Week 8: Electronics Design¶

Group assignment:¶

- Use the test equipment in your lab to observe the operation of a microcontroller circuit board (as a minimum, you should demonstrate the use of a multimeter and oscilloscope)

- Document your work on the group work page and reflect what you learned on your individual page

Individual assignment:¶

- Use an EDA tool to design a development board to interact and communicate with an embedded microcontroller

Group assignment:¶

- What is a multimeter and what is it for?

The multimeter is also known as a tester, and consists of a portable electrical device that allows measuring the different electrical quantities that are part of a circuit, such as currents, powers, resistances, capacities, etc.

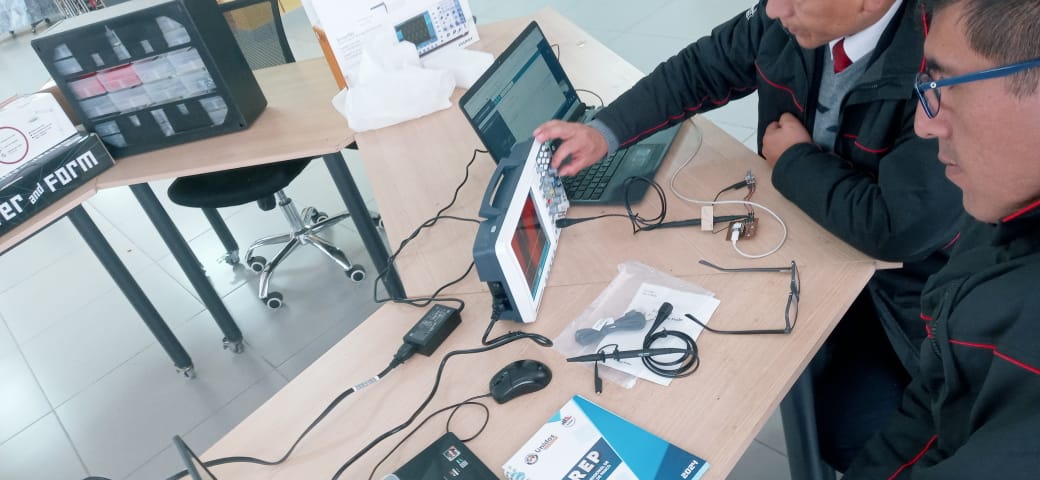

- What is an oscilloscope?

The term oscilloscope is used to name the electronic measuring instrument for the visualization of electrical signals at a given time. These signals are expressed in graphs in which a beam of electrons passes through a coordinate axis on a phosphor screen

Technical specifications¶

- Owon SDS7202 200MHz 1GS/s Deep Memory Digital Storage Oscilloscope, 2+1 Channel with VGA and LAN Interface

- OWON SmartDS SDS7202 Digital Oscilloscope

- Bandwidth: 200 MHz

- Sampling rate: 1 GS/s

- 10m recording length for each channel

- 8 inch 800 x 600 pixel large screen

Individual assignment:¶

- Use an EDA tool to design a development board to interact and communicate with an embedded microcontroller

To create a board we use the Kicad 8.0 software. Once created we will connect with the ESP32 C3 Microcontroller.

STEP 1: We enter the following address to download the kiCad 8.0 software: https://github.com/KiCad/kicad-source-mirror/releases/download/8.0.0/kicad-8.0.0-x86_64.exe

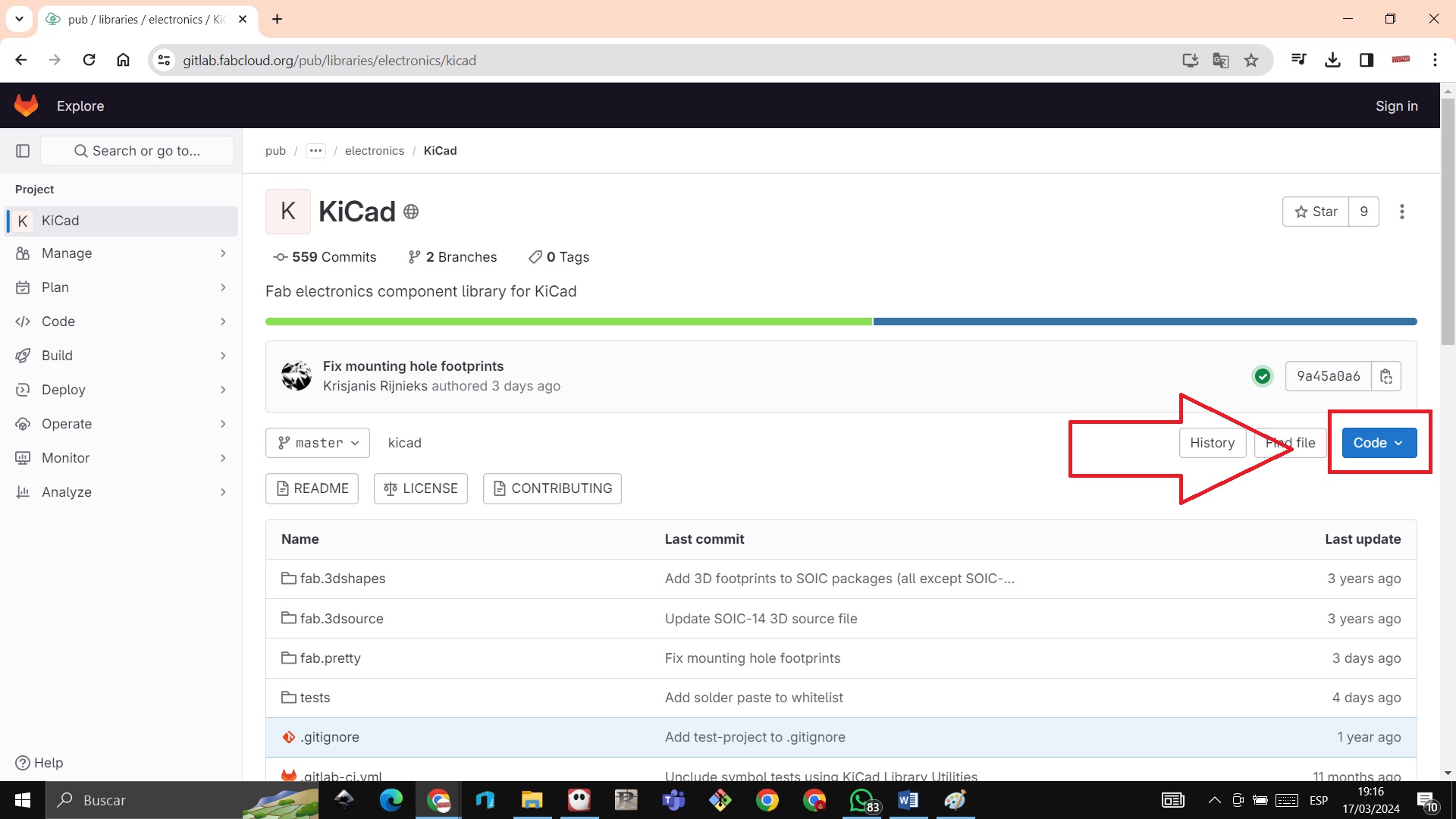

STEP 2: We enter the kiCad 8.0 library in Git Lab and download it in code and then in zip

https://gitlab.fabcloud.org/pub/libraries/electronics/kicad

STEP 3: We open kiCad 8.0 / file / new project

STEP 3: We open kiCad 8.0 / file / new project

STEP 4: We write the name of our sensor1 project and save it in a folder

STEP 4: We write the name of our sensor1 project and save it in a folder

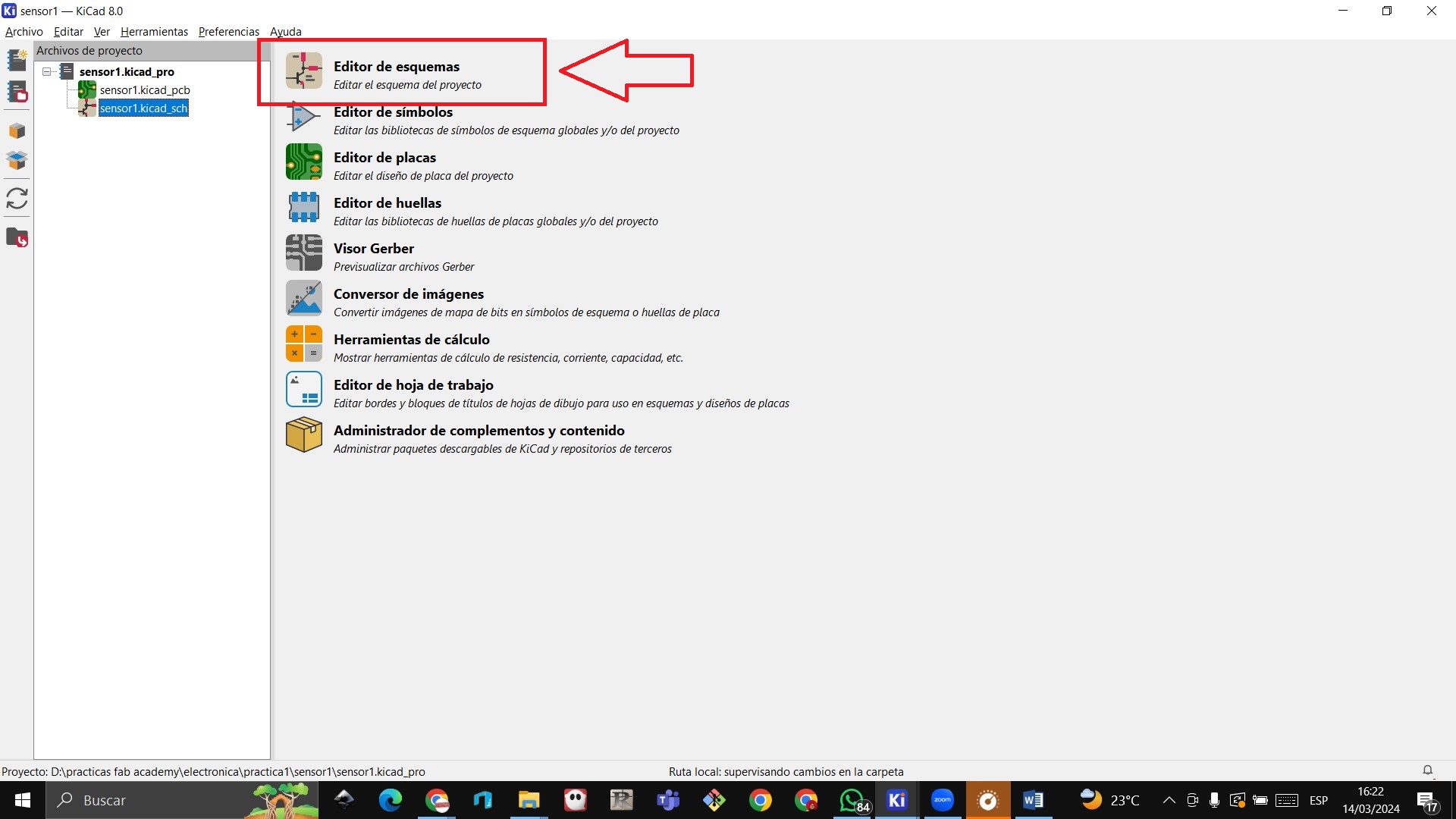

STEP 5: We write the name of our sensor1 project and save it in a folder and the following window will appear, then we click on the schematic editor

STEP 5: We write the name of our sensor1 project and save it in a folder and the following window will appear, then we click on the schematic editor

STEP 6: We click on the symbol editor to add the libraries

STEP 6: We click on the symbol editor to add the libraries

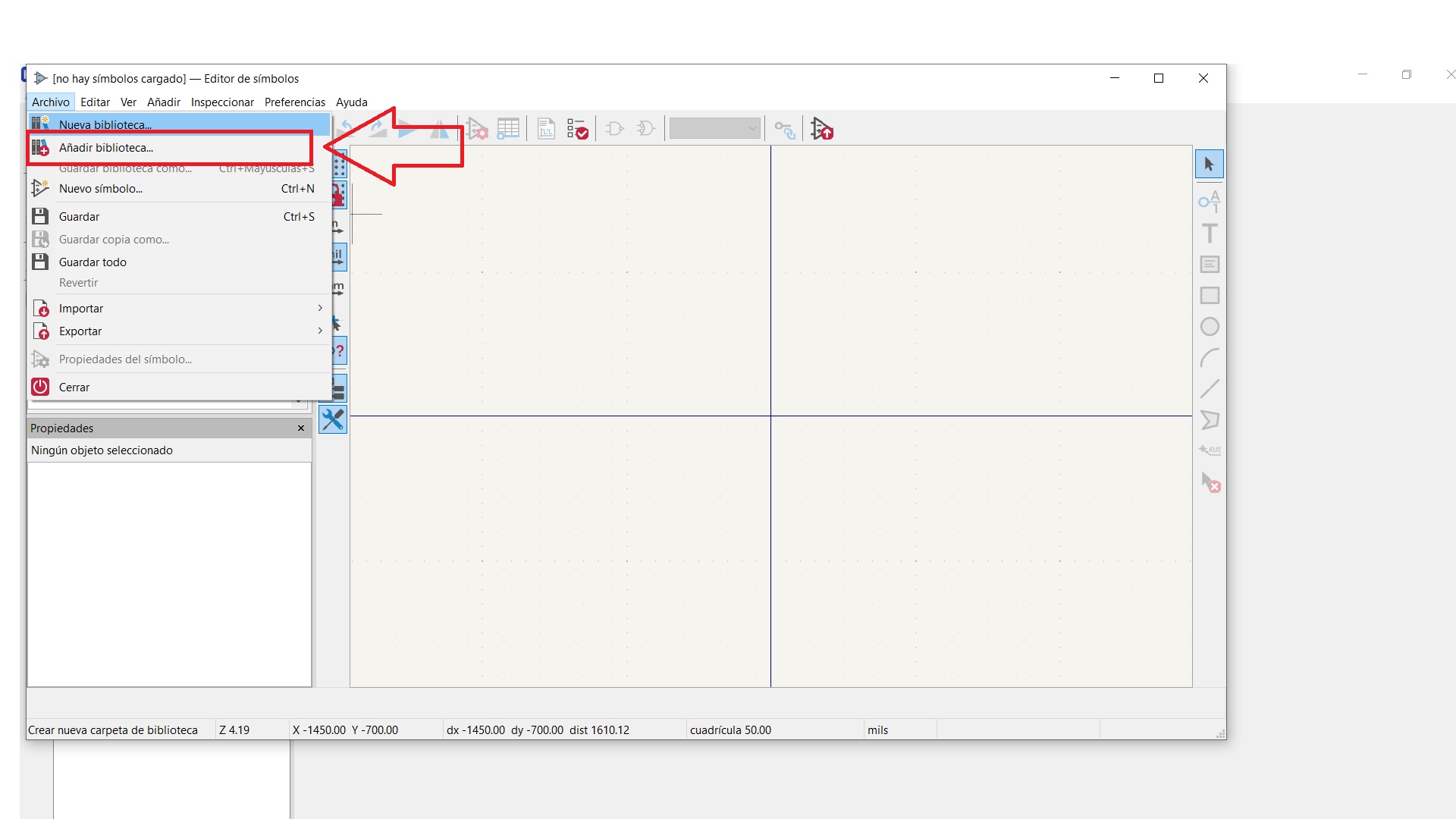

STEP 7: We go to file add library

STEP 7: We go to file add library

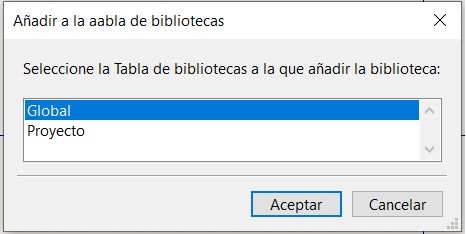

STEP 8: We choose global to add to all other projects.

