Project Management, Principles and Practices

(Week 1)

This week's Assignment was to understand the principles and practices followed at FabLab, which helped me learn, what exactly are we going to do in the upcoming weeks. In a week's time, I learned the basics of HTML, CSS, GitLab and even decided and sketched my final project. I understood the use of different commands used in terminal and how to use terminal to perform various tasks and actions including installing and configuring Git. I also learned how to do documentation using HTML, CSS and JavaScript.

Computer Aided Designing

(Week 2)

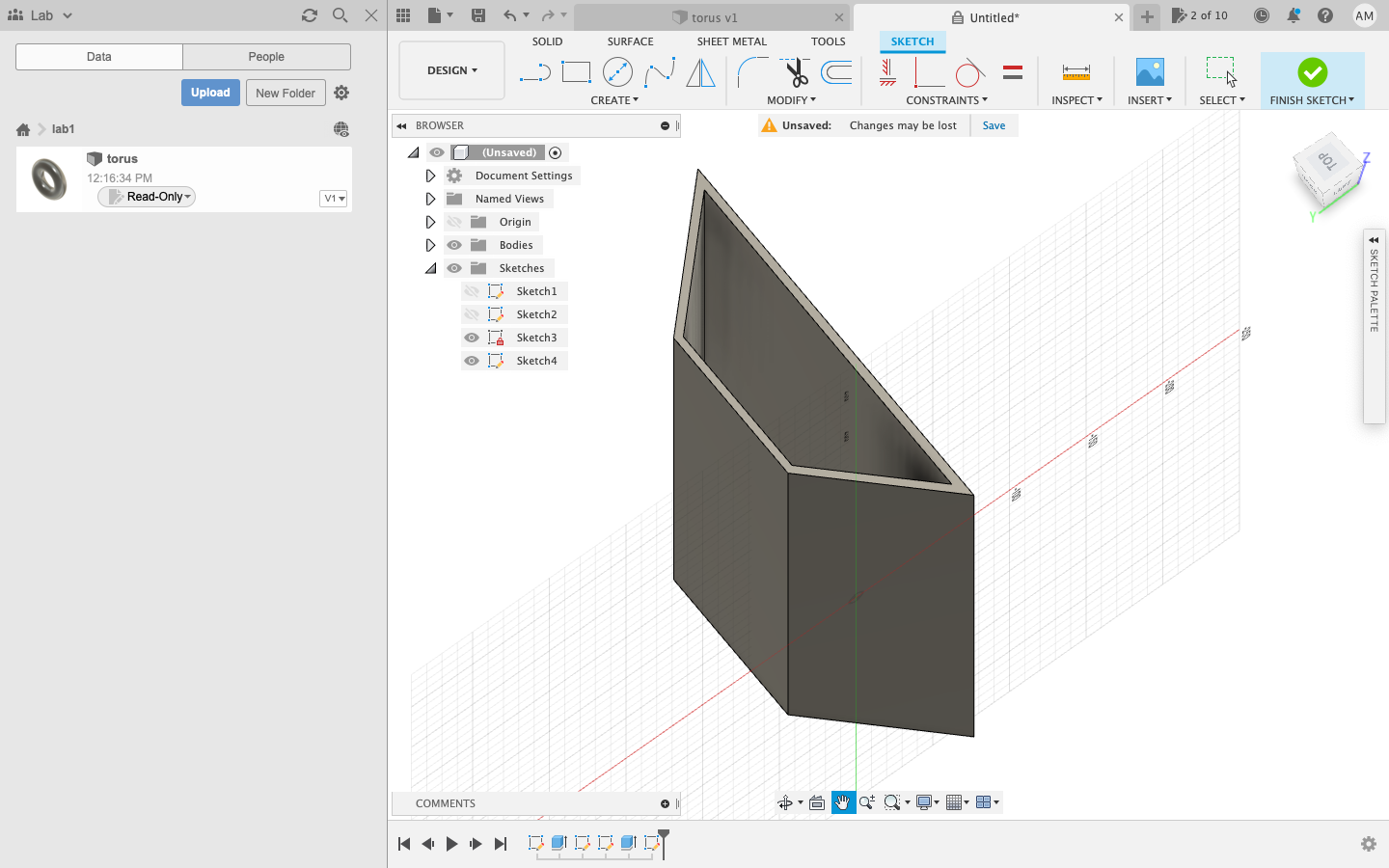

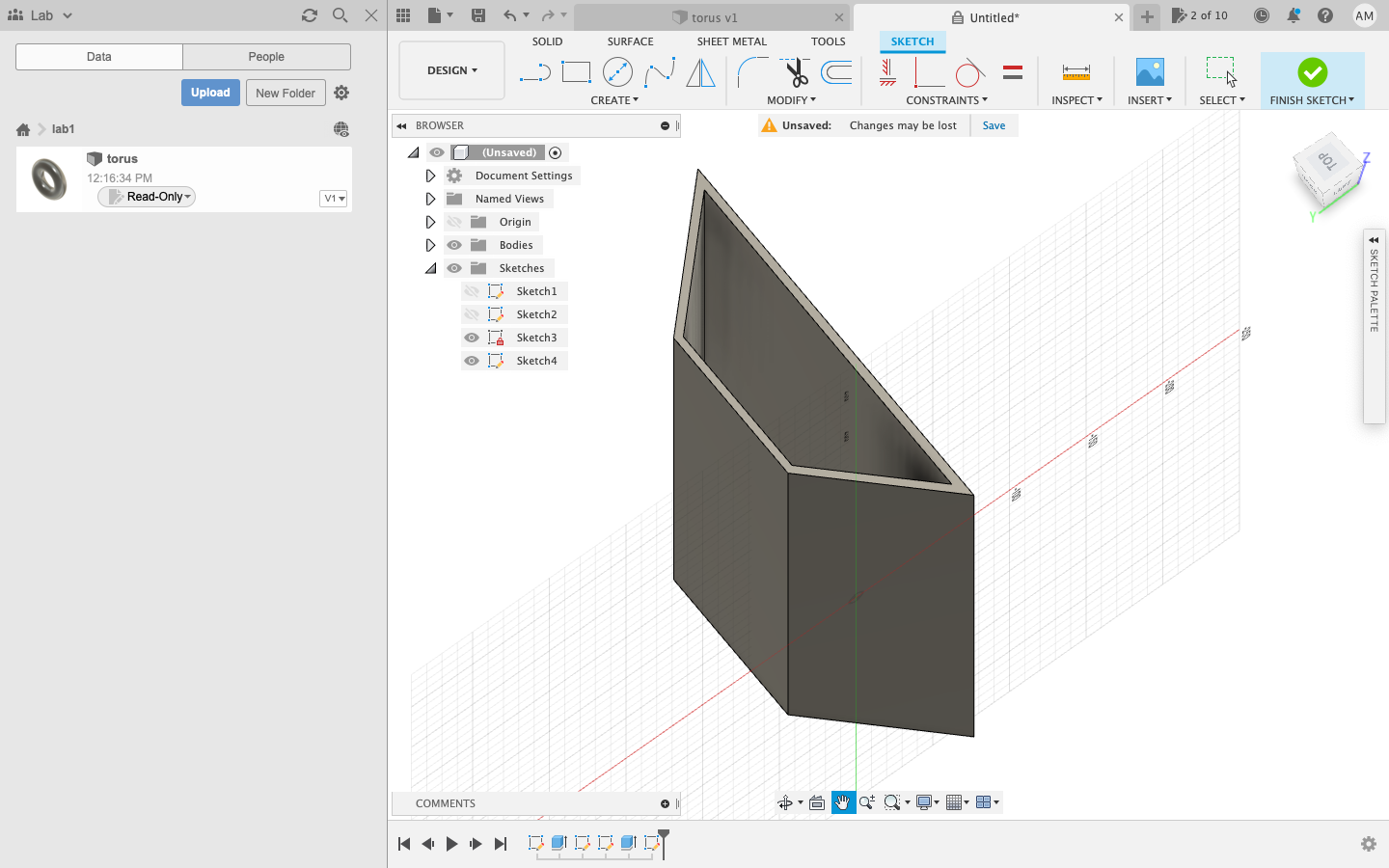

I was introduced to different kinds of design and how to do it. I got to try out multiple softwares to design Vector as well as raster designs in 2D design. I tried Gimp, Inkscape, Pixlr, Adobe Illustrator and Photoshop for 2D design and Blender and Autodesk Fusion 360 for 3D. This part was specifically fun because I was new to 3D design and i had to learn from scratch. I started by building and rendering easy shapes which was easy since Fusion has a really good User Interface. I initially could not try inkscape since i had issues installing the software. The available version of inkscape was'nt compatible on my laptop. I tried it out later on a PC in the lab. It was interesting as well as enlightening- the whole process.

