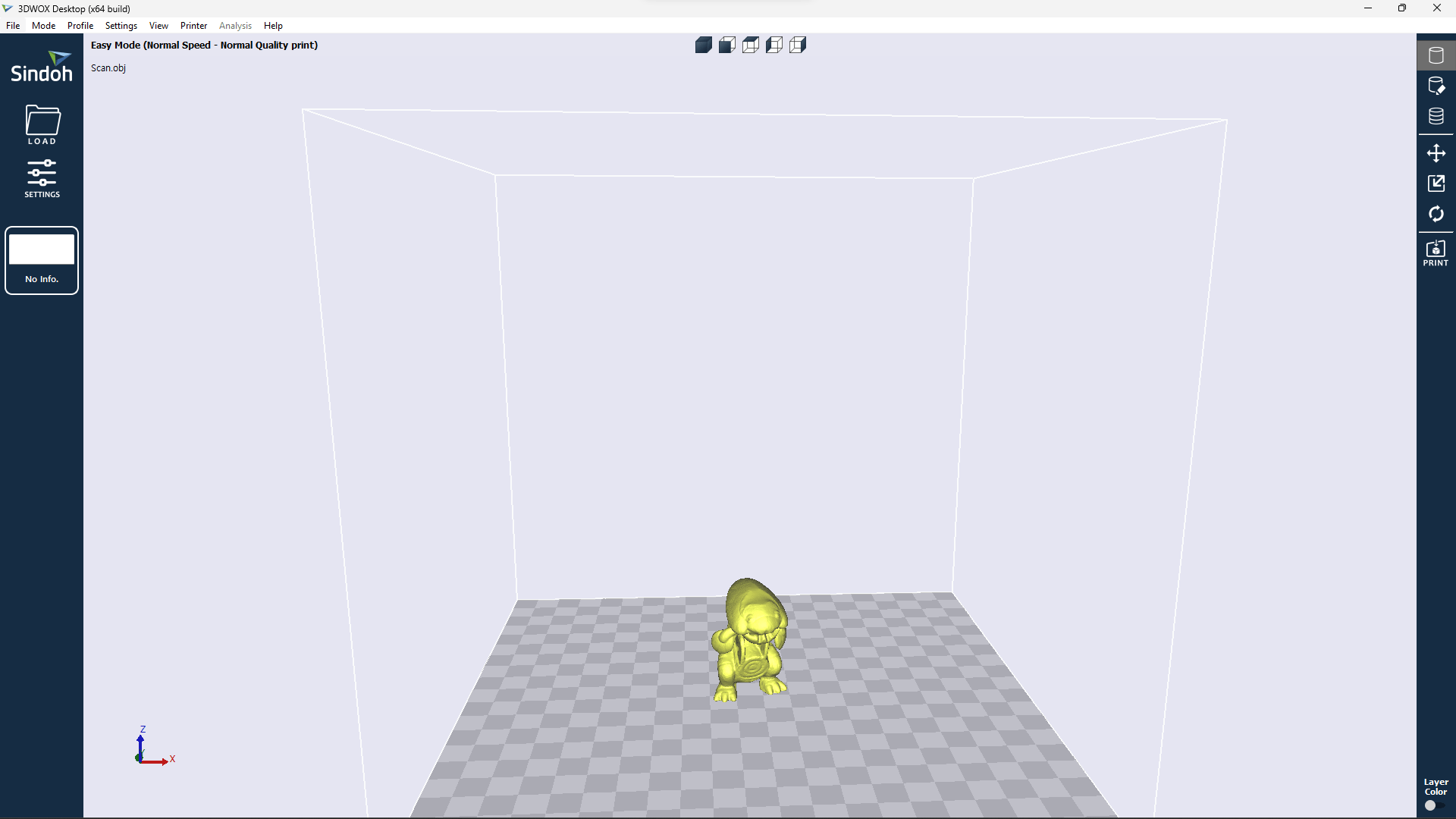

Is a technology has revolutionized the way everyone creates, its amazing how easy and accessibe is to own and use technology that allows us to create rapid prototypes and small-scale production.

