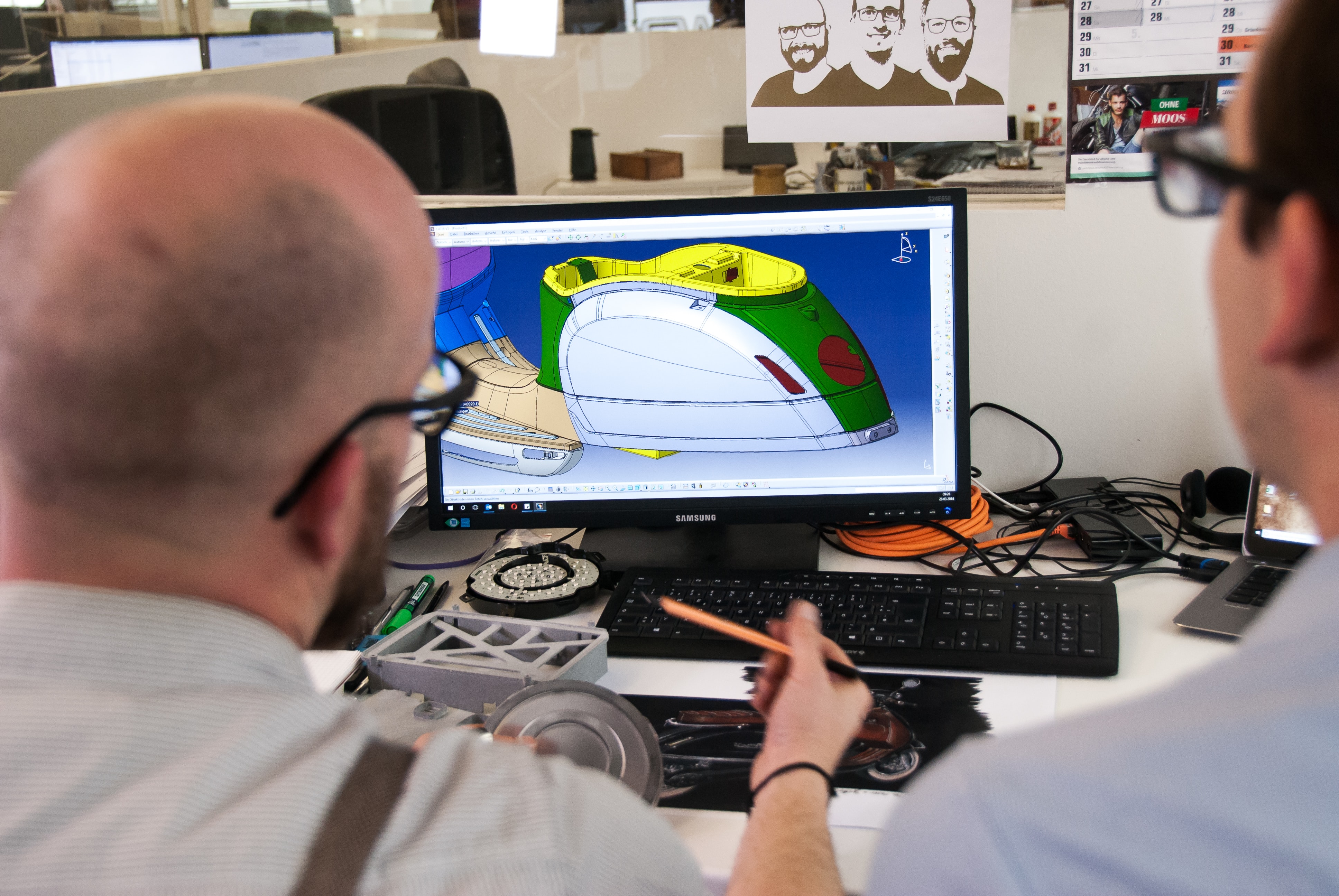

Computer Aided Design (CAD) software can be used to create a wide range of designs, including mechanical parts and assemblies, buildings and architectural designs, electrical and electronic systems, and 3D models for animation and visualization. The software typically includes a variety of tools for creating and manipulating geometric shapes, as well as features for adding annotations, dimensions, and other details to designs.

Overall, CAD has revolutionized the design process, enabling designers to create and test designs more efficiently and accurately than ever before. With the help of CAD software, designers can bring their ideas to life, optimize designs for performance and efficiency, and create products and structures that meet the needs of their clients and customers.