Computer Controlled Cutting

(Week 3)

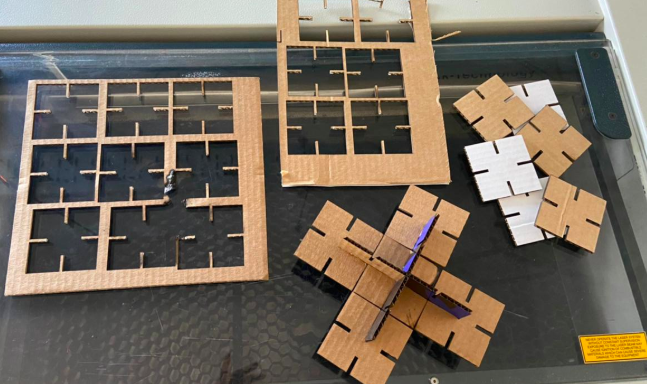

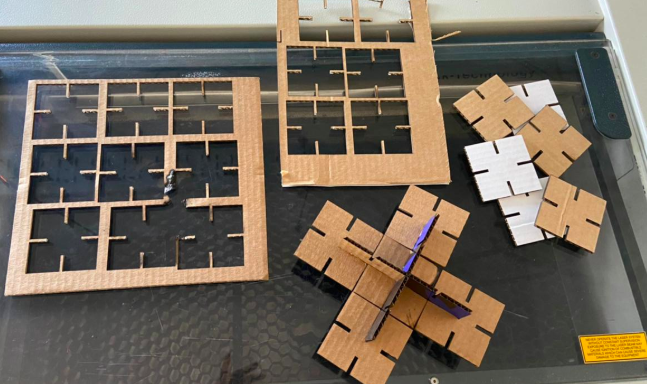

This week, was Computer Controlled Cutting where we got to learn, understand as well as work with multiple machines. I learned how to use a computer to control the working of these machines and how to control various parameters in these machines using a computer- Including speed, intensity, kerf, cutting force etc. I also learned about what types of designs are compatible for what machines and how mods are used and how it works.

Electronic Production

(Week 4)

