Week 10: Mechanical Design, Machine Design¶

Mechanical Design (part 1 of 2)¶

Group assignment:

Design a machine that includes mechanism + actuation + automation + application

Build the mechanical parts and operate it manually Document the group project

Individual assignment:

Document your individual contribution

Machine Design (part 2 of 2)¶

Group assignment:

Actuate and automate your machine

Document the group project

Individual assignment:

Document your individual contribution

PROTOTYPE CONSTRUCTION¶

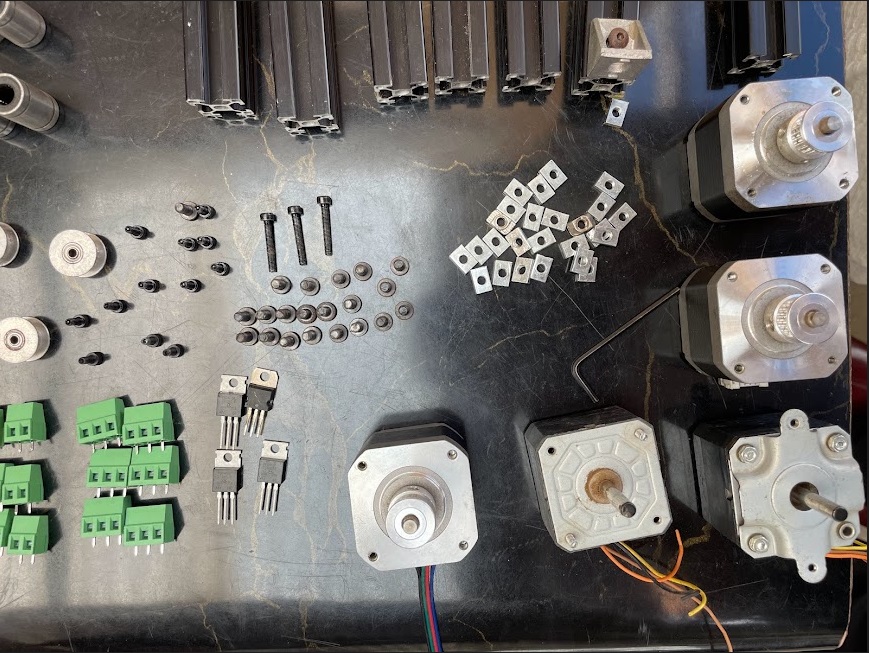

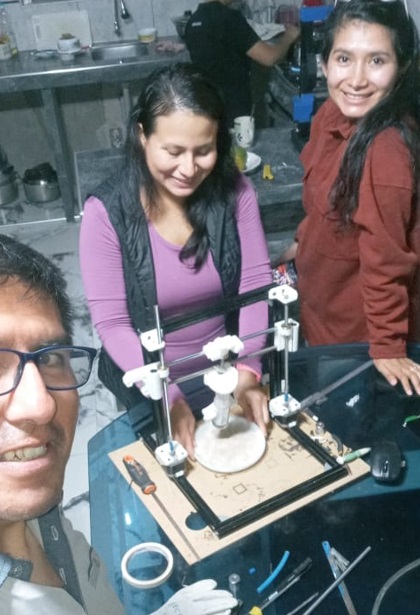

Teacher Wilber and I traveled to Lima to meet Maria and Silvana to carry out assignment 10 of machines for which we decided to build a 3D printer that can print images or letters with maca filament and the materials we need are:

- MATERIAL

- 2 M8 Z axis threaded rods

- 3 Nut T8

- V-SLOT PROFILE 20X20x300

- 2 GT2 timing belt half meter 6mmx1M X and Y axis

- 2 GT2 toothed pulley 22 teeth M5 motor for the X and Y axis

- 2 GT2 22 smooth toothed pulley M5 X and Y axis

- 6 smooth M8 rods of 30 cm Y, Z and X axis

- Working temperature: -30ºC ~ 70ºC

- 10 M8 linear bearings

- 1 M8 threaded rod for the extruder

- 8 90 degree angles per 20 mm

- 3 Flexible couplings M5xM8

- 1 Flexible coupling M8xM8 15 soles

- Nuts and bolts

- 100 SLIDING HAMMER HEAD NUT M5 (order more, they will be lost)