Assignment

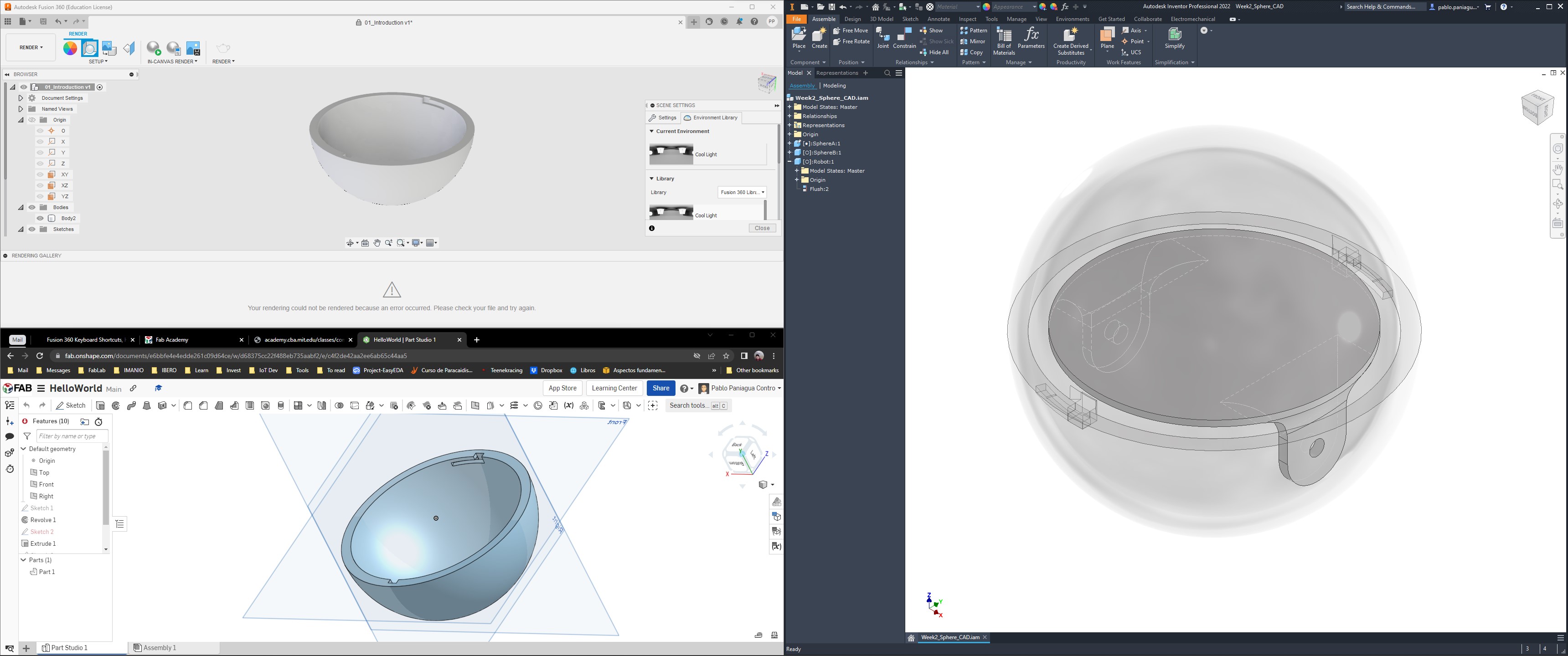

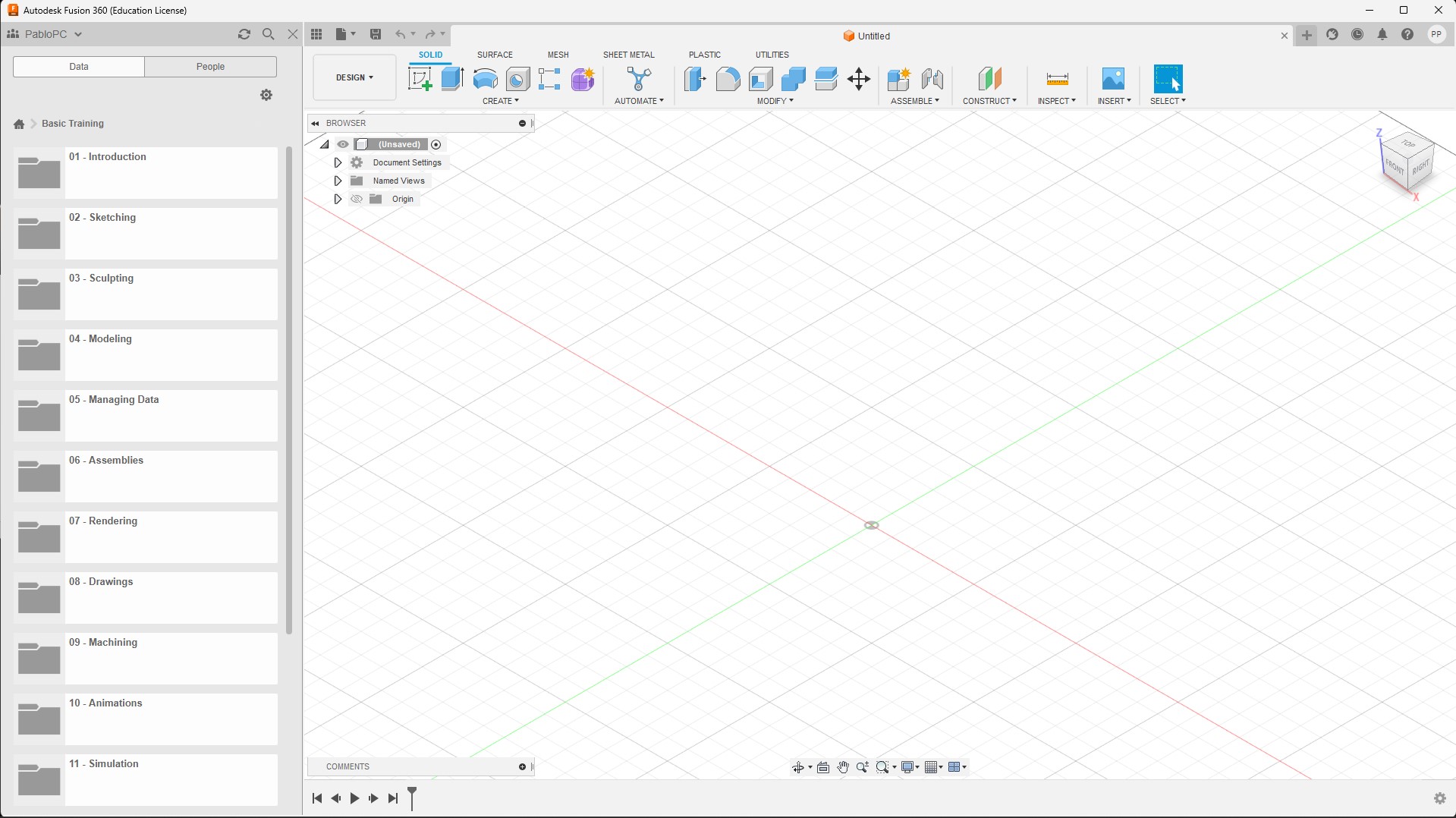

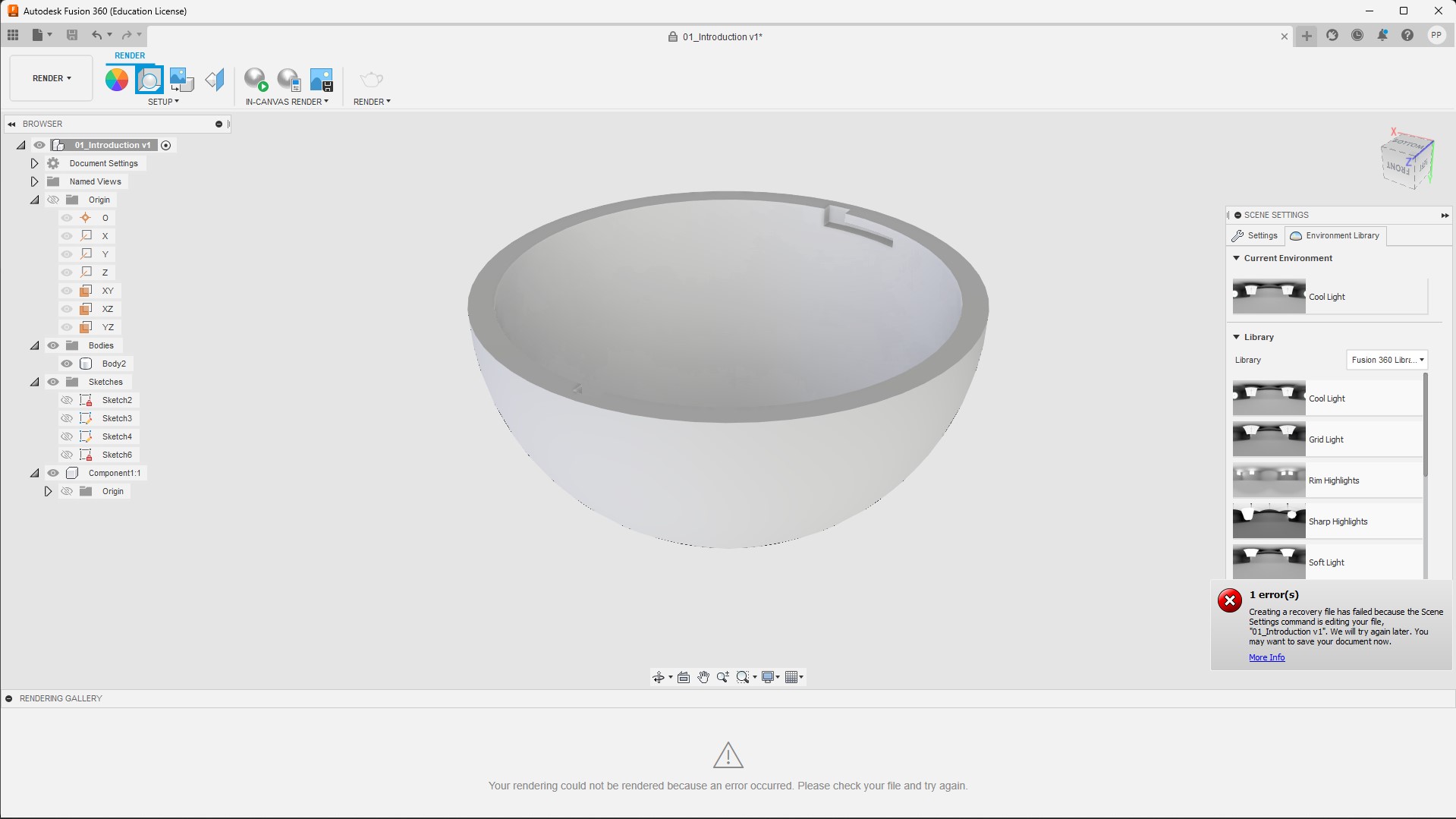

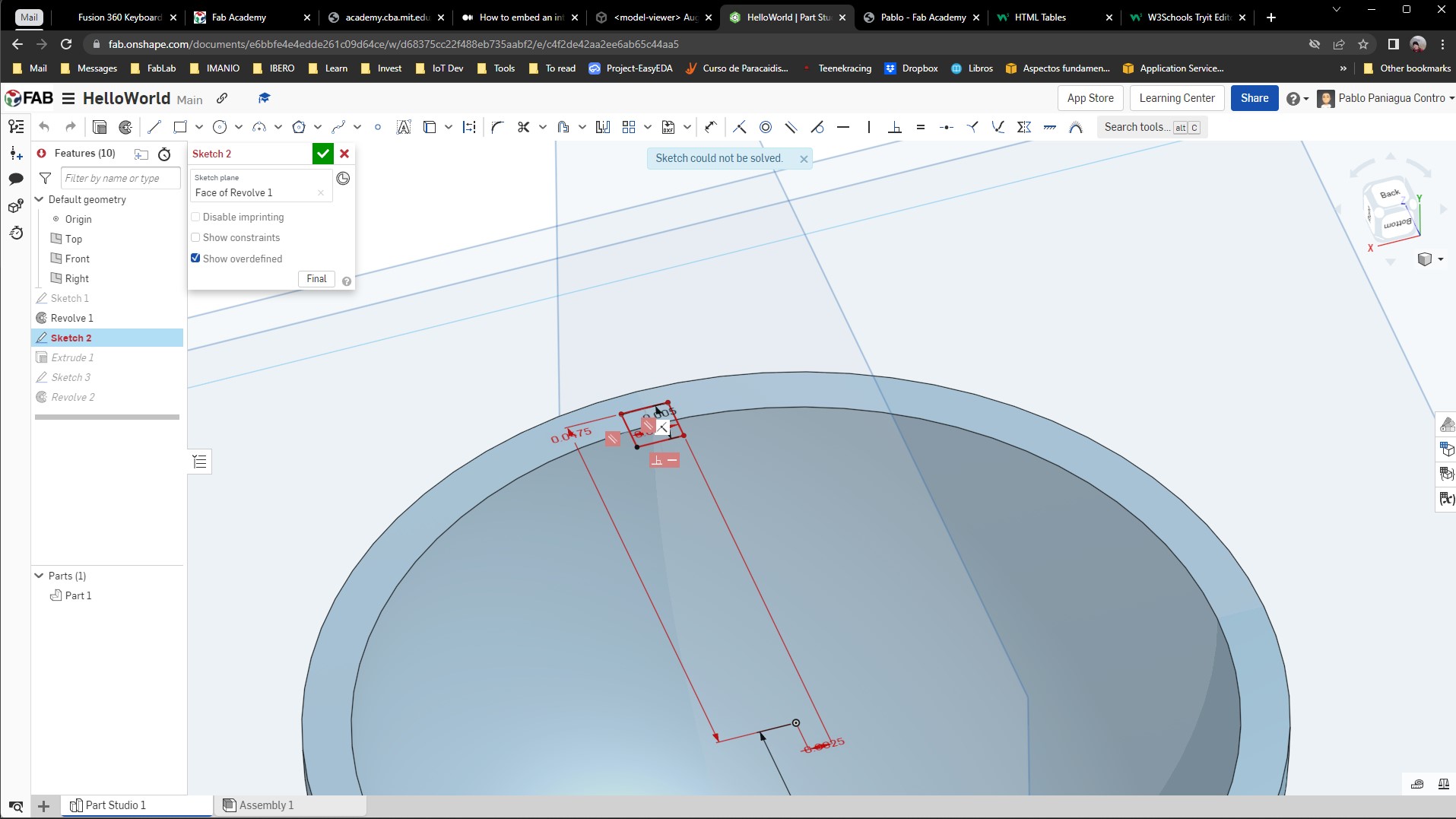

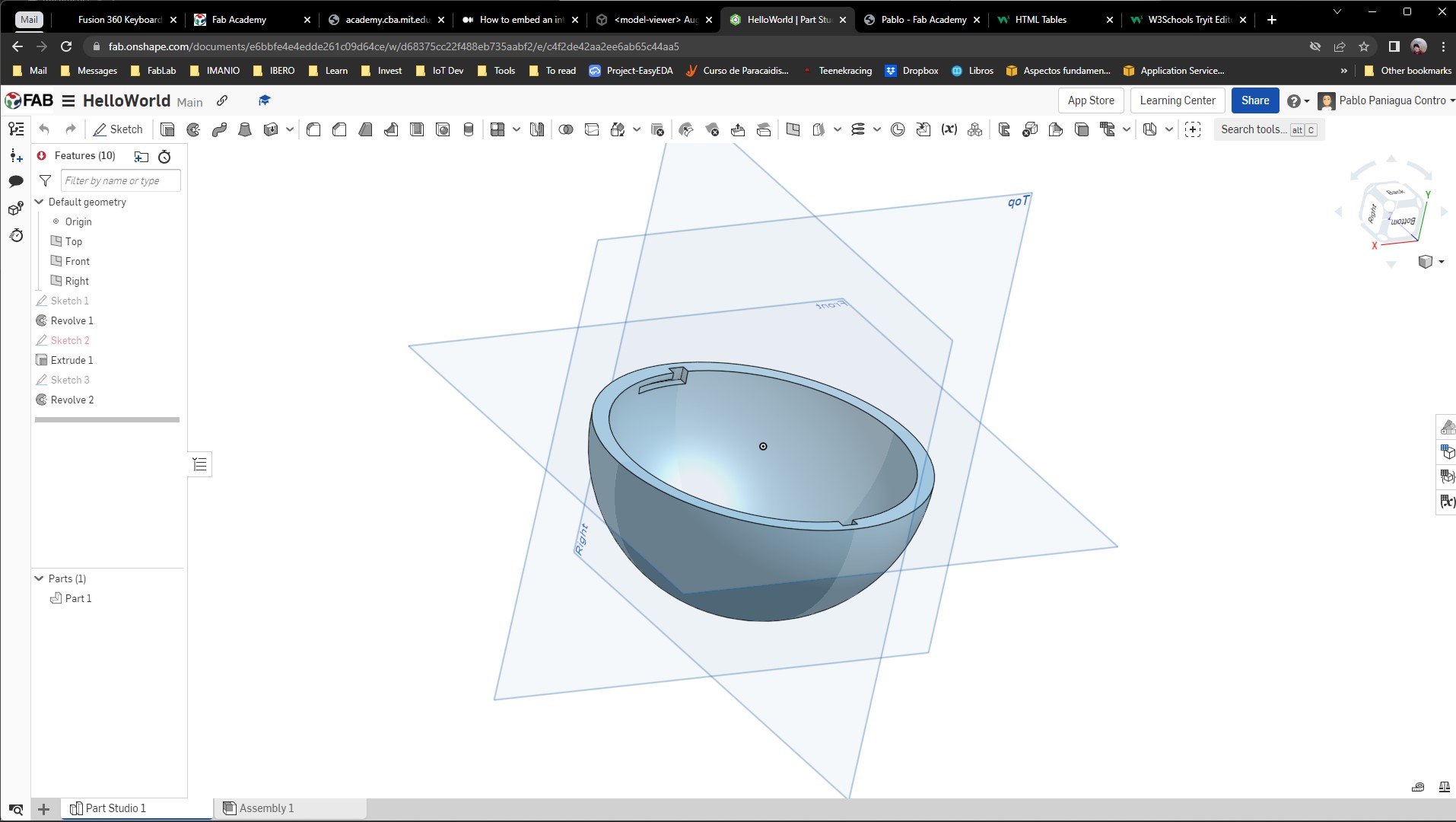

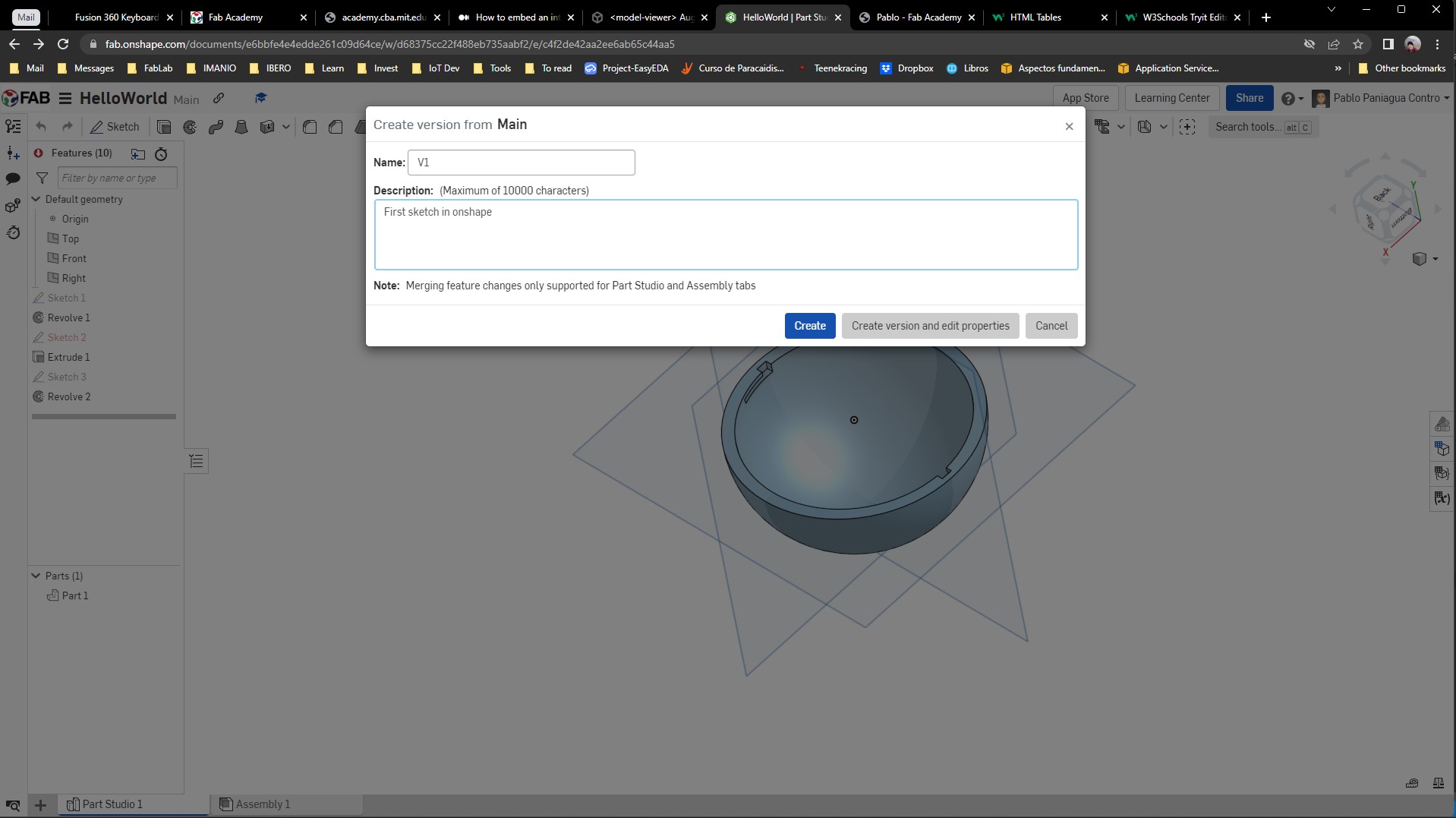

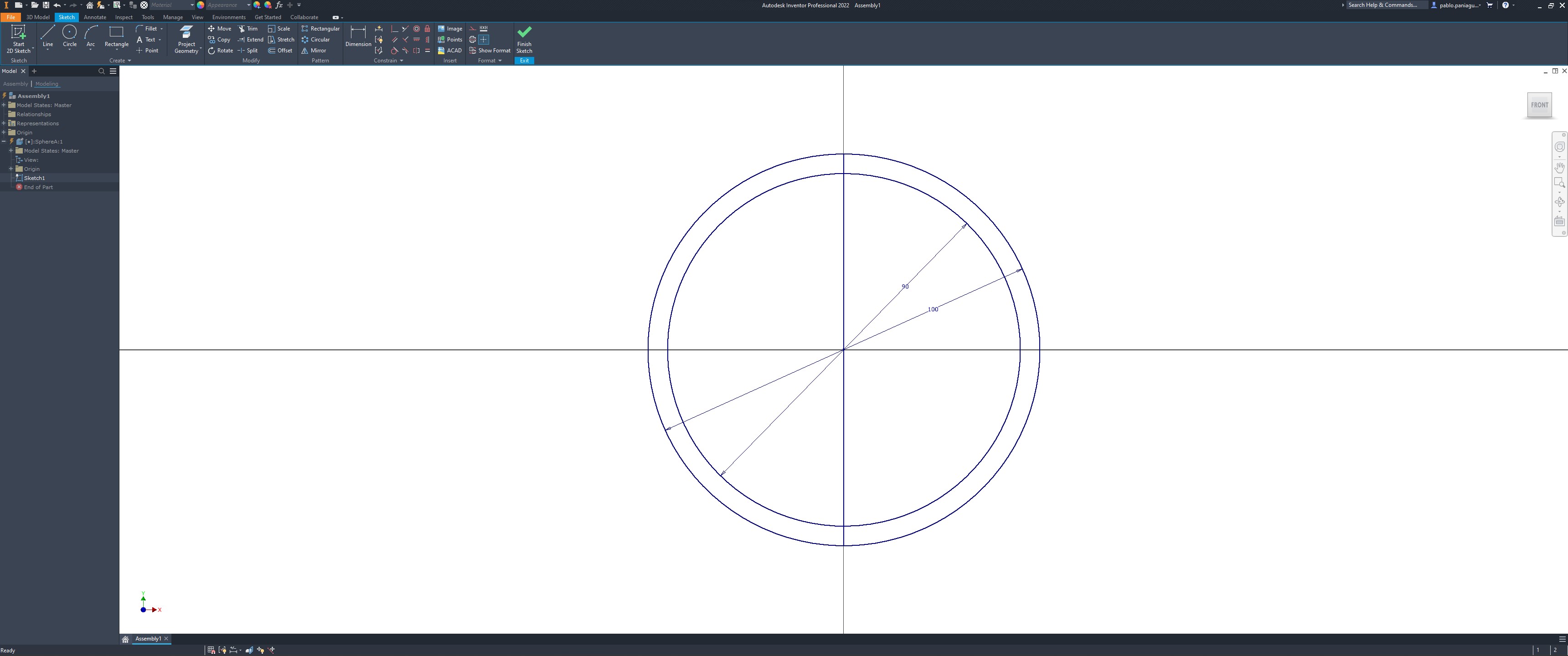

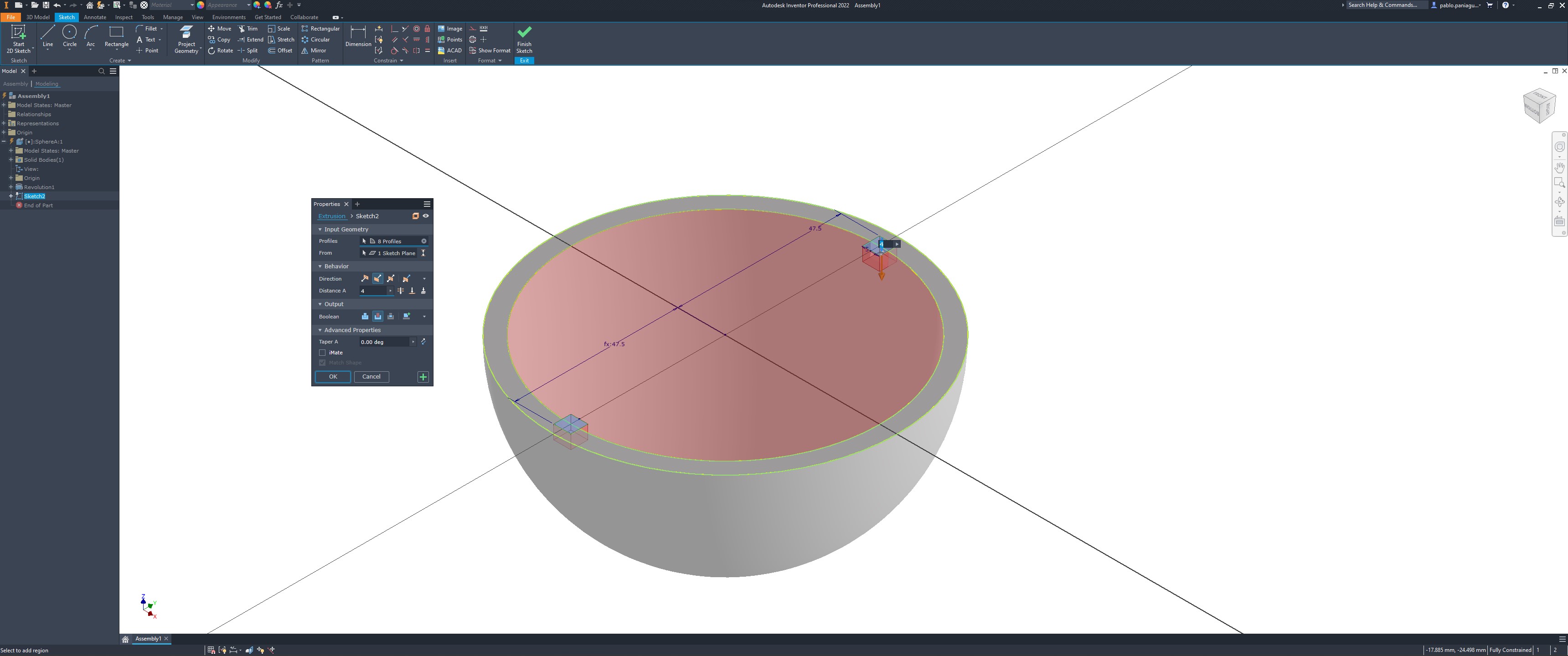