STEP 8: We choose global to add to all other projects.

STEP 9: We select the kicad-master folder and locate the fab.kicad_sym file

STEP 9: We select the kicad-master folder and locate the fab.kicad_sym file

STEP 10: We verify that it already pulls the fab folder and we close

STEP 10: We verify that it already pulls the fab folder and we close

STEP 11: We open the schematic editor, we are going to add symbols and then we choose the XIAO-ESP32C3 symbol and click accept

STEP 11: We open the schematic editor, we are going to add symbols and then we choose the XIAO-ESP32C3 symbol and click accept

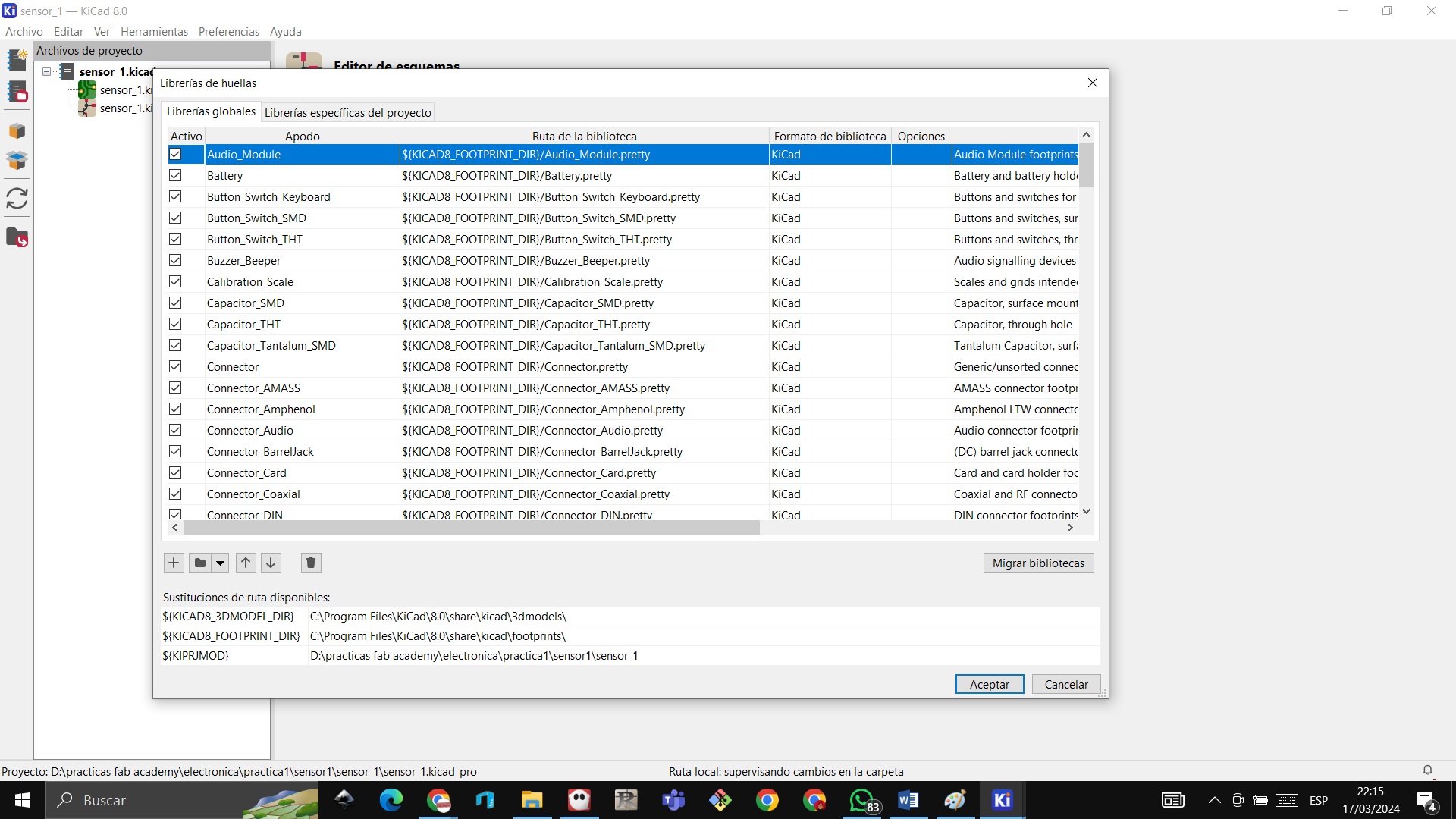

STEP 12: We manage the fingerprint library in the main /preferences/manage fingerprint library

STEP 12: We manage the fingerprint library in the main /preferences/manage fingerprint library

STEP 13: We create the fab folder and look for the Fab.pretty folder to add the libraries

STEP 13: We create the fab folder and look for the Fab.pretty folder to add the libraries

STEP 14: Now if we start designing our card, for which we go to the schematic editor, in adding symbols we go to the fab folder and look for them to have 7 connectors

STEP 14: Now if we start designing our card, for which we go to the schematic editor, in adding symbols we go to the fab folder and look for them to have 7 connectors

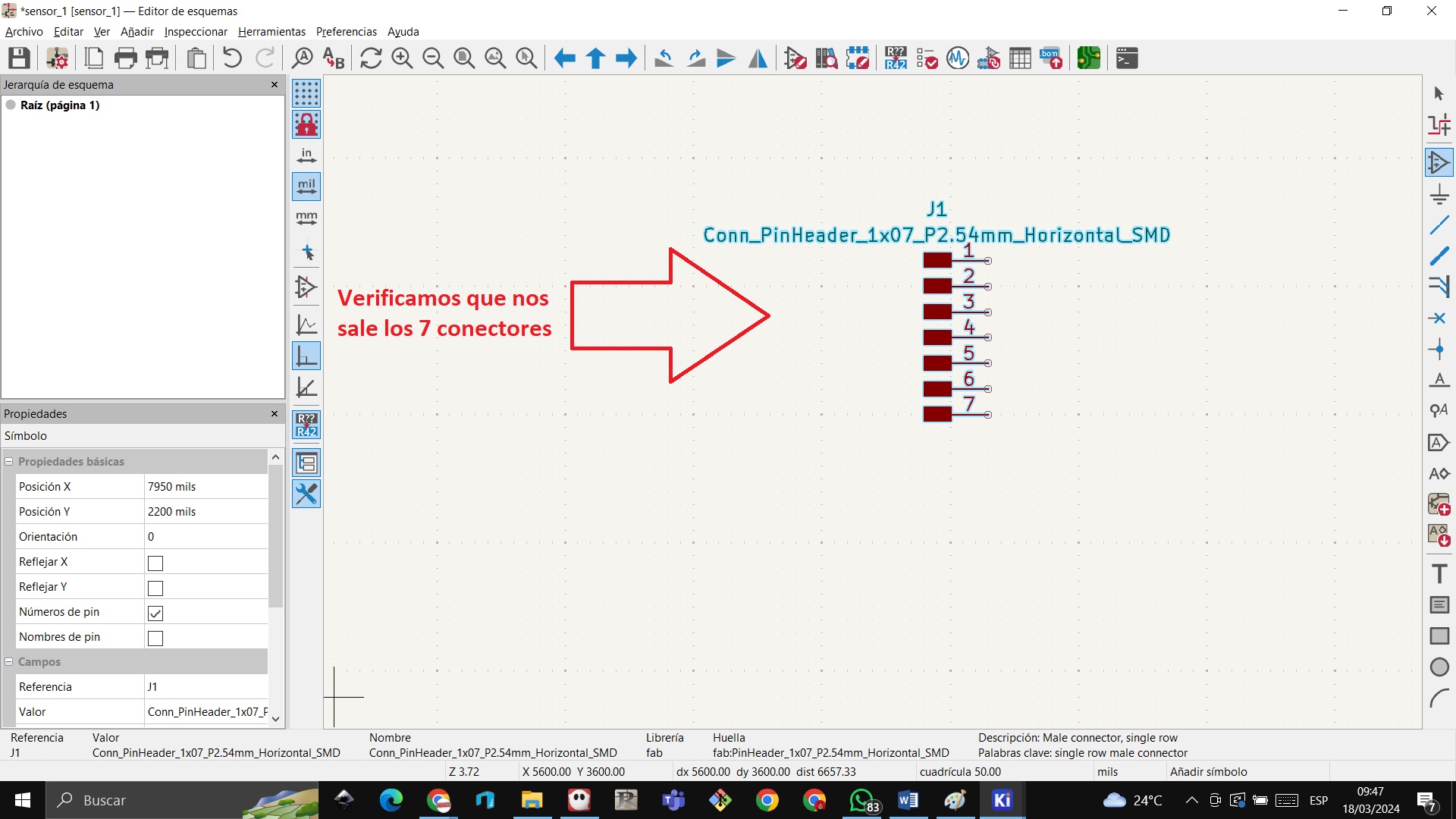

STEP 15: We verify that it comes out in the following way and the idea is to create the board to connect to the quentorres

STEP 15: We verify that it comes out in the following way and the idea is to create the board to connect to the quentorres

STEP 16: We orient ourselves from the image to create our plate

STEP 16: We orient ourselves from the image to create our plate

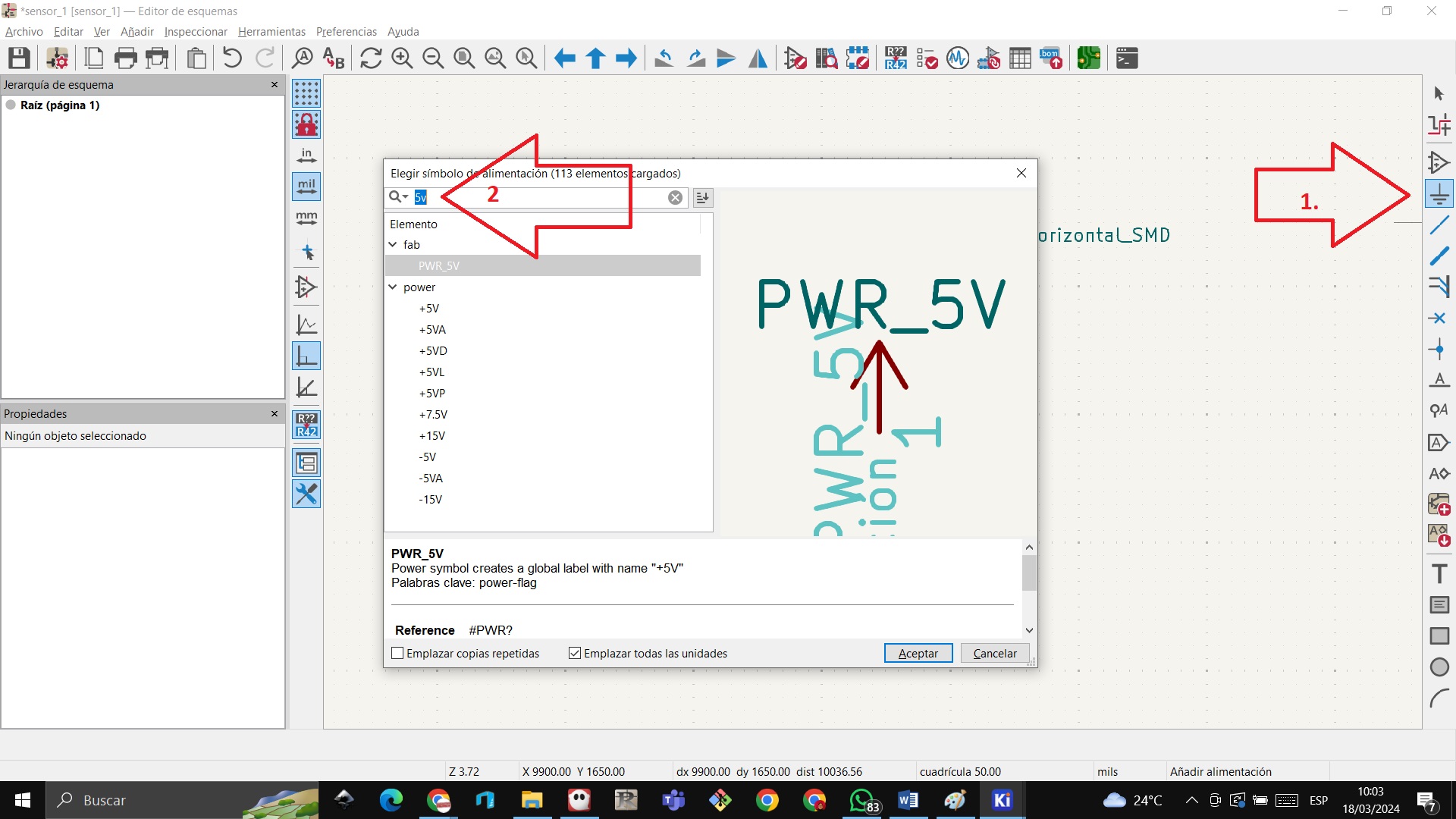

STEP 17: We are going to add power symbols and look for PWR_5V by writing 5V

STEP 17: We are going to add power symbols and look for PWR_5V by writing 5V

STEP 18: We locate the 5V with the mouse

STEP 18: We locate the 5V with the mouse

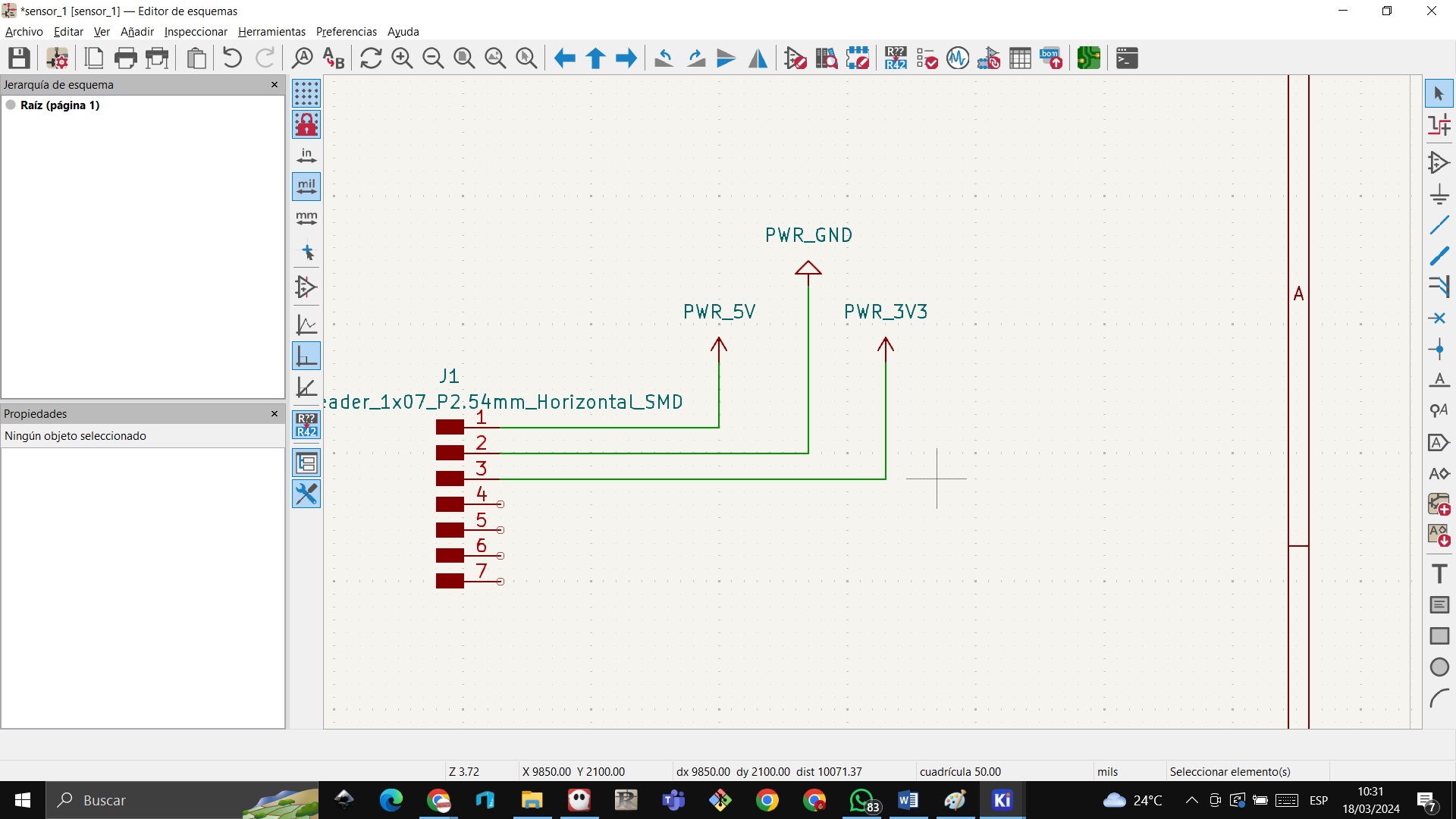

STEP 19: We do the same procedure with 3v

STEP 19: We do the same procedure with 3v

STEP 20: We enter the preferred GND of the fab folder, to rotate we select the symbol and press the letter R so that it can rotate and the letter G to move

STEP 20: We enter the preferred GND of the fab folder, to rotate we select the symbol and press the letter R so that it can rotate and the letter G to move

STEP 21: We click on ESC to exit any tool and then with the mouse pointer we join the tracks

STEP 21: We click on ESC to exit any tool and then with the mouse pointer we join the tracks

STEP 22: Now we define that we are going to connect a proximity sensor

STEP 22: Now we define that we are going to connect a proximity sensor

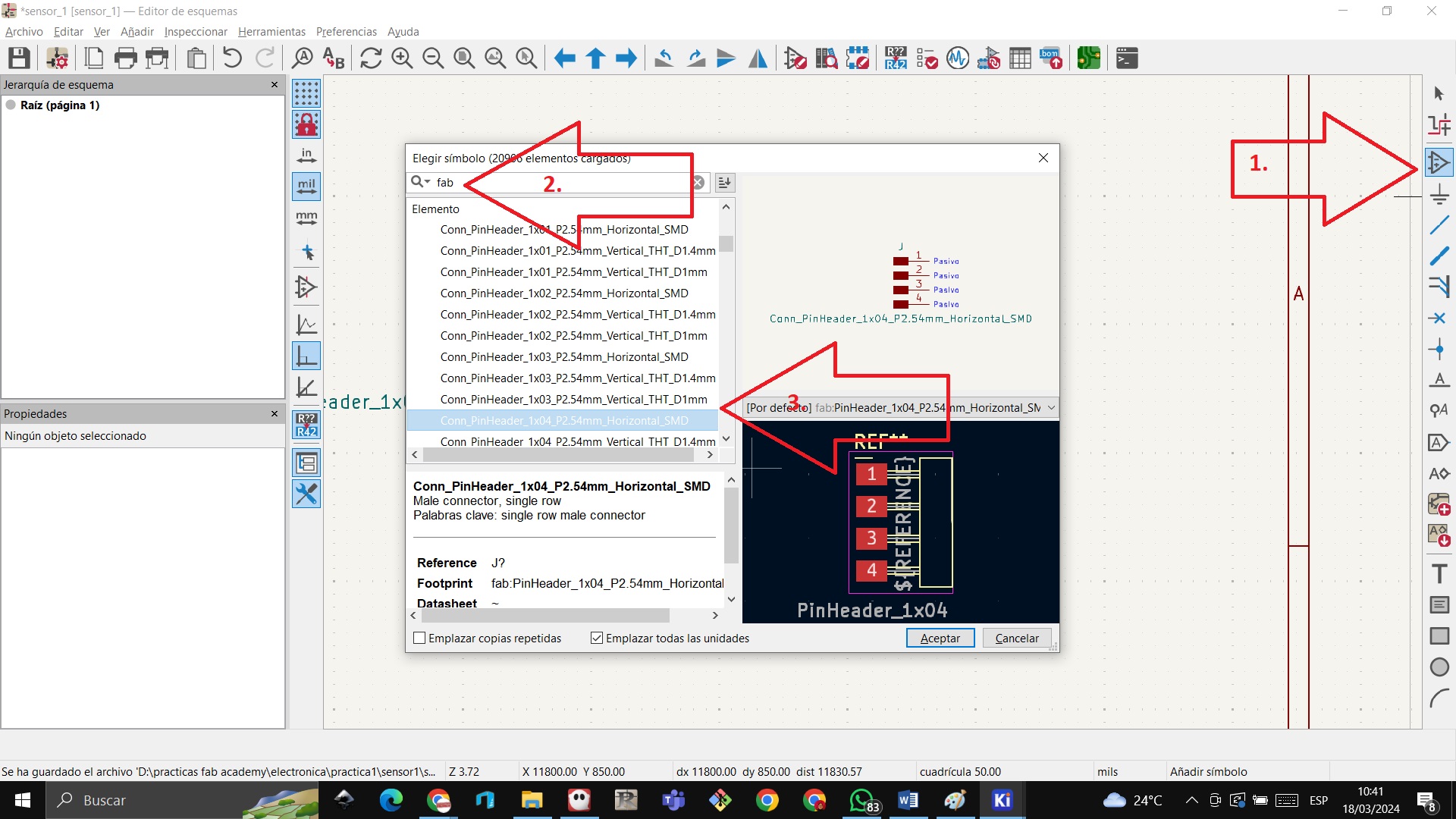

STEP 23: We now add 4 connectors for which we go to add symbols / the fab folder / and look for the 4 connectors

STEP 23: We now add 4 connectors for which we go to add symbols / the fab folder / and look for the 4 connectors

STEP 24: We mirror the 4-connector symbol

STEP 24: We mirror the 4-connector symbol

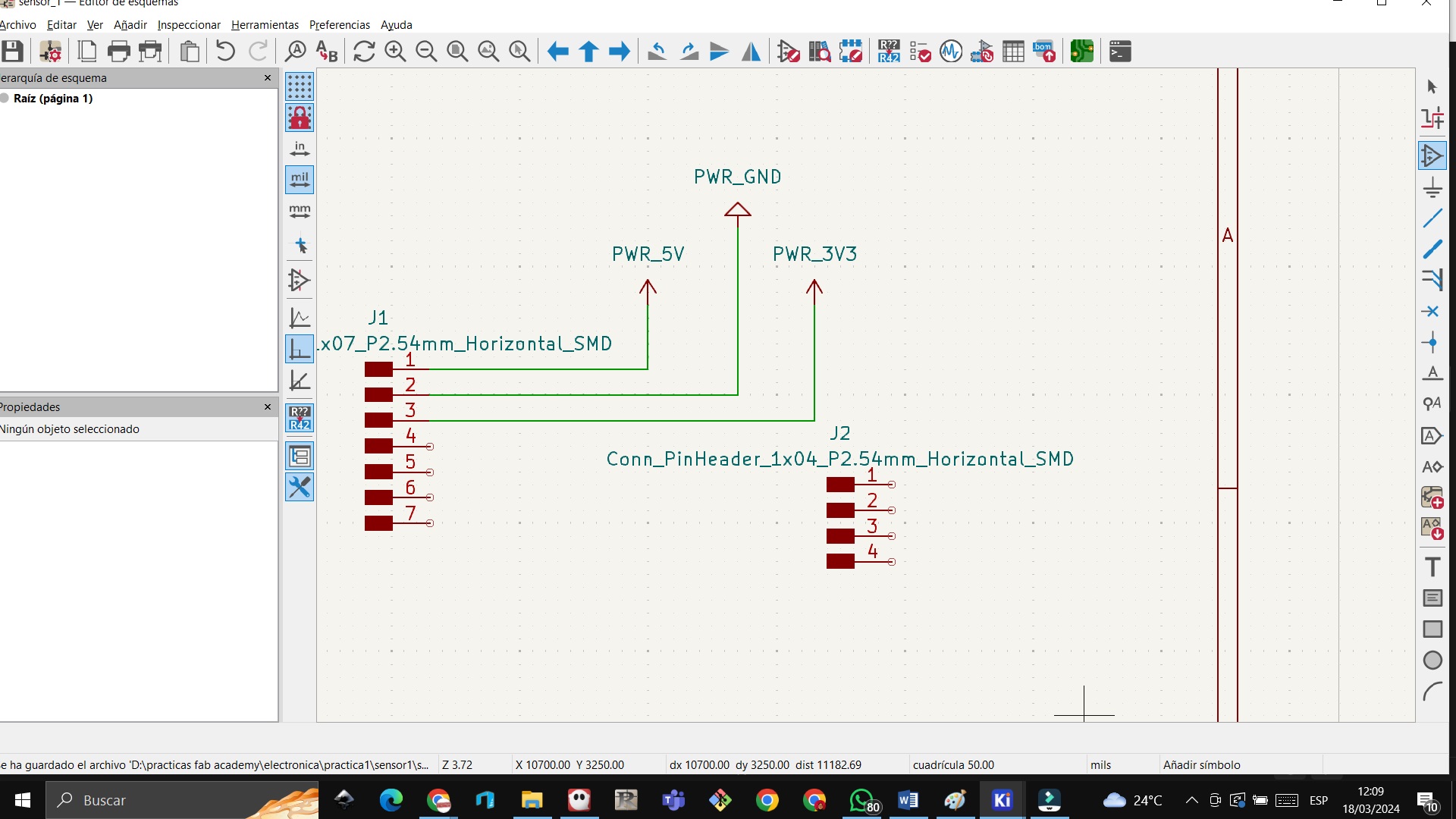

STEP 25: Select the 5v symbol then CTRL + D to duplicate and move and then connect

STEP 25: Select the 5v symbol then CTRL + D to duplicate and move and then connect

STEP 26: We add components, a switch and a resistor

STEP 26: We add components, a switch and a resistor

STEP 27: We add a 3v and GND

STEP 27: We add a 3v and GND

STEP 28: We connect the 3V, the switch and the GND

STEP 28: We connect the 3V, the switch and the GND

STEP 29: We enter a 1206 led and duplicate the GND with CTRL + D

STEP 29: We enter a 1206 led and duplicate the GND with CTRL + D

STEP 30: When it is joined it looks like this and we join it to pin 7

STEP 30: When it is joined it looks like this and we join it to pin 7

STEP 31: We click on verify fingerprints and we get that everyone has fingerprints

STEP 31: We click on verify fingerprints and we get that everyone has fingerprints

STEP 32: We update the schematic plate and if we see that there are no errors we update

STEP 32: We update the schematic plate and if we see that there are no errors we update

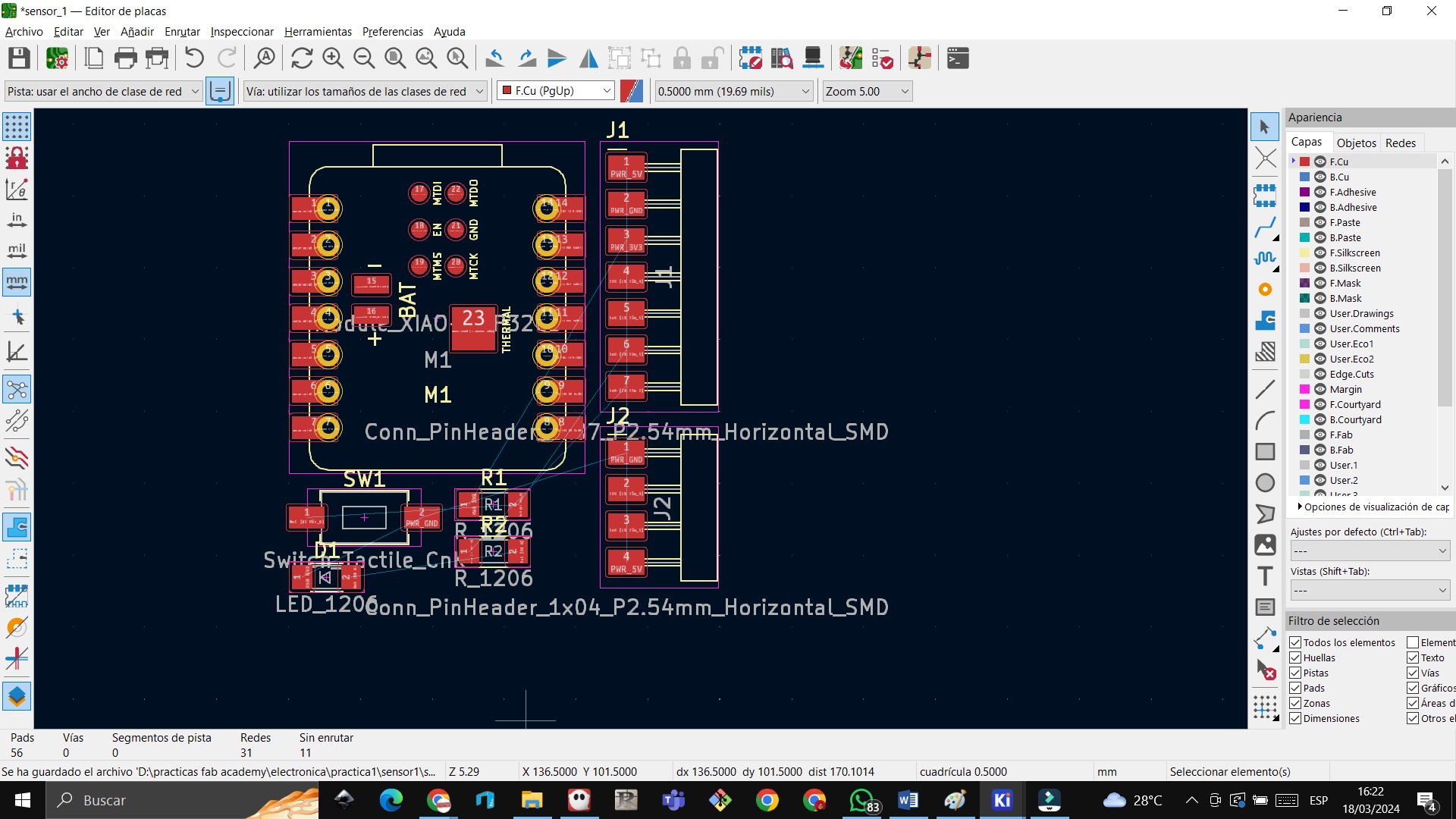

STEP 33: In the schematic we see the xiao esp 32 and our board that we are working on

STEP 33: In the schematic we see the xiao esp 32 and our board that we are working on

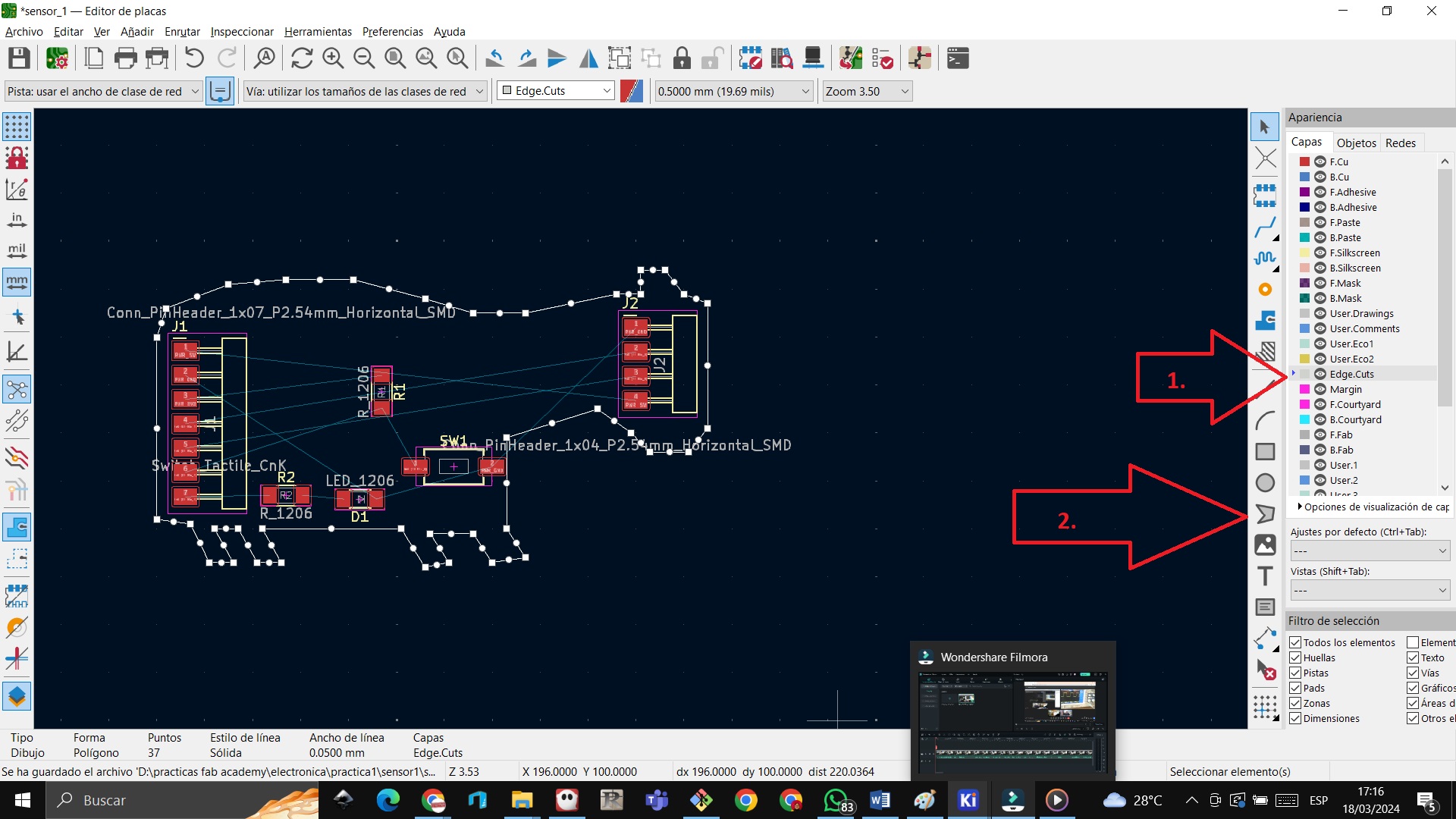

STEP 34: We enter Edge Cuts and then draw a graphic polygon

STEP 34: We enter Edge Cuts and then draw a graphic polygon

STEP 35: We click on the screen to show 3D viewer and we see that a moving image appears when we move the mouse

STEP 35: We click on the screen to show 3D viewer and we see that a moving image appears when we move the mouse

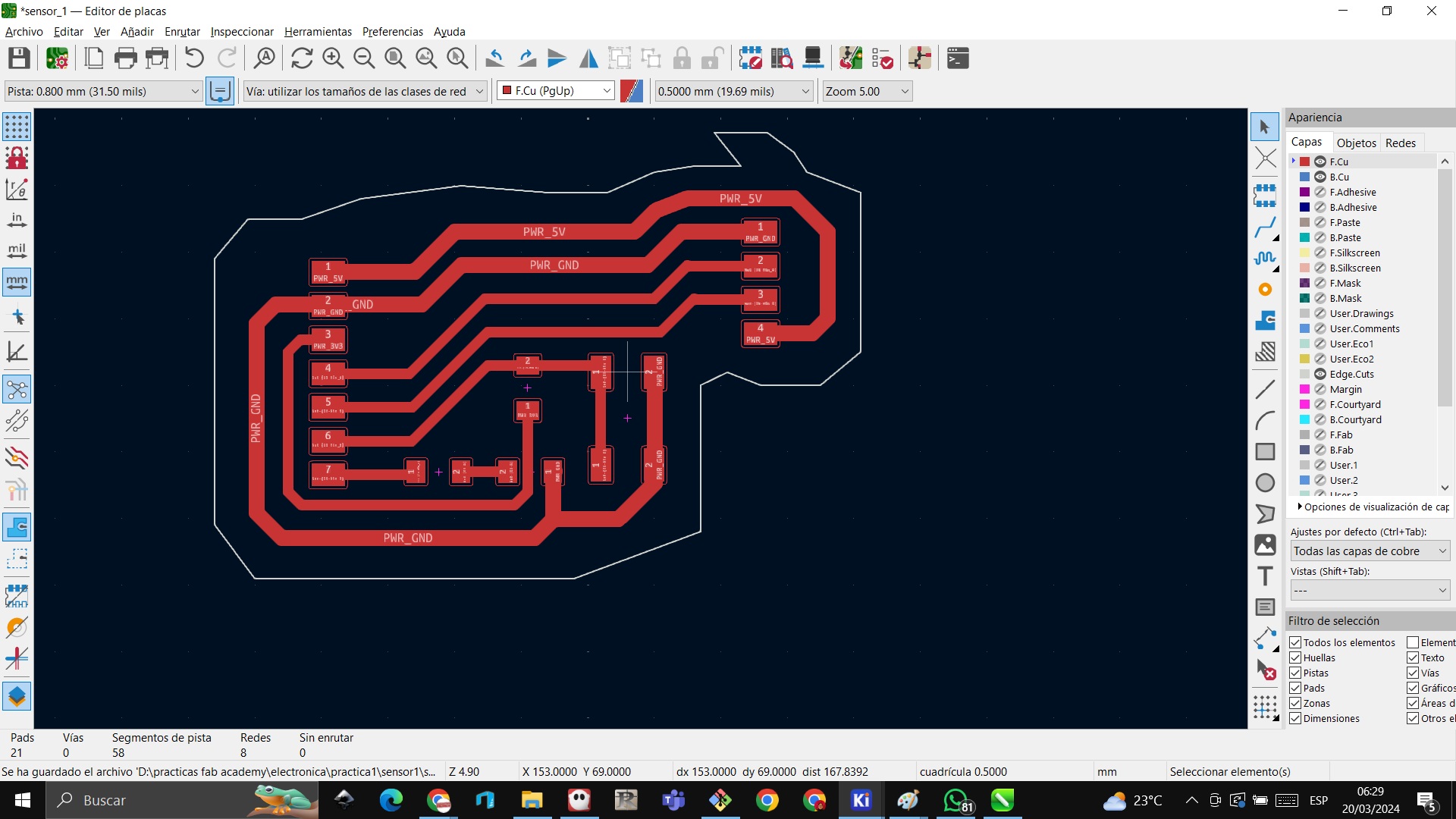

STEP 36: To design the width of the tracks we are going to edit defined sizes

STEP 36: To design the width of the tracks we are going to edit defined sizes

STEP 37: The following window appears and in the + sign we add the thicknesses of the tracks, 1.2mm is recommended since current passes through that track

STEP 37: The following window appears and in the + sign we add the thicknesses of the tracks, 1.2mm is recommended since current passes through that track

STEP 38: We choose which track to work with in our case with the 1.2mm and then on the route tracks icon

STEP 38: We choose which track to work with in our case with the 1.2mm and then on the route tracks icon

STEP 39: We click on a component and it automatically activates where to connect it

STEP 39: We click on a component and it automatically activates where to connect it

