Project Development

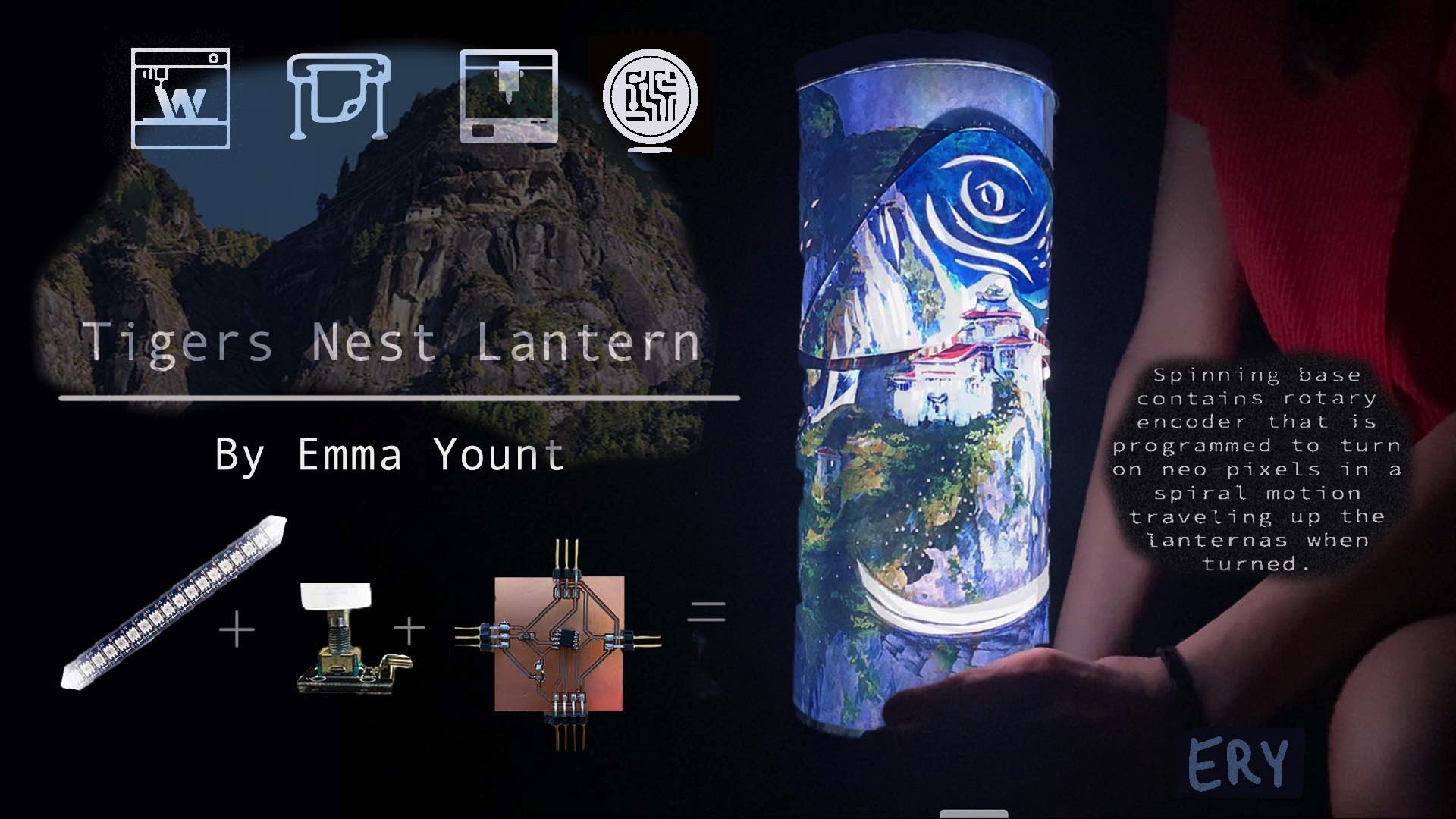

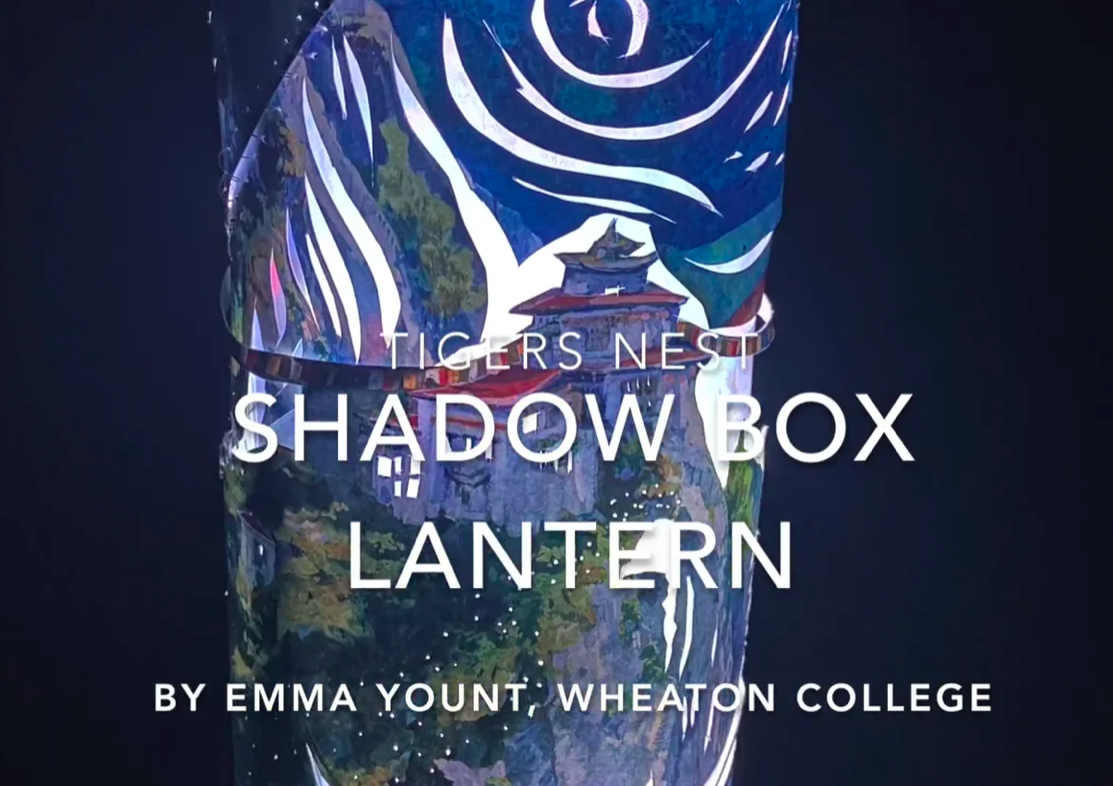

Shadow Box Lantern of Tigers Nest

About My Design

~Questions to answer~

What will it do:

lantern that can rotate and lights turn on in a spiral up the design as a person physically rotates the baseWho has done this before?

Shadow box/tunnel book artist Andrea DezsöLamp artist design I am inspired by

Led rotary encoder demo inspiration

What will you design:

artwork on lantern, cut out sections, code that turns on lights when turned, Base electrical components, 3d modelWhat Materials and Components will be Used:

paper will be used, lights will be used, Link to my inventory final expensesWhat Parts and Systems will be Made:

code for lights, lantern artwork was made using photoshop, Prototype for the turning base was printed and designed using the 3d printer and fusion 360what processes will be used:

link to video for neo pixel link to neo pixel codeWhat questions need to be answered:

How do I make the lights turn when rotated? Will all the parts I ordered work for my design?How will it be Evaluated:

My final project should be evaluated by the lanterns ablity to have the lights turn on when rotated and the craftmenship of lazercut paper cut out in the correct location of my 2d paper design Final Project Action Steps:

1. Design Lantern base and rotation device

2. Create 3D printed rotatation device

3. Test paper graphics already created during 2D and 3D design week in printed base

4. research code and connections for rotary encoders

5. Test out circuit board connections and code on breadboard

6. Create KiCad Schematic and mill board, solder parts and program!

7. design storage space for electrical components in lantern

8. take videos, photos and notes of process along the way!!