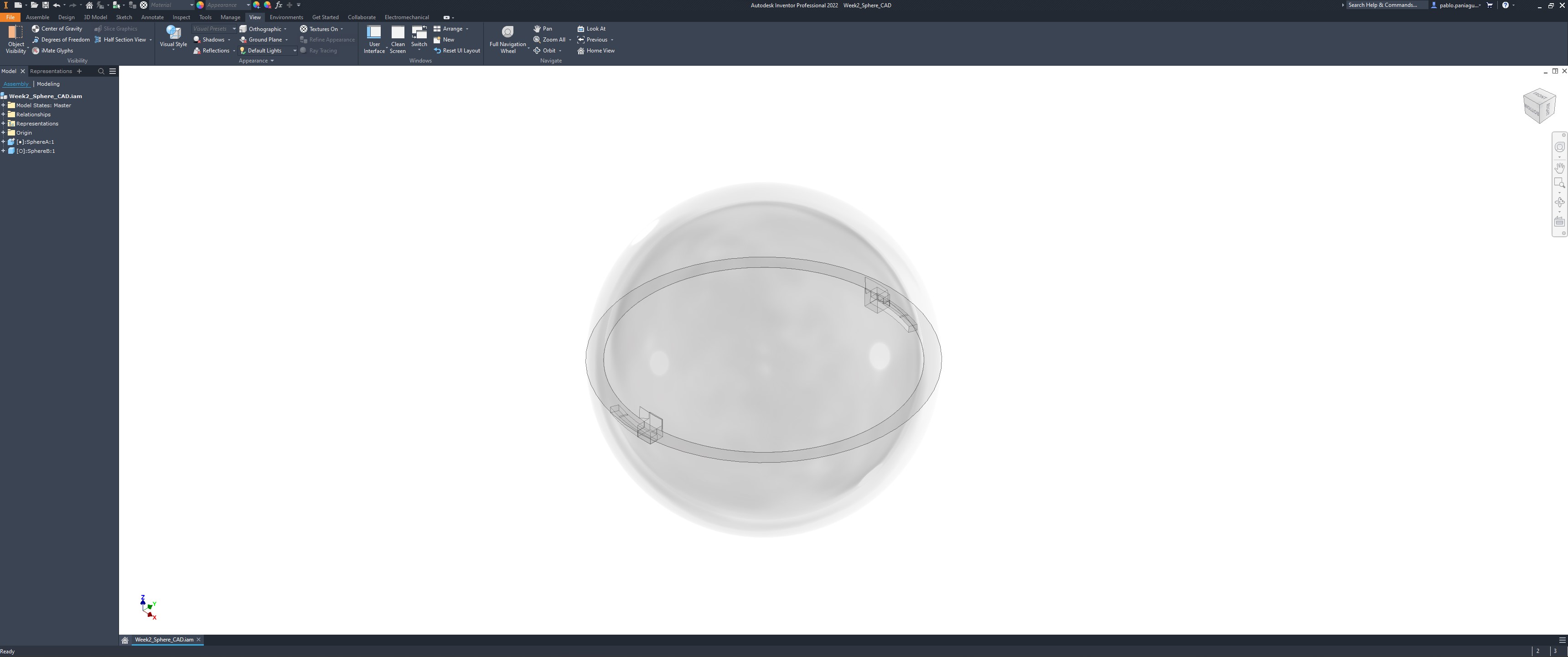

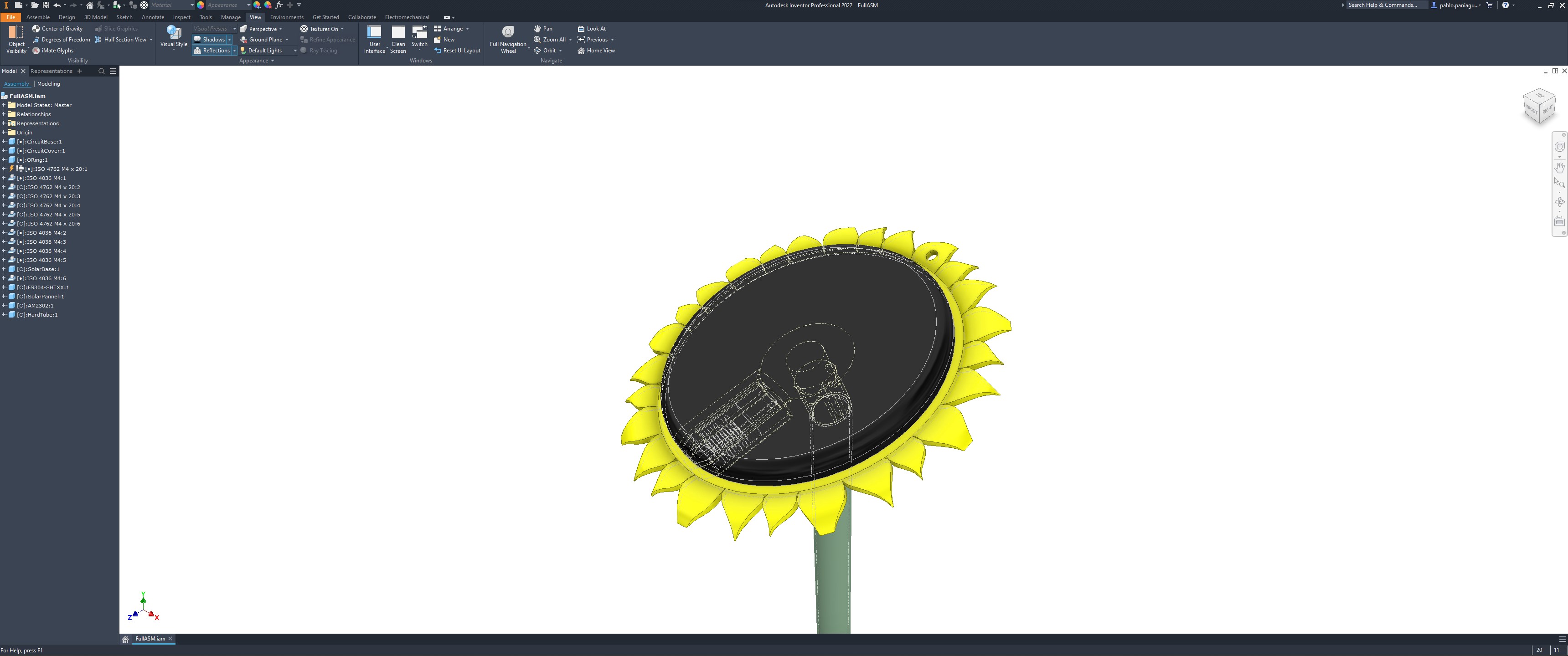

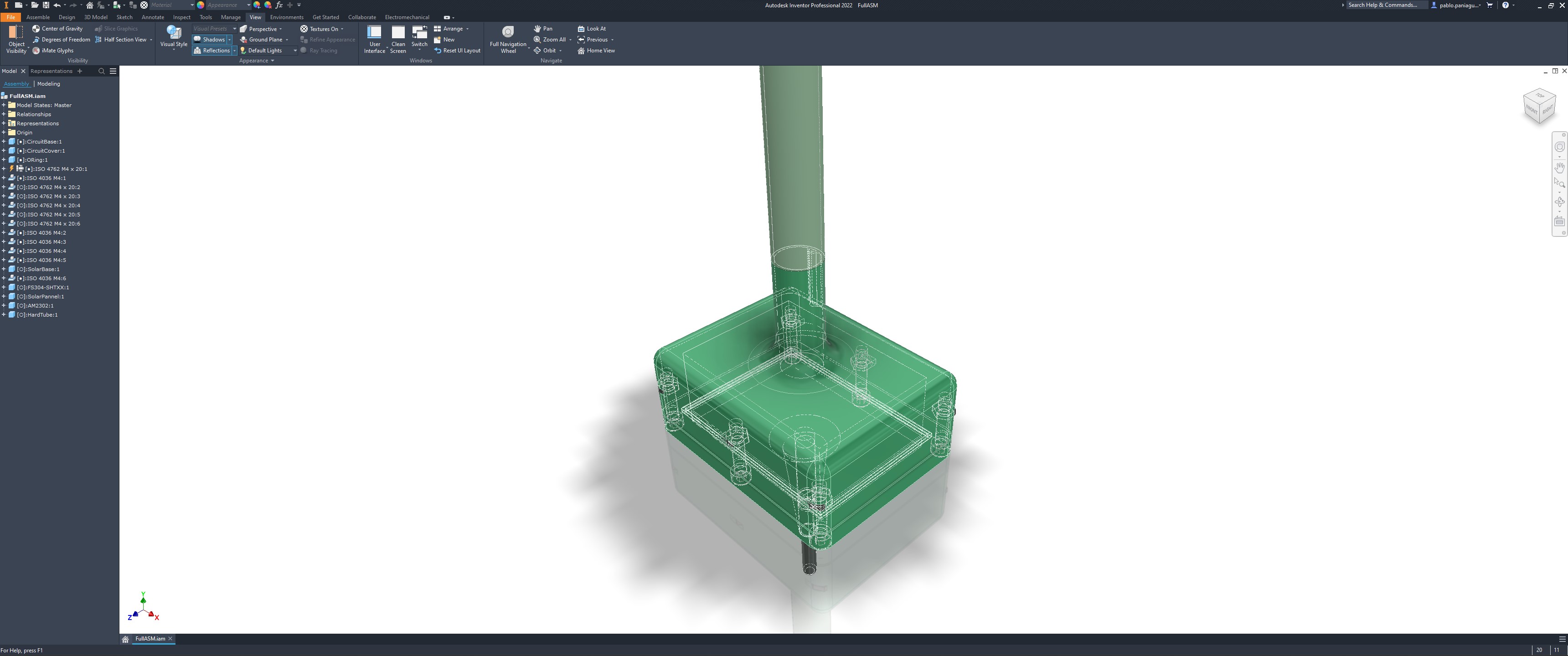

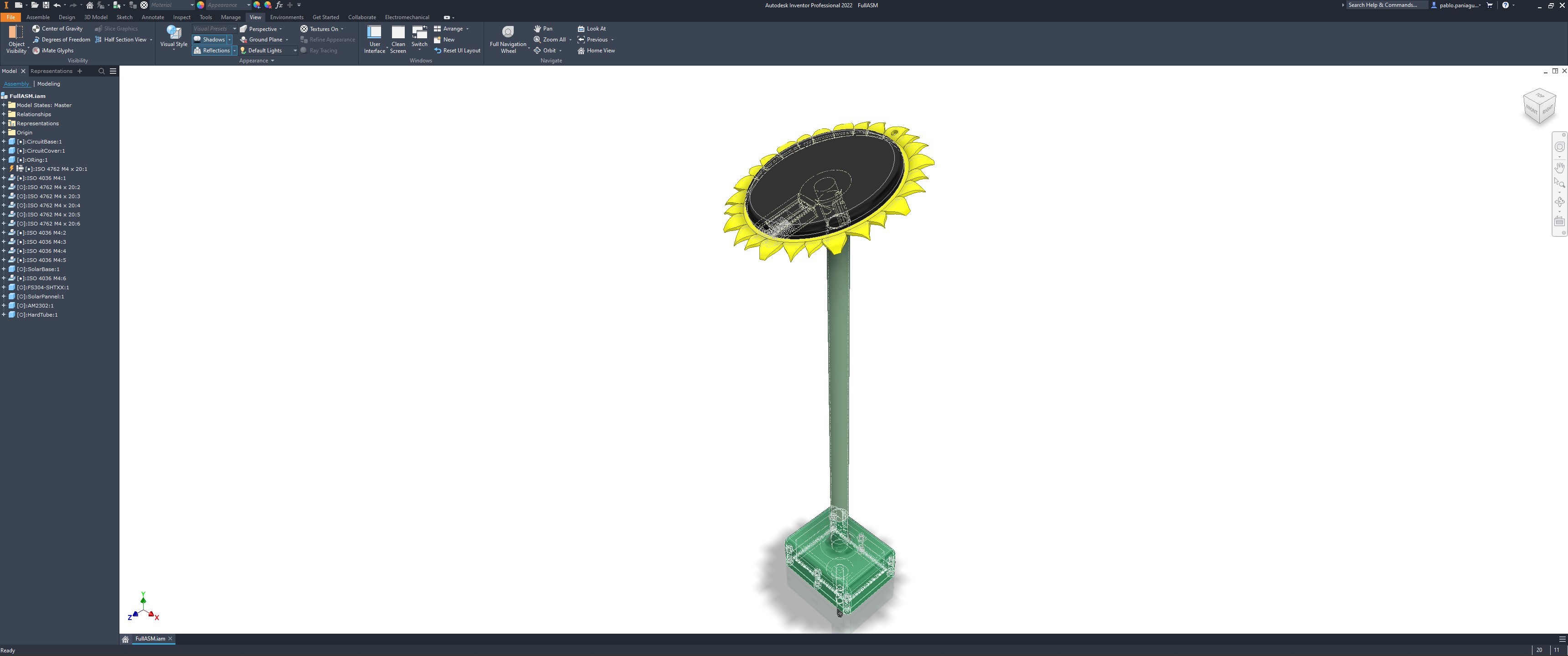

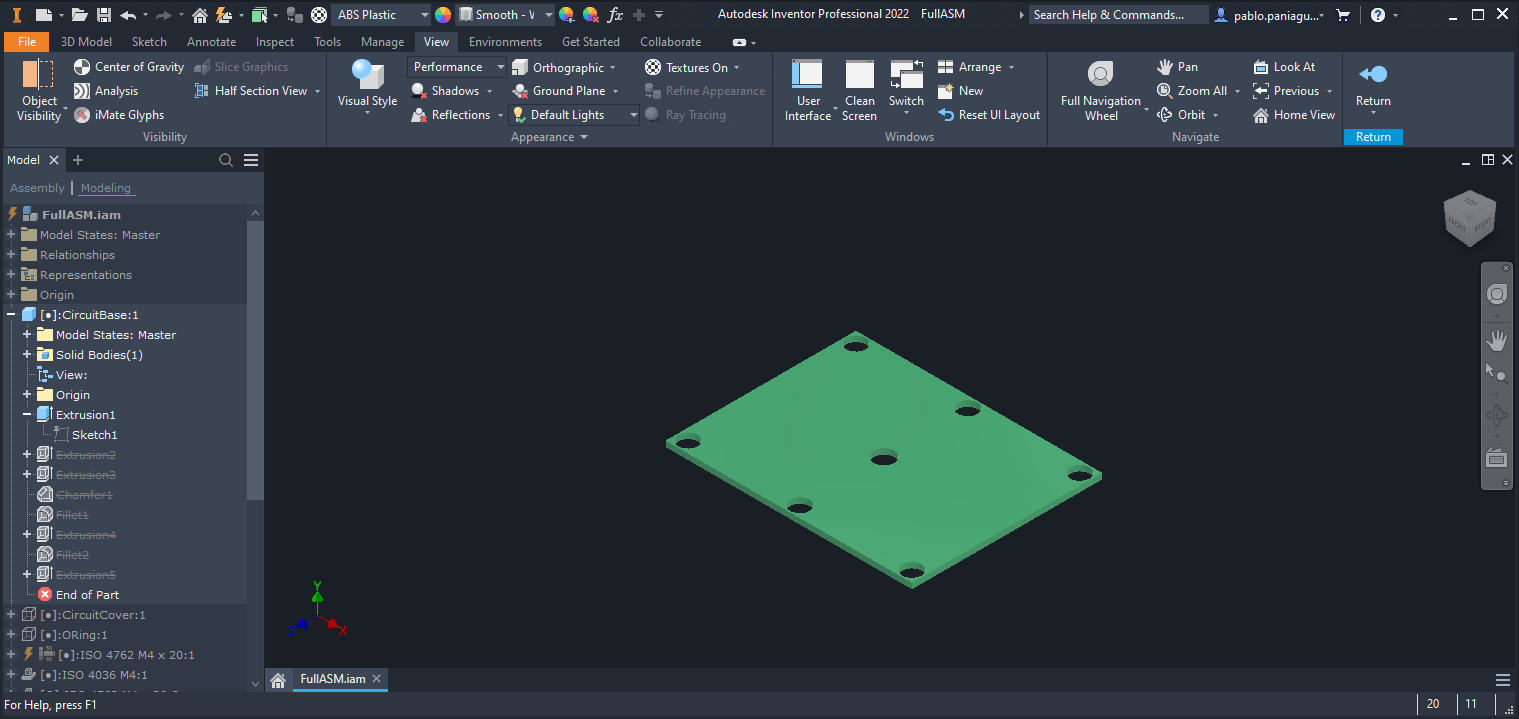

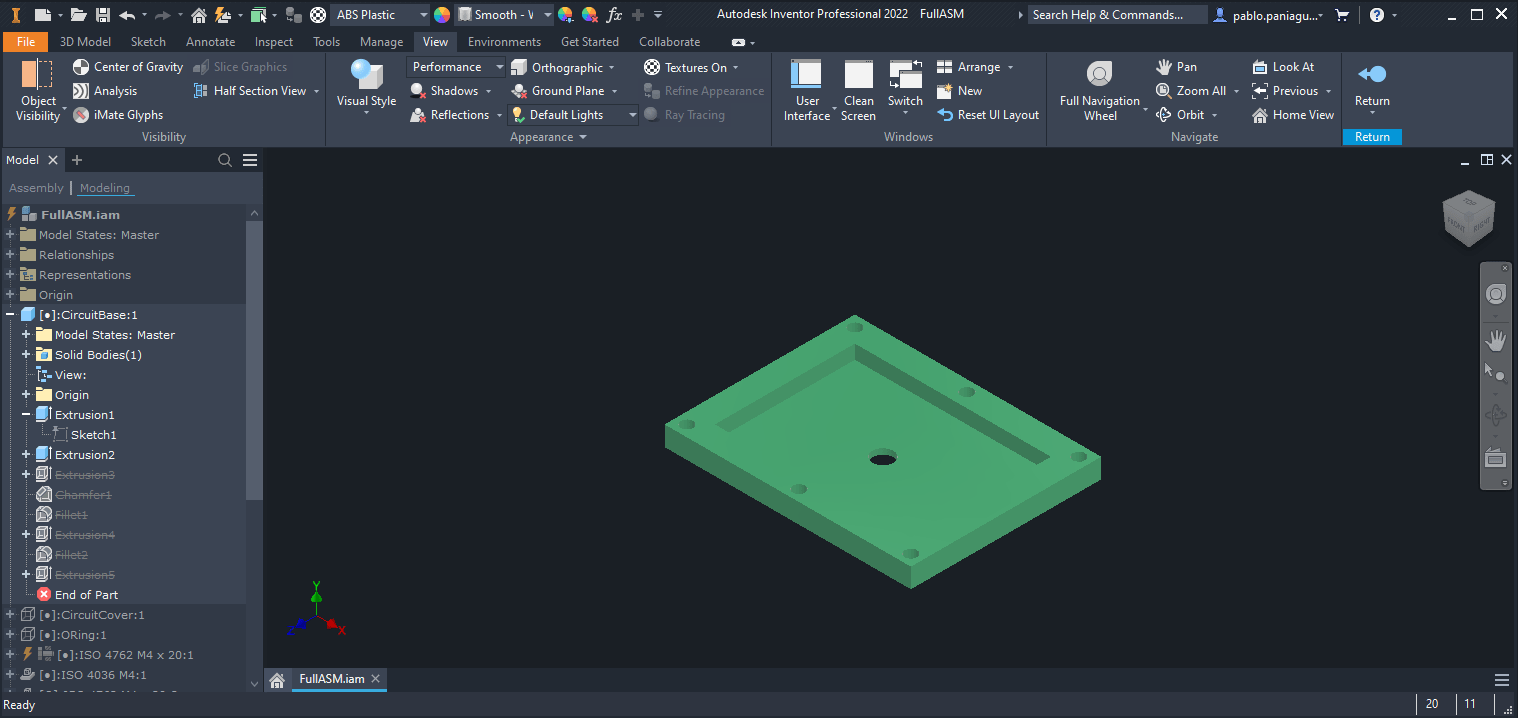

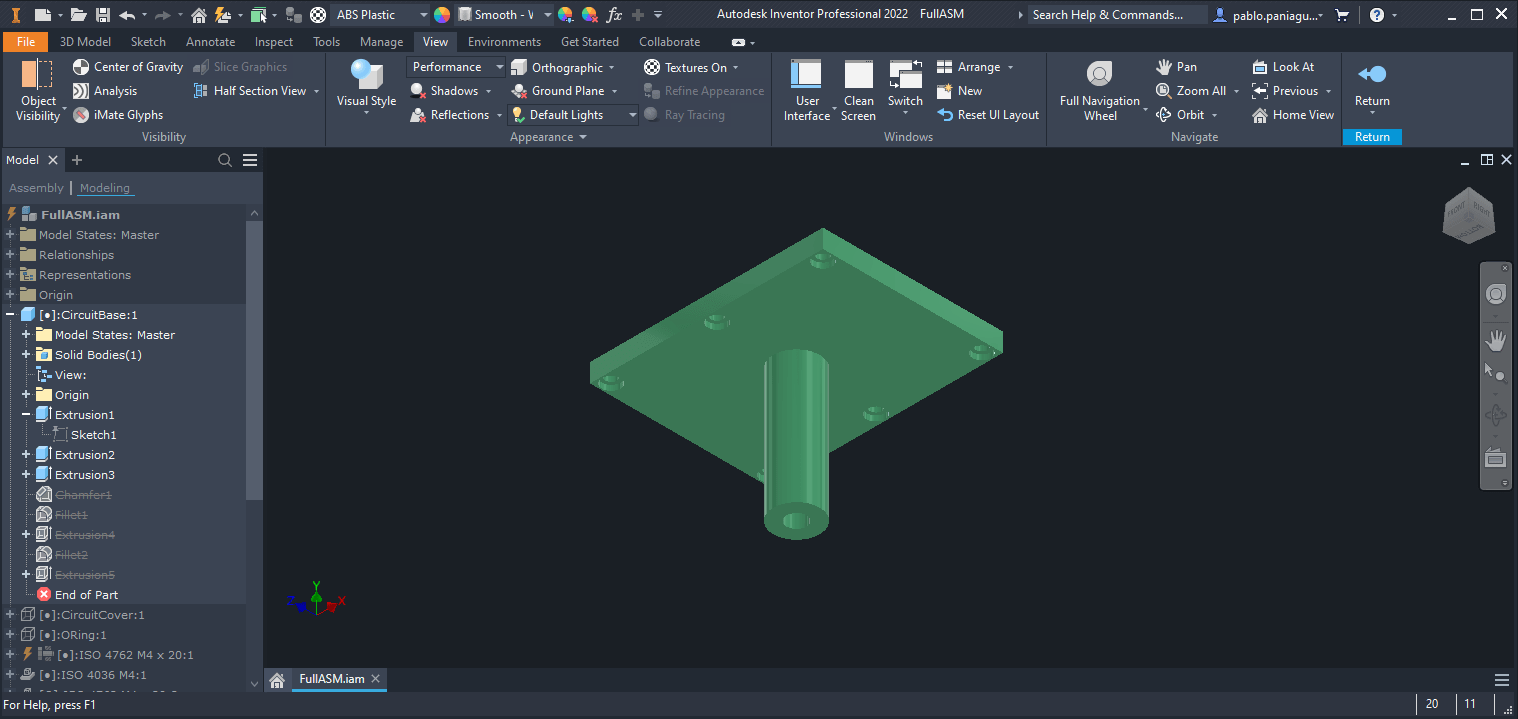

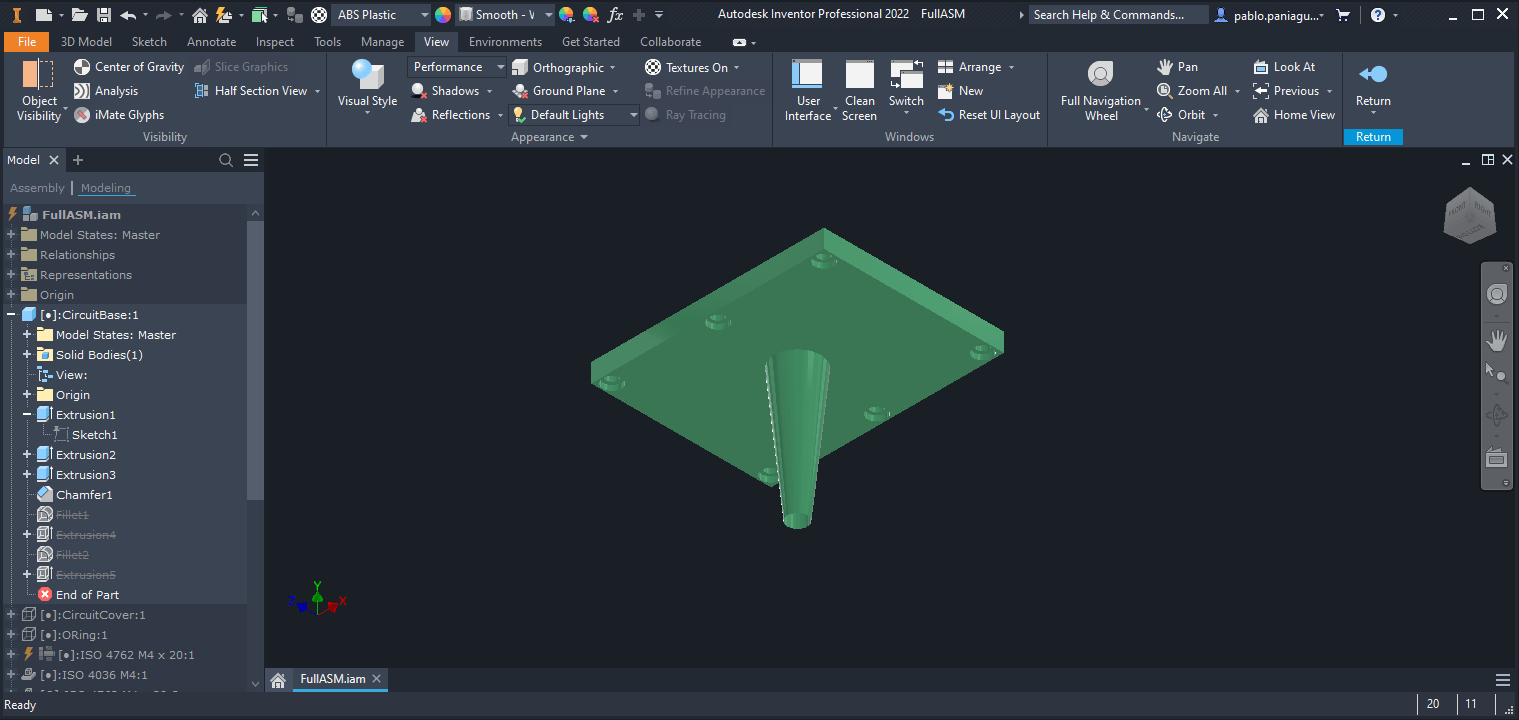