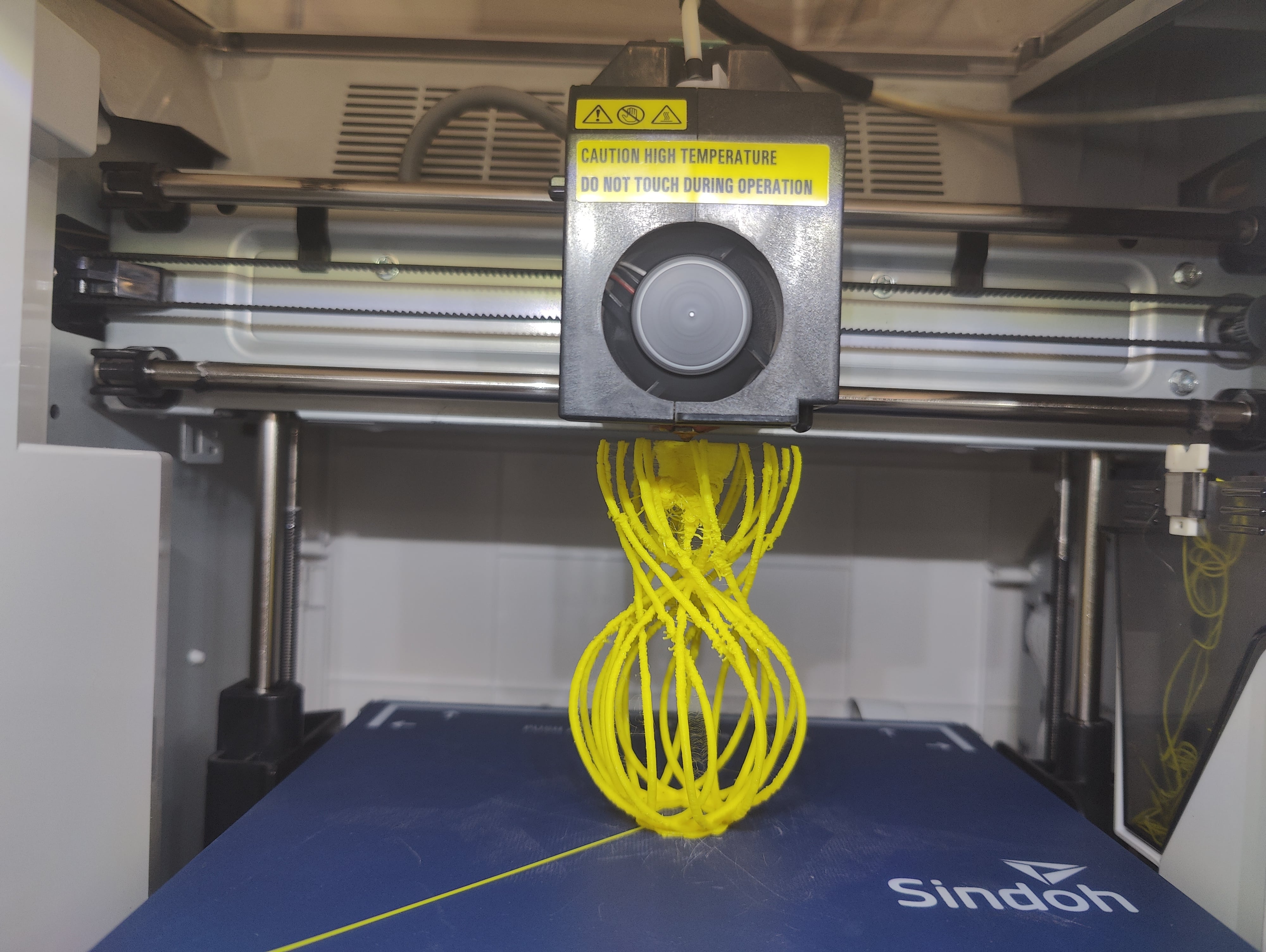

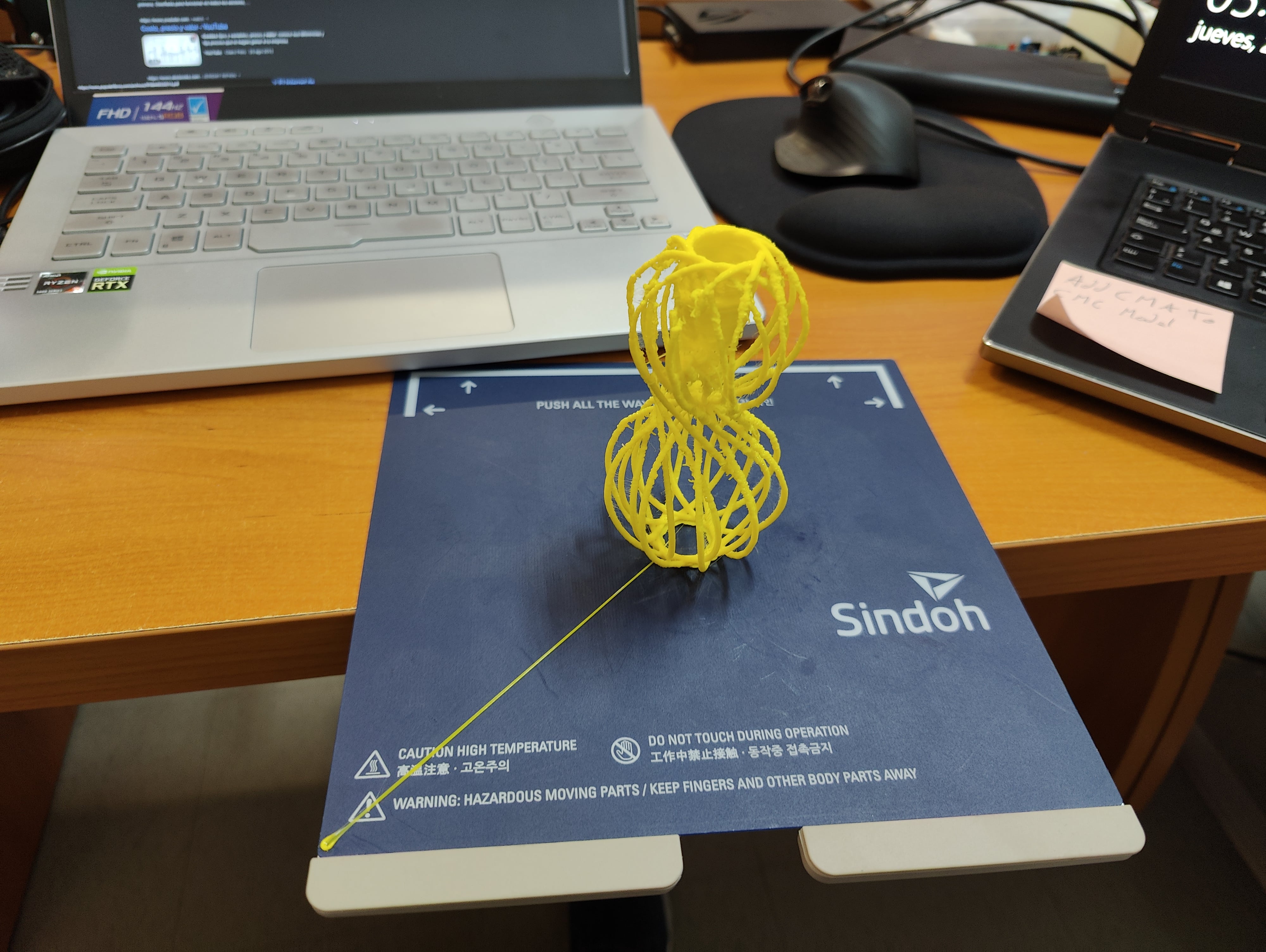

3D printing offers many advantages over traditional manufacturing methods, including the ability to create complex geometries that would be difficult or impossible to produce with other methods, such as injection molding or CNC machining. 3D printing also enables the production of small batches of parts or products without the need for expensive tooling, which can be cost-prohibitive for small businesses or individuals.

Overall, 3D printing is a powerful tool that is changing the way we design, create, and produce objects. As the technology continues to evolve, it is expected to have a significant impact on manufacturing, supply chain management, and product development in the years to come.