- 40 M3 engine bolts

- 100 M5 screws Electronic

- Arduino Mega

- 3D Printer Controller Board RAMPS 1.4 Arduino Mega Shield

- 5 Stepper motor NEMA 17 42x39mm 4.2Kg

- 2 100k thermistors (to see the temperature at which material is worked in the environment)

- 1 Lcd Graphic 128x64 Shield Ramps 1.4 3d Printer

- 5 Cable for stepper motor, 1 meter long, 4 wires, with HX254 Female

- Inputs for motor (Nema 17)

- 12V and 20A power supply with power cable

- 3 Limit Switch Module for 3D Printer

- A4988 Stepper Motor Driver Module for Pololu

FABRICATION AND ASSEMBLY¶

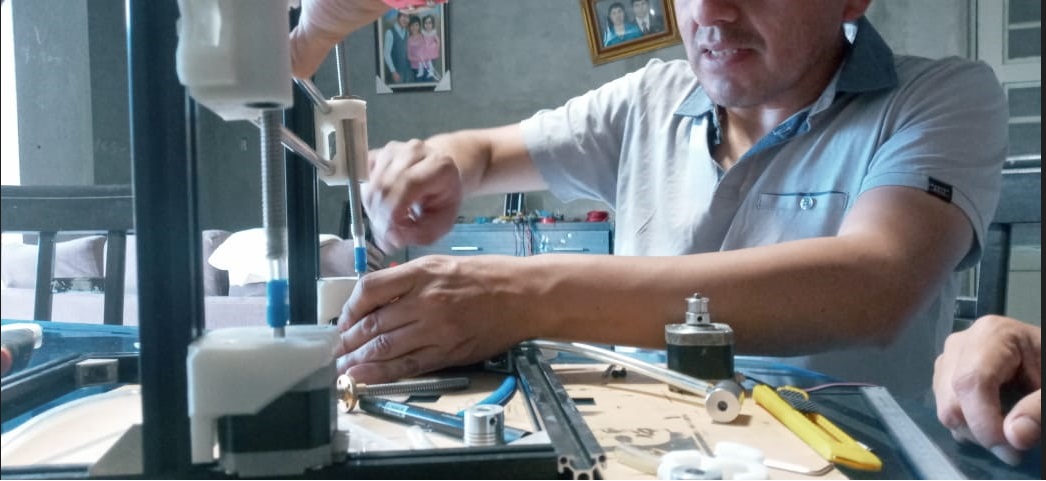

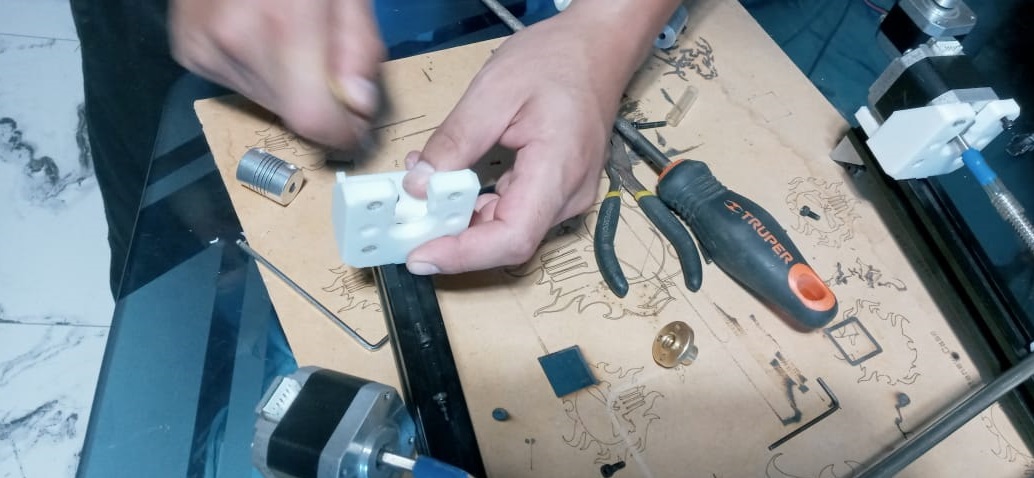

To make the 3D printer we had to buy recycled printers and electronic components

My support in the work was to put the 2 motors on the structure, it was complicated since I had no experience and it took several hands and adjustment with the 3D printed parts.