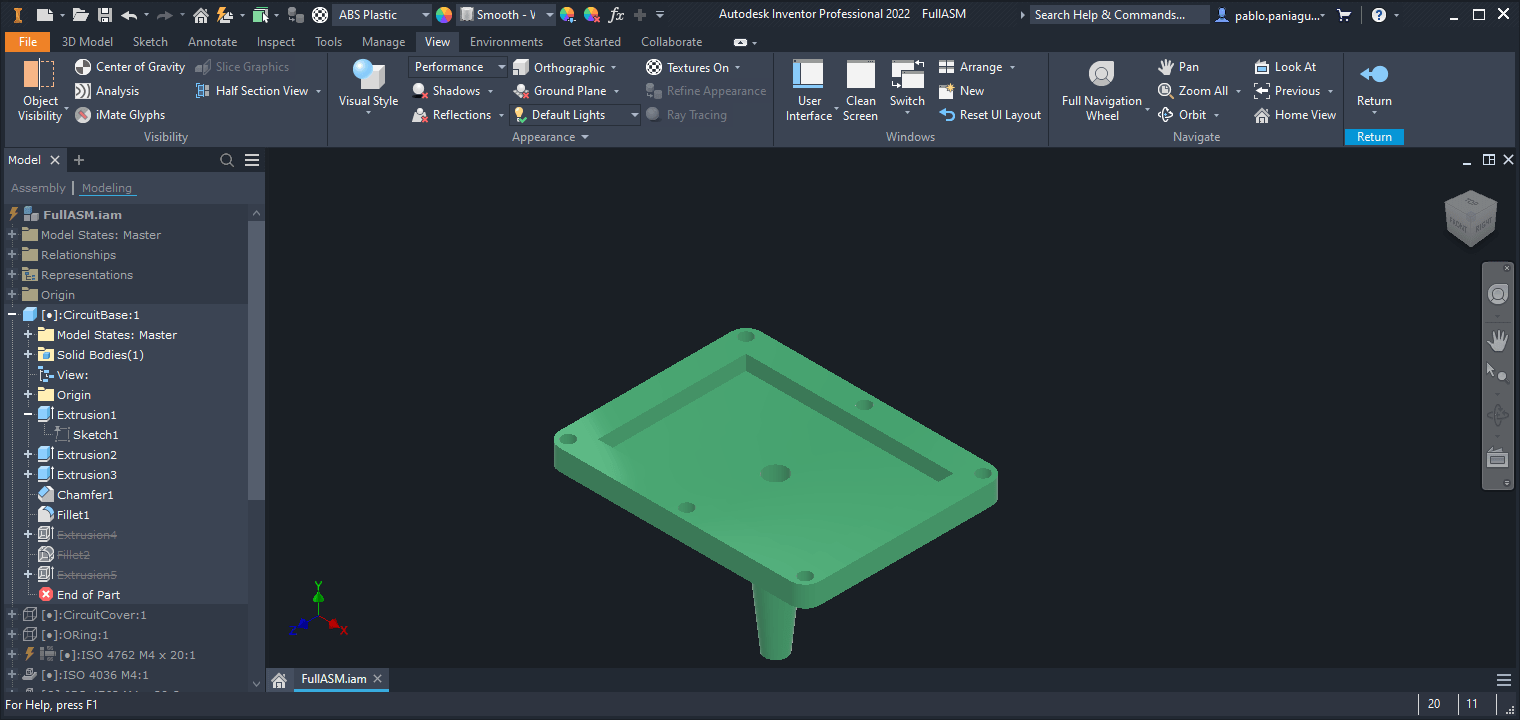

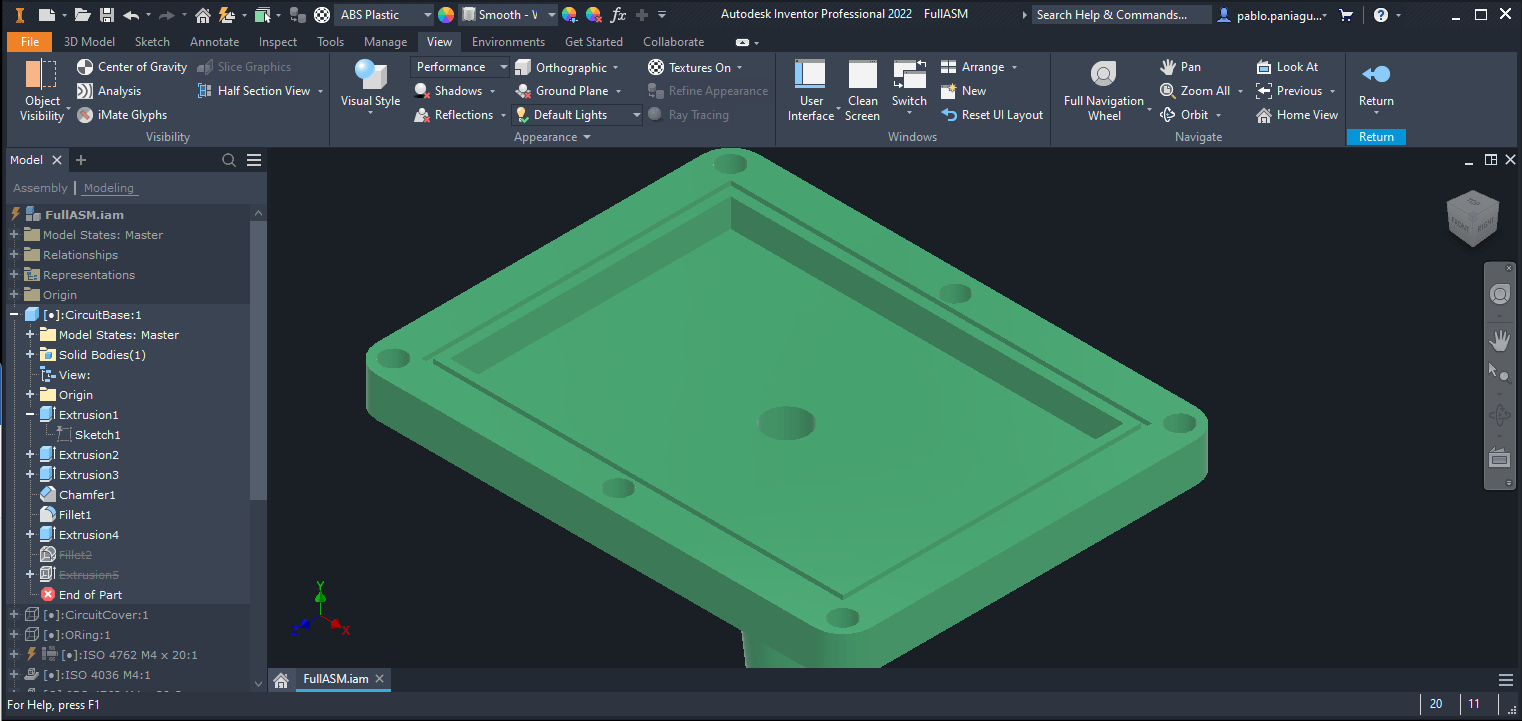

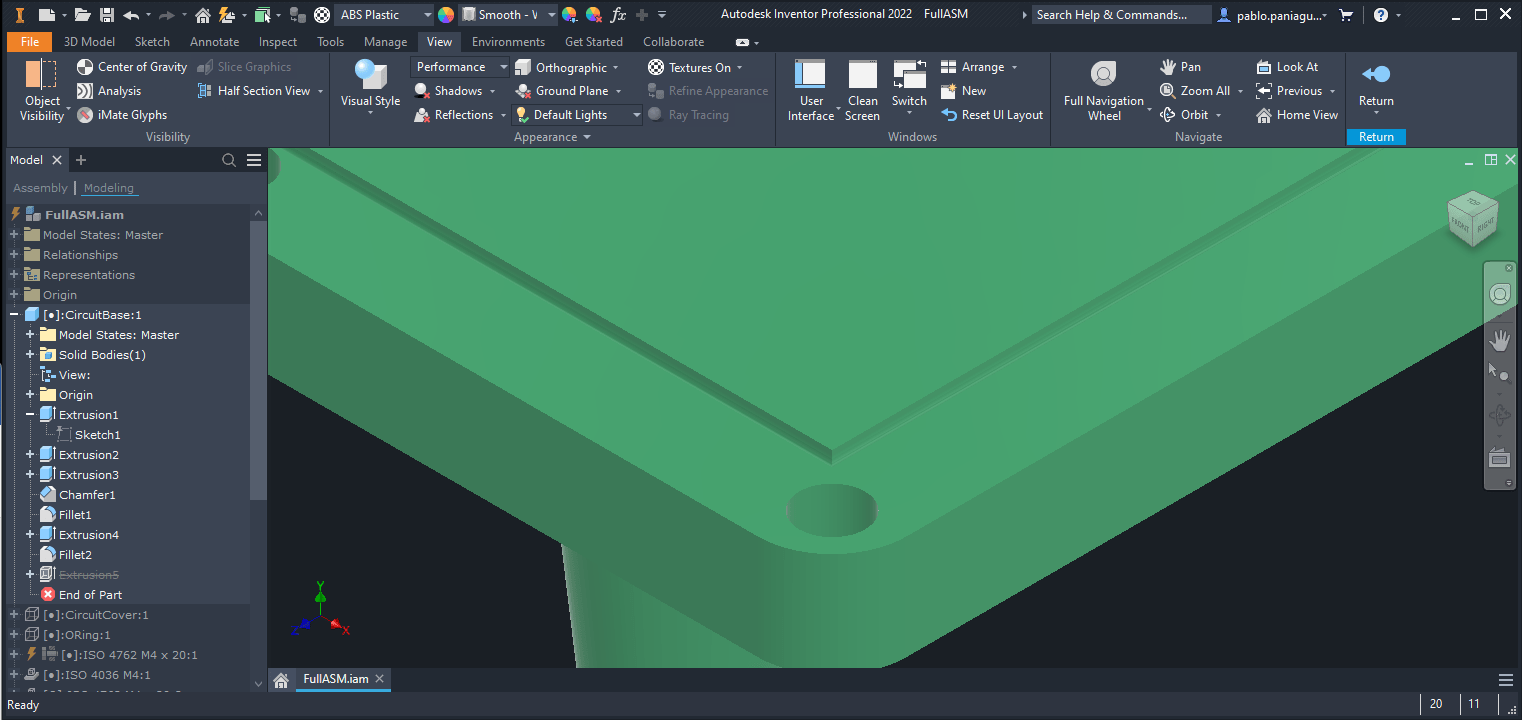

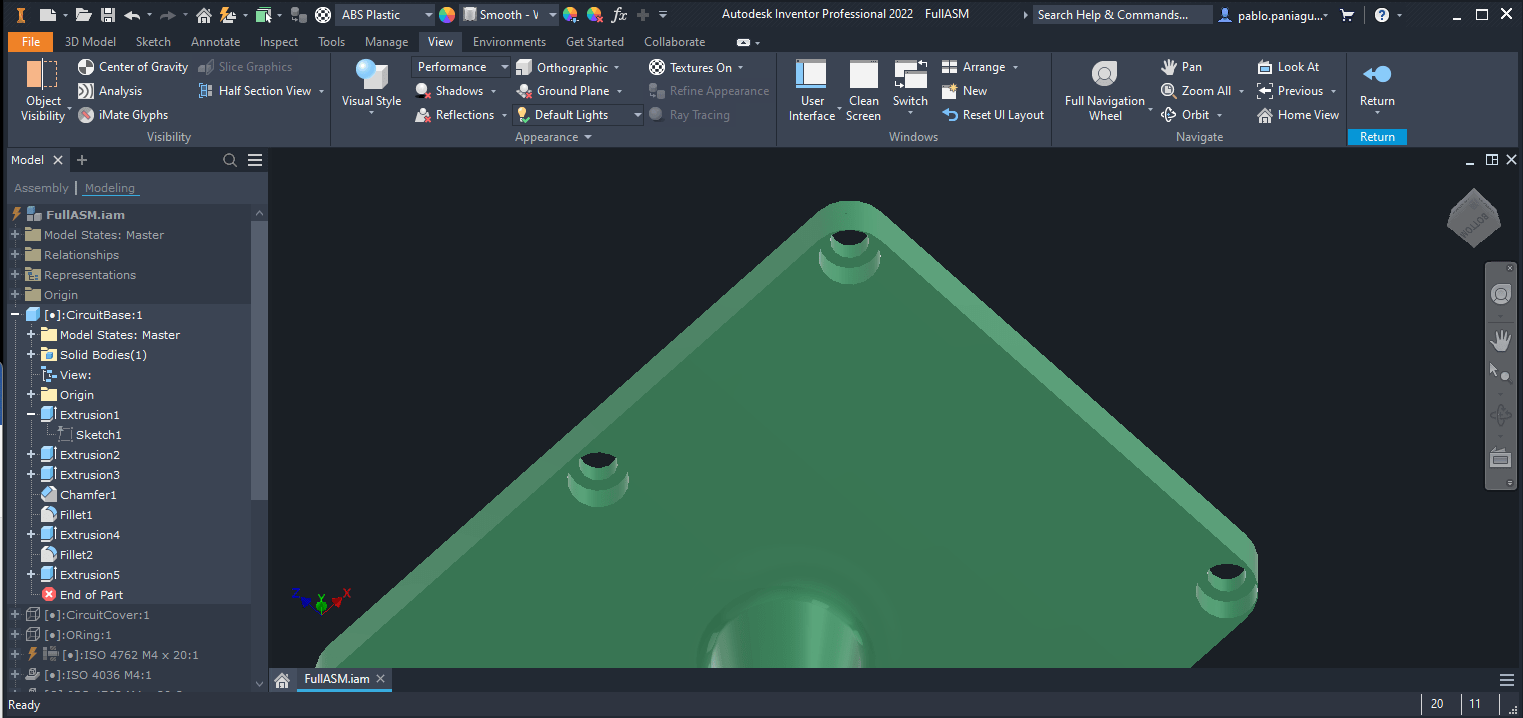

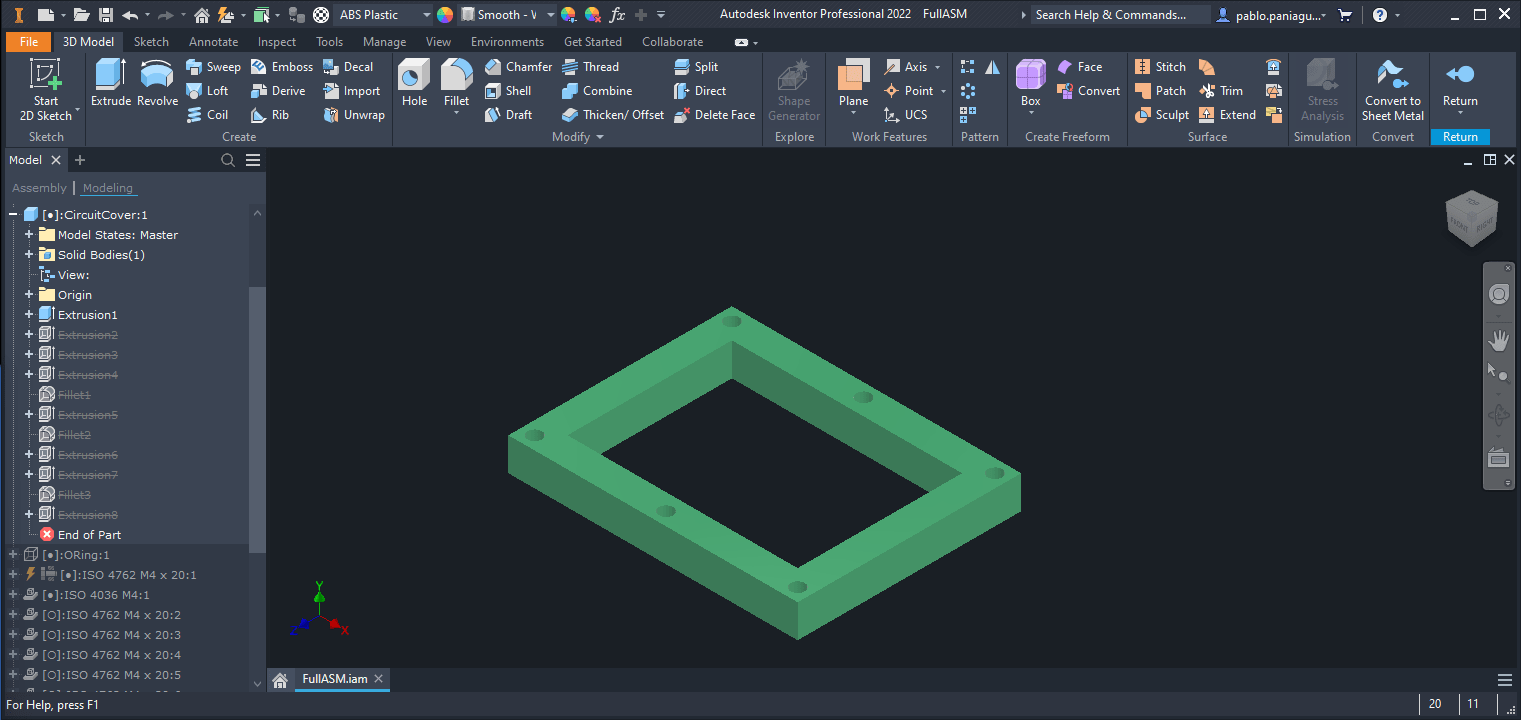

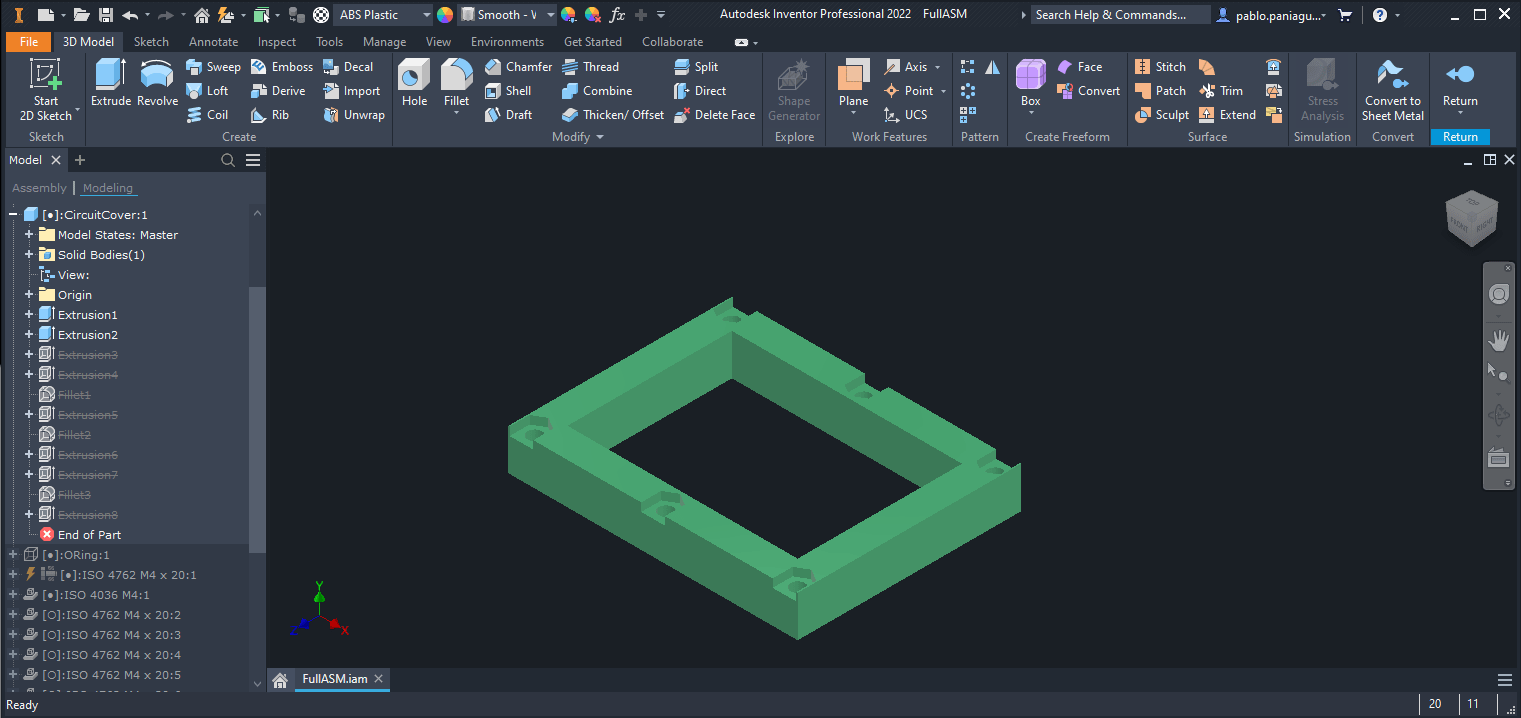

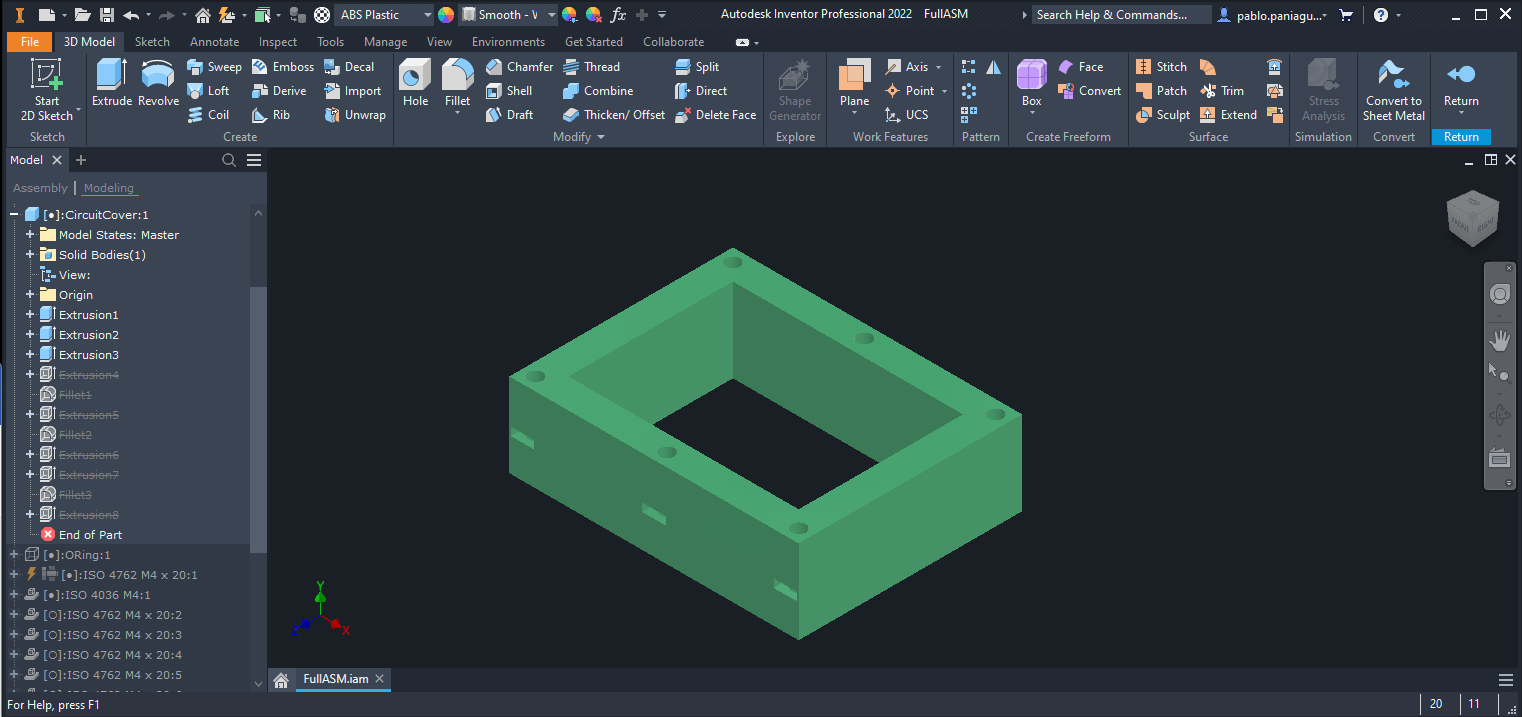

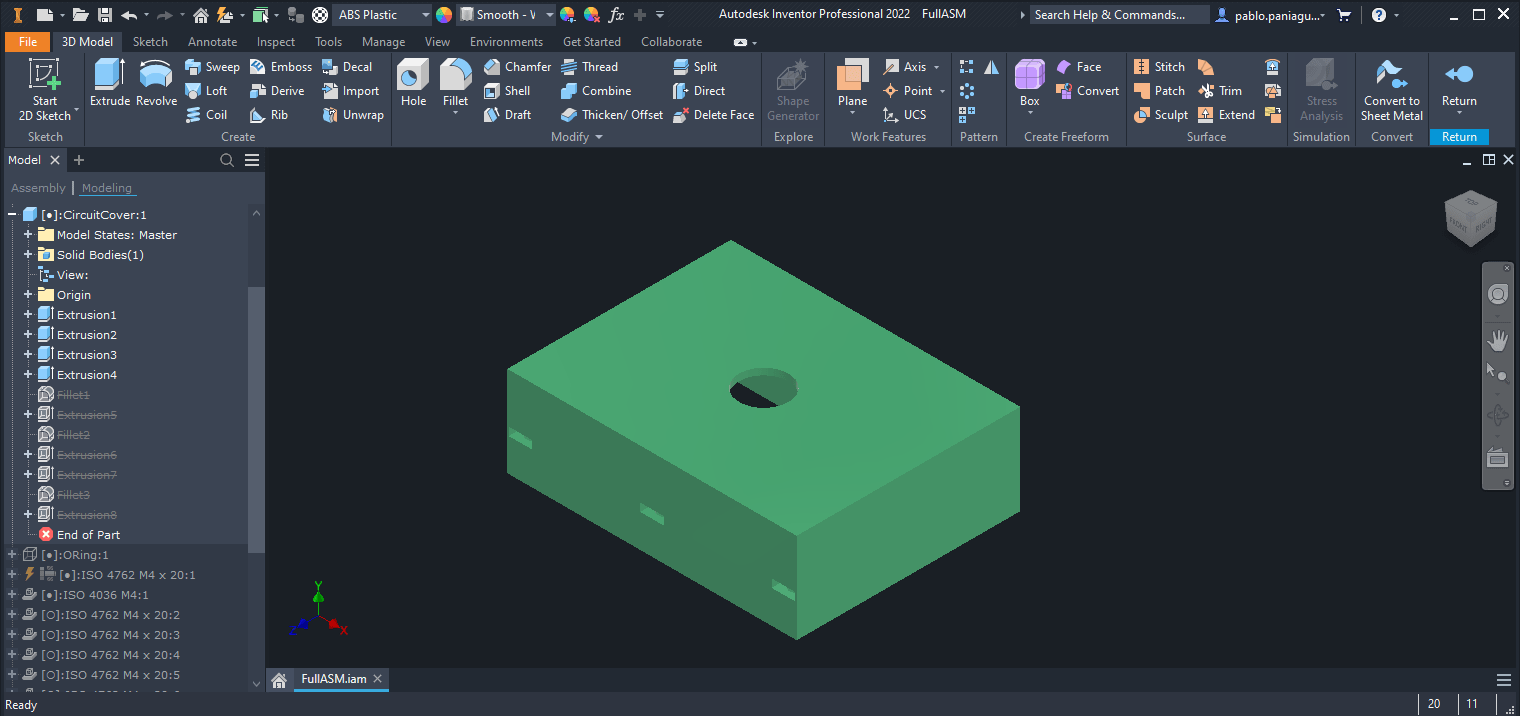

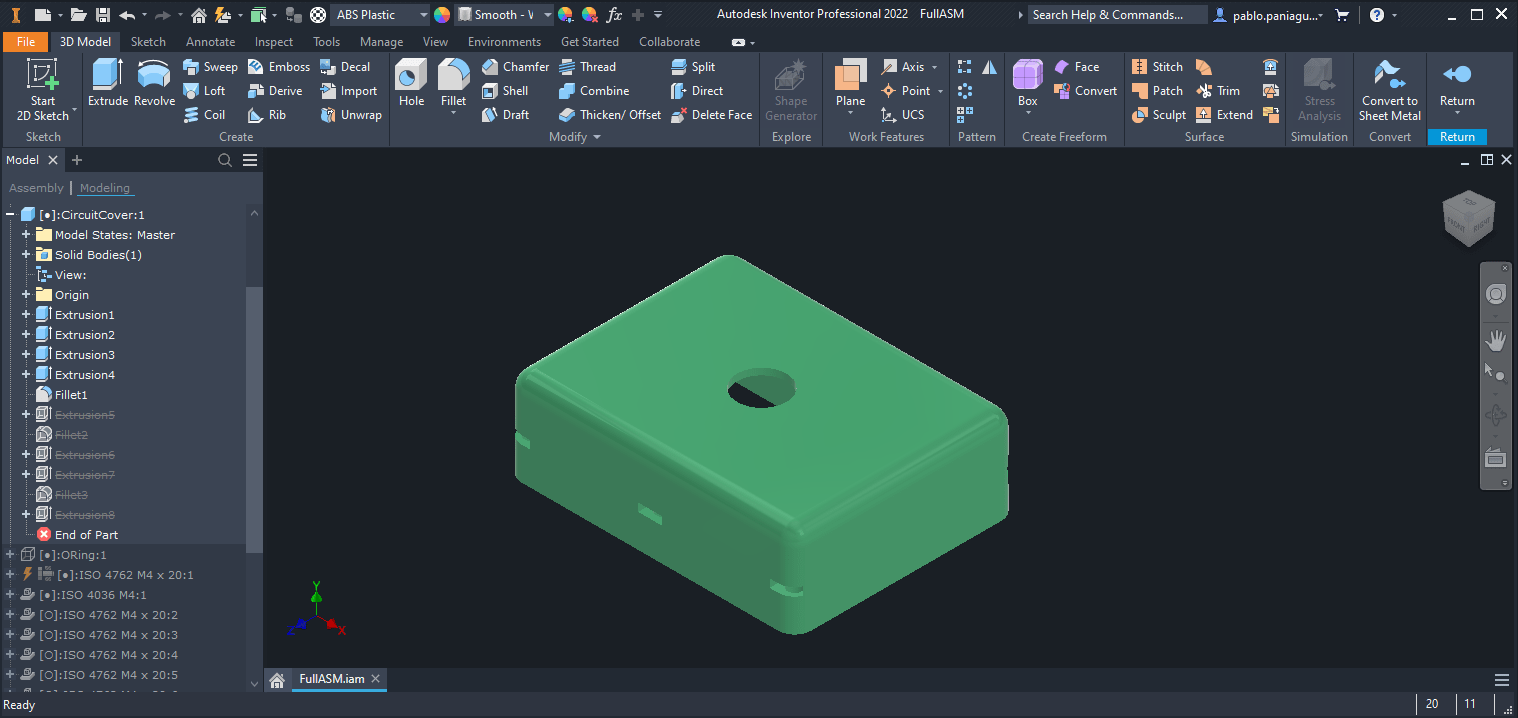

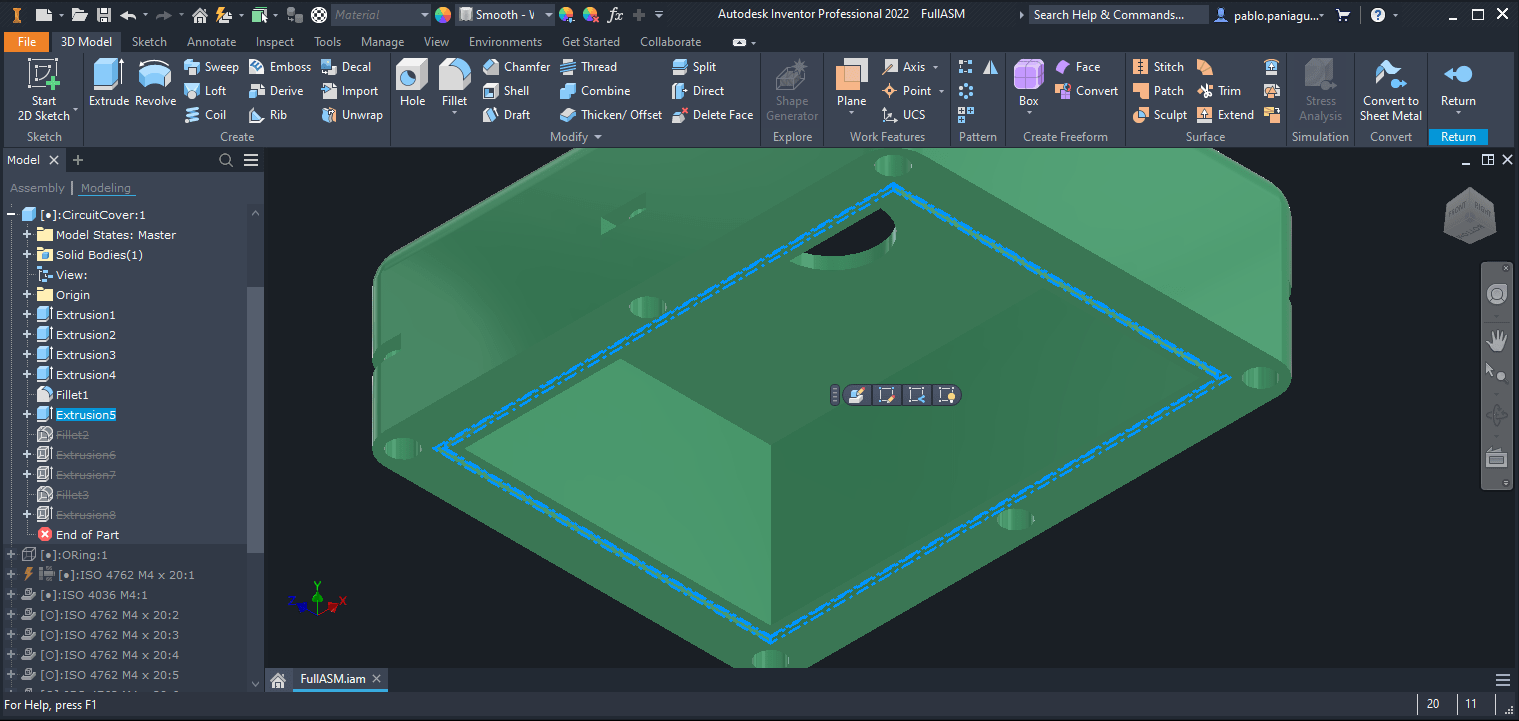

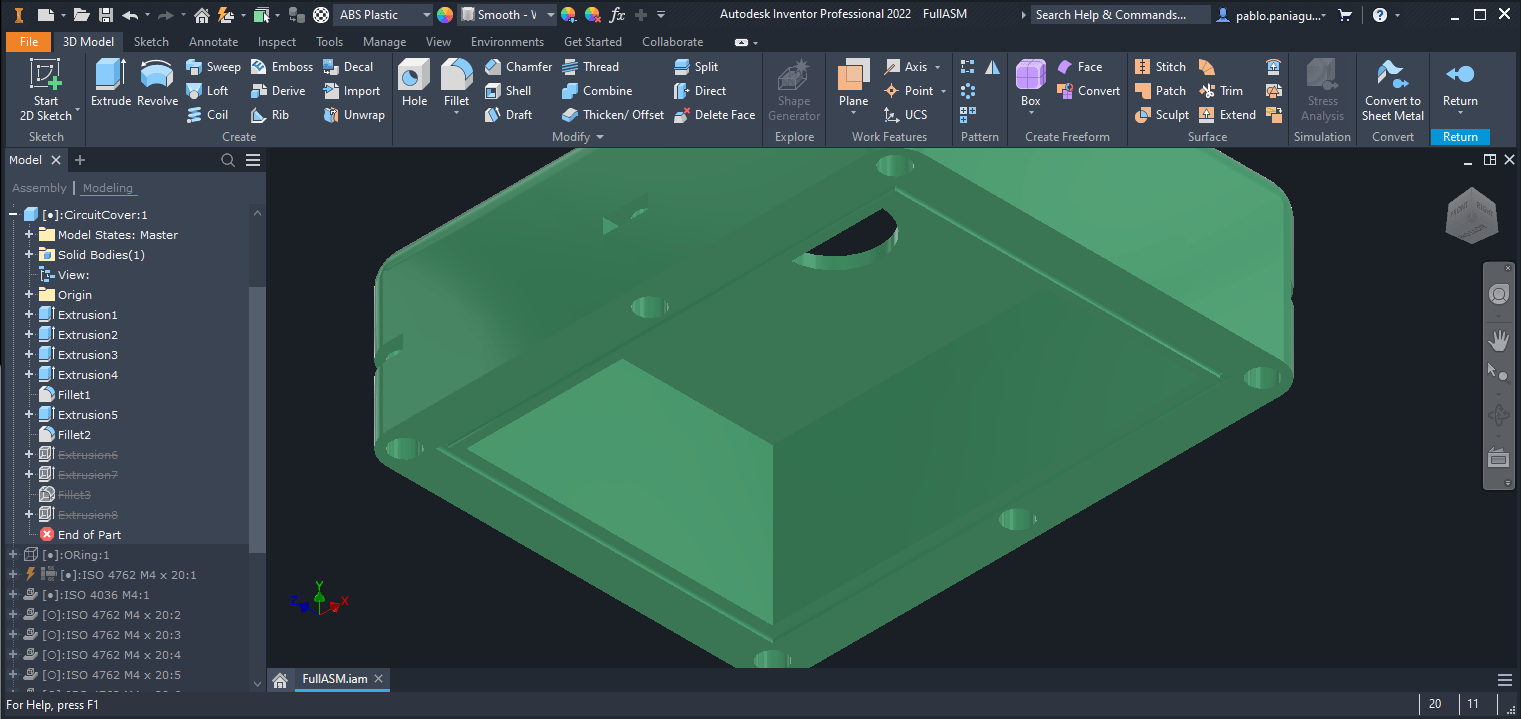

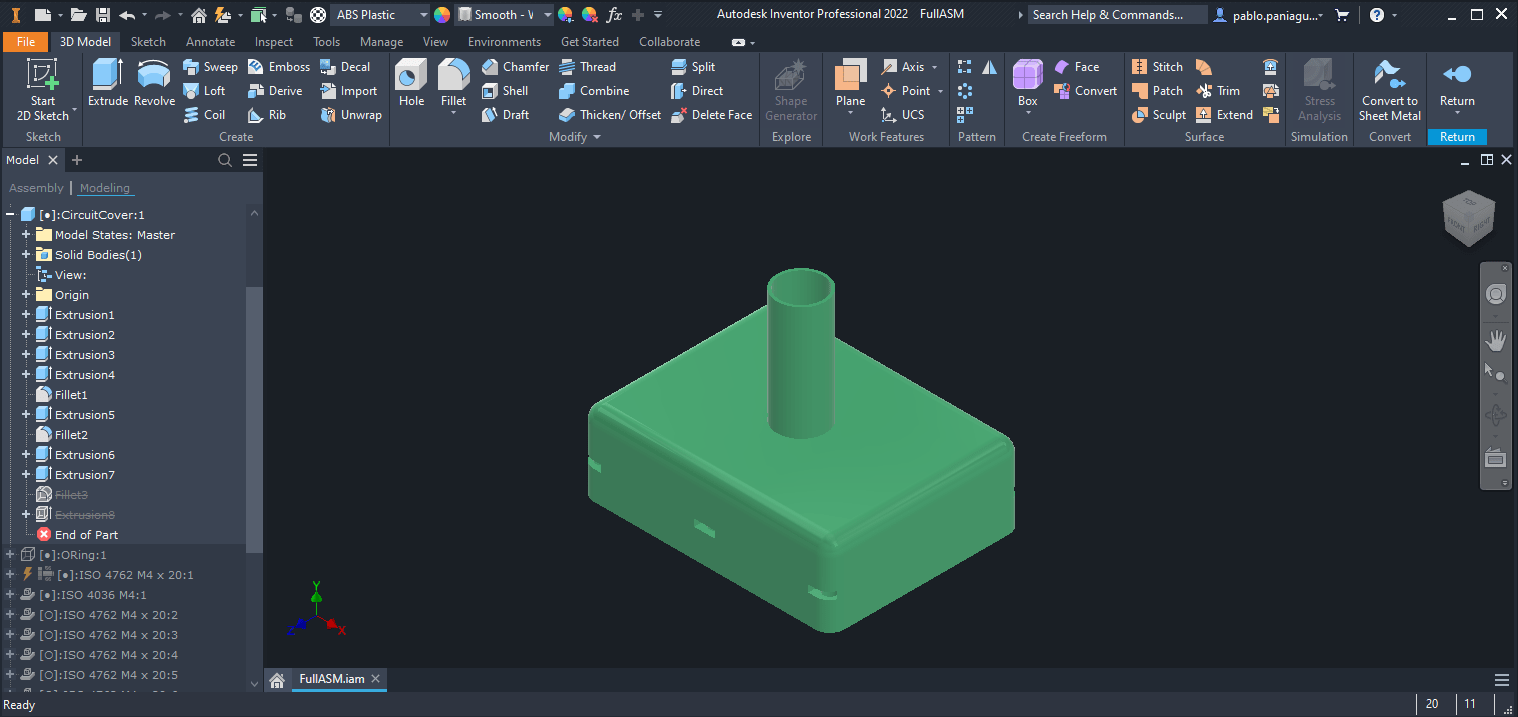

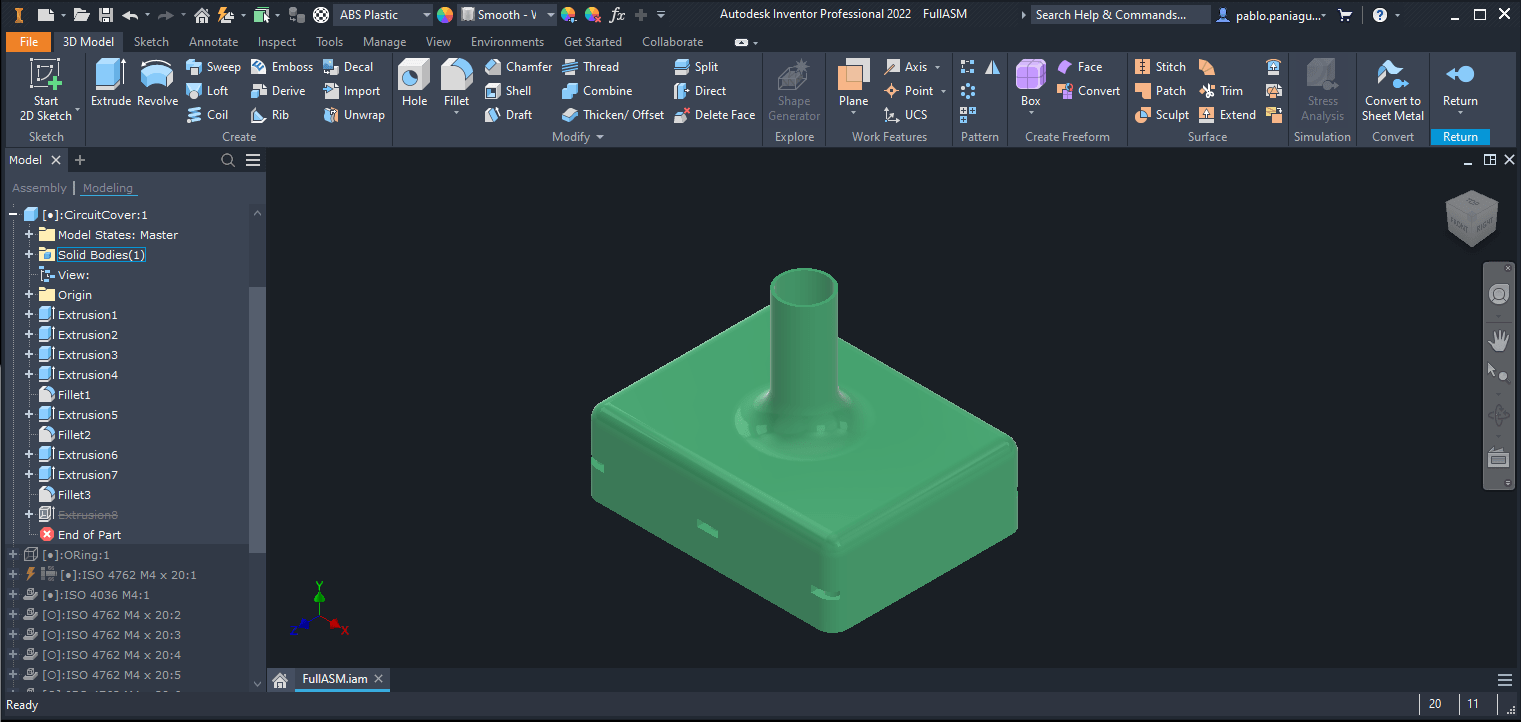

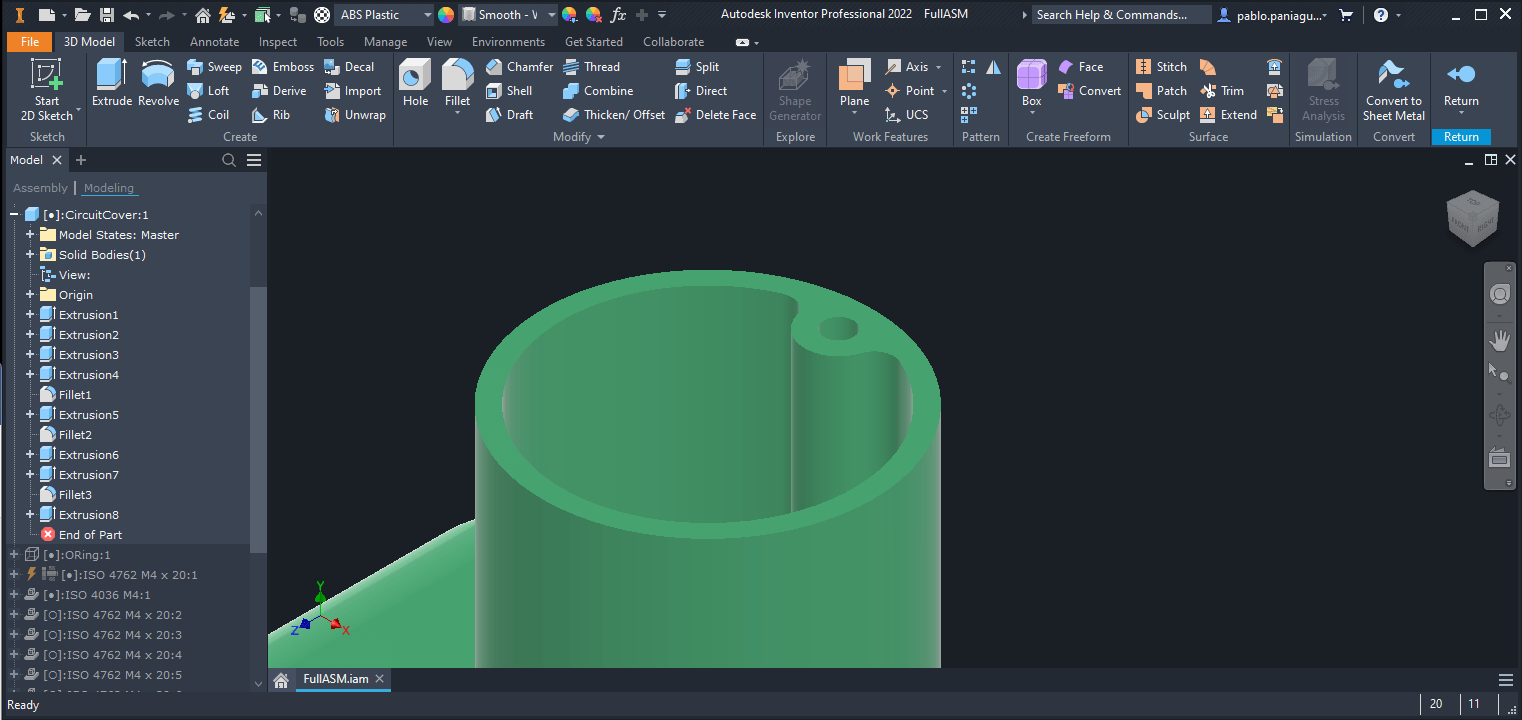

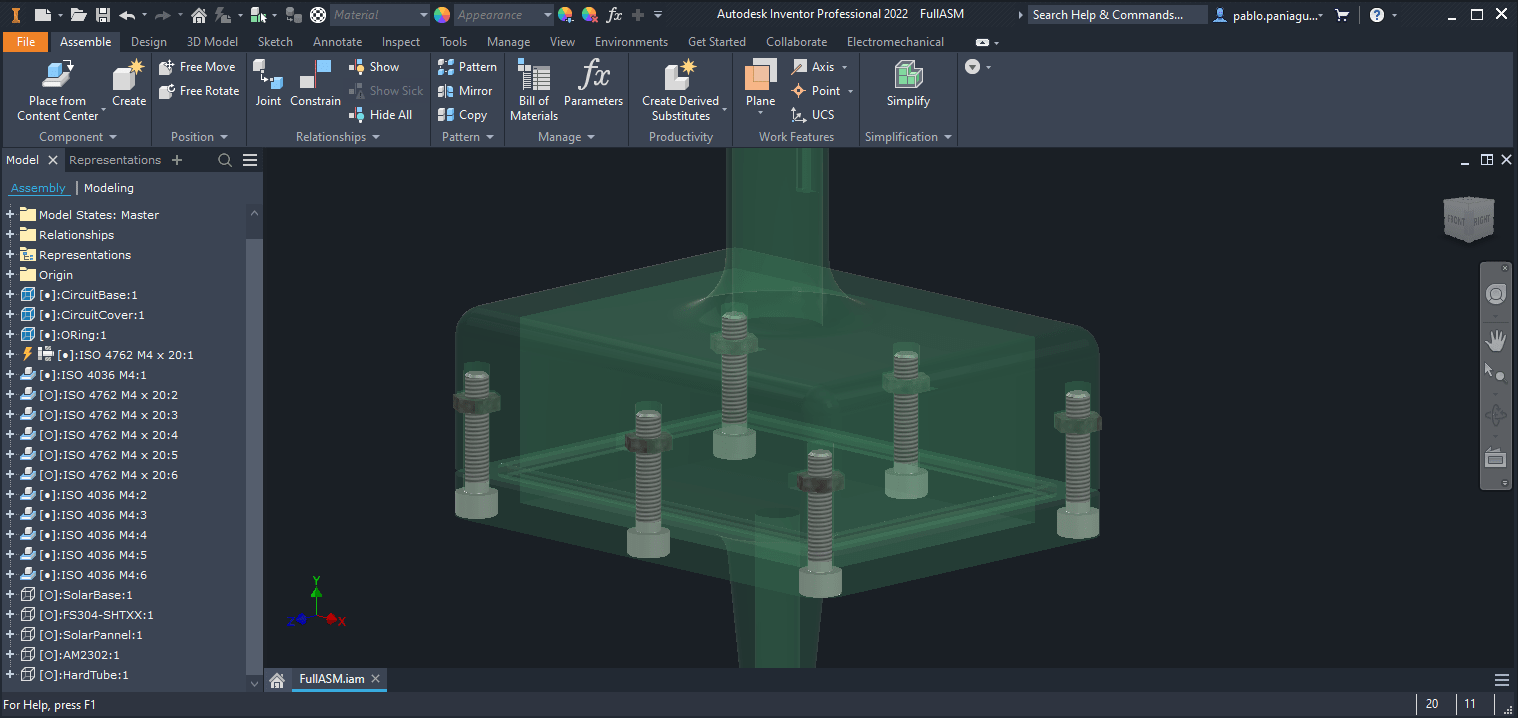

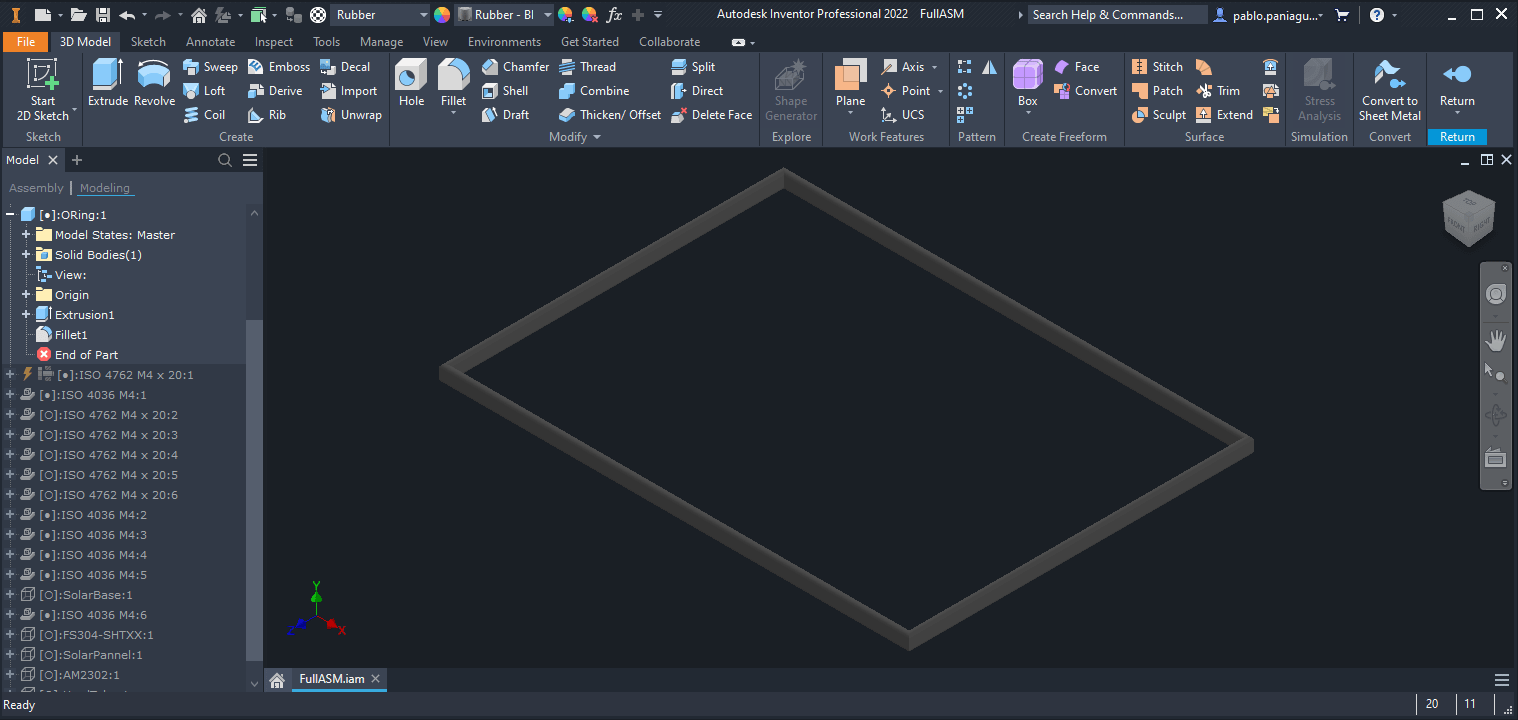

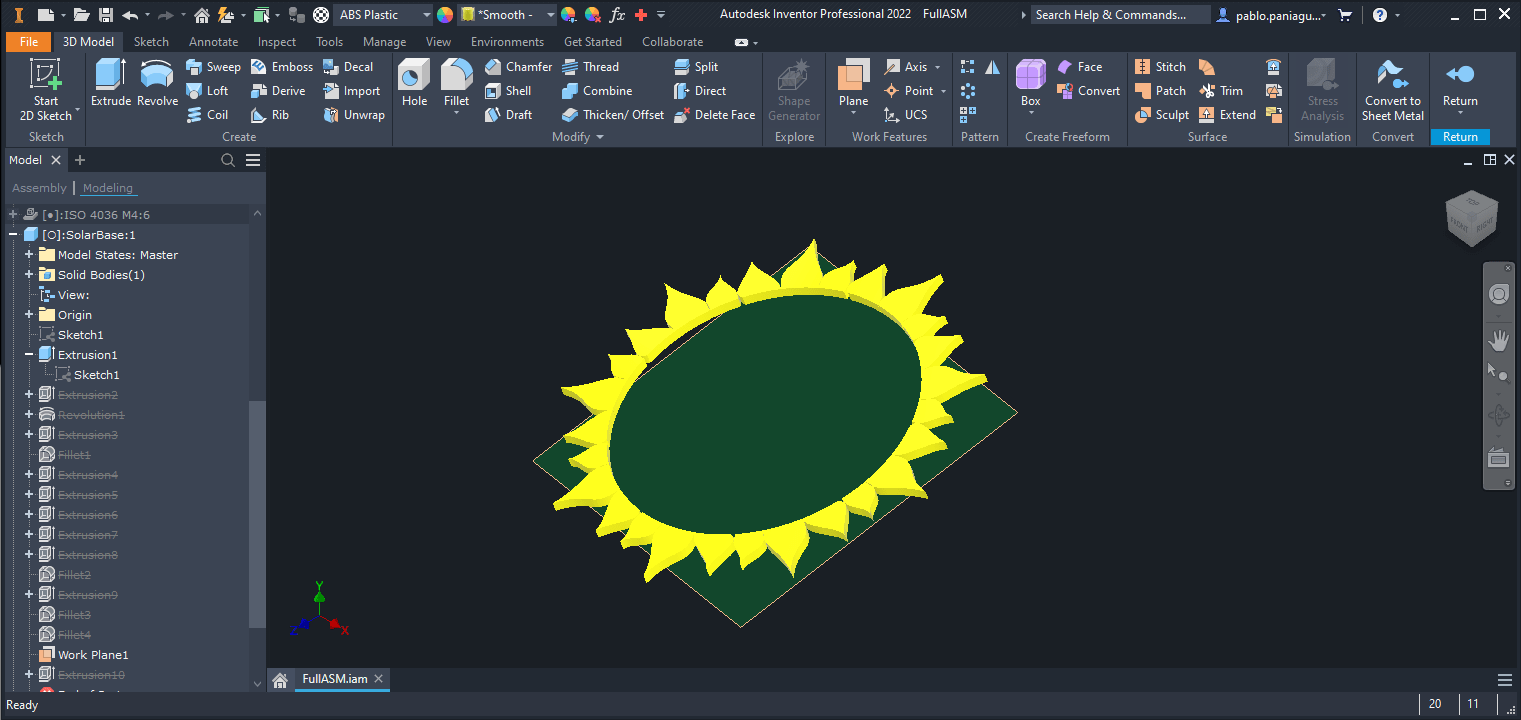

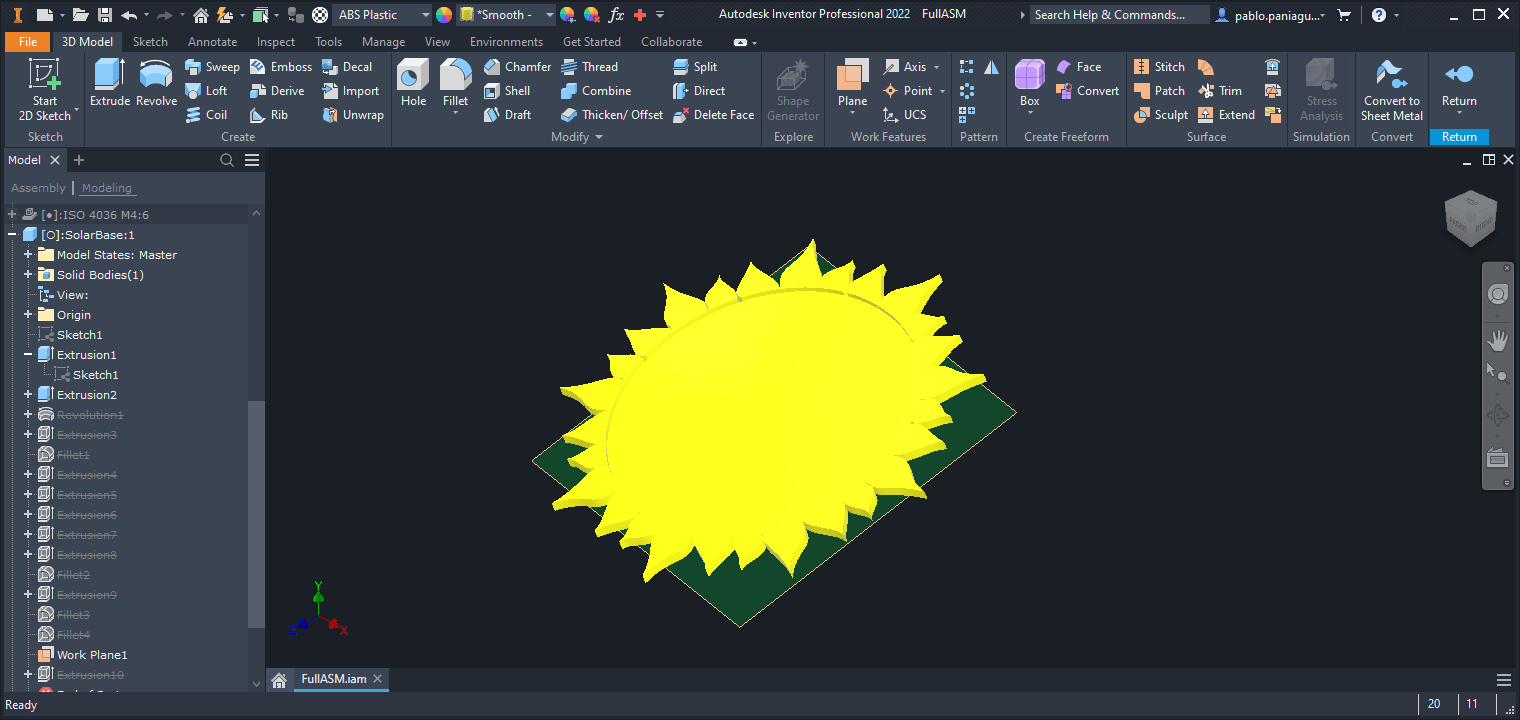

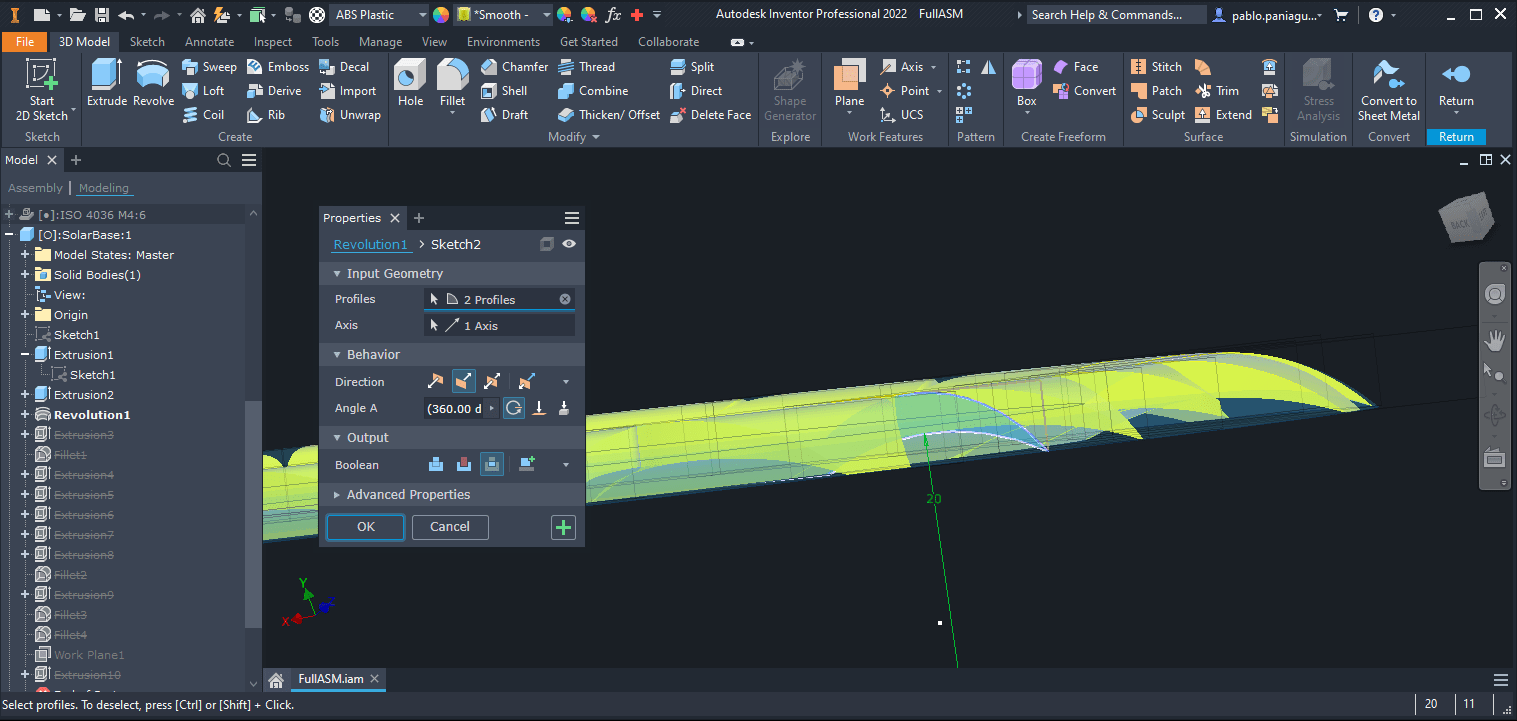

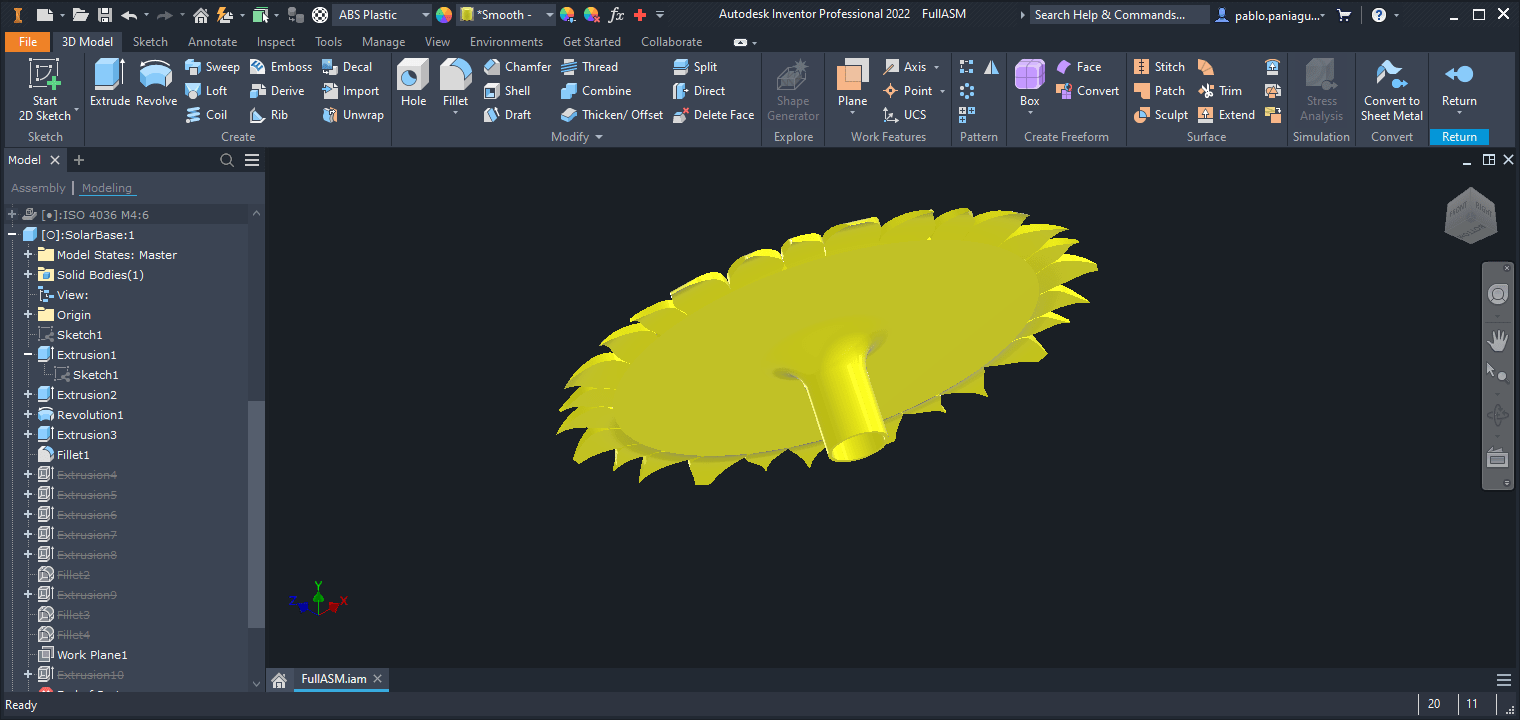

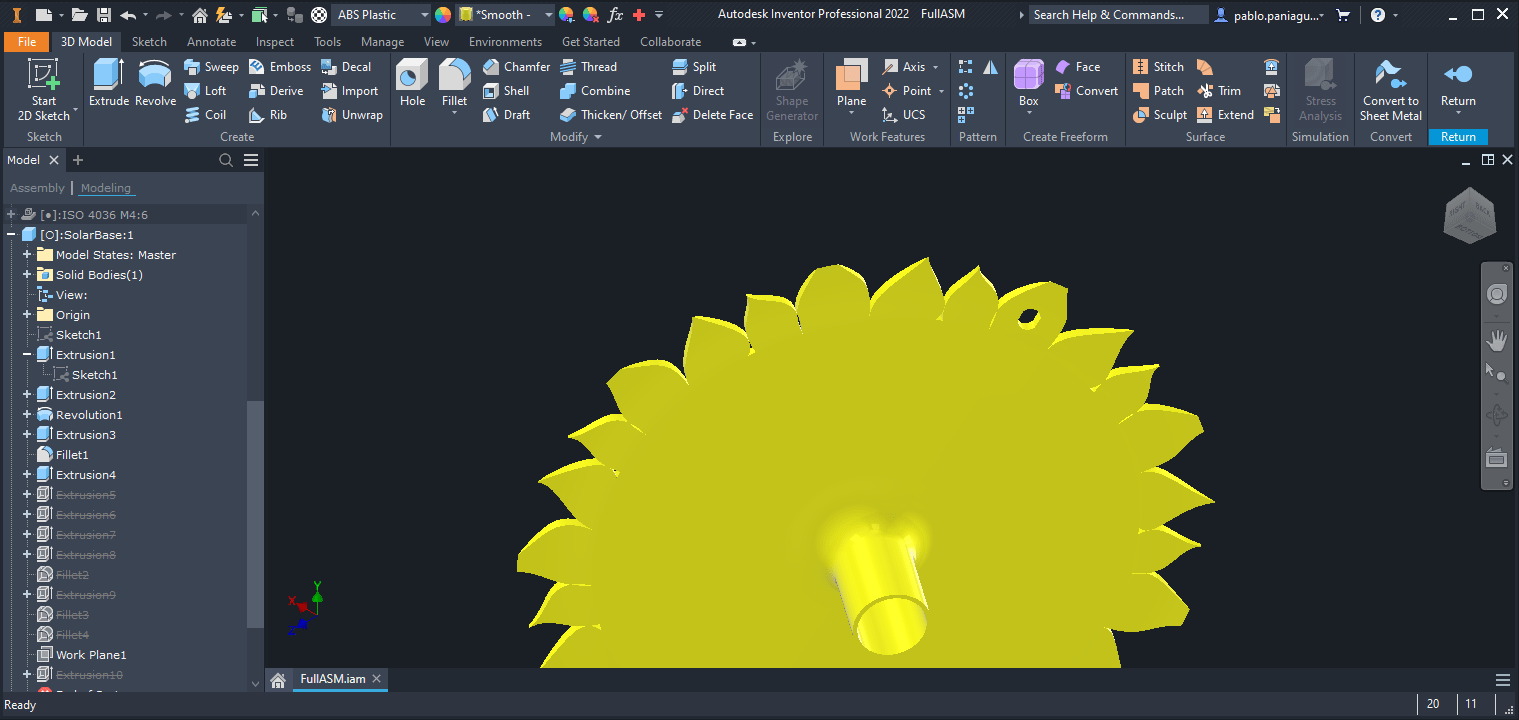

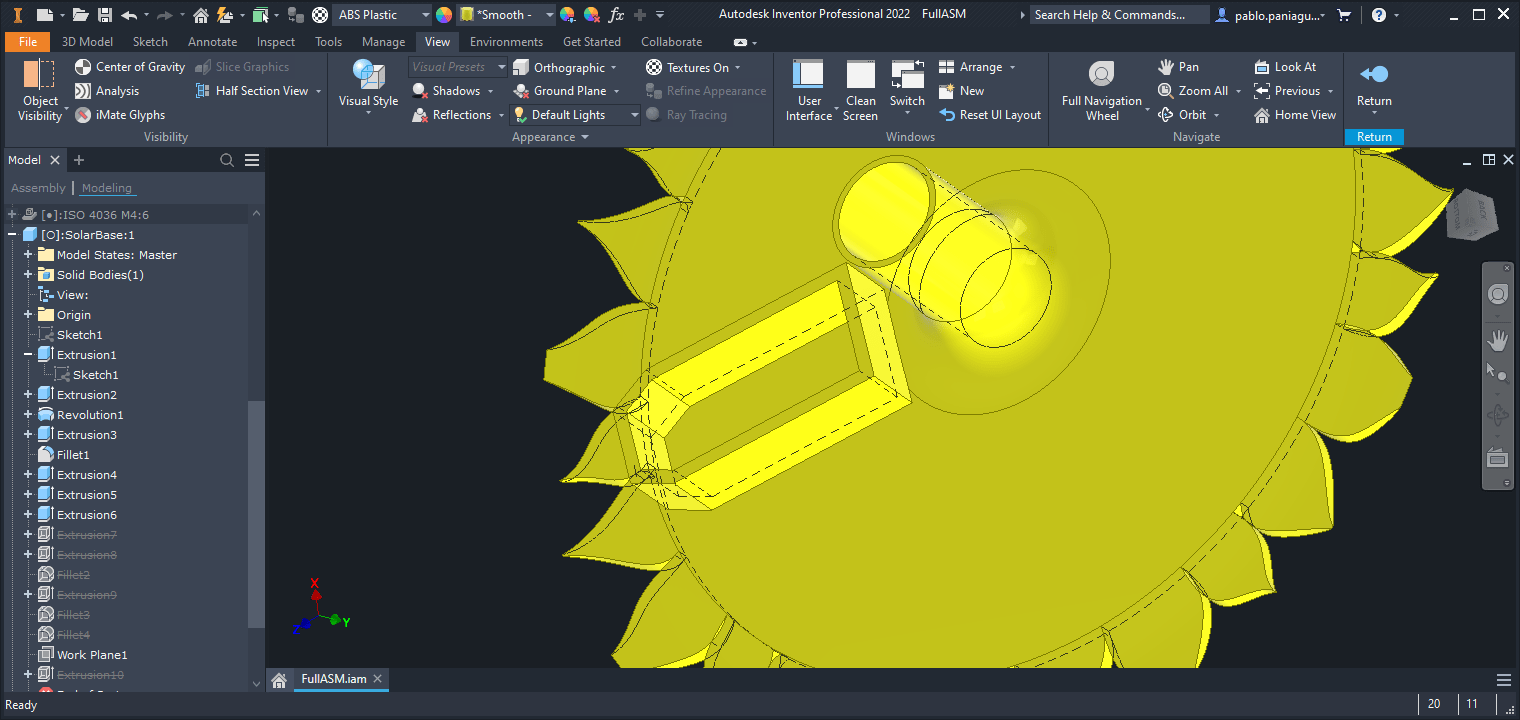

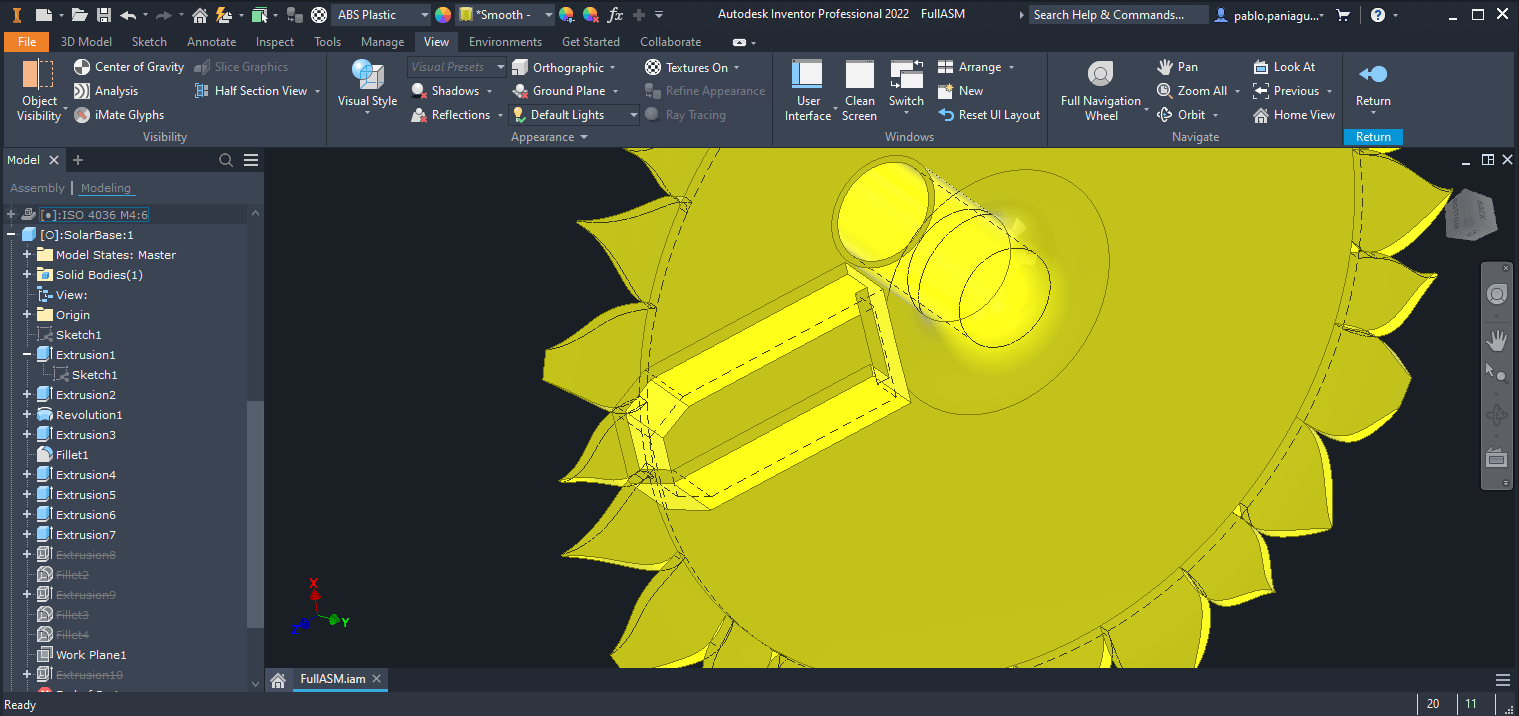

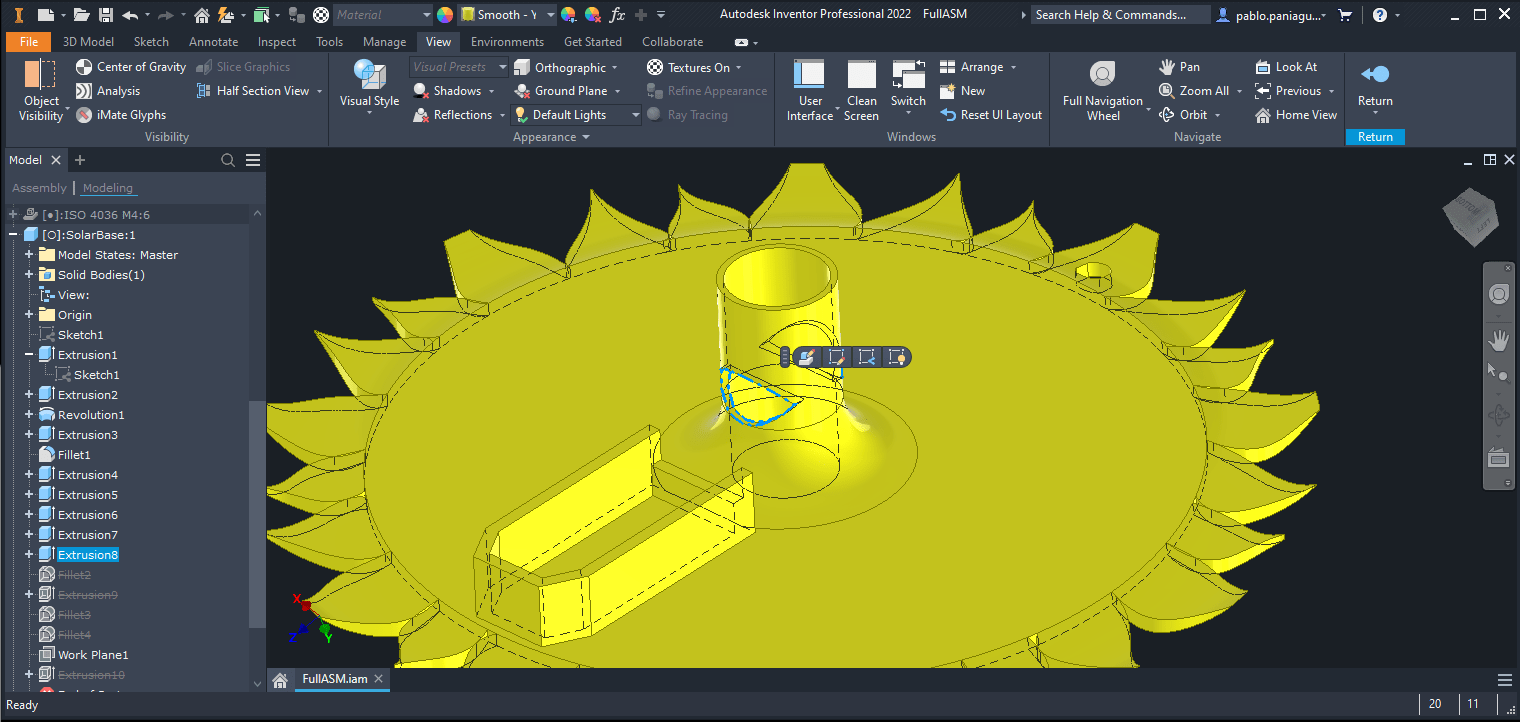

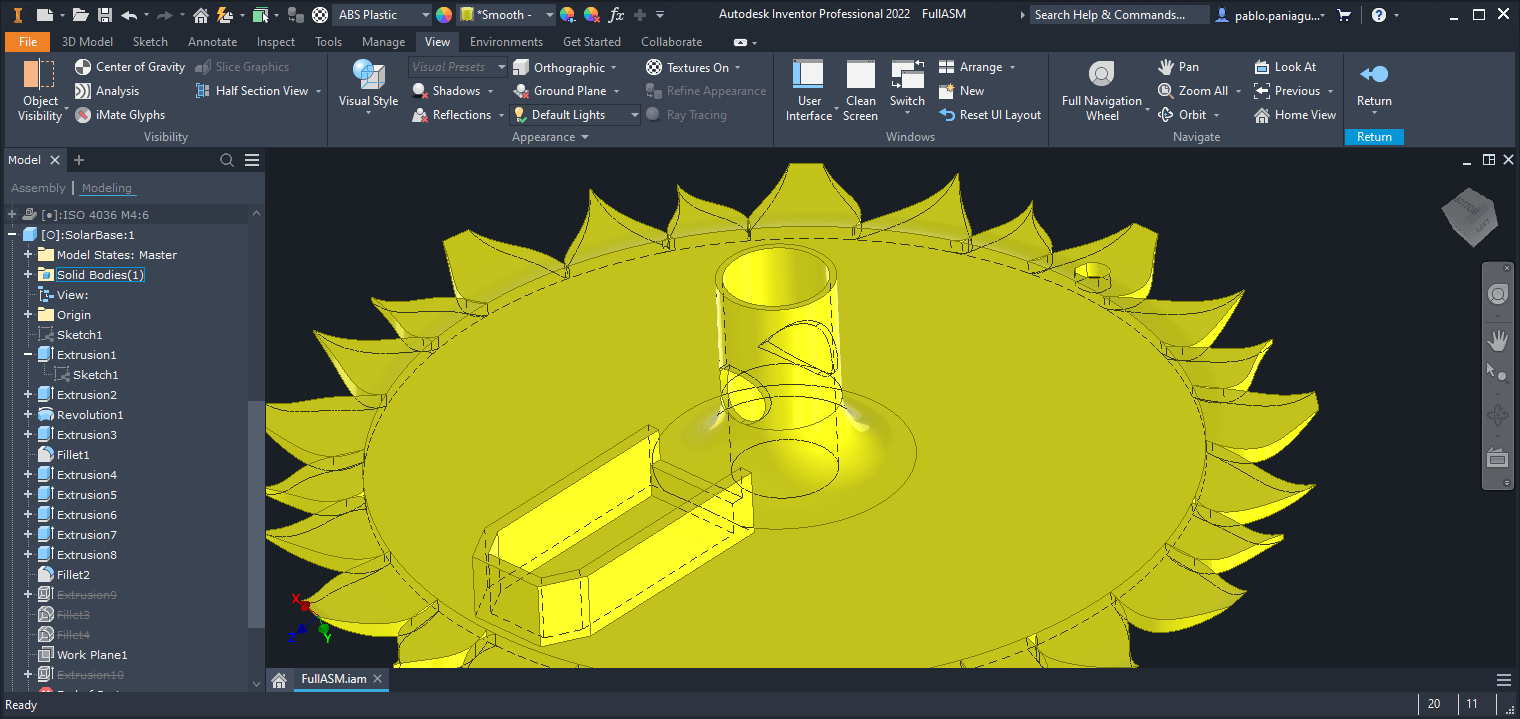

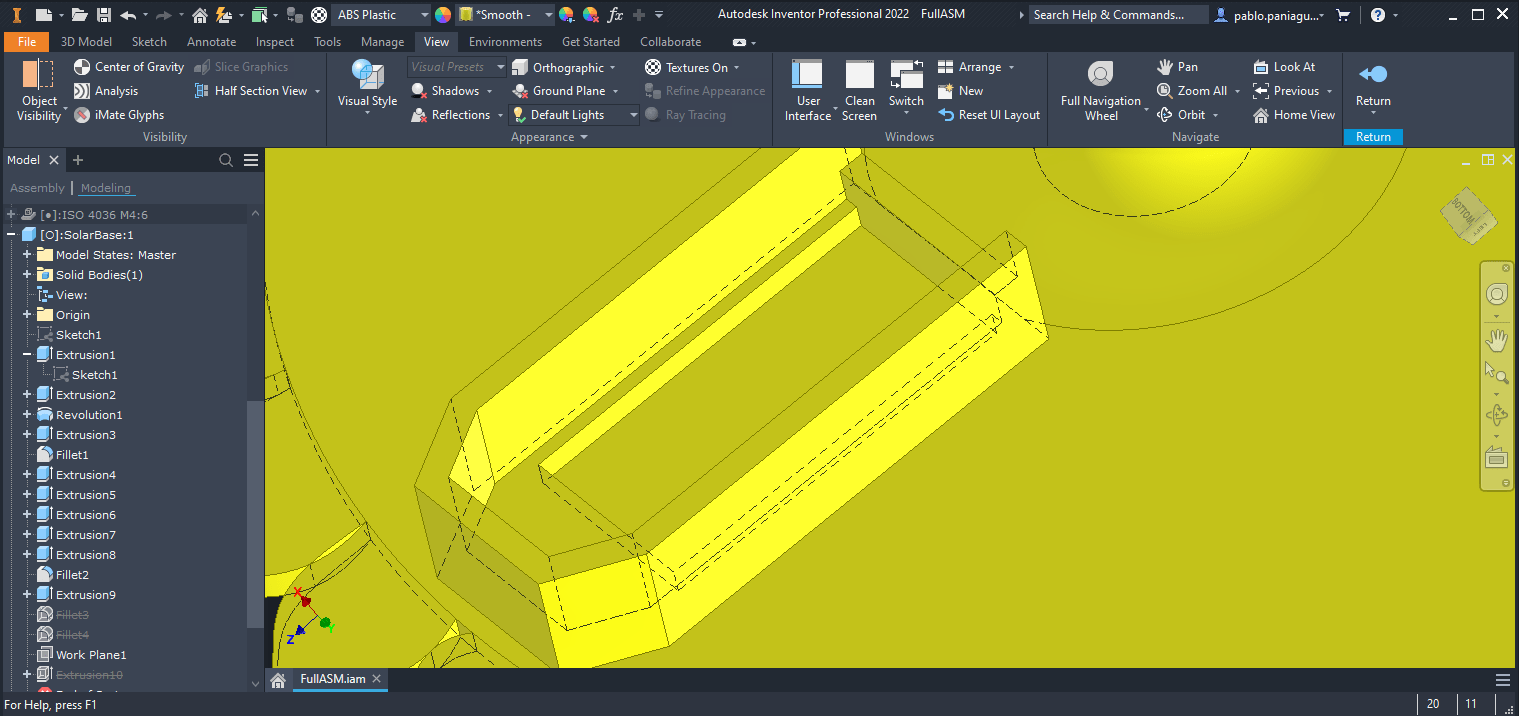

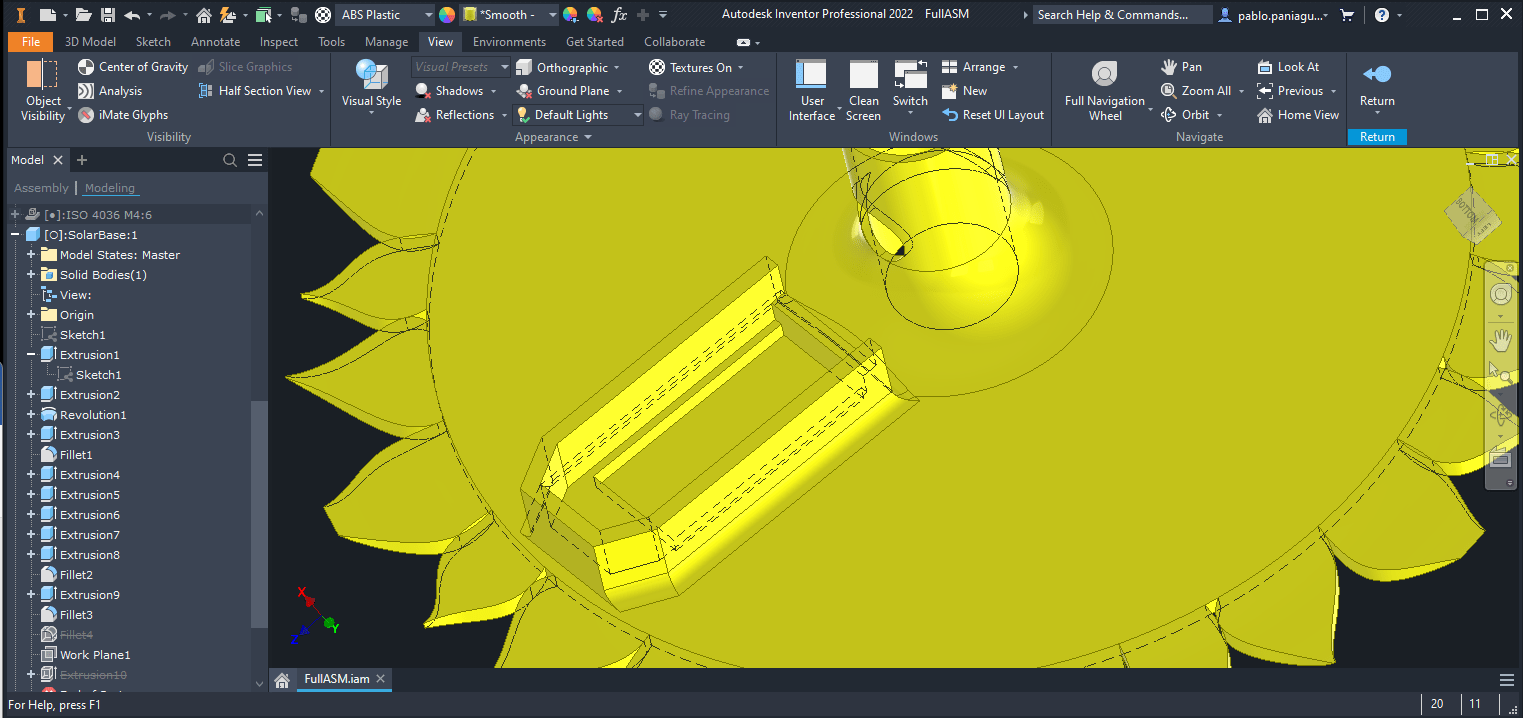

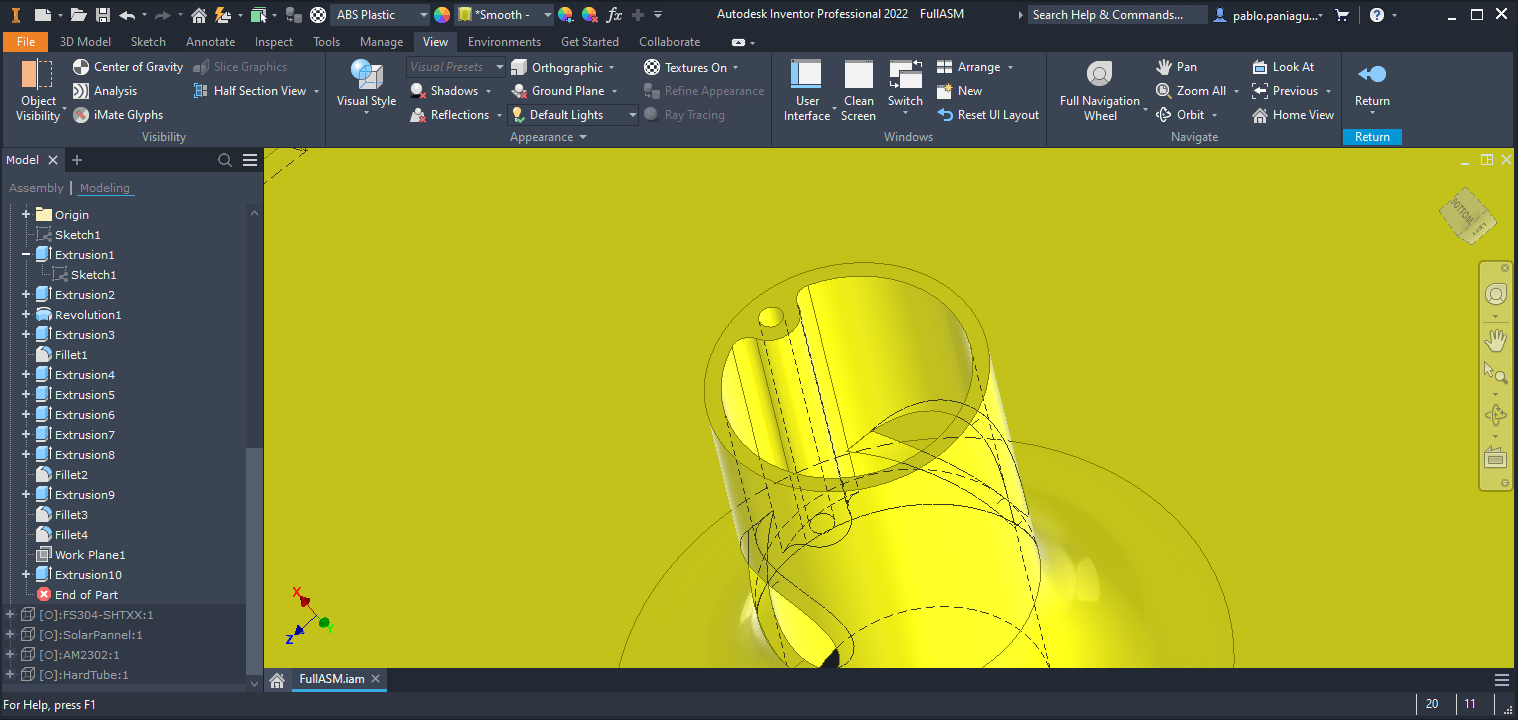

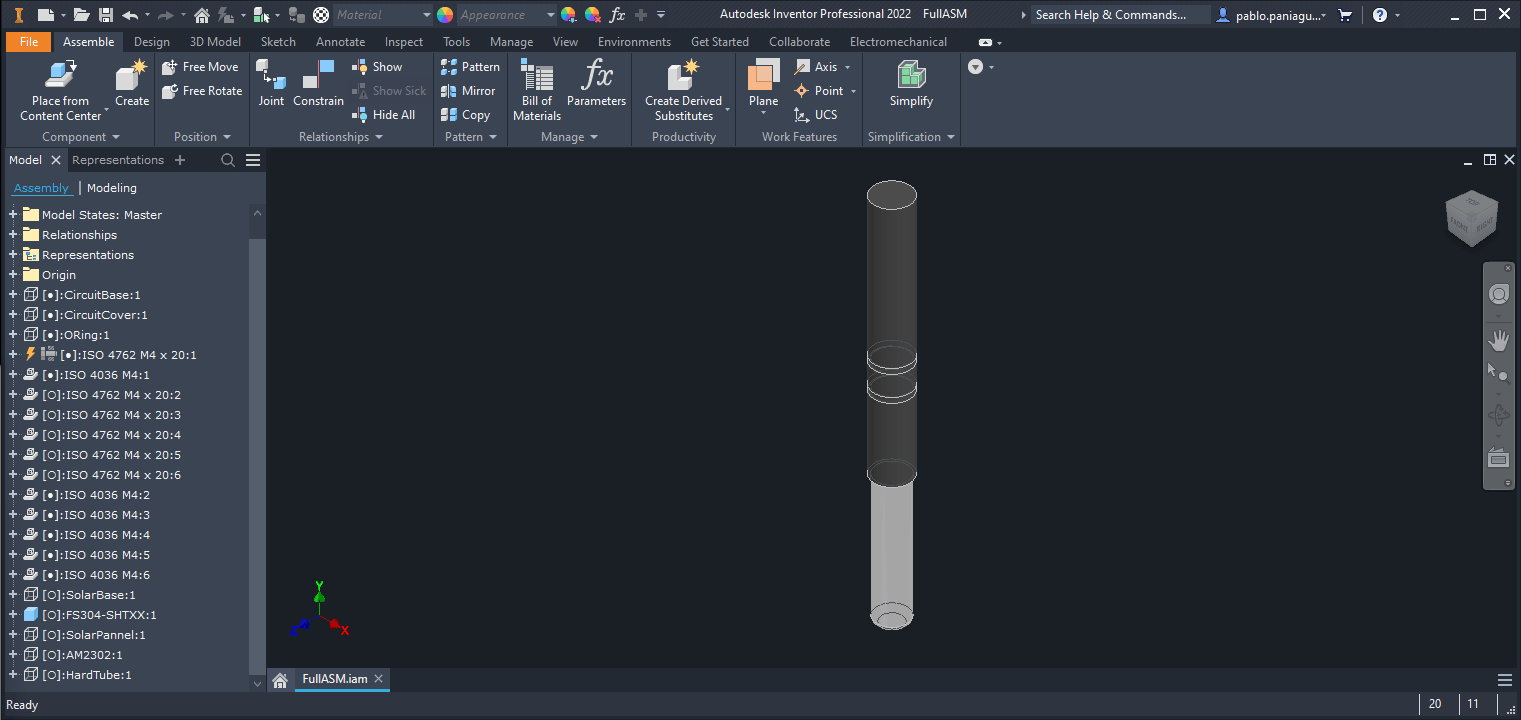

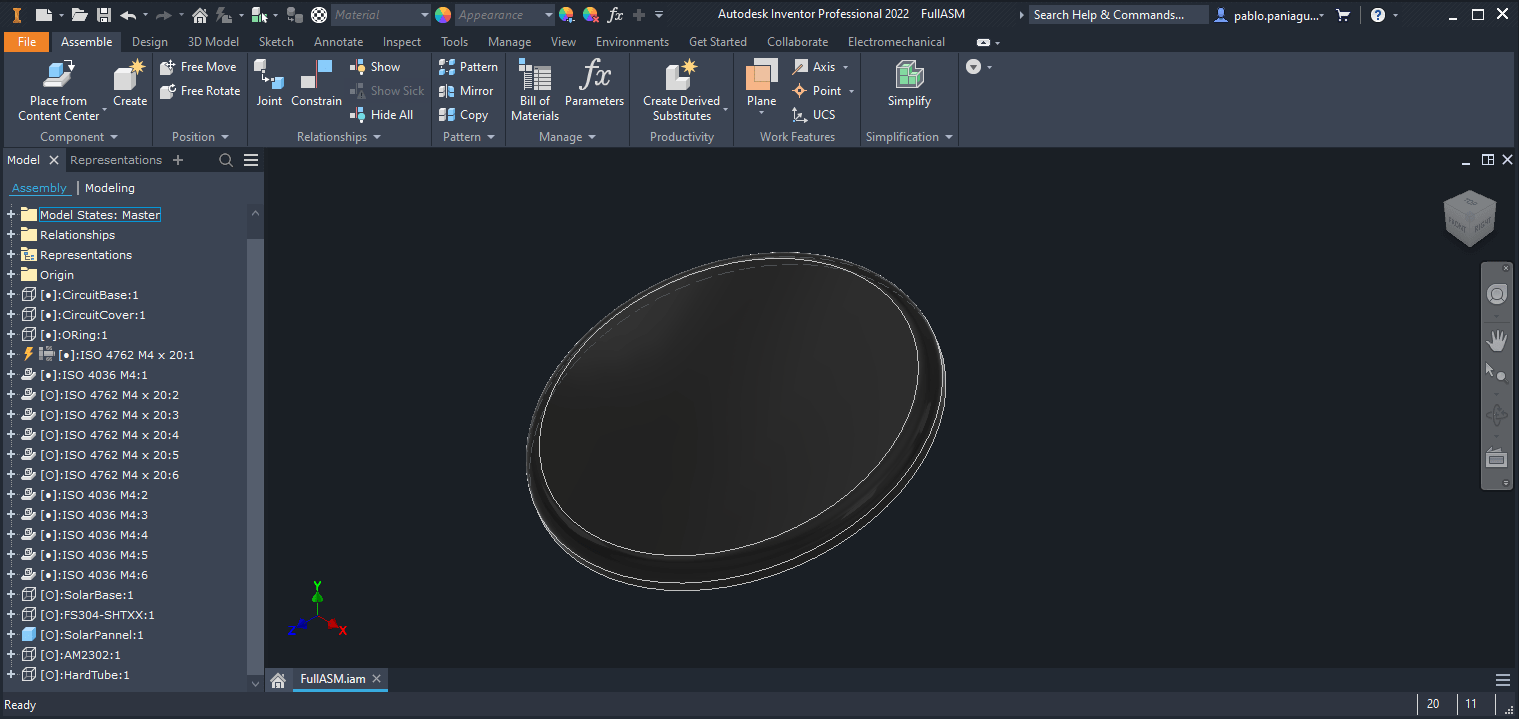

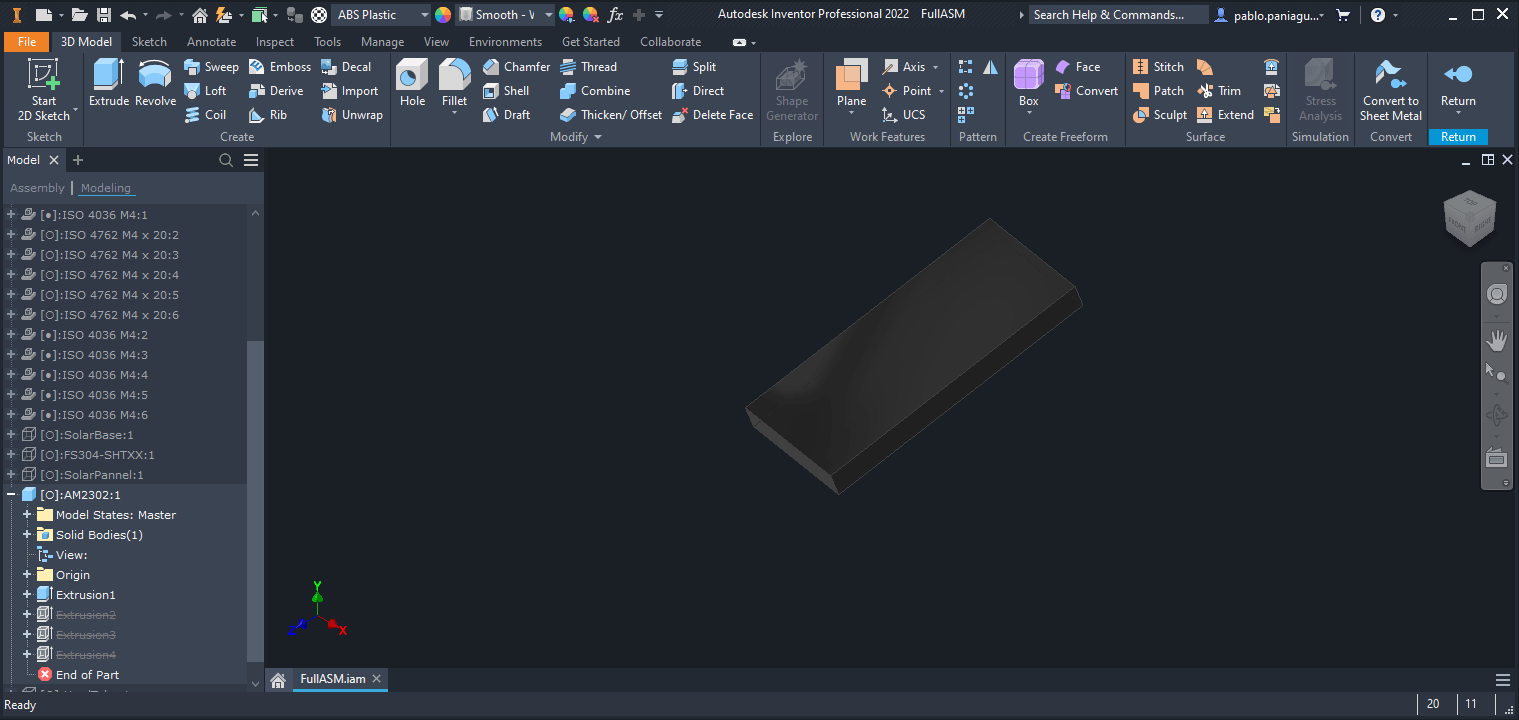

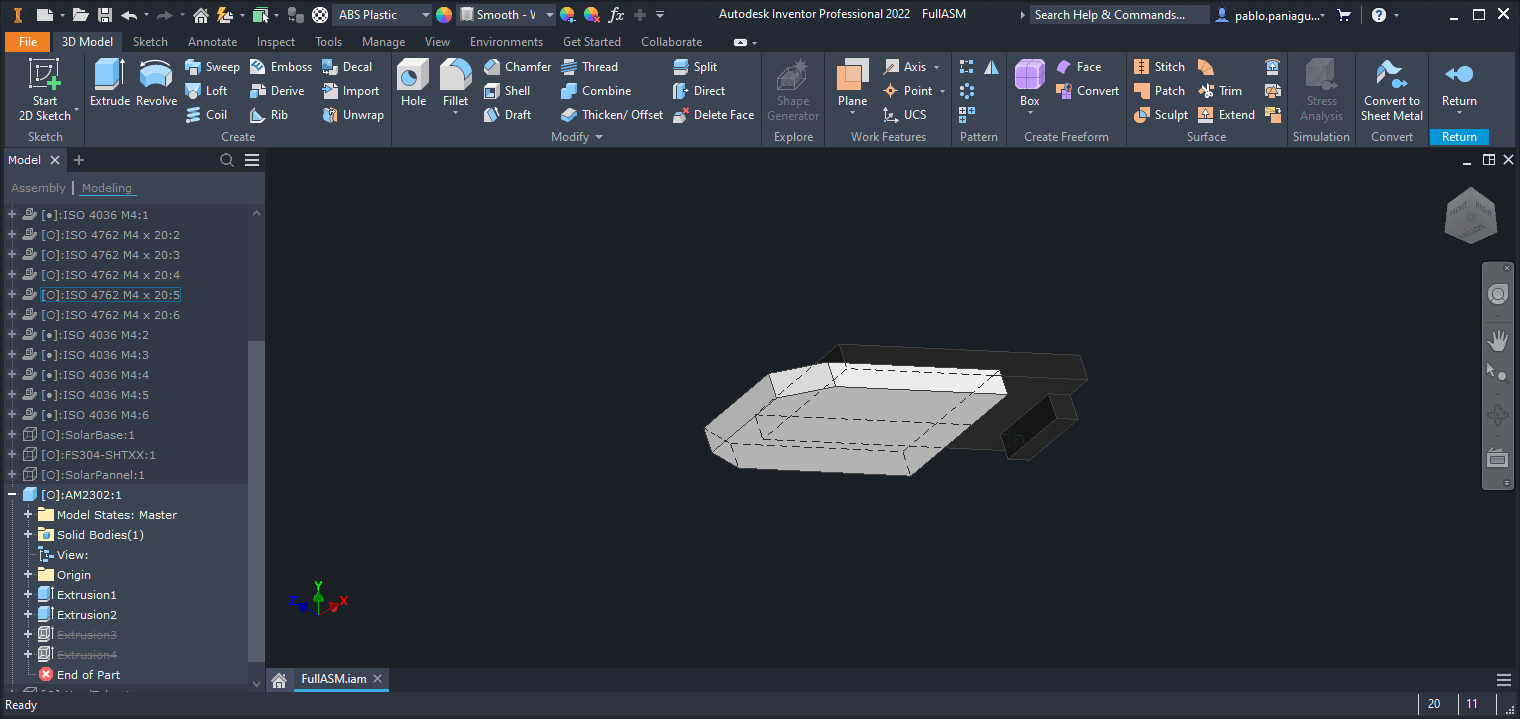

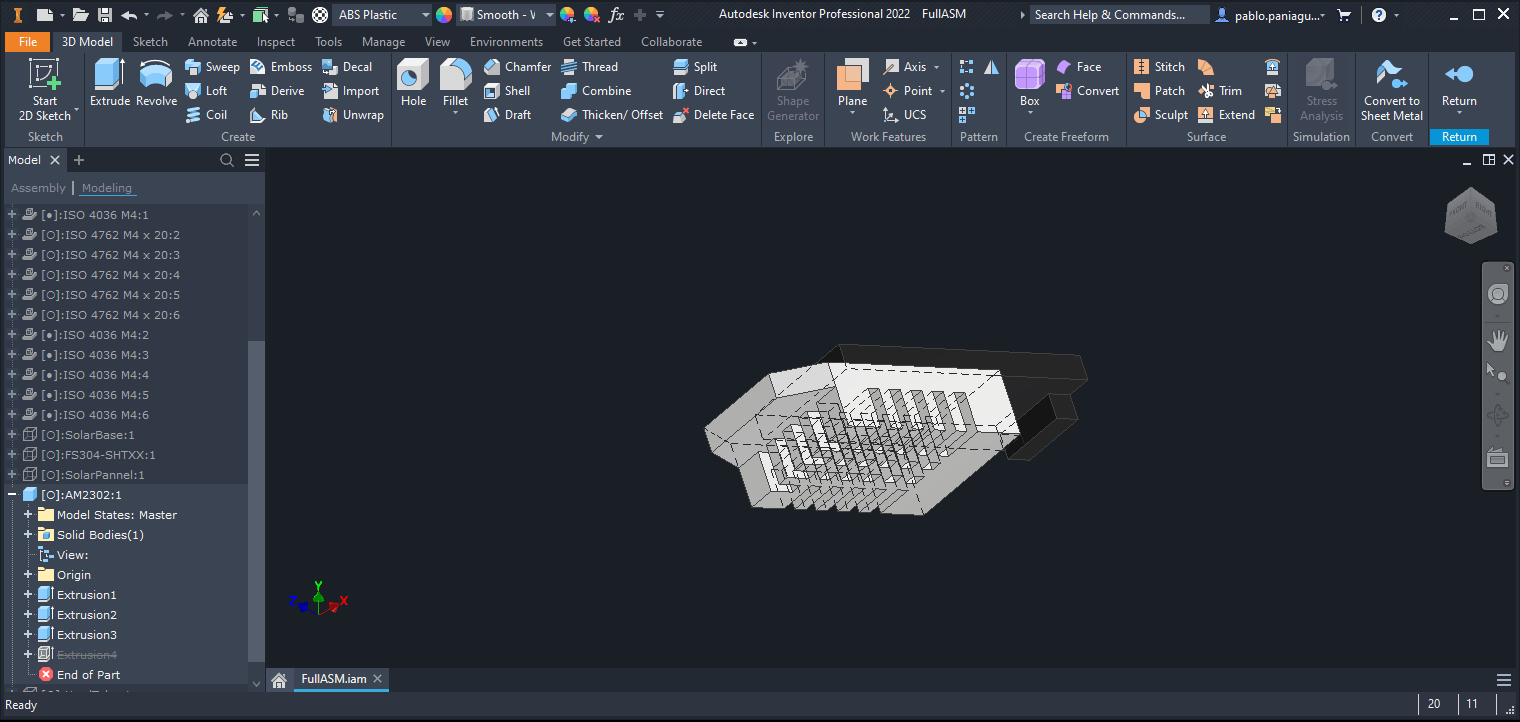

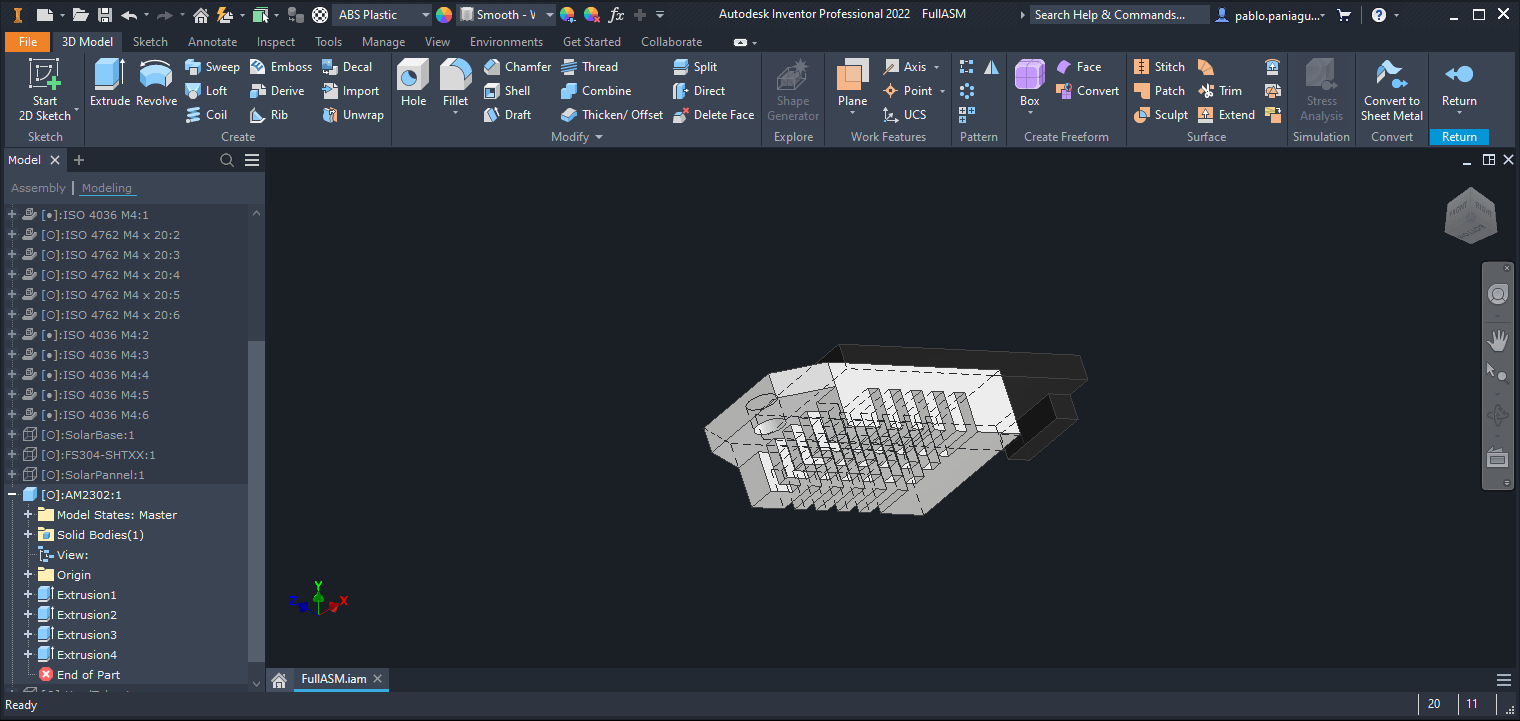

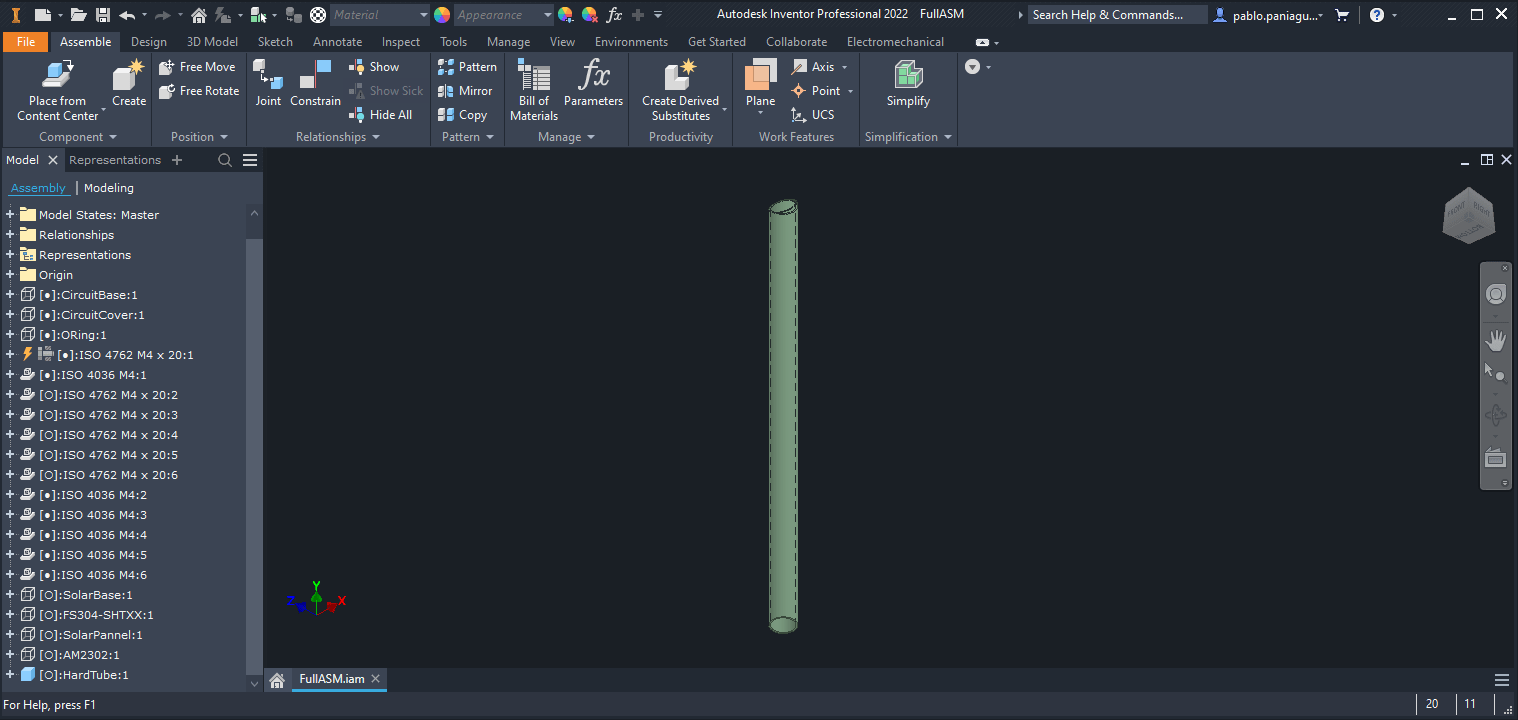

For this week I researched for the most used CAD softwares and compared their advantages and disadvantages, then I tested the ones that sound better to me and modeled the same piece to see how i liked or not the UX, then I selected one of them to model a piece for my final project.