STEP 40:They are left this way

STEP 40:They are left this way

STEP 41: Now we go to mill it, for that we have to go to appearance and we choose to show all the layers without copper

STEP 41: Now we go to mill it, for that we have to go to appearance and we choose to show all the layers without copper

STEP 42: We export in SVG

STEP 42: We export in SVG

STEP 43: We choose F.Cu and we already have the file

STEP 43: We choose F.Cu and we already have the file

STEP 44: We change the Switch from 2 pins to 4 pins and follow the same process

STEP 44: We change the Switch from 2 pins to 4 pins and follow the same process

STEP 45: Entering the updated switch

STEP 45: Entering the updated switch

STEP 46: Con el cambio del switch termino asi

STEP 46: Con el cambio del switch termino asi

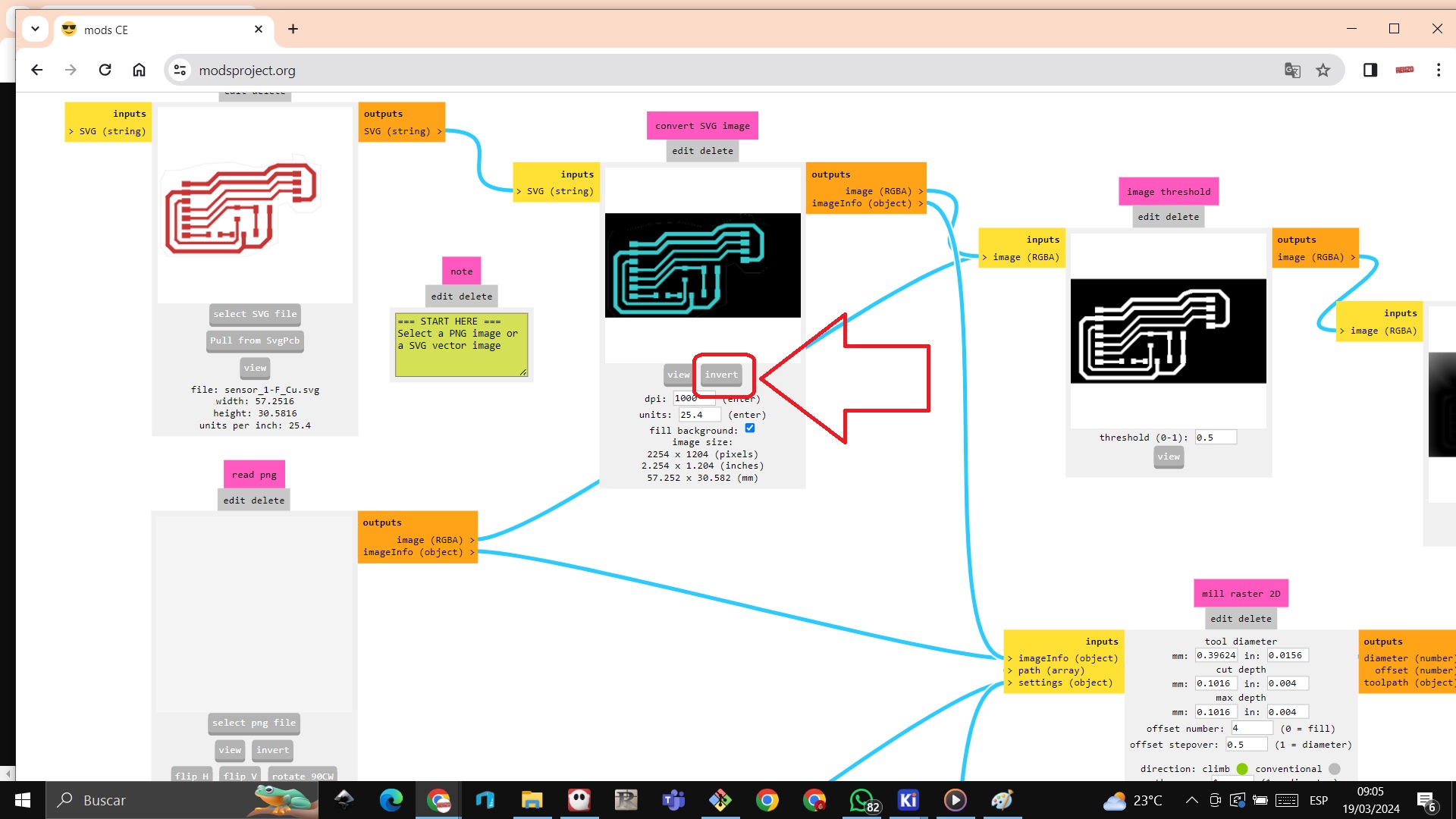

We now use mods project to be able to print the plate

We now use mods project to be able to print the plate

STEP 1: We enter the url https://modsproject.org/ right click programs

STEP 2: We choose WILL 2D PCB

STEP 2: We choose WILL 2D PCB

STEP 3: We enter the SVG file

STEP 3: We enter the SVG file

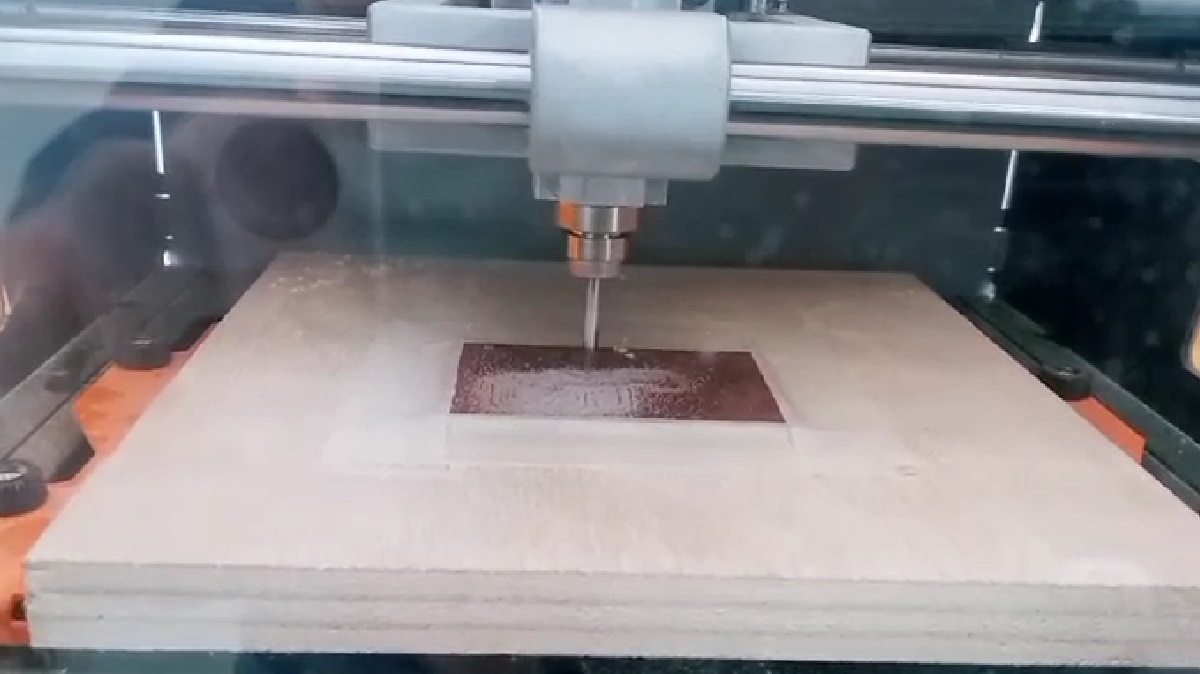

STEP 4: We open the SRM-20 milling machine software where we calibrate the X, Y, Z axes at their 0 point then click on CUT to load the gcode generated by the MODS

STEP 4: We open the SRM-20 milling machine software where we calibrate the X, Y, Z axes at their 0 point then click on CUT to load the gcode generated by the MODS

STEP 5: We start the plate milling process

STEP 5: We start the plate milling process

After trying so much with strawberries and srm - 20

After trying so much with strawberries and srm - 20