My support in the work was to put the 2 motors on the structure, it was complicated since I had no experience and it took several hands and adjustment with the 3D printed parts.

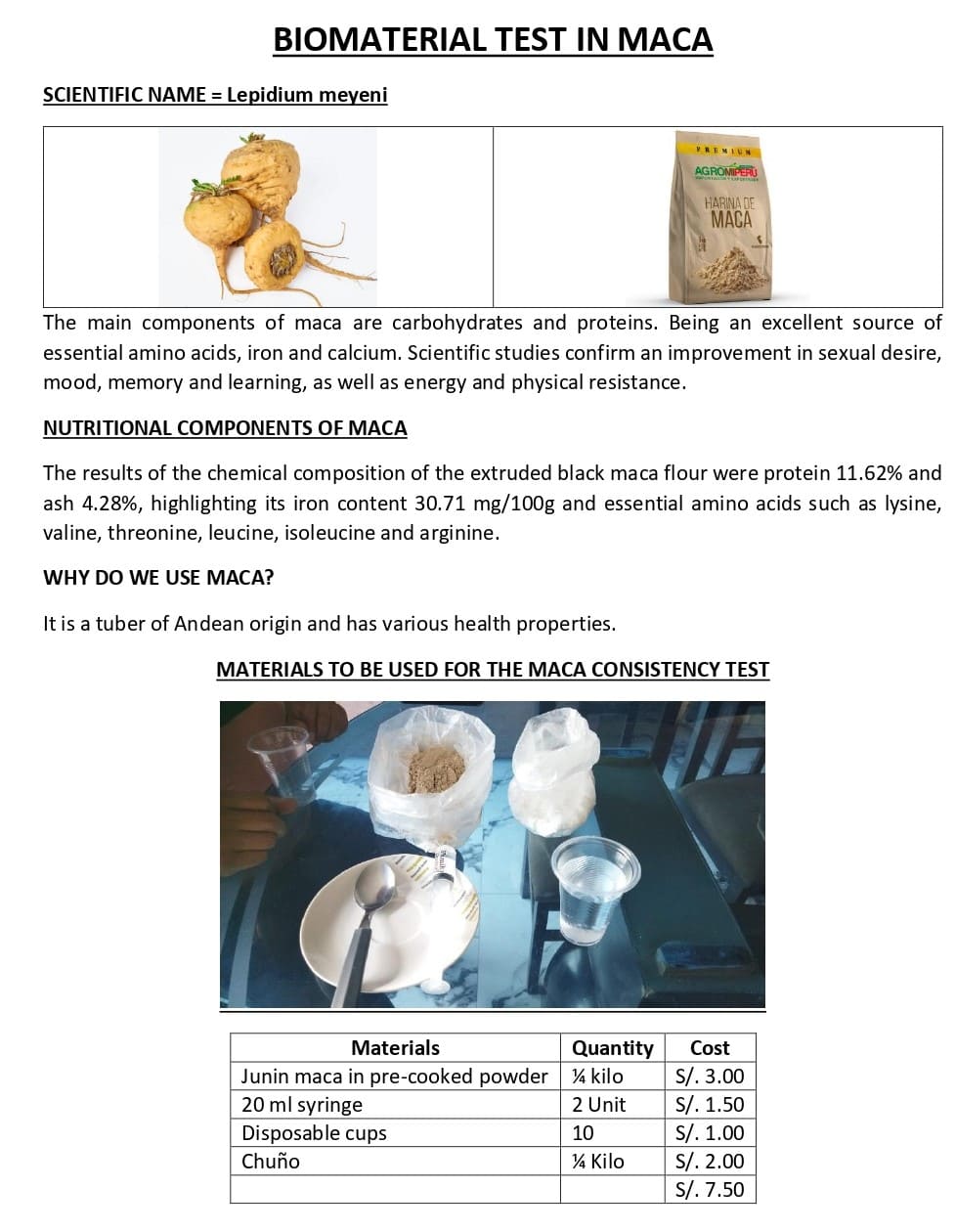

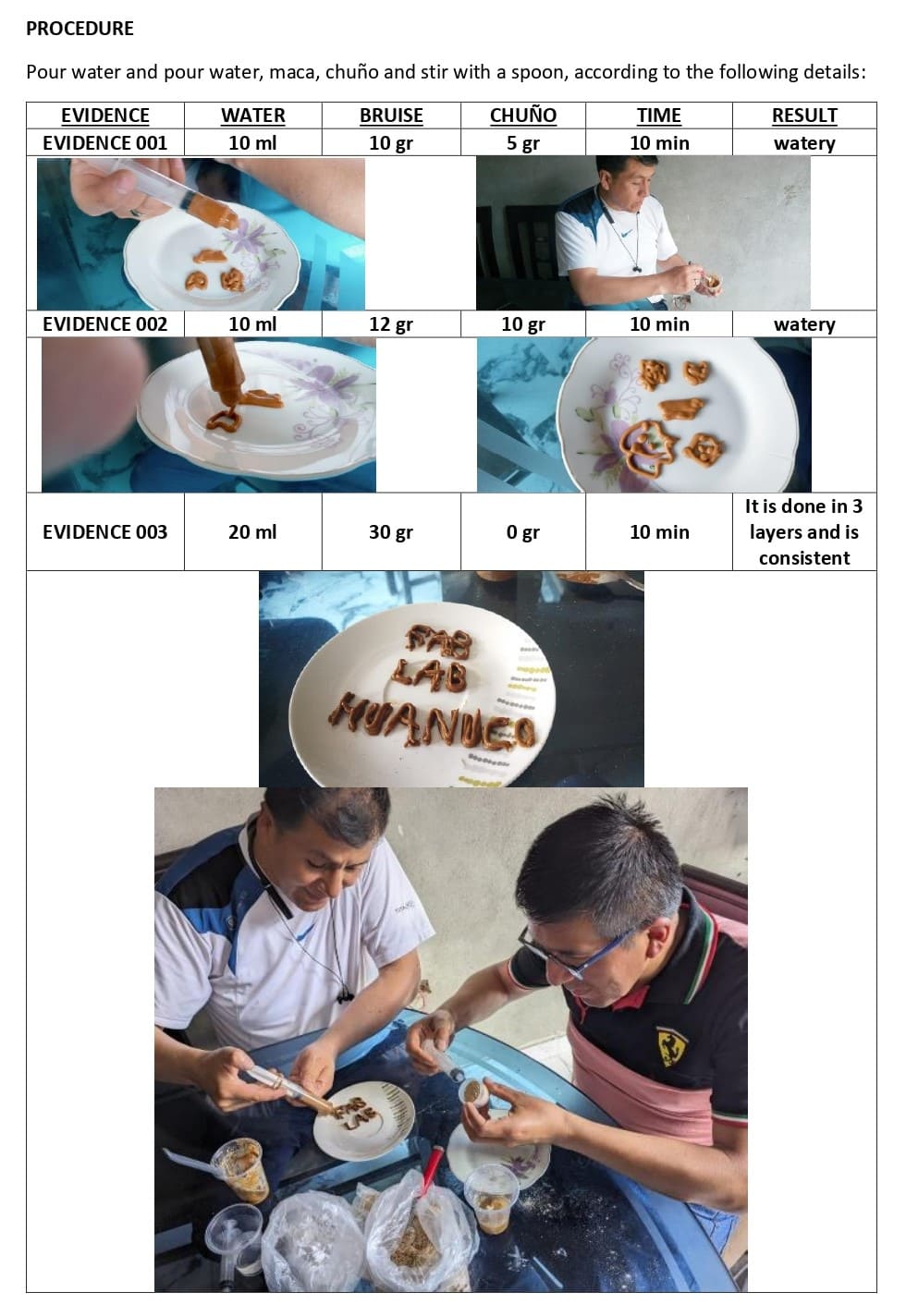