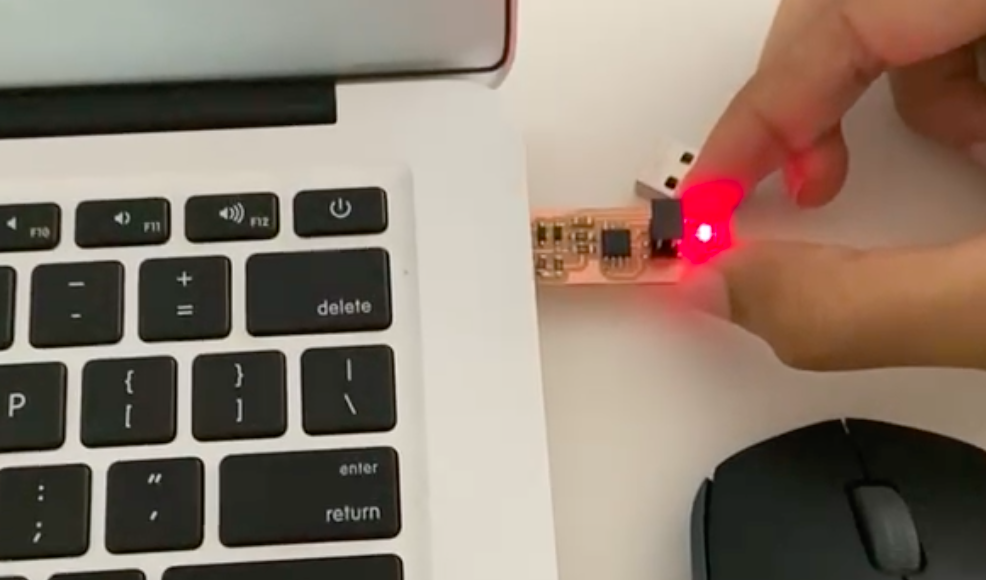

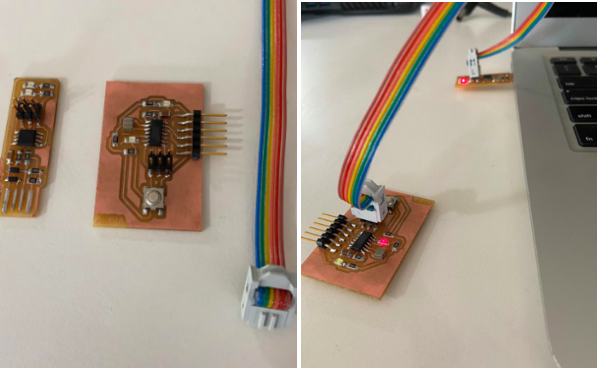

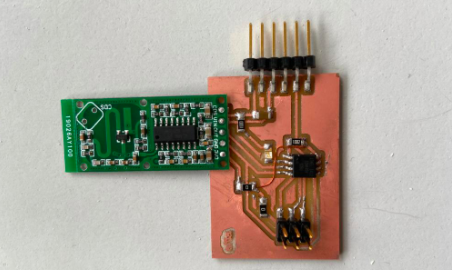

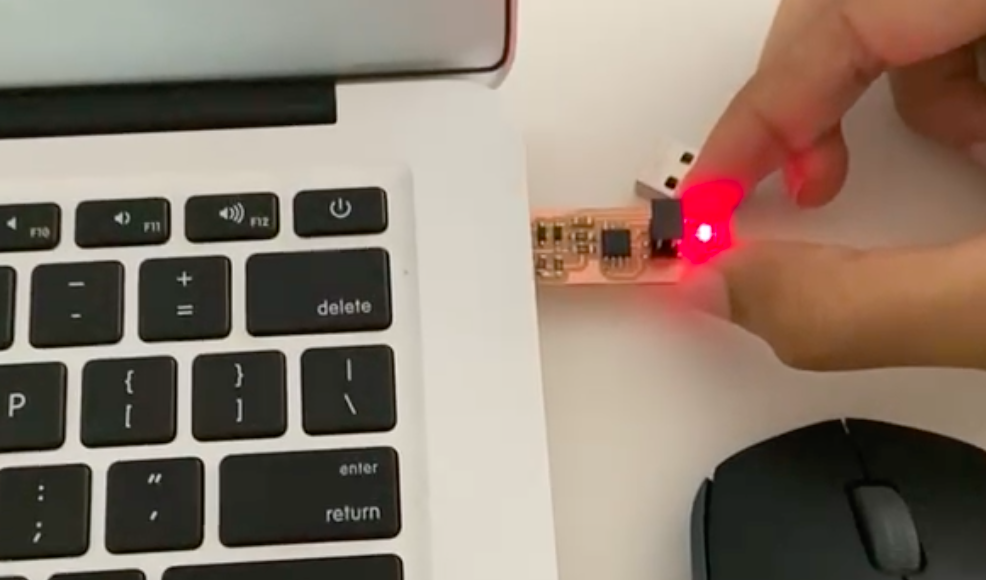

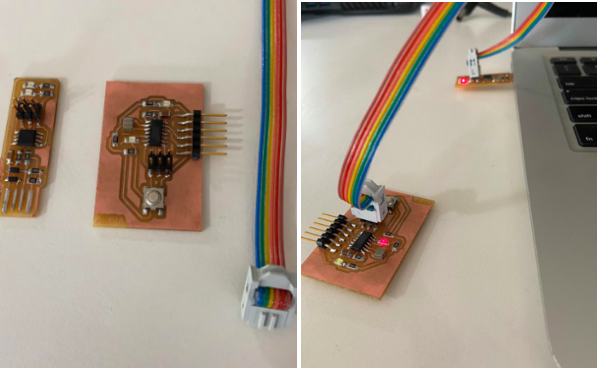

This week, for electronic production, we dealt with PCB milling machine and electronic components. We did soldering as well as programming.

The individual assignment for this week was to make an in-circuit programmer by milling and stuffing the PCB,

and to test it.

3D Printing and Scanning

(Week 5)

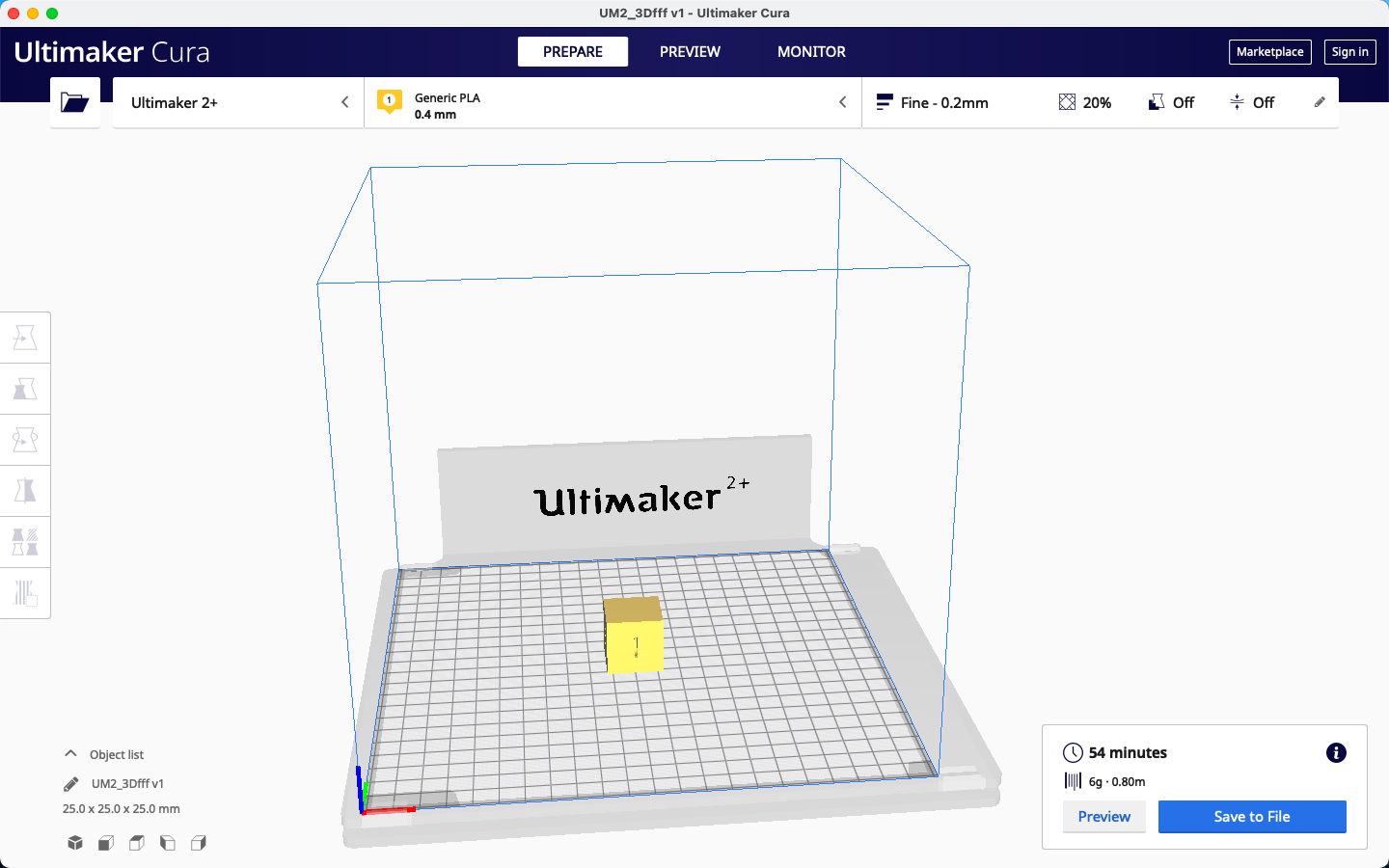

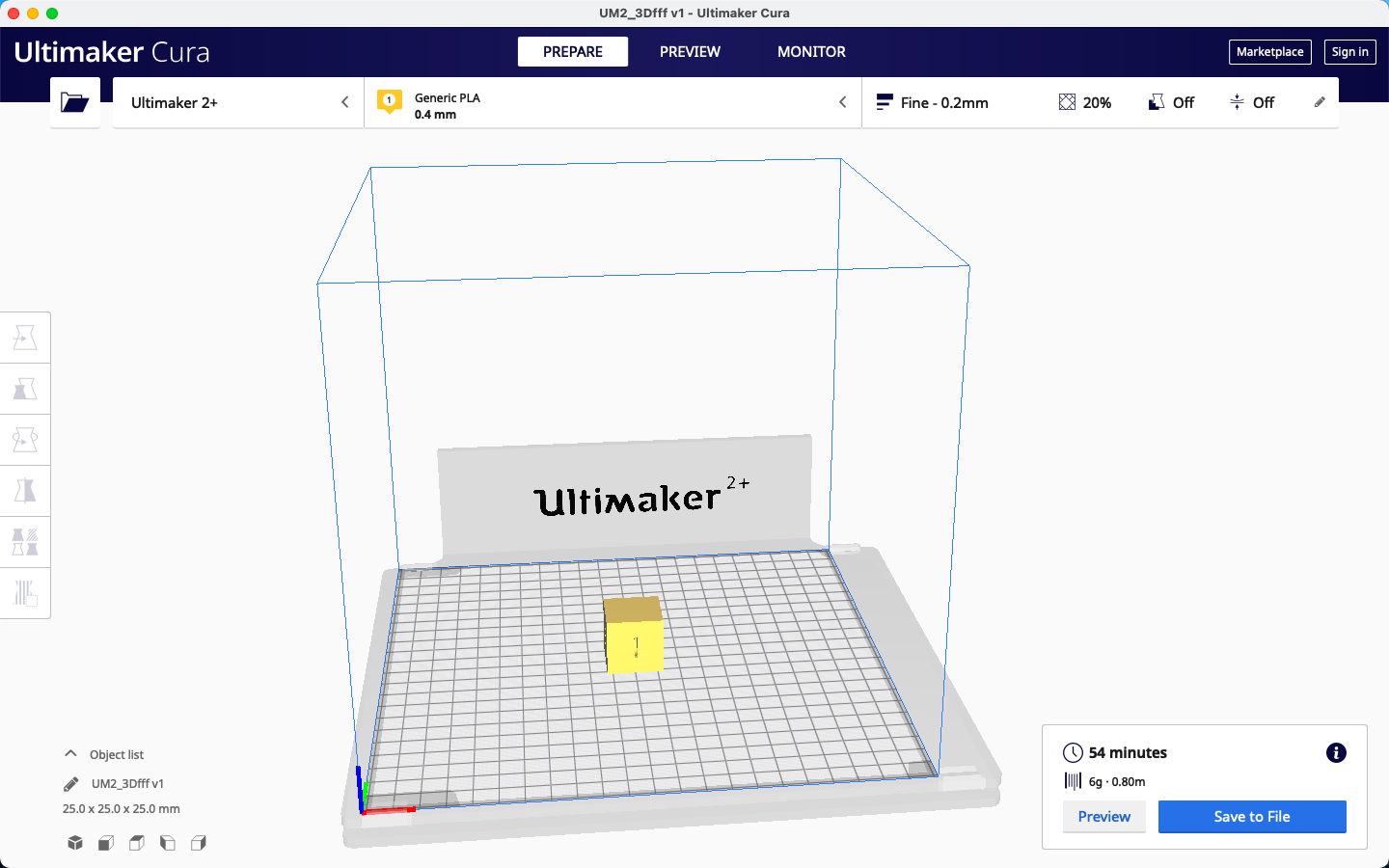

This week, fro 3D printing and scanning, we had both individual as well group assignments regarding the same. The group assignment was to test the design rules for our 3D printer. The Individual Assignment was to design and 3D print an object that could not be made subtractively and 3D scan an object.

We use the ultimaker for 3D printing.

Electronics Design

(Week 6)

This week's aim was to understand and design circuit boards and process them. We started off by understanding the basic components in a circuit, what they are used for and how it is supposed to arranged. Though I have a little experience soldering components before, soldering such small sized components to the precision was quite challenging. I also got to use components ive never used before. This week was fascinating and got me exploring an area that I have always loved to explore.

Computer Controlled Machining

(Week 7)

For this week's individual assignment we had to make something big using the CNC machine. The goal was to design, mill and then assemble the pieces. For this week's group assignment we had to test runout, alignment, speeds, feeds, and tool paths of our CNC machine.

Embedded Programming

(Week 8)

For this week's individual assignment we had to program the board we made previously, read a micro controller data sheet, and experiment with different architectures. For the group assignment we need to compare the performance and development workflows for different micro controller families.

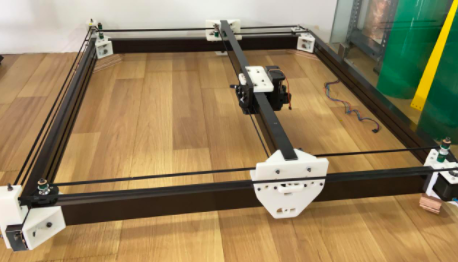

Machine Week

(Week 9)

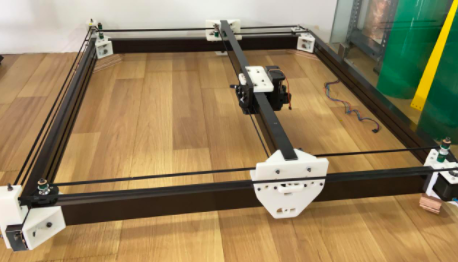

In this nineth week of Fab Academy, the assignment alloted to us is a group assignment where we had to make a machine with the contribution of all the members. The main challenge to us was the one week schedule which is too short for making a cool machine.

Input Devices

(Week 10)

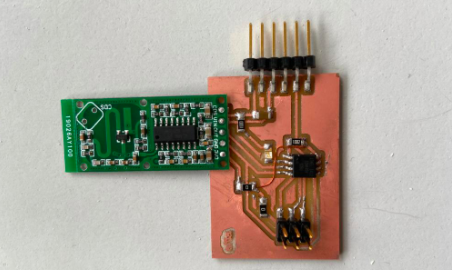

In the tenth week of Fablab, we got introduced to various sensors to get inputs. We all tried a sensor each to understand the working and look out for applications. I used the doppler Radar sensor and made a motion detector.

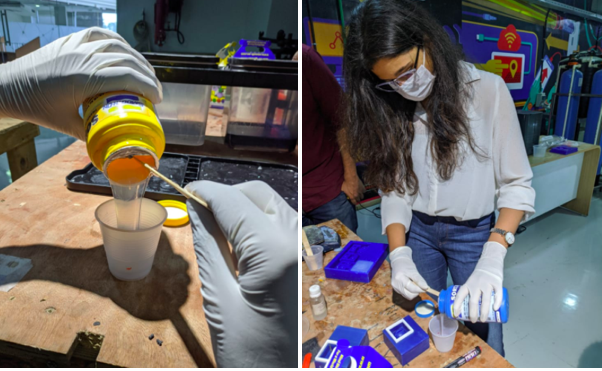

Molding and Casting

(Week 11)

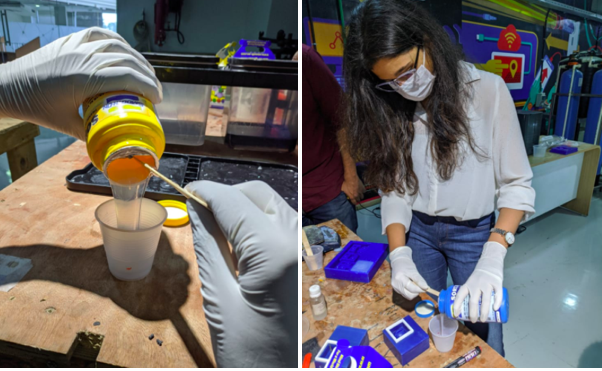

This week at fablab was Molding and Casting.

Molding is the process of manufacturing by shaping liquid or pliable raw material using a rigid frame called a mold or matrix. This itself may have been made using a pattern or model of the final object. ...

Output Week

(Week 12)

For this week's individual assignment, I decided to make a board for a Servo Motor. I decided to go with the servo motor because I intend to use a servo motor for my final project. I planned to integrate the input for the final project along with this, so I can use it to do that too.

I am using the MG995 servo motor for this. I also tested using the 9g micro servo.The idea is to make the servo sweep angles with respect to the input from the ultrasonic sensor.

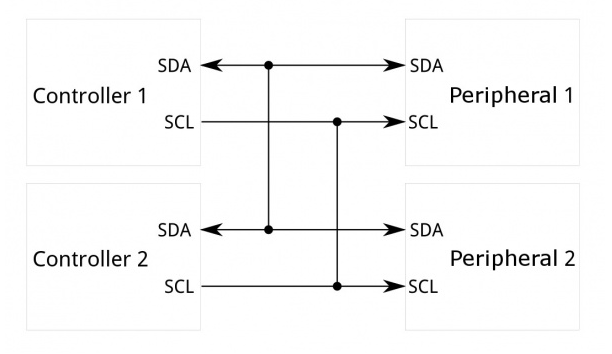

Networking and Communication

(Week 13)

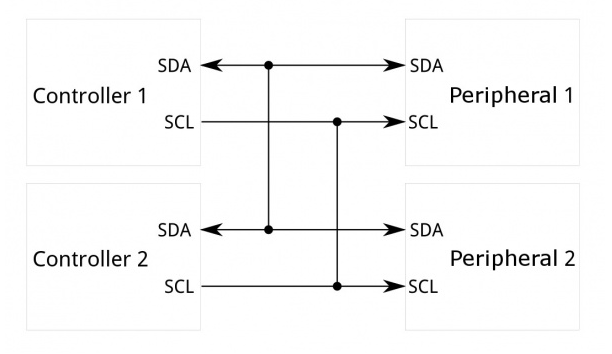

This week, we are going to learn about how to connect 2 or more boards with or without wires. The main idea for this week is that we have some way of communication between boards so that this understanding will help to to connect more boards when needed in different projects.

Interface and application programming

(Week 14)

For this week's work, I wanted to do something using processing, as it is one software that always fascinated me. It is also very easy to use especially if you have some basic idea about the Java IDE. I wanted to use the bunny board that I made in the previous week and use it to play songs with my keyboard and that was supposed to create patterns on the screen. I was very fascinated about the whole thing and my colleague Saheen helped me troubleshoot and gave me a better understanding of the whole thing.

Wildcard week

(Week 15)

In the fifteenth week of Fab Academy, the aim is to design and produce something with a digital fabrication process (incorporating computer-aided design and manufacturing) not covered in another assignment, documenting the requirements that your assignment meets, and including everything necessary to reproduce it

Application and Implication

(Week 16)

This week at FabAcademy is to propose the final project and document more about it, while answering a few major questions including-

What will it do?

Who has done what before?,

What will I design? ,

What materials and components will be used?,

Where will they come from?,

How much will they cost?,

What parts and systems will be made?,

What processes will be used?,

What questions need to be answered?,

How will it be evaluated?

Invention, Intellectual Property and Income

(Week 17)

In this seventeenth week of Fab Academy, the goal is to develop a plan for dissemination of your final project, prepare drafts of your summary slide and video clip and put them in your root directory.

I have to

-Demonstrate the plan for dissemination of your final project.

-Prepare draft of summary slide and video clip

-Think about future scope for this project

-Start the work if you haven't done anything till now

-Learn about the process of patenting, trademark, copyright and promote open sourcing

Project Management

(Week 18)

week 18 assignment is to Complete My final project and tracking my progress: what tasks have been completed, and what tasks remain? what's working? what's not? what questions need to be resolved? what will happen when? what have I learned?