9. Put all components together and add artisitic finishing touches

10. write up design process on website and finish creating final video and poster

Update on Project Process

SO our school is completely gutting and renovating the building where our lab is located. In late march our lab had to completely move out and relocate to a building across campus. But then...about a week after the lab finished moving in, the fire department shut our lab down because of safety concerns. So all our lab equipment had to be dispersed across campus to various buildings since not just one building could contain our lab. I did not think this would be a big issued until the location of the soldering station (digital lab) did not have enough female to male wire connector, or someone took the usb port back to the main lab (bookstore lab) when I was working in the digital lab… or I was in the bookstore coding and then fried my attiny and had to walk back to the digital lab to solder one pin...or when there was no working multimeters in the bookstore or when I the power supply was in the digital lab or was it in the fiber lab?? Here is a photo of my step count during the day. I believe I went back and forth over 15 times gathering everything I needed just to work on my board. I now all went to the soldering stationThis was a bit of a frustration. Our fab lab was divided across campus because our initial new location was shut down because of the fire department and safety issues of having all our lab tools located in the converted book store now digital lab.

So my time line plan to finsh my project got pushed back 3 days when I was having significant issued with milling, soldering and coding my circuit board and led lights. Read more about these struggles in Input Device week

For the full finished process of making my lantern View on Final Poject page