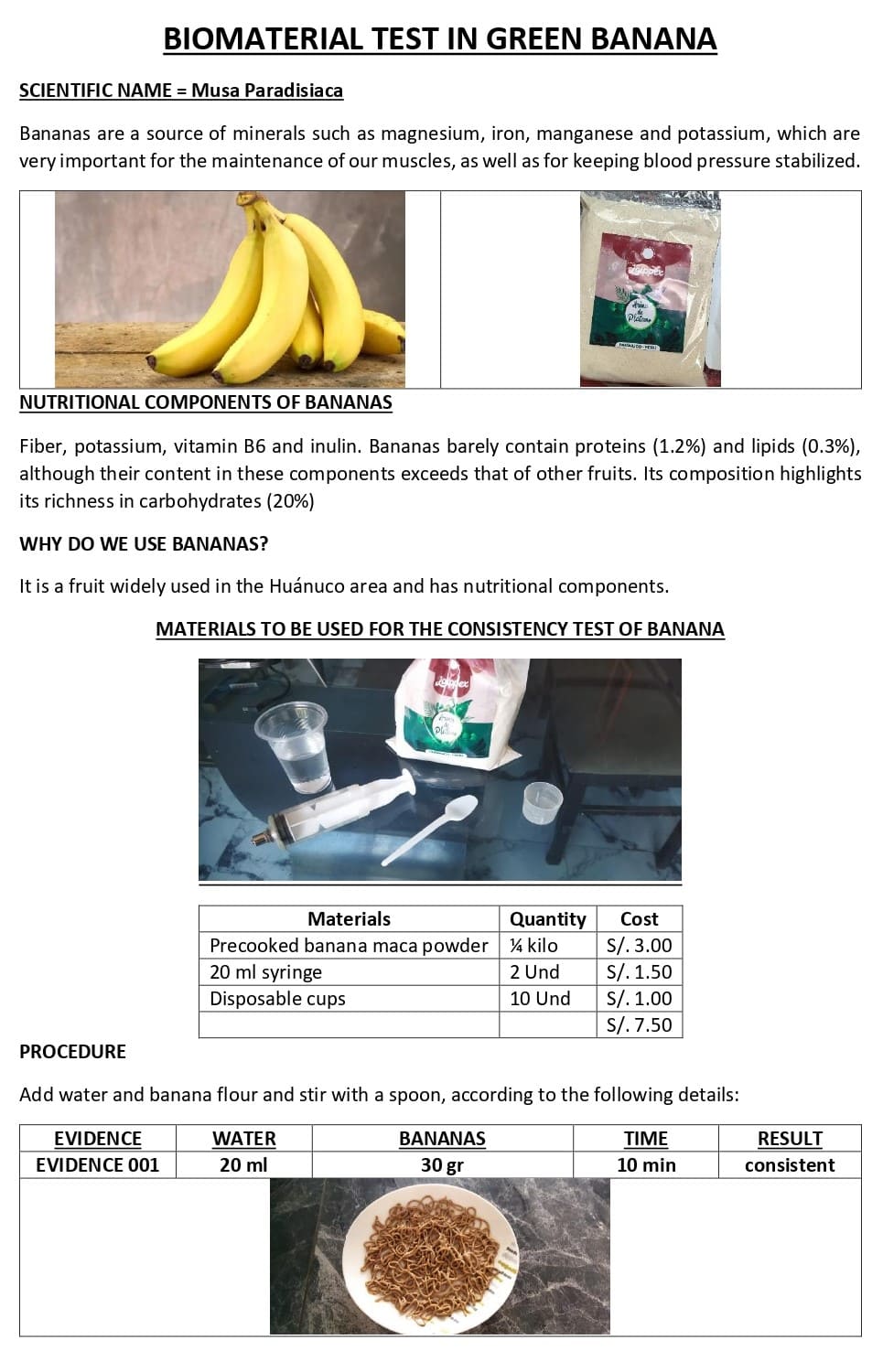

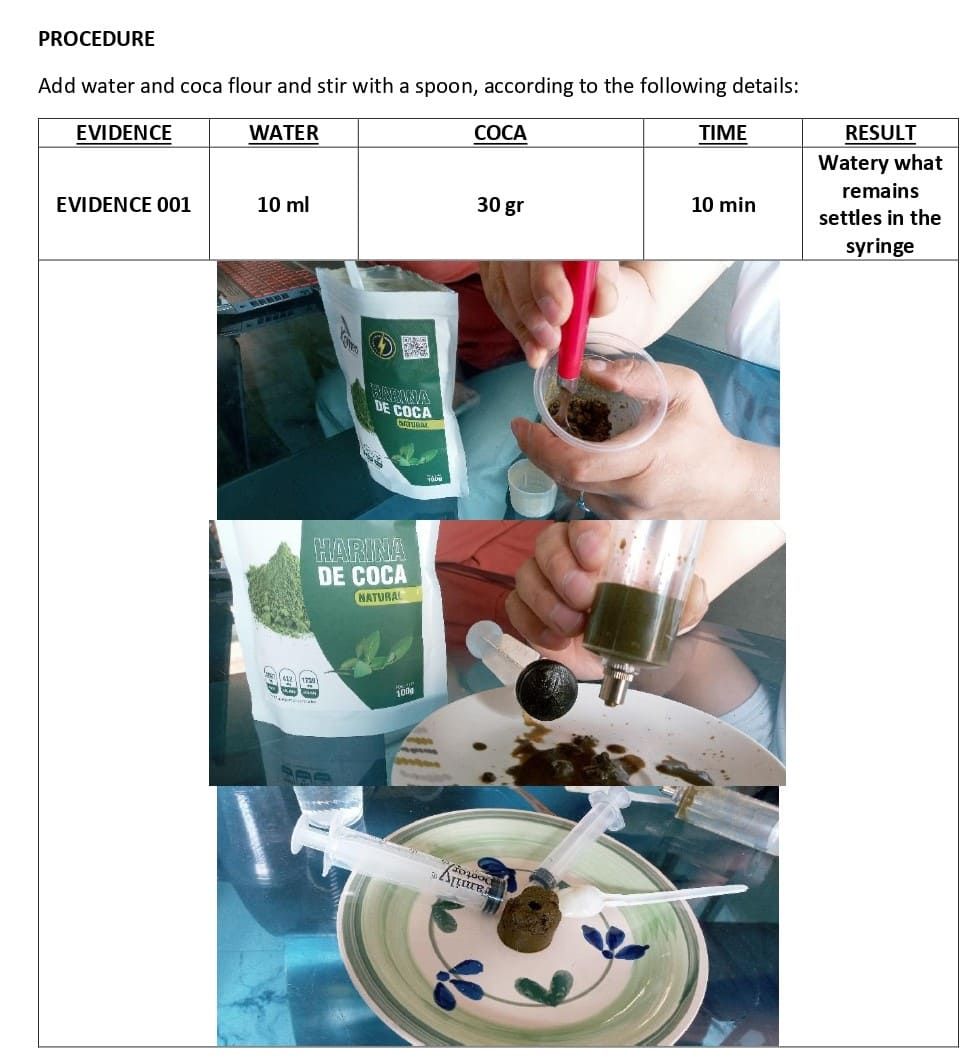

BIOMATERIALS TESTING¶

Master Wilber and I had to carry out the testing of the biomaterials for which we did the test with maca, tocosh, coca flour and the results were: