Week 7: Computer-Controlled Machining¶

Group assignment:¶

- Complete your lab’s safety training

- Test runout, alignment, fixturing, speeds, feeds, materials and toolpaths for your machine

- Document your work to the group work page and reflect on your individual page what you learned

Individual project¶

Make (design+mill+assemble) something big

Group assignment:¶

-

Safety in the laboratory¶

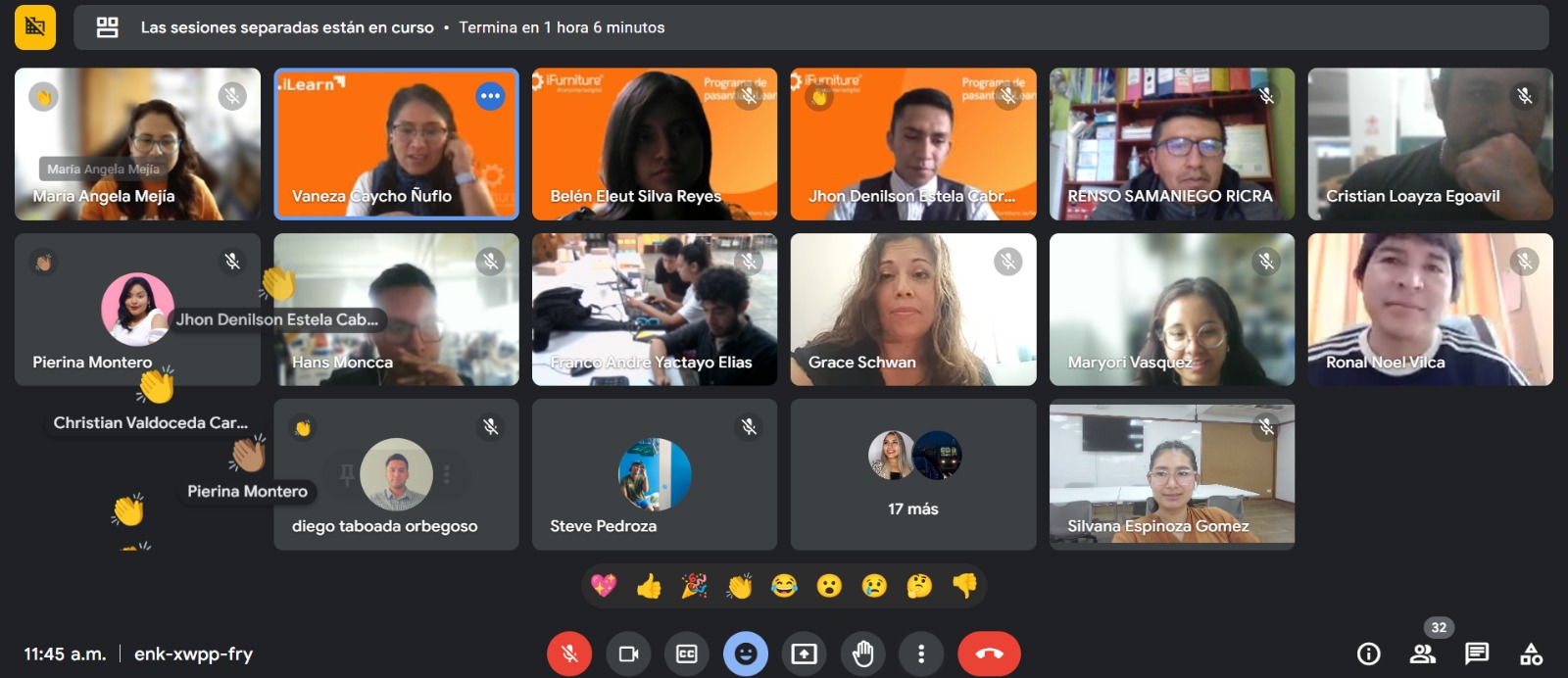

Ya hemos recibido La charla de parte de la empresa ifurnituri referente a temas de seguridad mediante zoom All the students of the fab Academy 2024 were present

All the students of the fab Academy 2024 were present

The topics of safety signals at work were discussed and it was explained at every moment that we would have to use each signal. There were several signs that I didn’t know

The topics of safety signals at work were discussed and it was explained at every moment that we would have to use each signal. There were several signs that I didn’t know

The topics of the stripes were touched on, especially the green one, which I didn’t know and I found it very interesting since it indicated an emergency condition.

The topics of the stripes were touched on, especially the green one, which I didn’t know and I found it very interesting since it indicated an emergency condition.

También se nos proporcionó los planos de ubicación de las máquinas en donde se tenía que tener presente las ubicaciones de las máquinas para el acceso del personal.

También se nos proporcionó los planos de ubicación de las máquinas en donde se tenía que tener presente las ubicaciones de las máquinas para el acceso del personal.

It was reported regarding the types of milling cutters for cutting wood with the CNC, there were different types of shapes and sizes

It was reported regarding the types of milling cutters for cutting wood with the CNC, there were different types of shapes and sizes

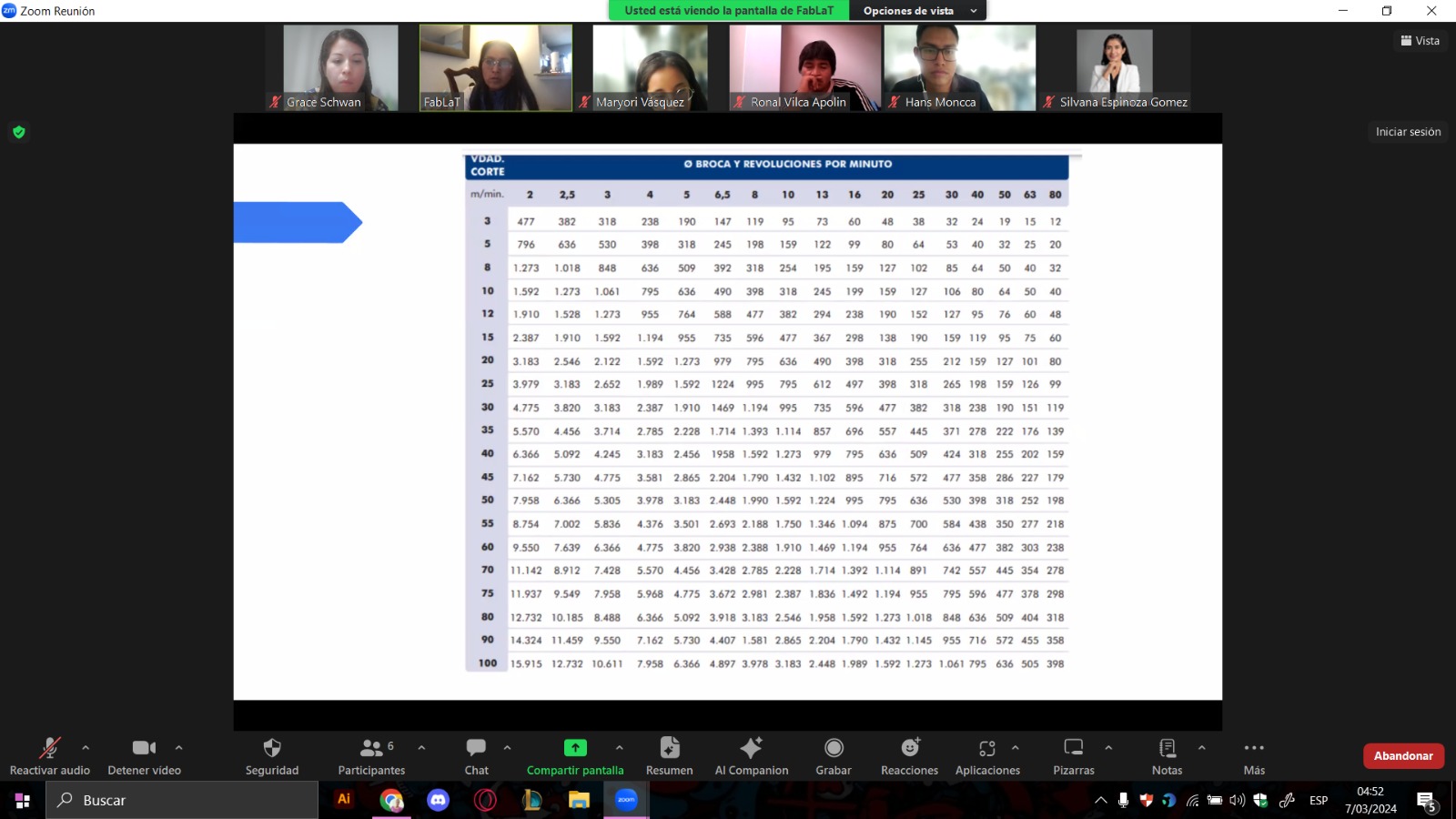

We also saw the topics of the cutting speed table on the CNC

We also saw the topics of the cutting speed table on the CNC

We see which drill bit to use and the revolutions per minute

We see which drill bit to use and the revolutions per minute

For safety we put on the helmet, glasses and ear plugs, also the gloves before starting to work and don’t forget the safety shoes.

For safety we put on the helmet, glasses and ear plugs, also the gloves before starting to work and don’t forget the safety shoes.

Wilbert did the same in putting on the safety equipment without first putting on our jackets because of the very cold weather in our city on Cerro de Pasco

Wilbert did the same in putting on the safety equipment without first putting on our jackets because of the very cold weather in our city on Cerro de Pasco

-

Test runout, alignment, fixturing, speeds, feeds, materials and toolpaths for your machine¶

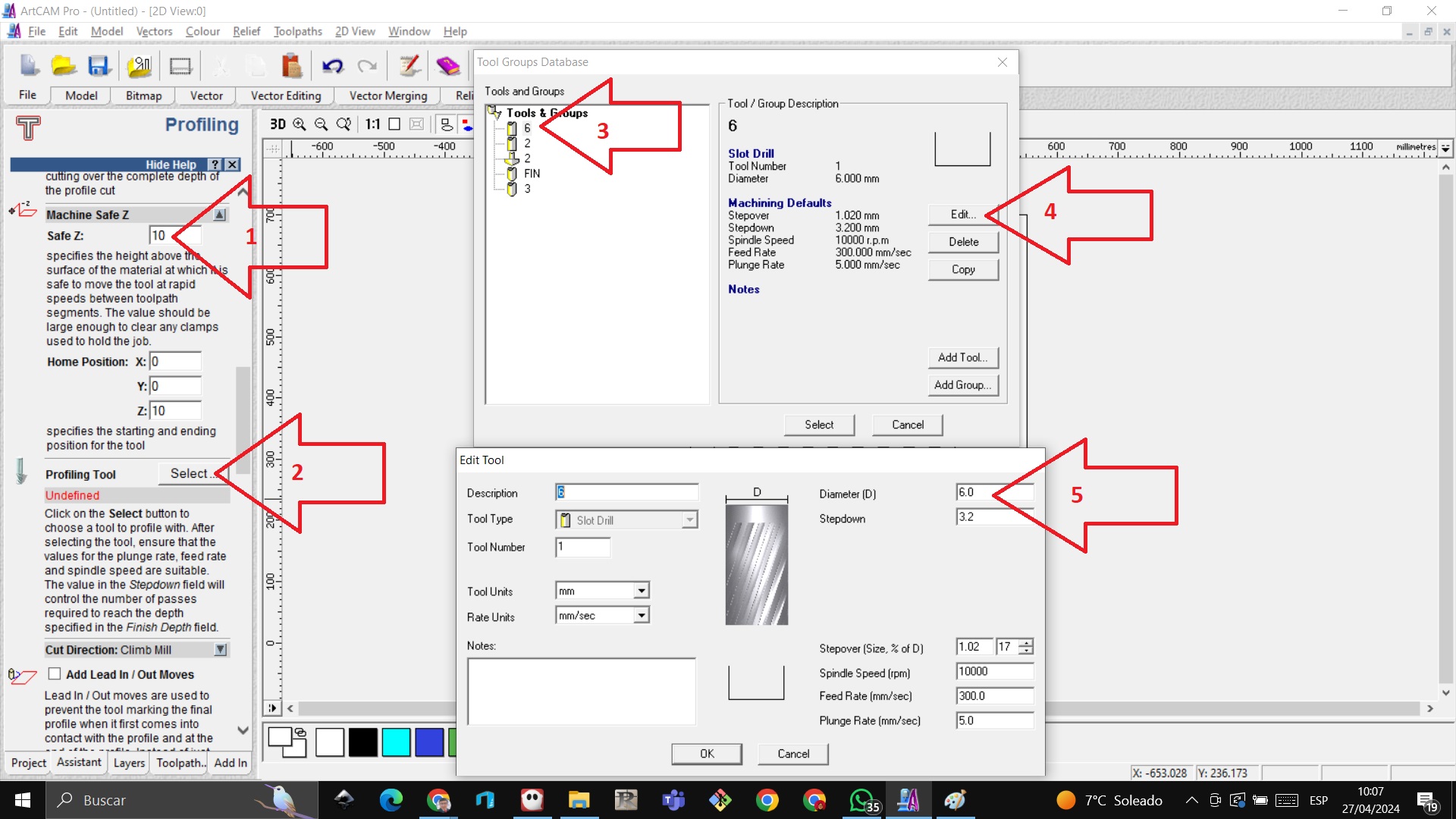

We begin by measuring with the vernier the diameter of the drill to use this average 6mm We use the tools to adjust the drill bit on the CNC milling machine

We use the tools to adjust the drill bit on the CNC milling machine

We begin to adjust the cutter with the tools

We begin to adjust the cutter with the tools

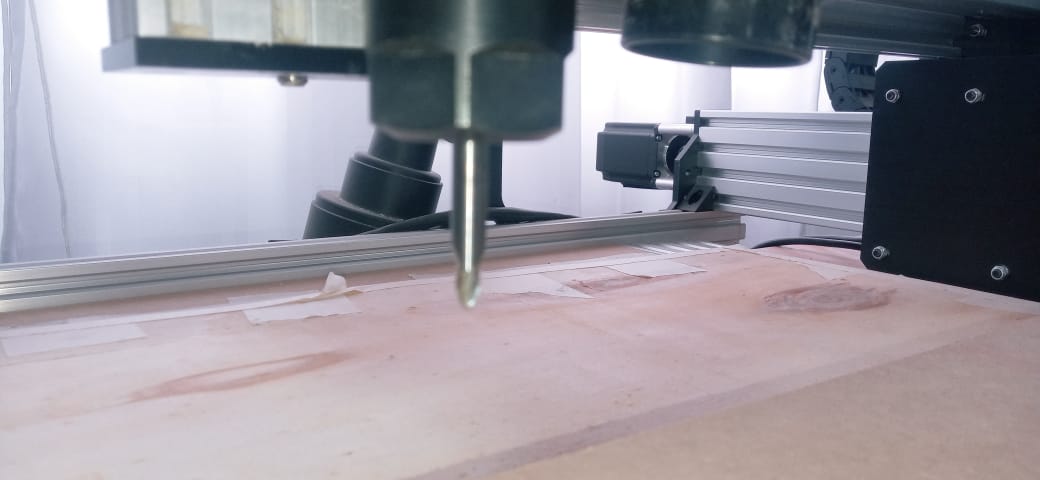

Mill ready to work with the CNC

Mill ready to work with the CNC

Our work area has a 50 by 70 cm work area division and there we put the 15 mm thick MDF, fixing it to the bed by nailing the edges so that our material does not move.

Our work area has a 50 by 70 cm work area division and there we put the 15 mm thick MDF, fixing it to the bed by nailing the edges so that our material does not move.

We turn on the machine and verify that the speed of the cutter is at zero

We turn on the machine and verify that the speed of the cutter is at zero

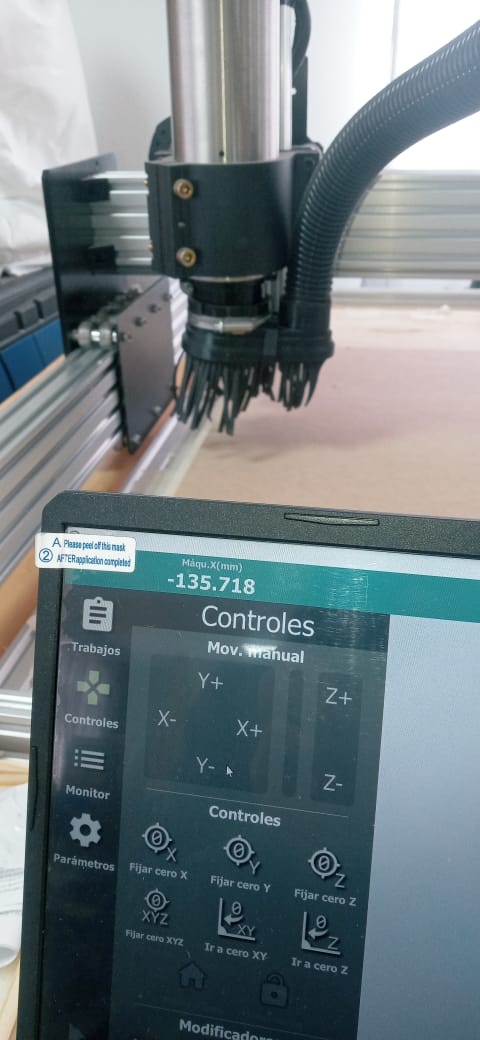

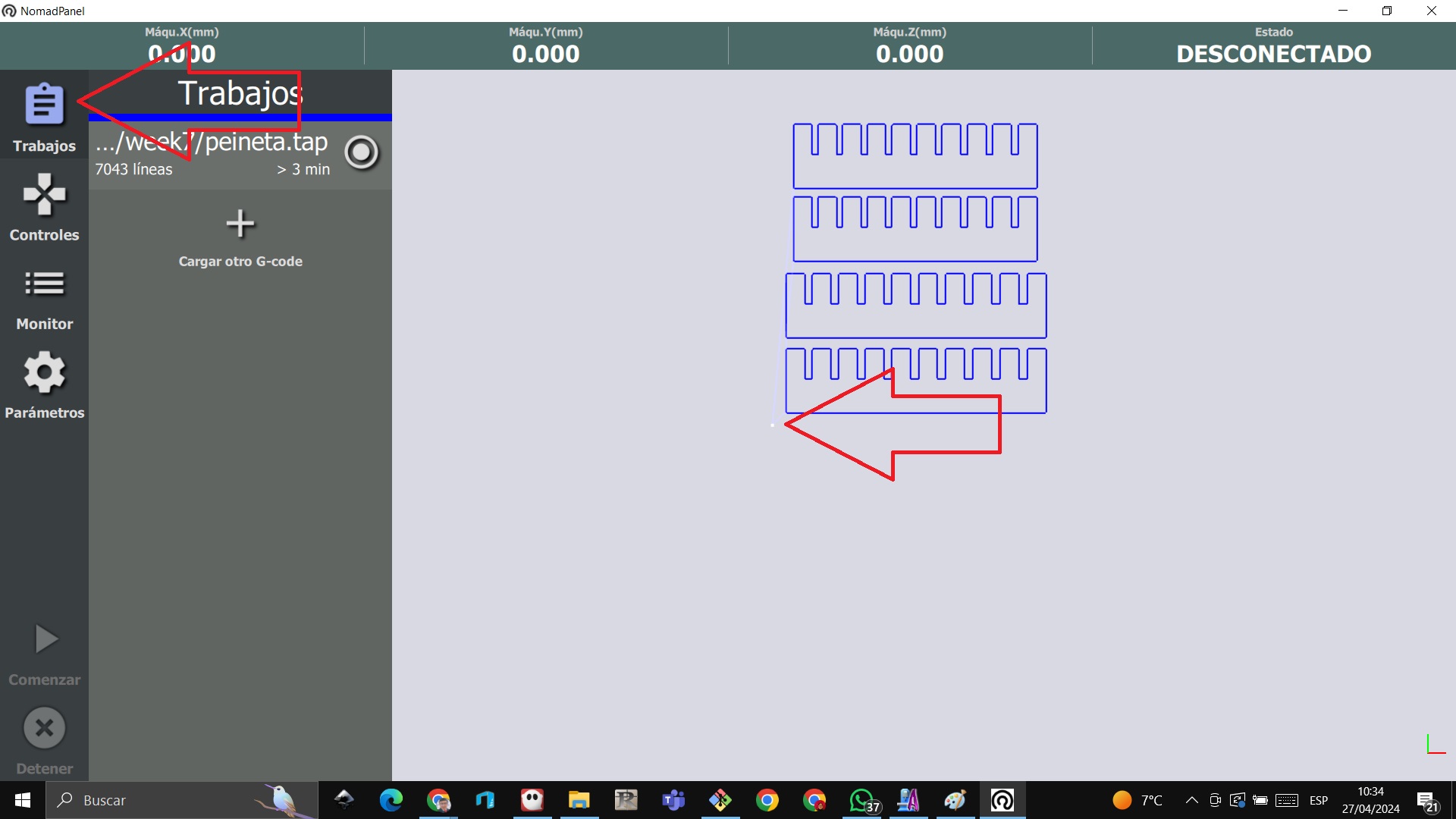

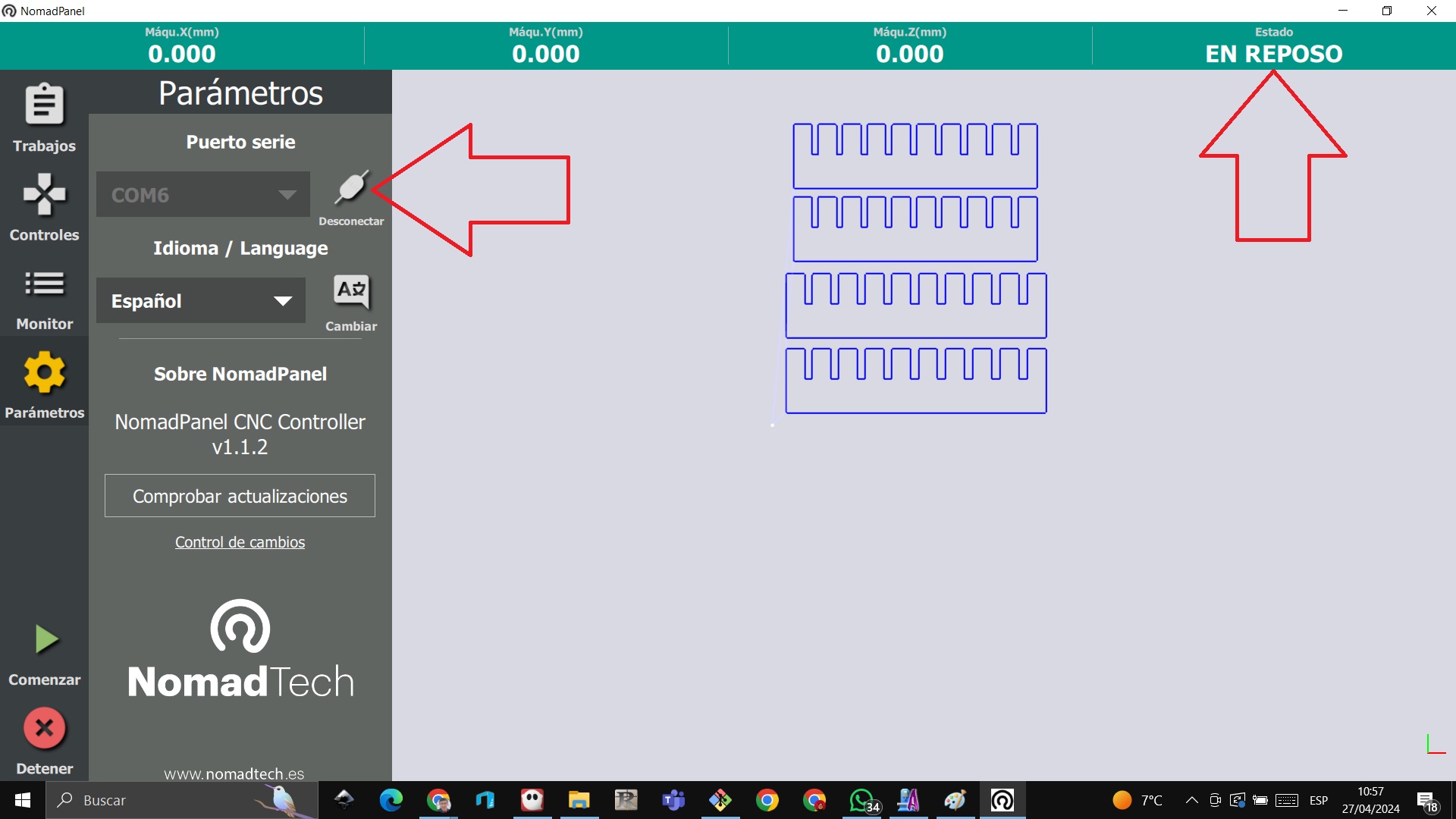

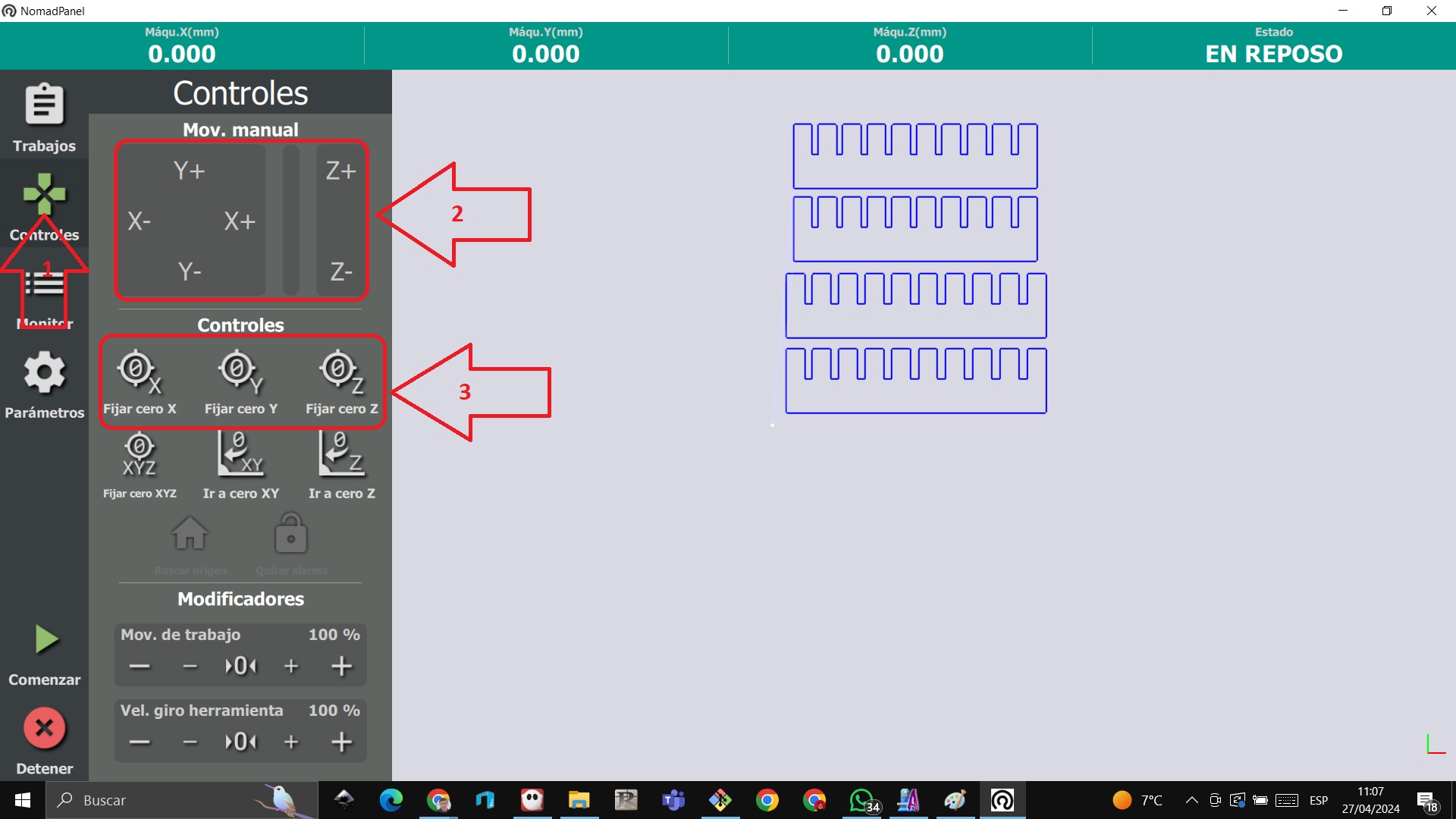

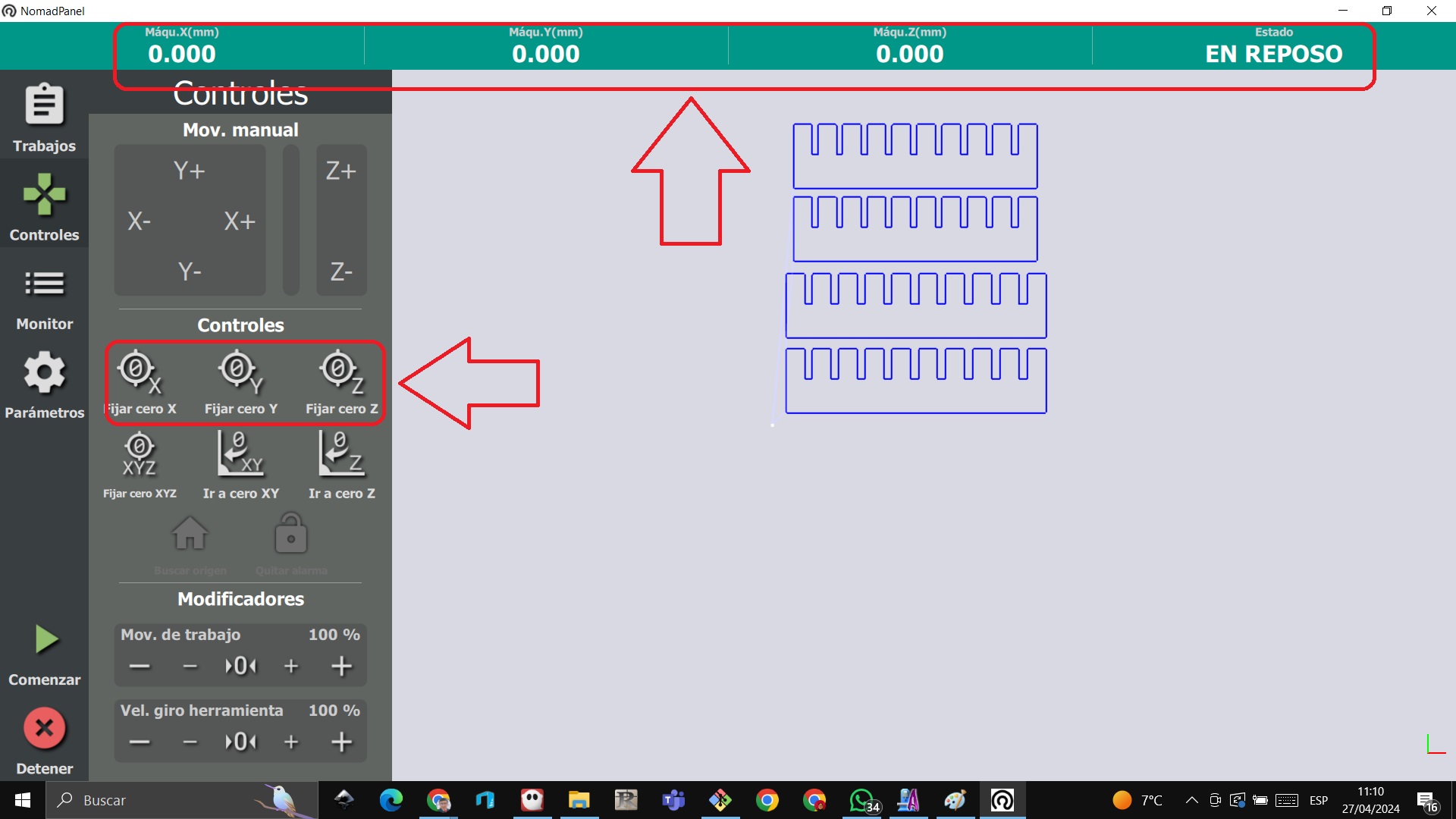

We open the nomad panel software and start looking for the starting zero point of our work in the x and z axes

We open the nomad panel software and start looking for the starting zero point of our work in the x and z axes

We increase the speed according to the board indicated in the safety regulations for cutting 15 mm MDF

We increase the speed according to the board indicated in the safety regulations for cutting 15 mm MDF

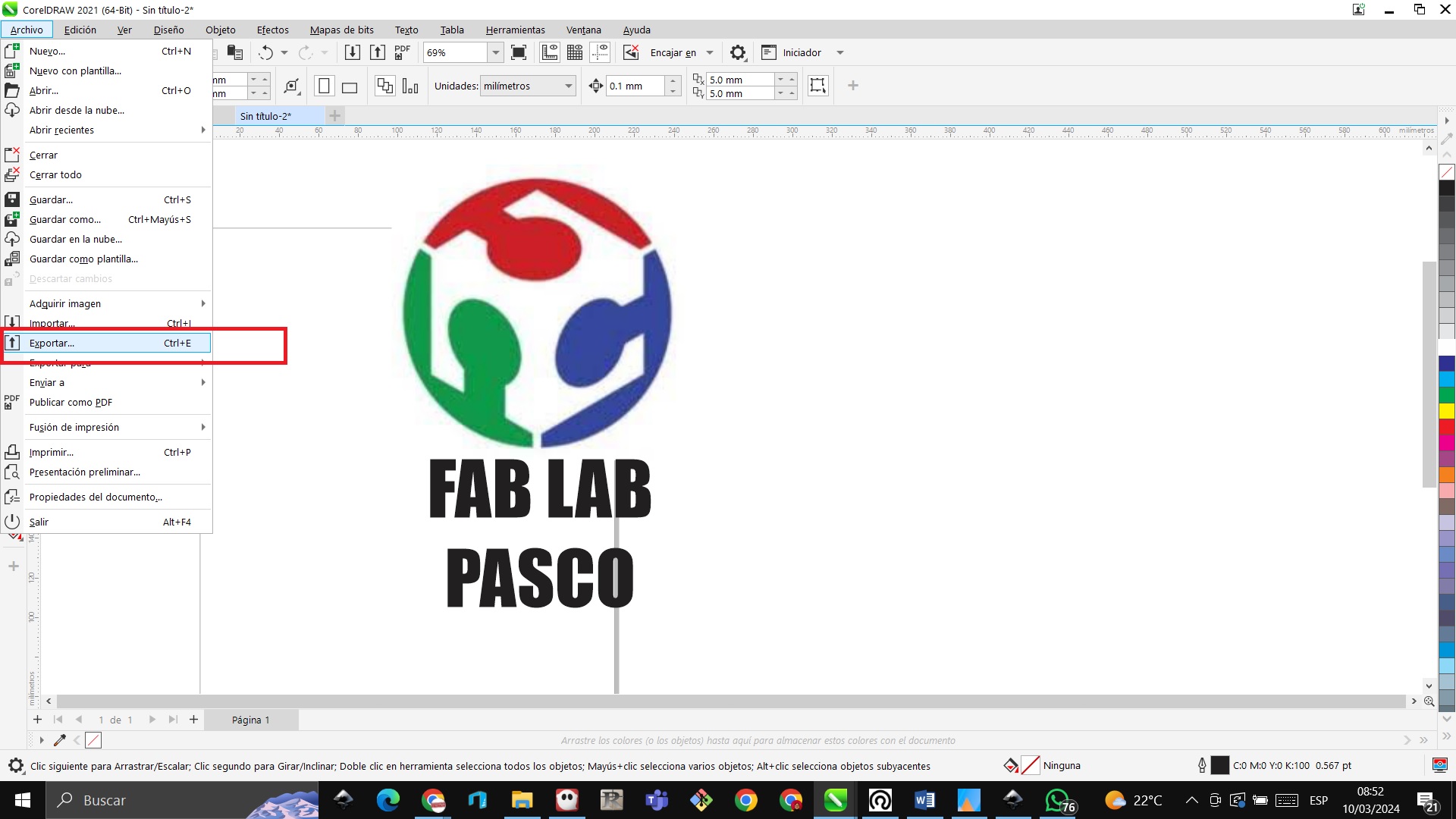

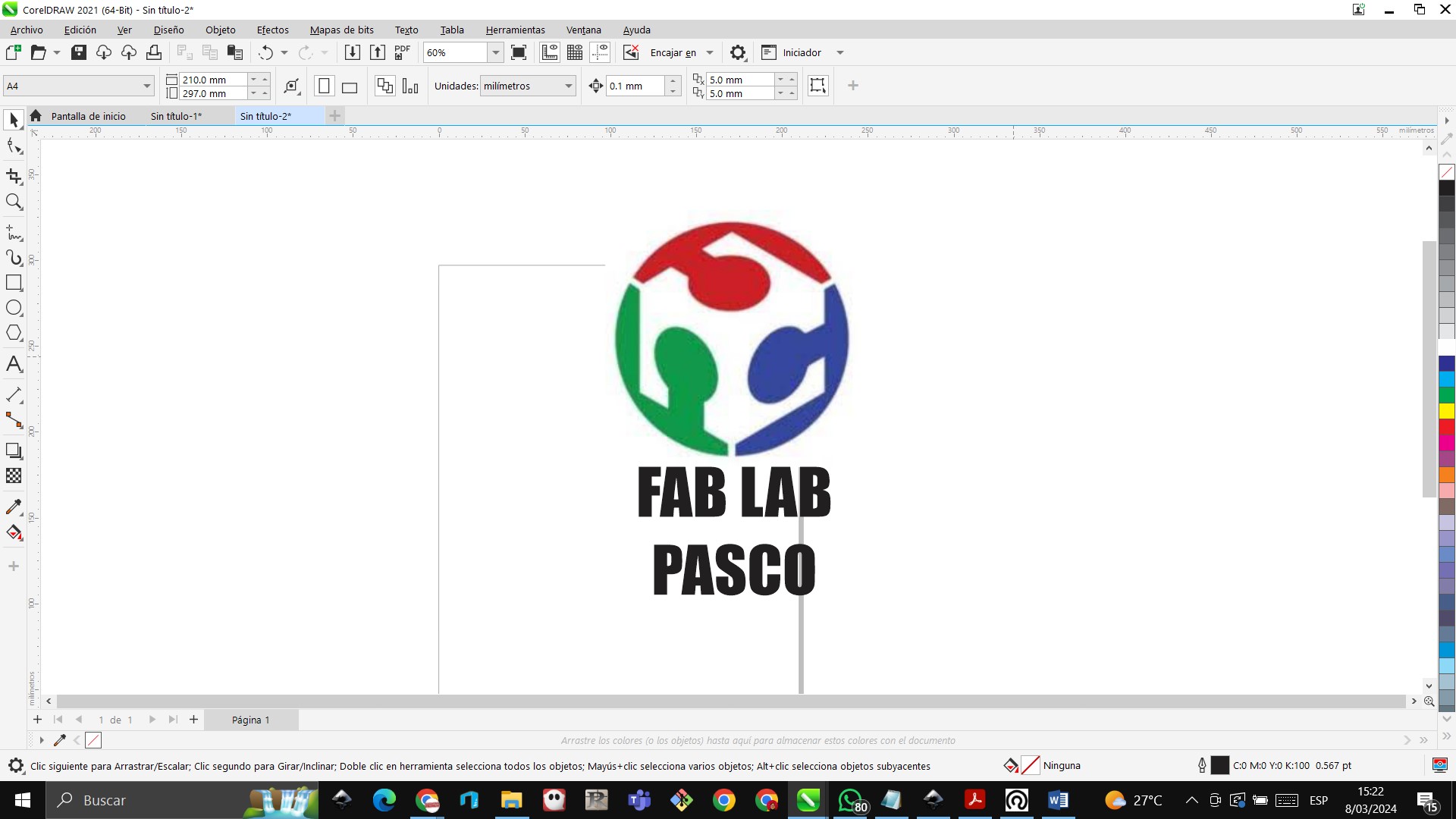

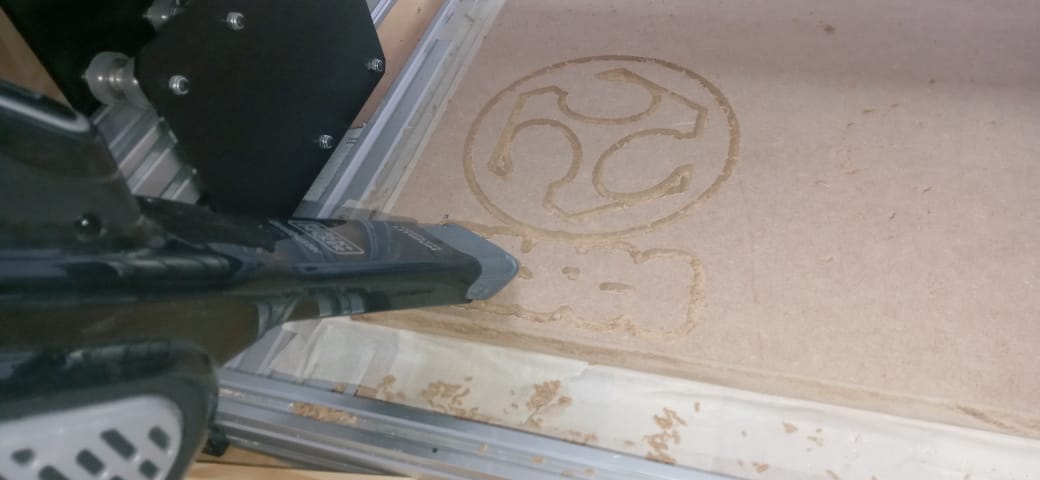

We open Coreldraw to be able to work on our logo and design it

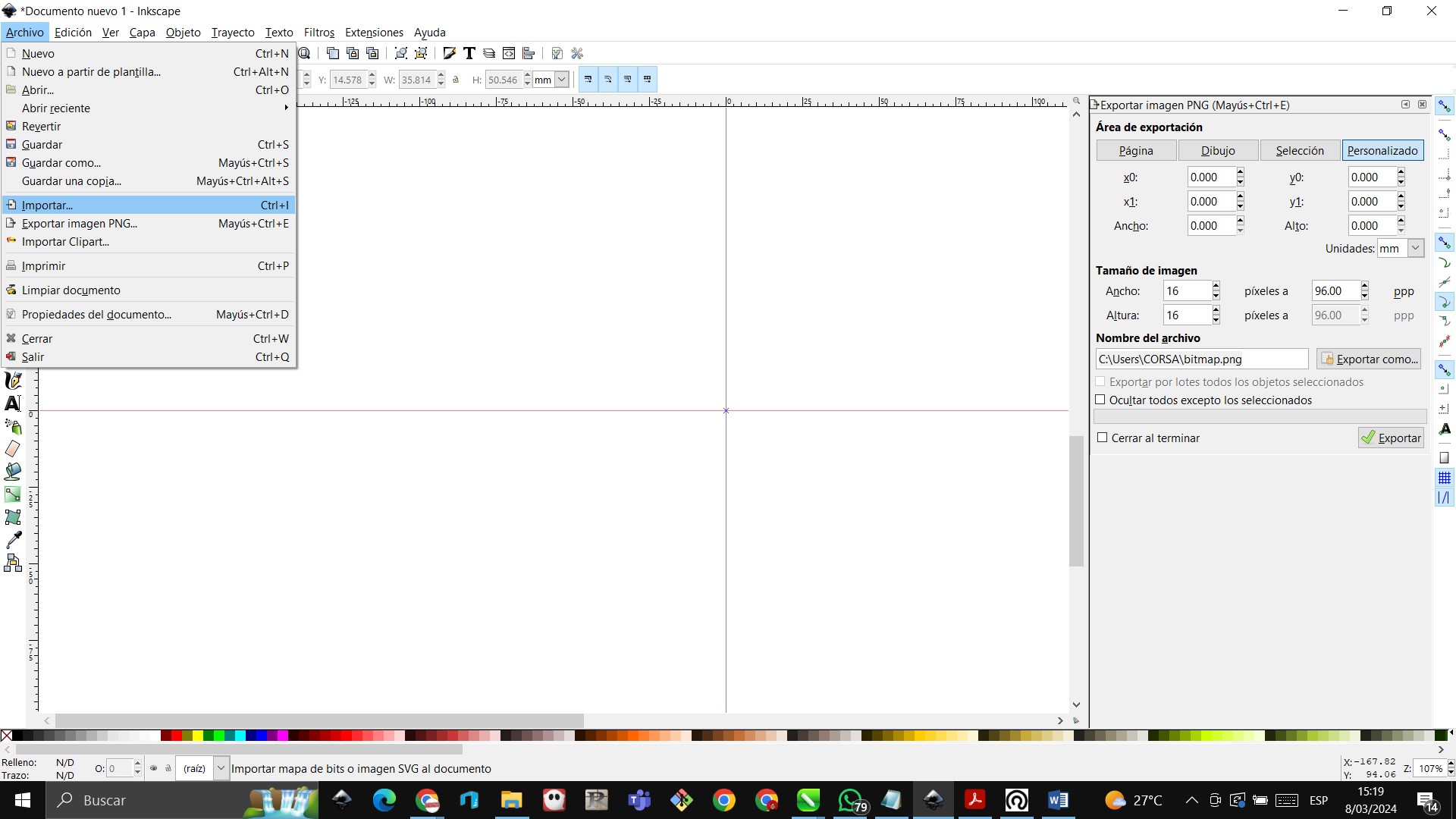

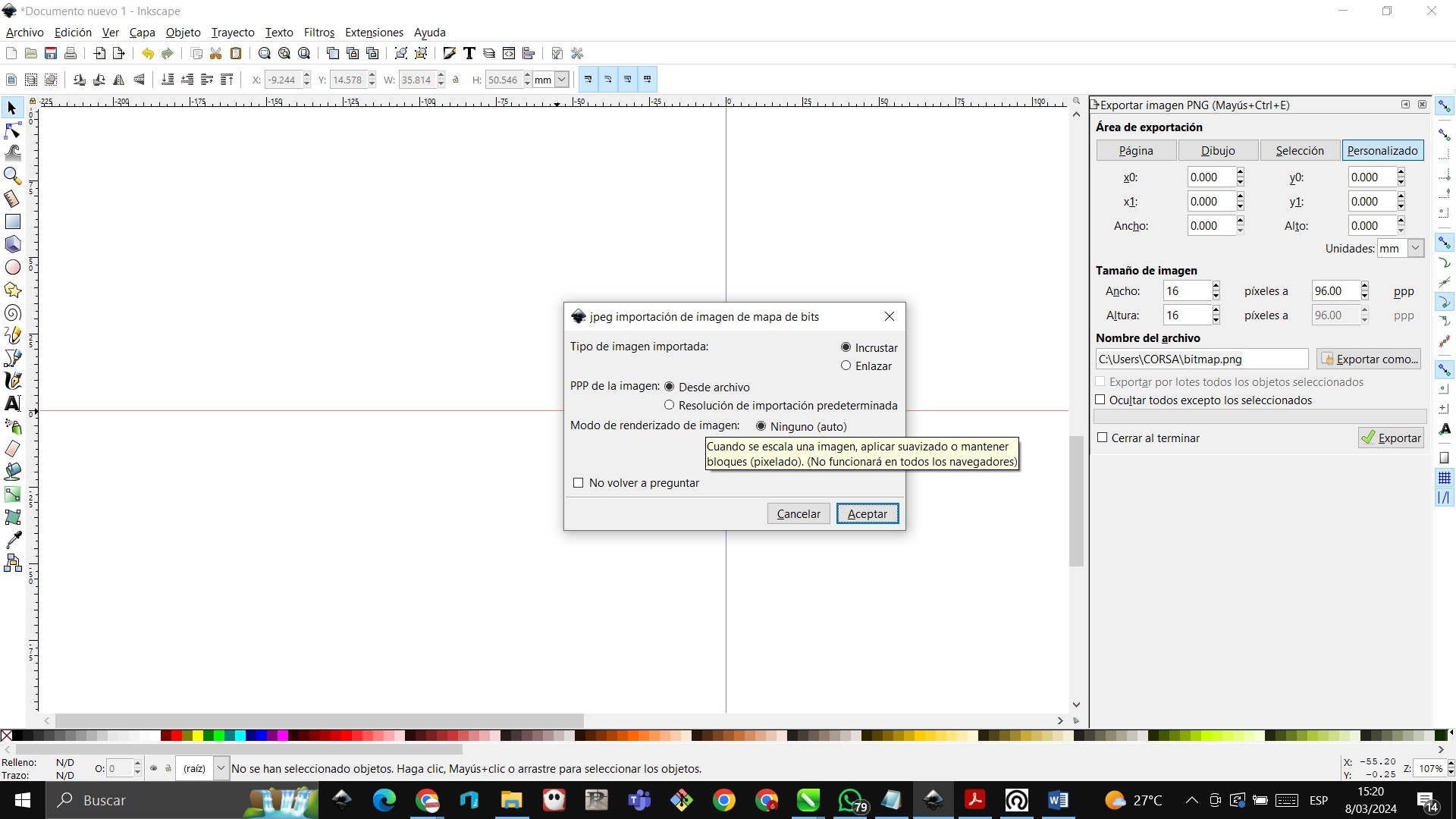

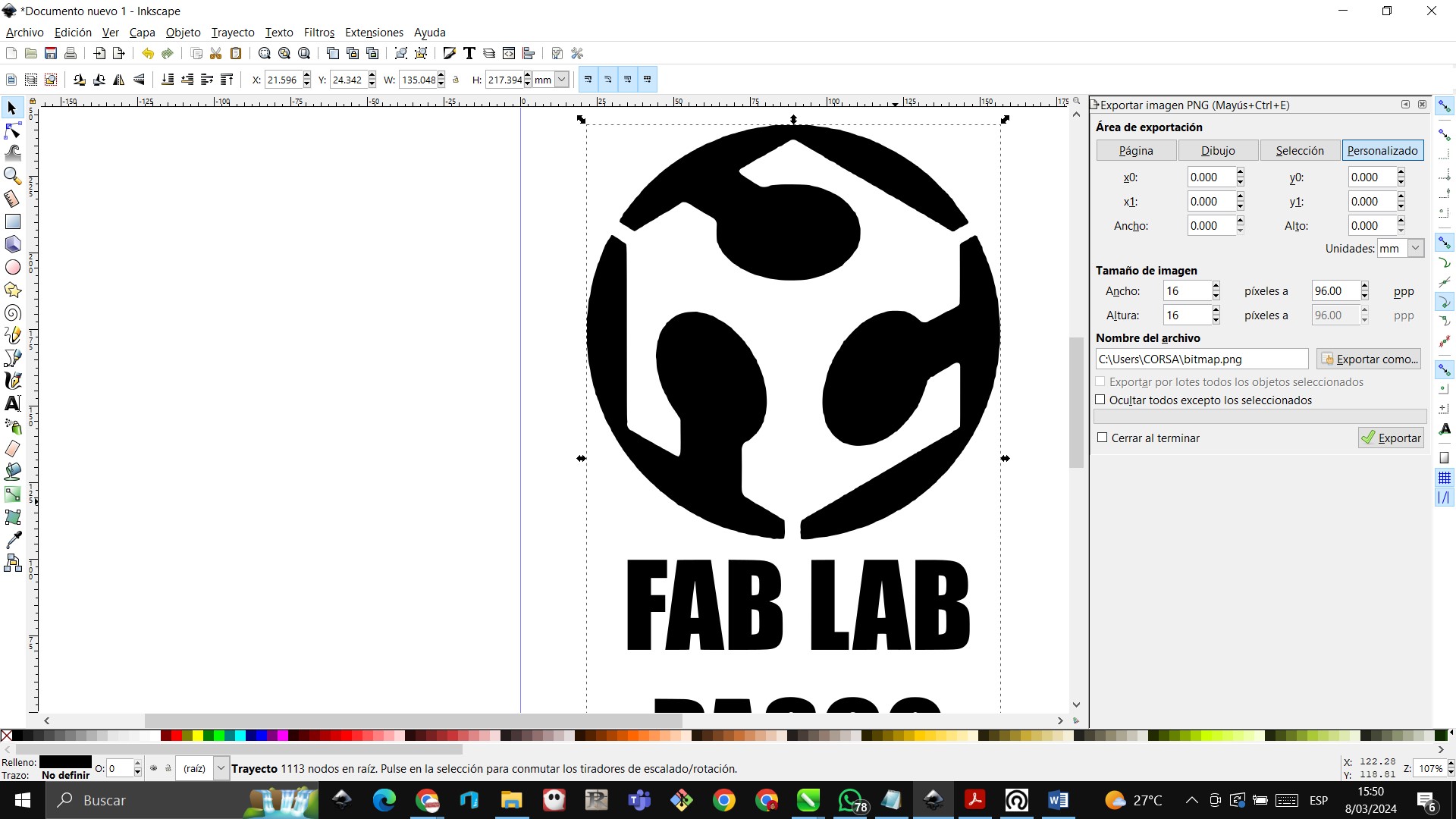

We open the Inskape software and import the image

We open the Inskape software and import the image

We are looking for the image to import, in this case it is the logo of the fab lab pasco

We are looking for the image to import, in this case it is the logo of the fab lab pasco

Then we accept to finish the import of the file

b pasco

Then we accept to finish the import of the file

b pasco

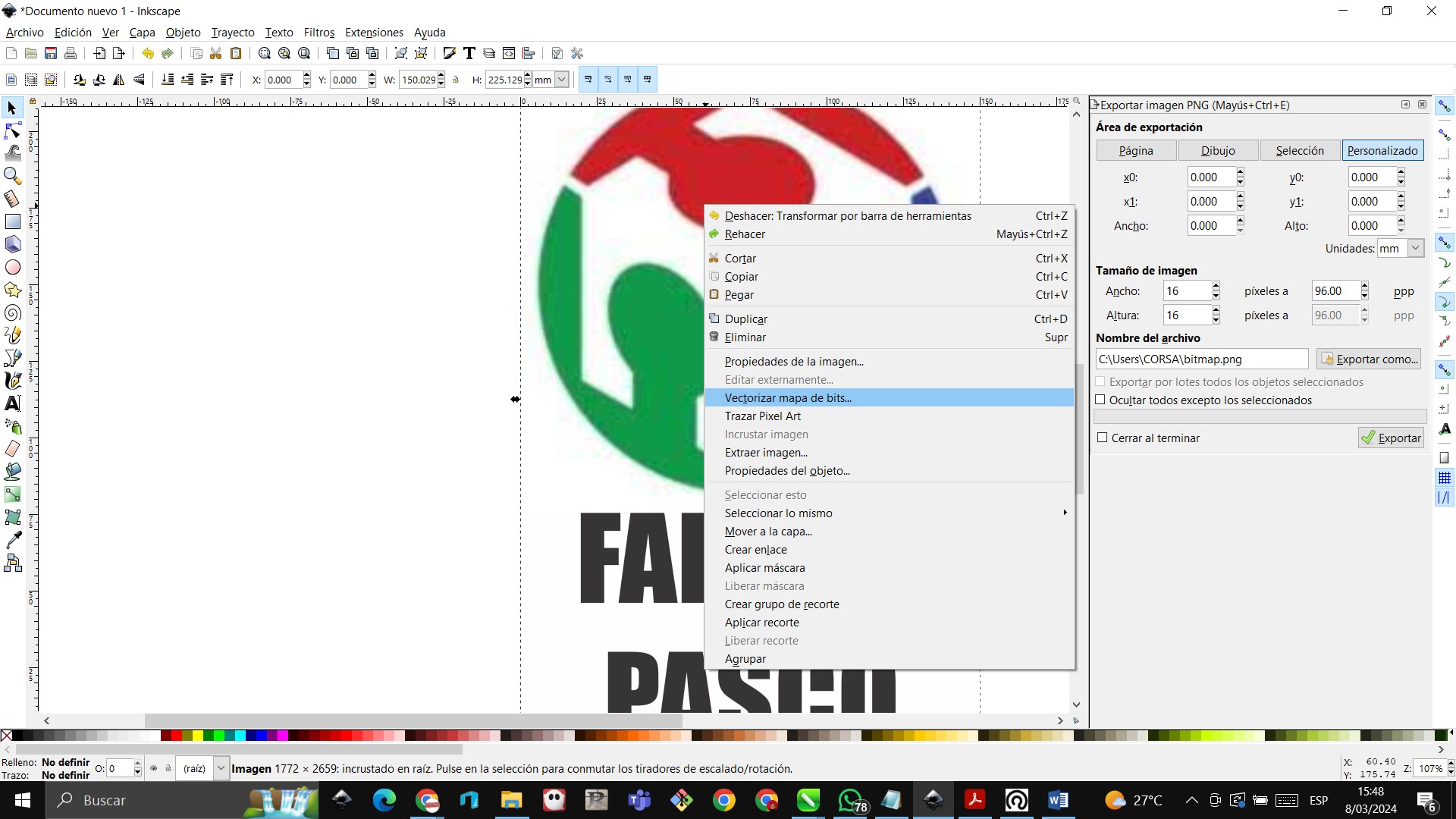

Now we have to vectorize for which we right click

Now we have to vectorize for which we right click

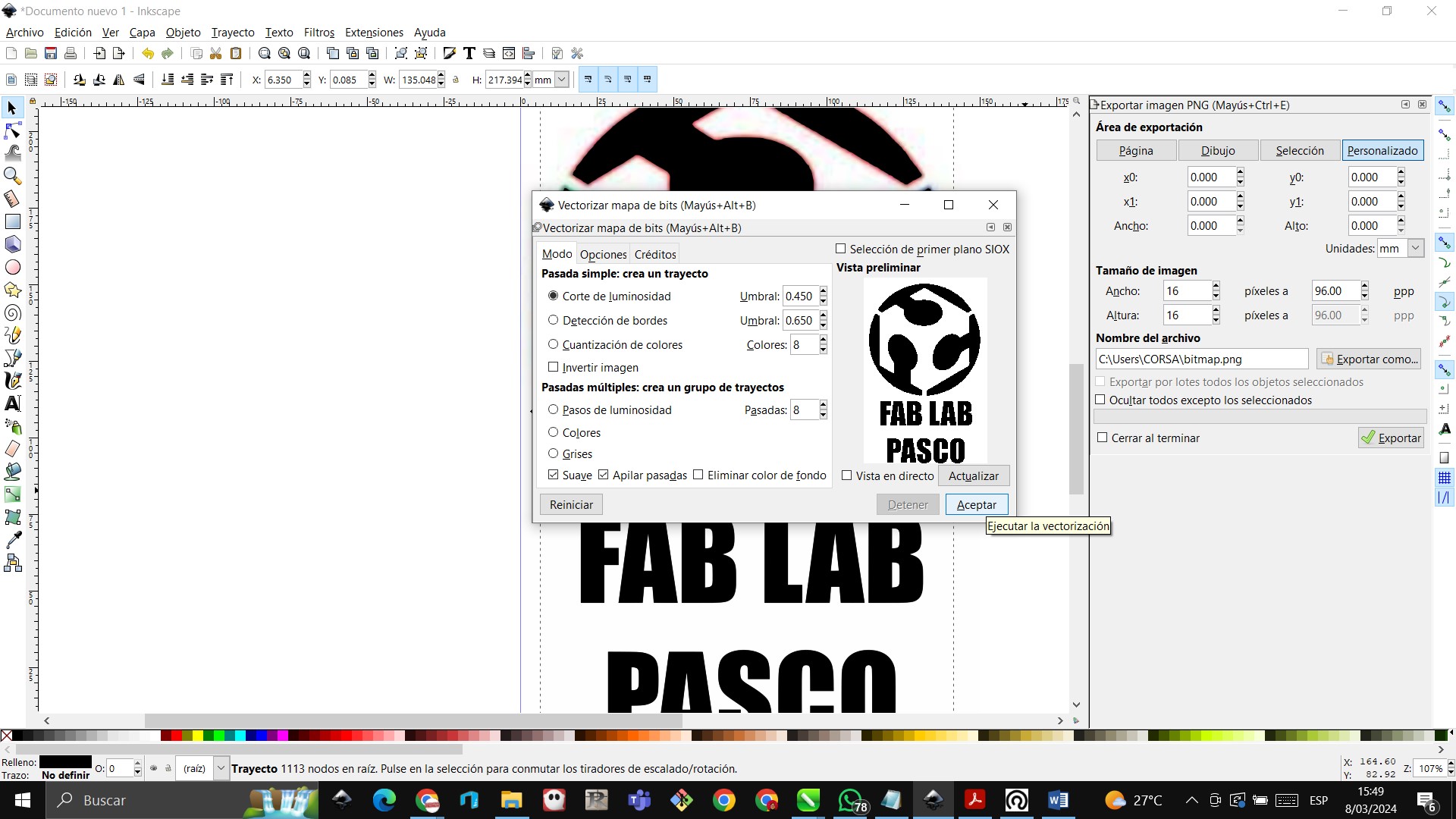

We get vectorized bitmap and we click on accept

We get vectorized bitmap and we click on accept

Once vectorized we get 2 images, the vectorized one and the initial image, which we eliminate and we are left with the vectorized one.

Once vectorized we get 2 images, the vectorized one and the initial image, which we eliminate and we are left with the vectorized one.

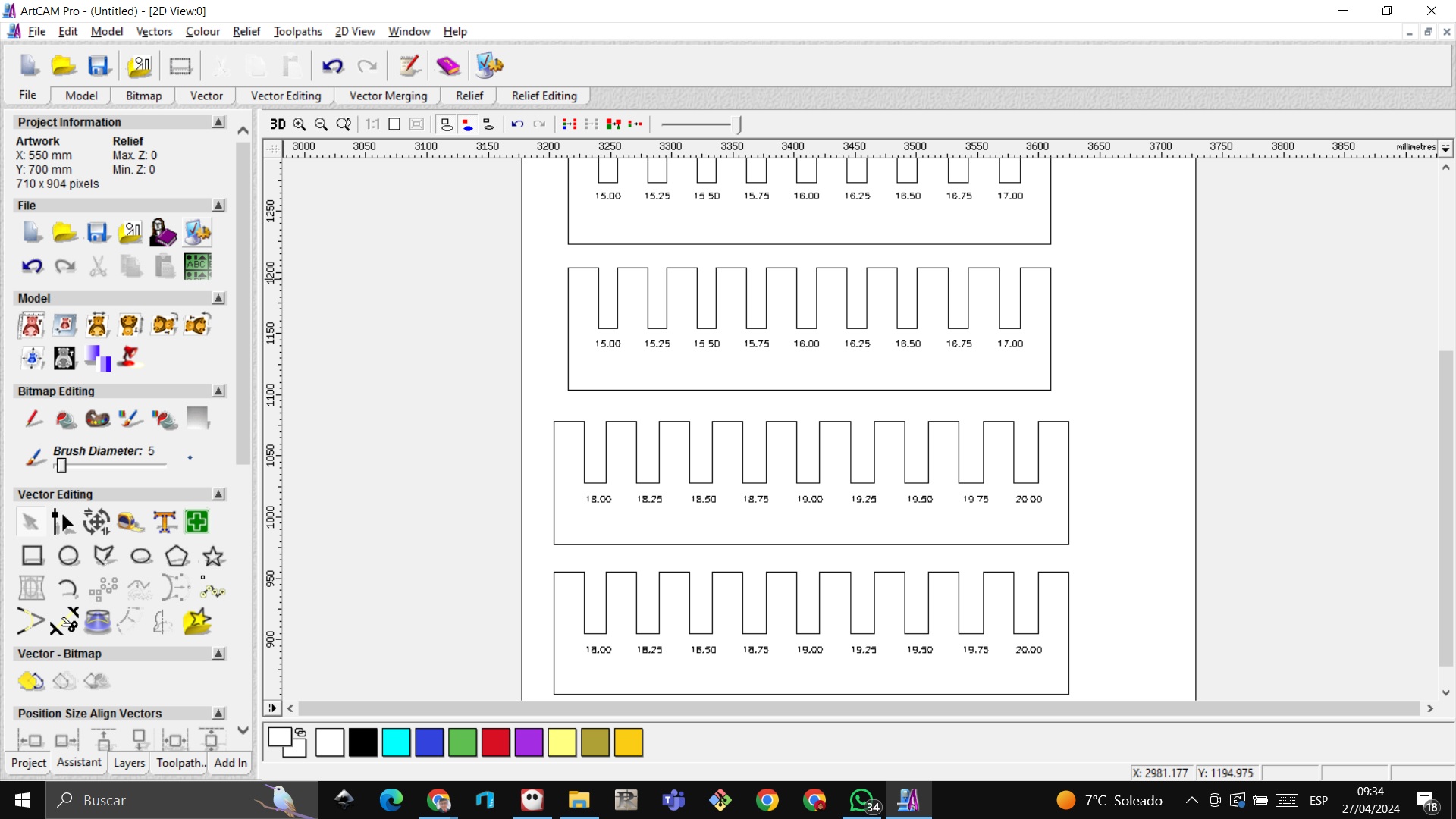

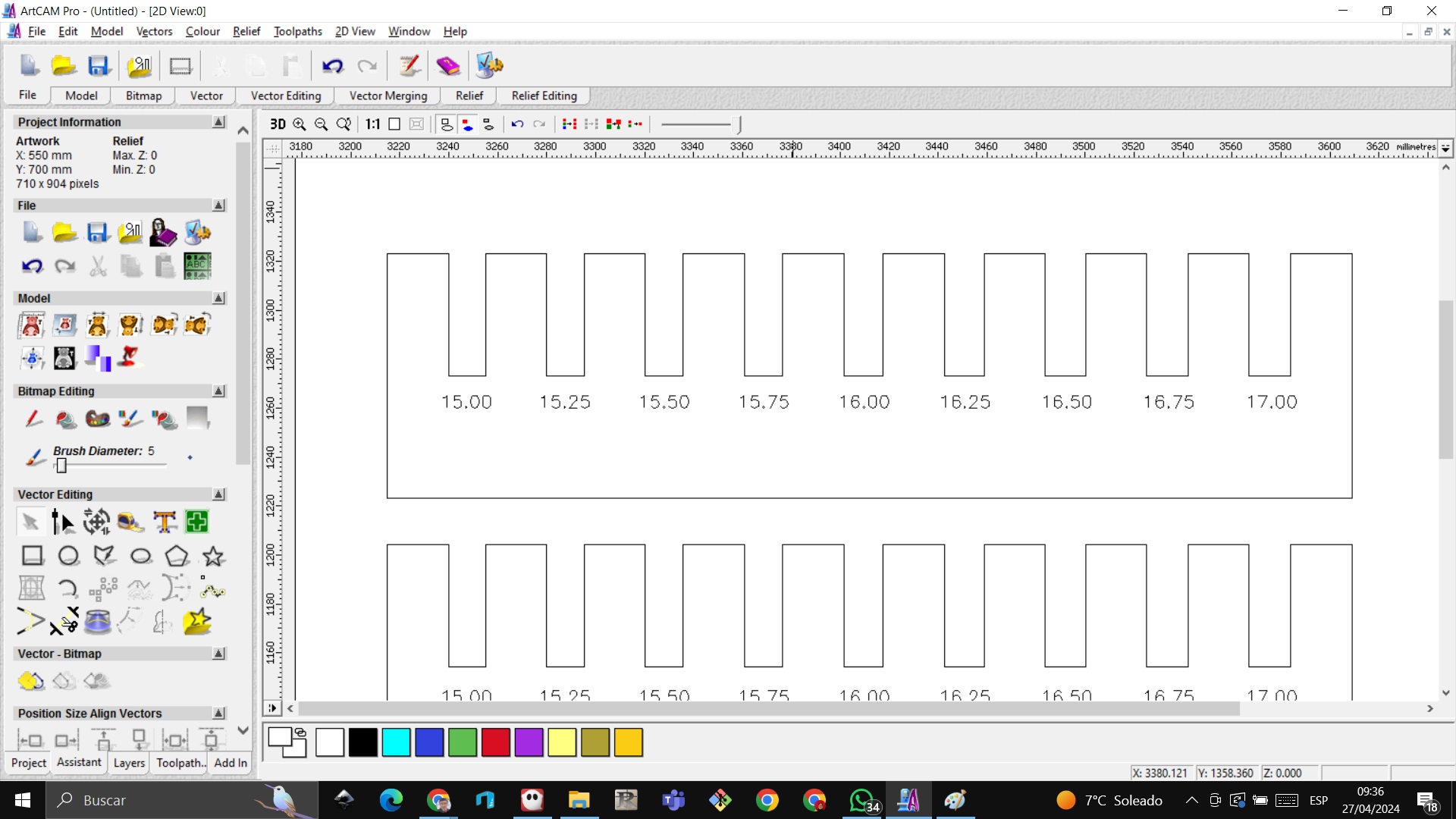

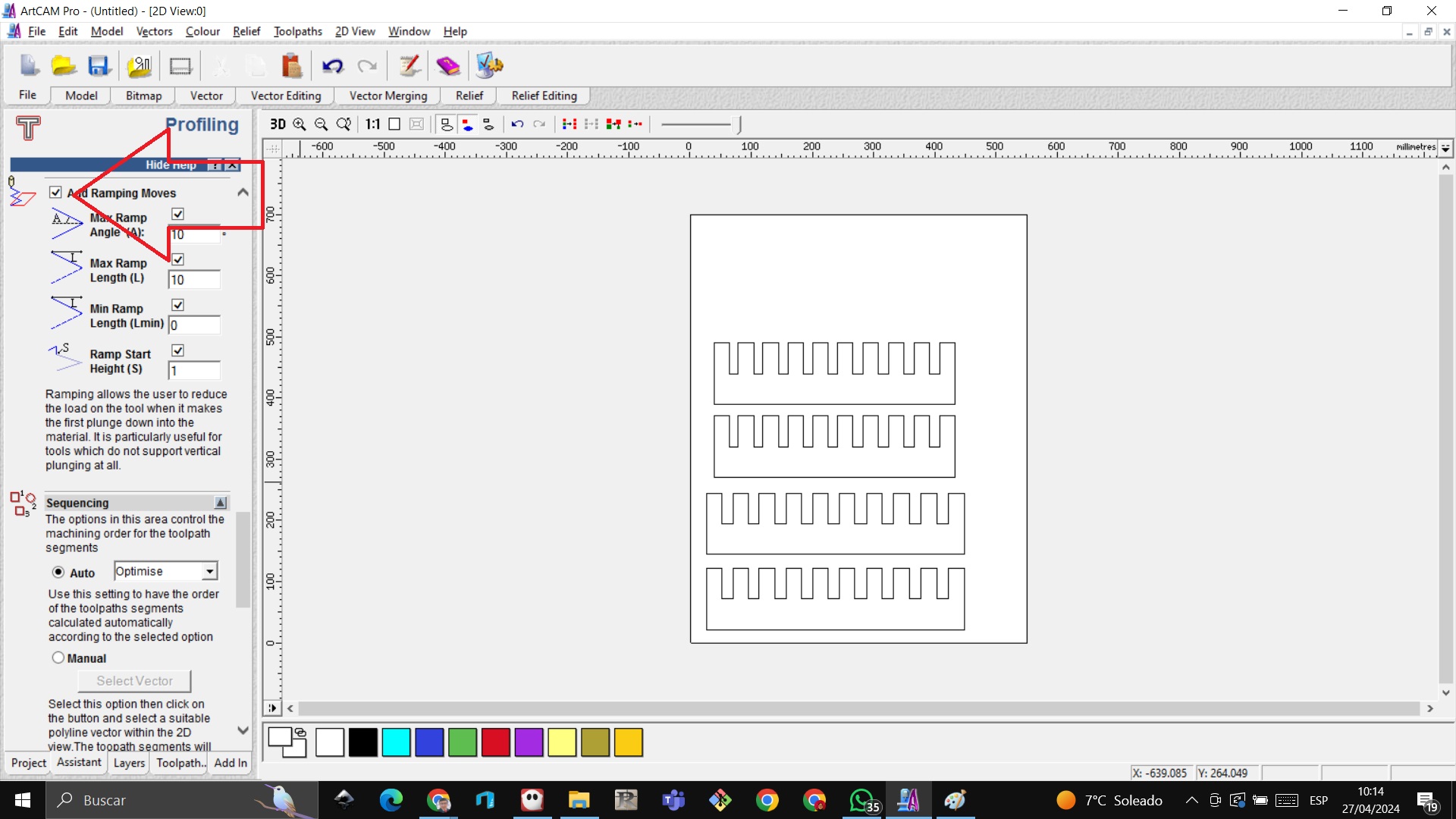

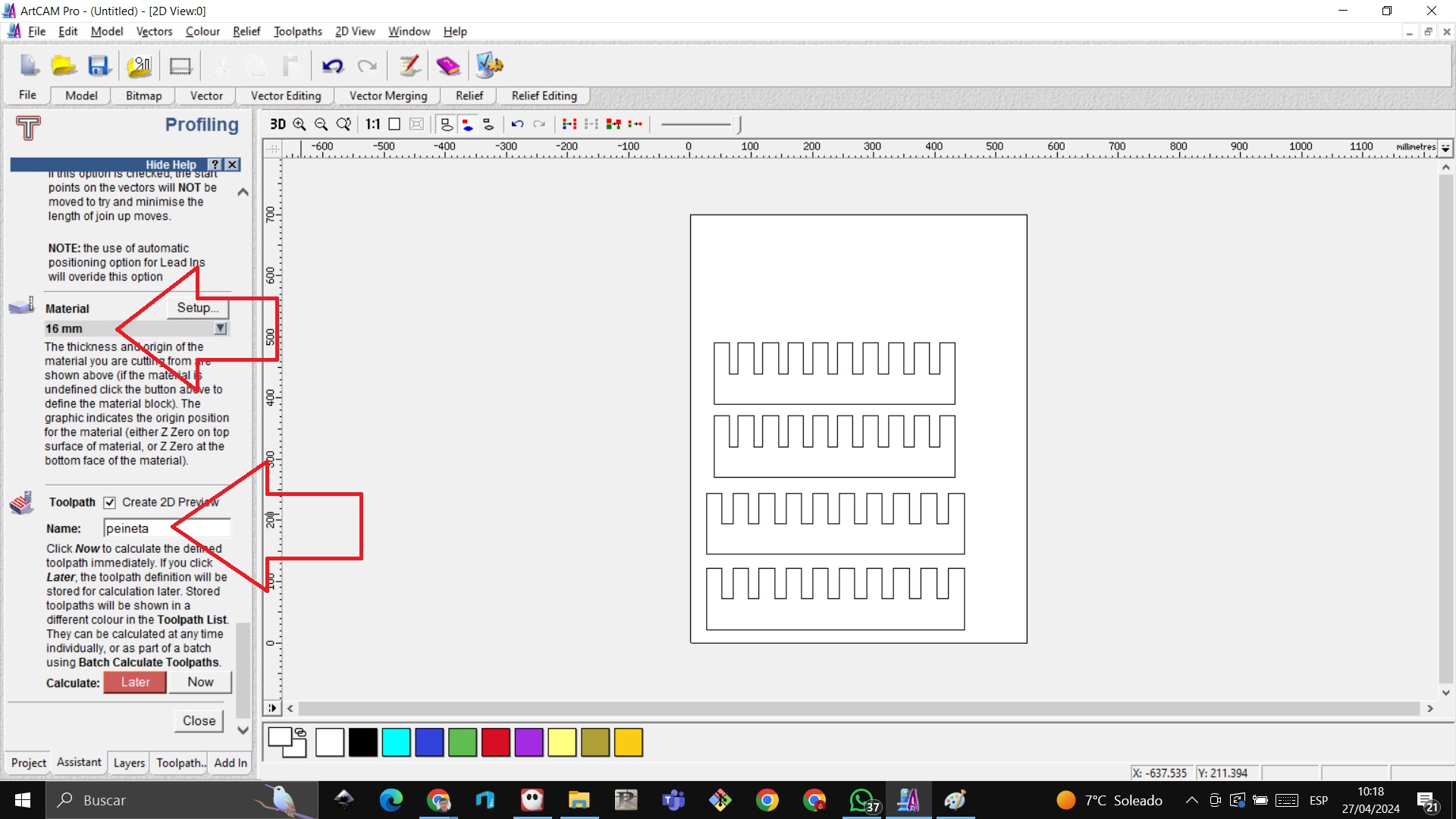

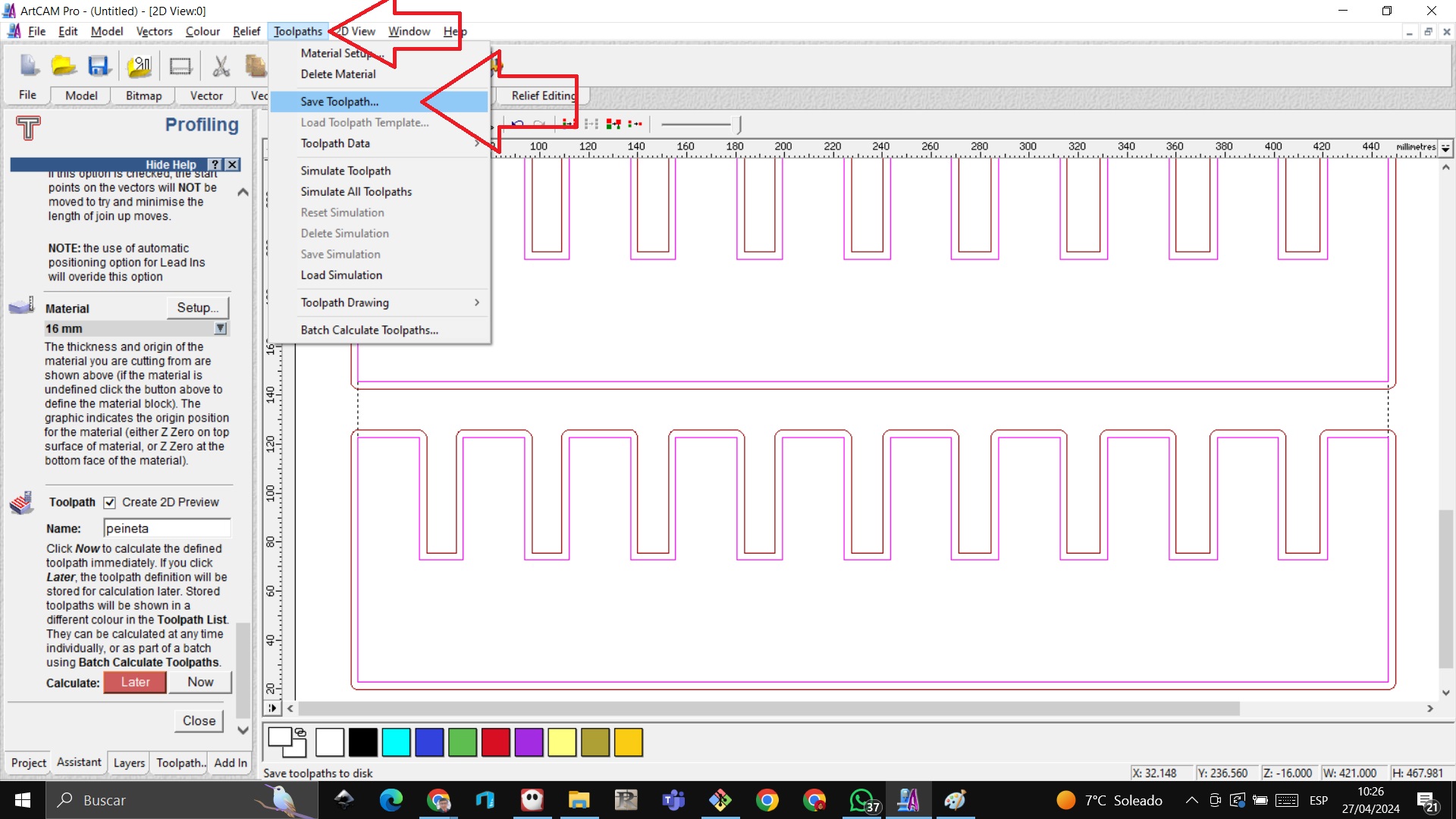

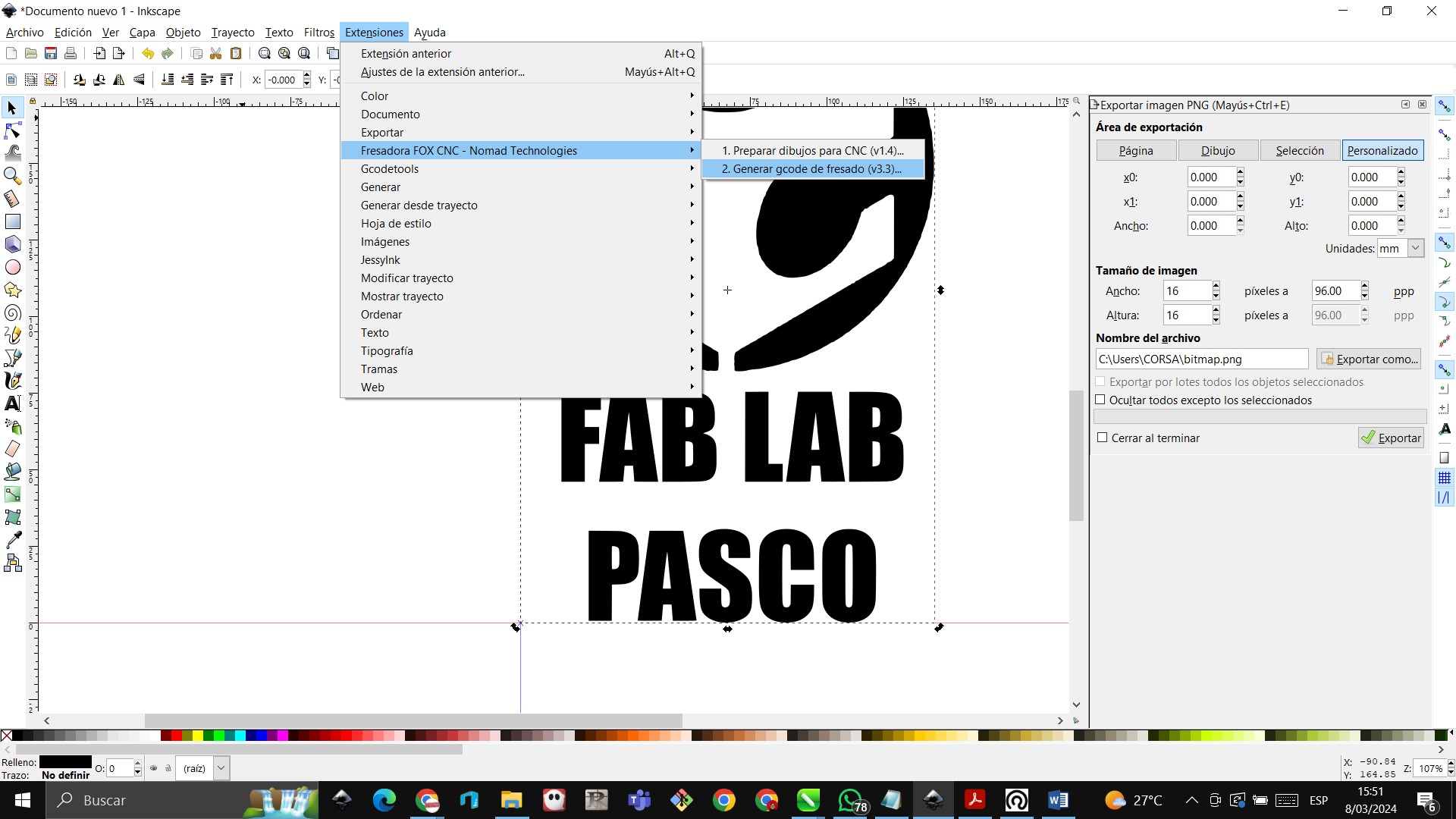

We go to the extensions tool and look for the red fox cnc milling machine and generate its gcode and place the parameters for the test exercise

We go to the extensions tool and look for the red fox cnc milling machine and generate its gcode and place the parameters for the test exercise

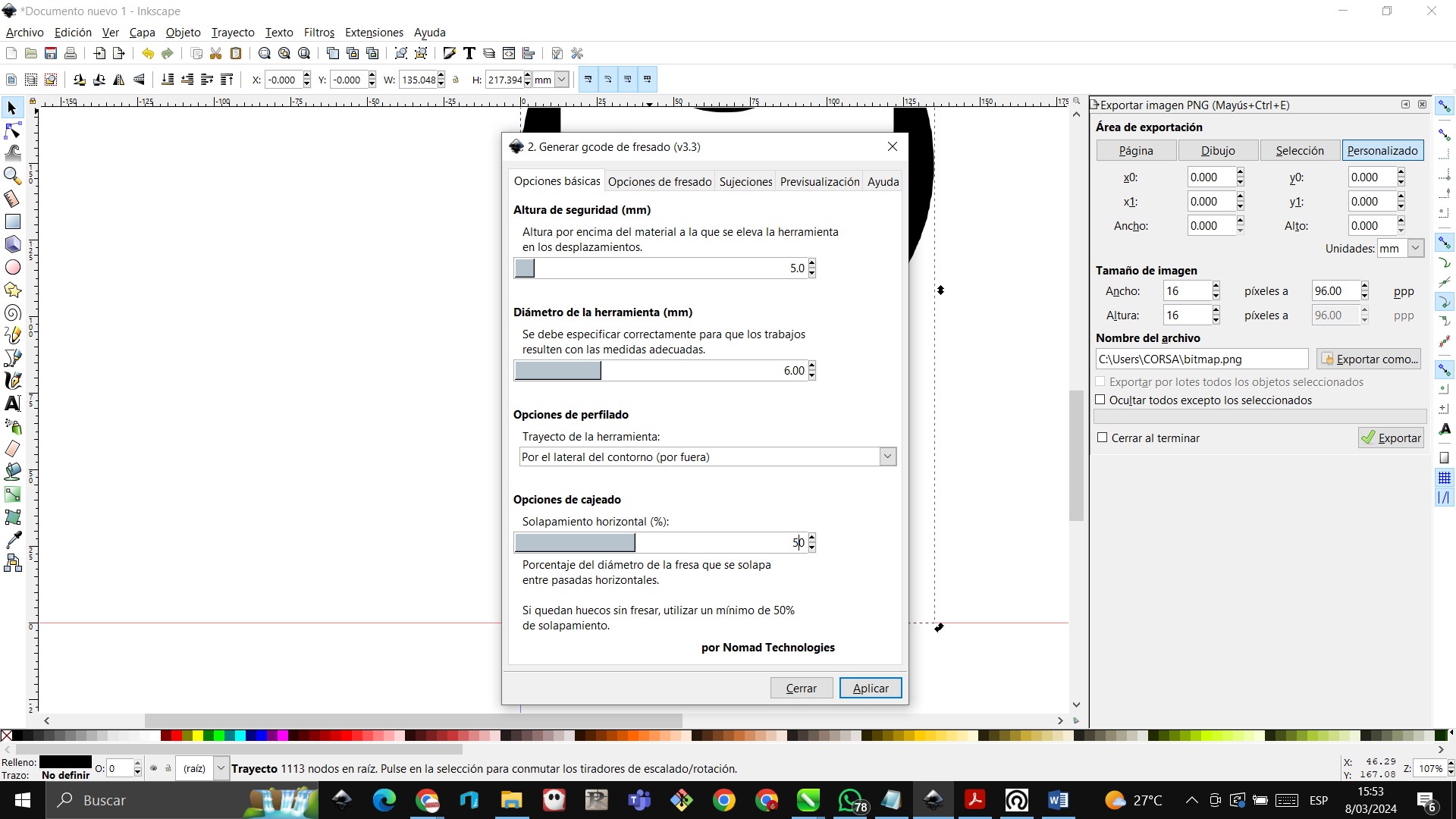

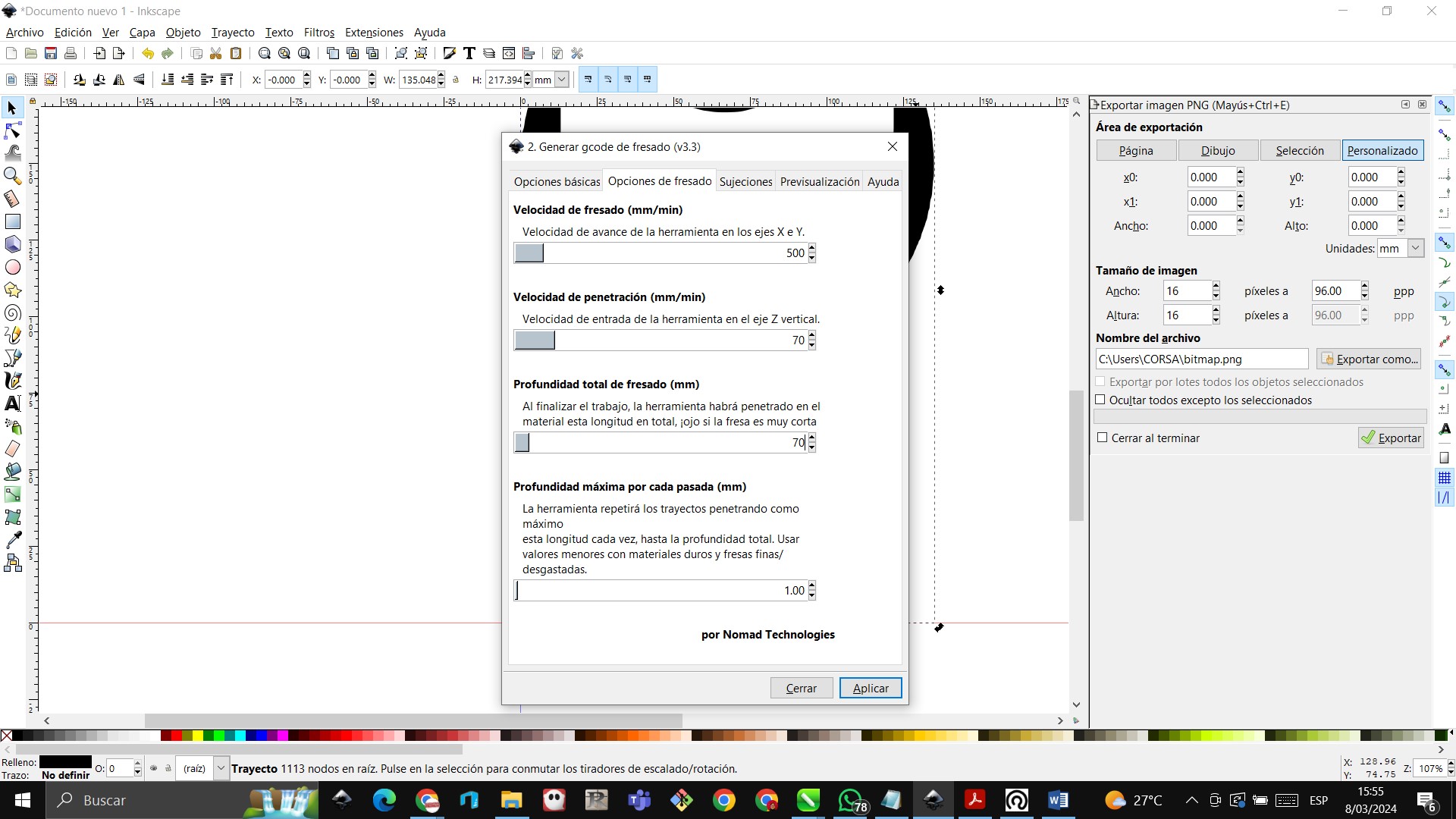

Here we see the basic options such as safety height in movements, tool diameter, horizontal overlap

Here we see the basic options such as safety height in movements, tool diameter, horizontal overlap

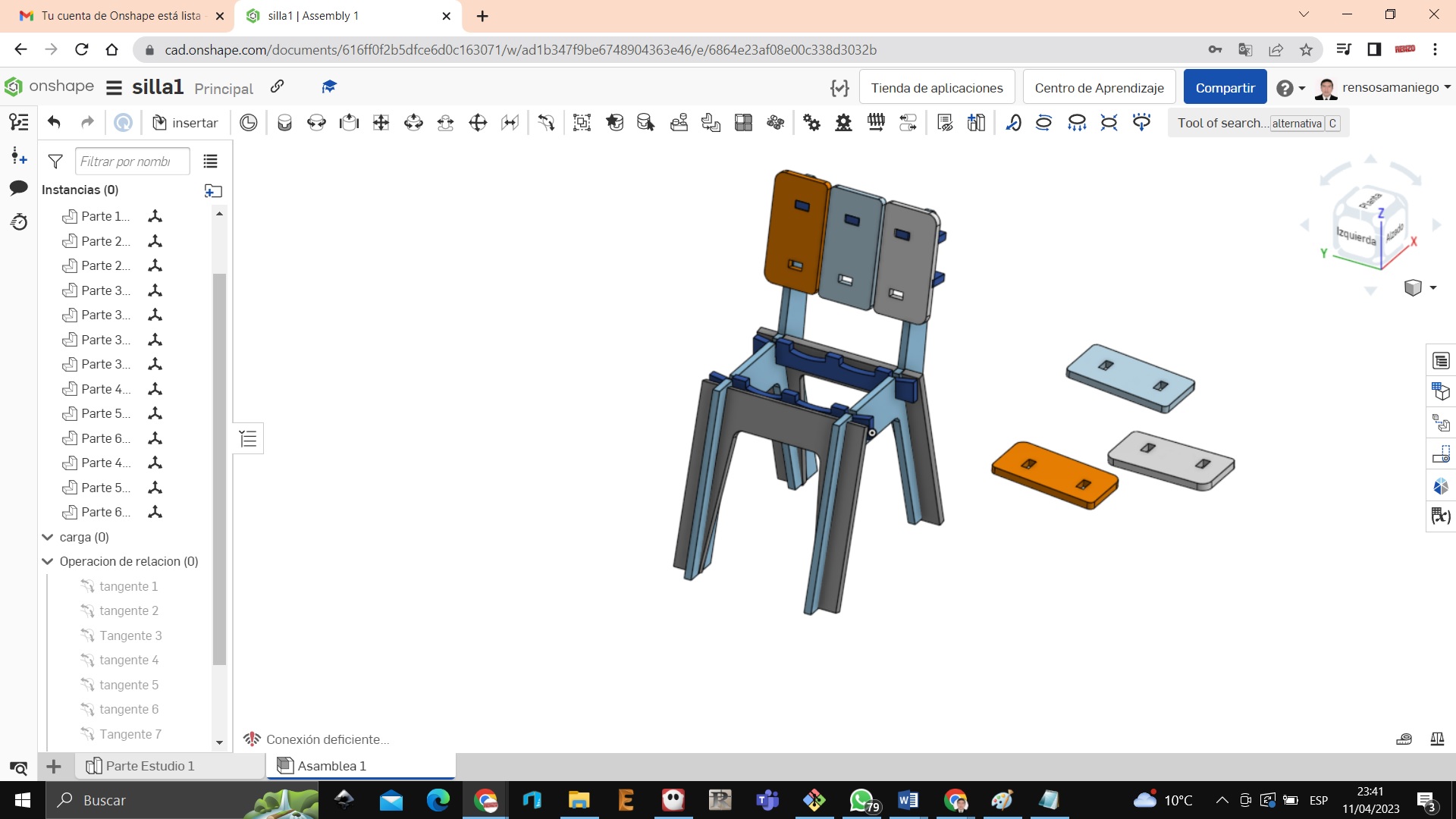

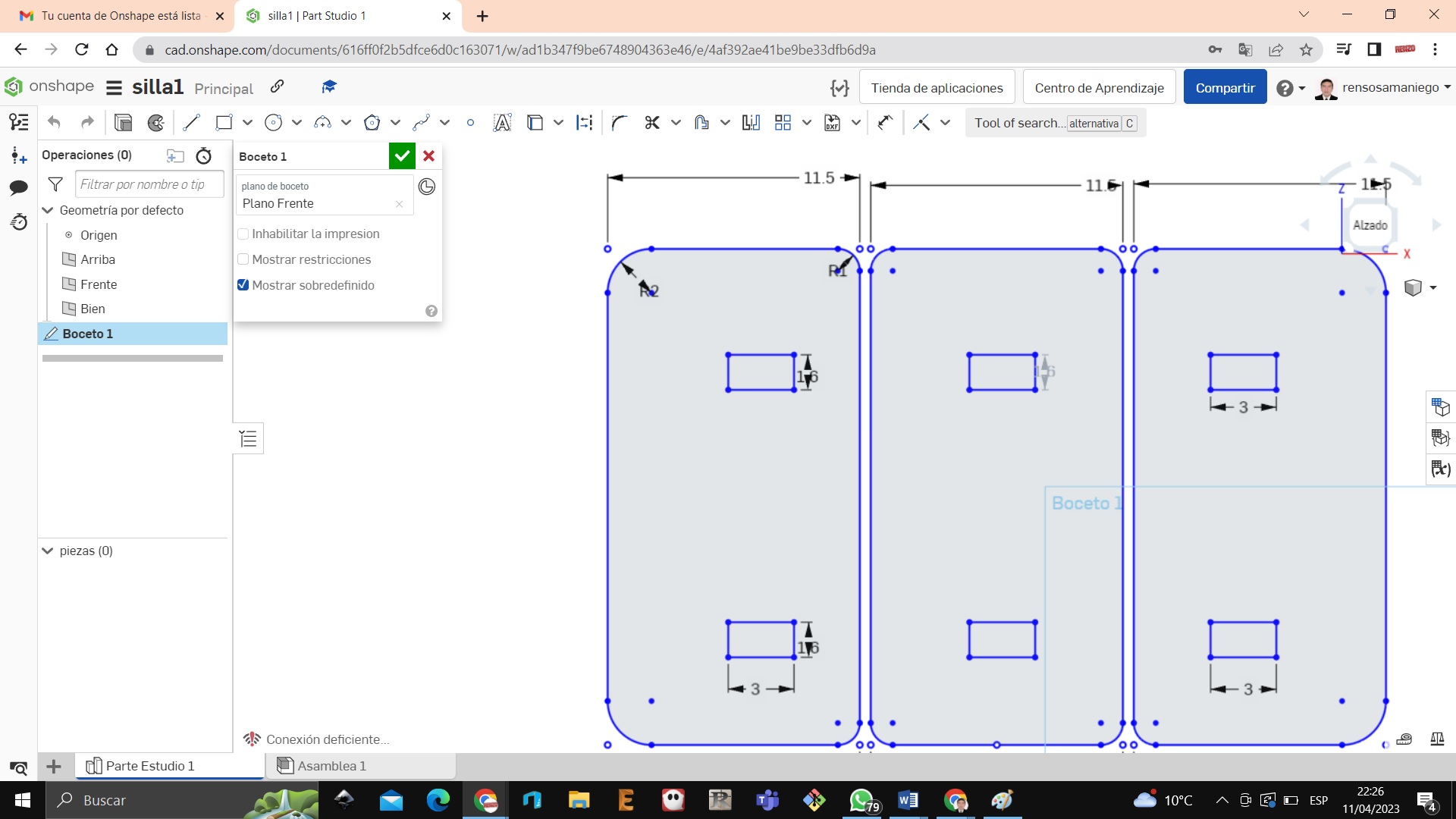

Creating a chair with onshape¶

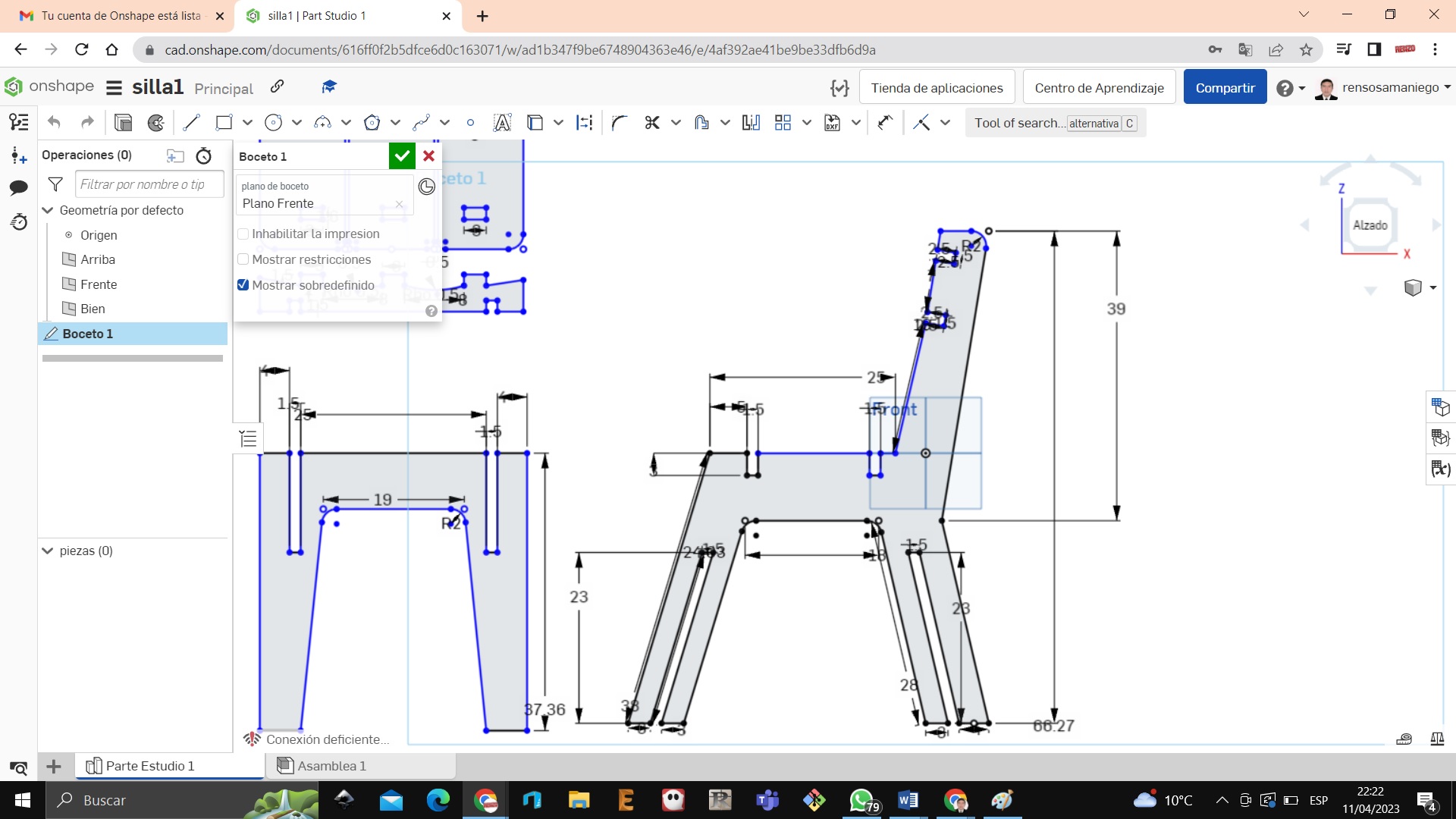

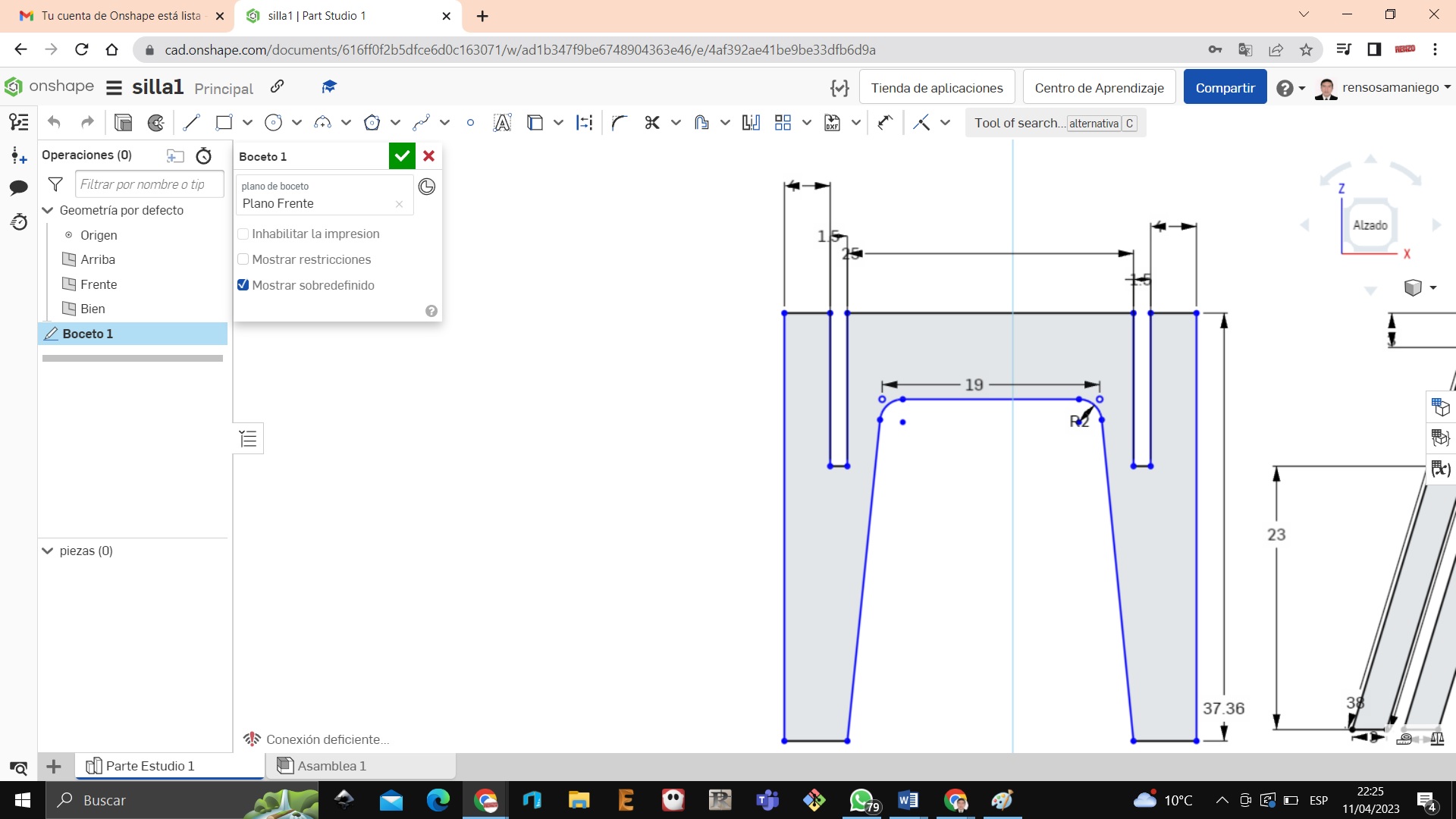

We entered the Onshape program and designed our assembly chair without bolts, we made the main part of the chair

Then we continue with the front legs, taking into account that they will be assembled without bolts.

Then we continue with the front legs, taking into account that they will be assembled without bolts.

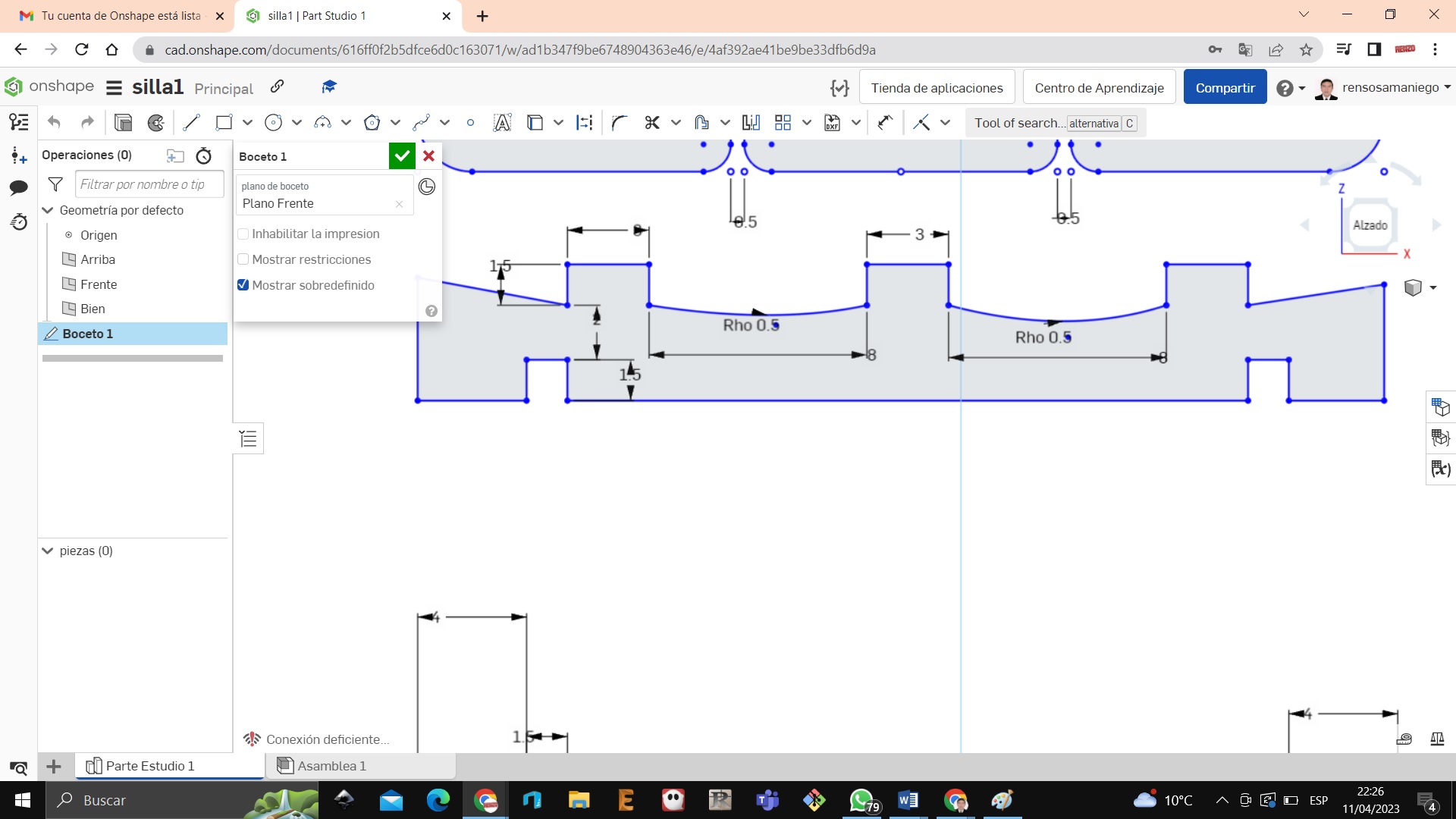

These parts are the support of the chair to sit there are 2 and for the back there are 3 units

These parts are the support of the chair to sit there are 2 and for the back there are 3 units

Now it is to make the back of the chair, do it in 3 parts

Now it is to make the back of the chair, do it in 3 parts

Then extrude all the work to 1.5cm

Then extrude all the work to 1.5cm

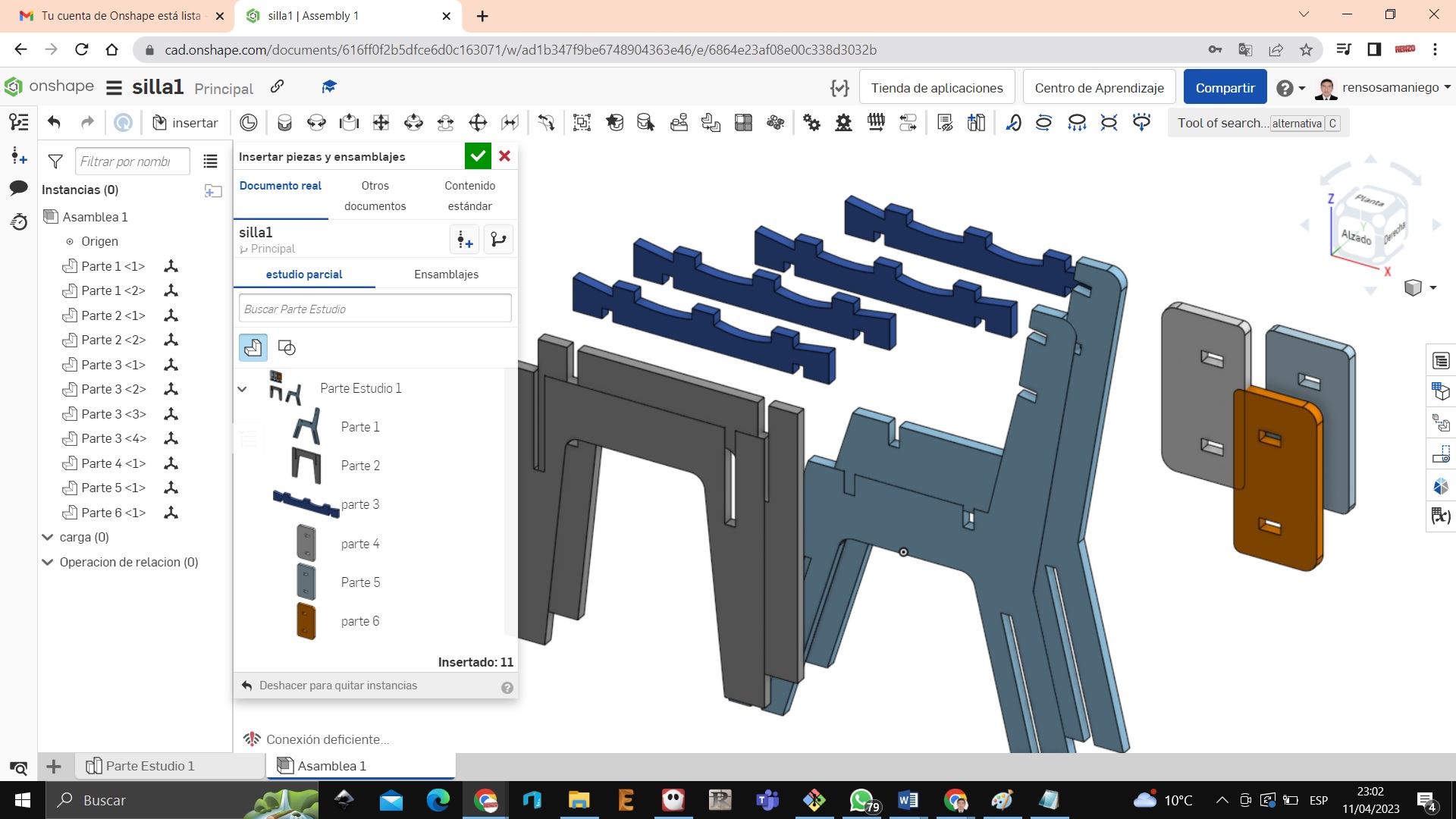

Assemble the chair entering the molds we need and duplicate it

Assemble the chair entering the molds we need and duplicate it

Assemble the parts of the chairs with the tangent relationship tool to join the parts

Assemble the parts of the chairs with the tangent relationship tool to join the parts