Archive¶

Fab Shop (Archival)¶

Fab Shop is a trifecta of low cost digital fab machines that together can make each other to a very low level of components. The goal is to have each machine cost under $300 in parts to build. It seems that a Lathe, Mill and 3D Printer may be the perfect trifecta in my mind.

All machine parts will be fabricated on the trifecta of machines from raw bar and round stock, except for open source MakerSlide machine ways and common fasteners and bearings. This will allow the trifecta of machines to replicate themselves at a lower cost. Initial Fab Shop machine builds will be completed in guided workshops held at the MSI Chicago Fab Lab in 2020.

I have studied the MTM website for years and have extensive notes on machine ideas. I am also drawing inspiration from David Gingery’s book series on Build Your Own Metal Working Shop From Scrap book series. I call this project Fab Shop.

Above: Fab Shop Advertisement, designed in Inkscape

Project Management Timeline¶

| Target Date | Task |

|---|---|

| March 15 | Delays due to Chicago Rapid Response Manufacturing Project |

| May 14 | Delays due to Chicago Rapid Response Manufacturing Project |

| May 15 | Refocus trifect of machines to: CNC foam cutter, 3D printer CNC LatheMill |

| May 16 | Reset Timeline, re-focus CNC Foam cutter (Casting patterns, model aircraft, medium to large format foam sheet cutting) |

| May 18 | Basic CAD Design of CNC Foam cutter |

| May 25 | Advanced CAD Design |

| June 1 | Delay due to moving Chicago Uptown Fab Lab back to MSI |

| June 8 | Design and fab circuit boards |

| June 15 | Manufacture and assemble prototype machine |

| June 22 | Wire and test machine |

| June 29 | troubleshoot machine, iterate, improve |

| July 6 | Present machine to Fab Academy |

After discussion with Blair Evans and KP Nfr it emerged that I need to keep in mind the balance of Fab Academy topics I am learning and their connection with my Fab Shop project. For example Blair mentioned that I may not want to build a whole cnc control board, but rather just a stepper driver sub board. I could also build a oled touchscreen machine interface into a sub project for the class requirements. Building these sub-modules would be easier to accomplish and inform my understanding of commodity cnc control boards that may be a better fit for the day or two long mass builds for Fab Shop Machines.

Fab Shop Redirect¶

In May of 2020 a few things happened to redirect the focus of the Fab Shop project. Major delays happened due to my work organizing and running a Chicago Rapid Response Manufacturing Project to make PPE. And the MSI wants me to work on flight based fabrication for the refurbishment and re-opening of the 727 airplane exhibit. The casting and molding Fab Academy session also reminded me that large molds and patterns can be made on a medium format CNC foam sheet cutter. I also have always wanted to make a CNC foam cutter that is more capable and easy to use compared to my first CNC machine I built the PhlatPrinter.

Essentially, the laser cutter is one of the most powerful and easy to use machines in a Fab Lab. However Laser cutters are extremely expensive. Laser cuters are not easy to install and run at home.

A CNC foam sheet cutter is easy to use at home and is easier to install and run at home. Most importantly is that a CNC foam sheet cutter can be fabricated in a Fab Lab for around $300. A foam cutter can easily 0.6 x 1.2 meter (2x4 foot) foam sheet processing capability. This is much larger than a small laser cutter, and rivals a large bed laser cutter.

The 1st Fab Shop machine to be design, fabricated and built will therefore be a CNC Foam Sheet Mill.

In 2018 I purchased a warehouse full of high quality mechatronics parts that were going to be liquidated.

From this inventory the following parts will be used to build to build Fab Shop Machines:

Materials¶

| Quantity | Description |

|---|---|

| 1323 | Stepper Motor - NEMA 17 |

| 127 | Stepper Motor Bracket |

| 35 | Stepper Motor - NEMA 23 |

| 196 | MakerSlide Aluminum Extrusions 1000mm long |

| 40 | 40x40, 20x80, 20 x 40mm Aluminum Extrusions |

| 78 | Quiet Cut Spindles |

| 1189 | HDPE Sheets |

| 843 | Acrylic sheets |

| 79 | Drag Chains |

| 64 | gShield |

Origin Story¶

The first ideas for Fab Shop started emerging around July 2019 when I started to think about what kind of project I might want to do for Fab Academy 2020. I was especially inspired by several long discussions with Nadya Peek and Jens Dyvik and by the machines they have designed and built over the years.

On the evening of November 19 2019 the core ideas for Fab Shop finally culminated…

The goal of Fab Shop is to demonstrate that Fab Labs can reproduce the means of digital fabrication, with a set of low cost DIY machines that are easy to build and replicate. A Fab Lab would host guided workshops to help people in the community build Fab Shop machines. Builders would also benefit from the technical skills of building machines from the ground up, allowing them to be unafraid to take apart and fix off the shelf digital fabrication machines. This will allow people to create mini Fab Labs in their homes, apartments, and communities. With iteration over time this will allow communities to design and build the means of production to make things to improve their lives. In conjunction with larger arc projects, like Fab city, this will lead to everyday citizens being able to design and produce customized products that match many outputs of the current industrial manufacturing complex. As a bonus scrap bin Linux computer building will be taught, to allow low or no cost digital design pc’s to be built.

Core Fab Shop Machines are:

3D Printer (Sci Bot)

Mill (Sci Mill)

Lathe (Sci Turn)

Optional Machines are:

Design Computers Running Linux (built from discarded computers)

Foundry in a Box w aluminum casting upgrade (Sci Cast)

Foam Sheet Router (Sci Rota)

Machine components will be manufactured, as much as possible, using raw materials like:

3D Printer Filament

Sheet, bar, and rod stock of metal plastic, and wood

Ingots of metal

Plus common hardware like:

Fasteners: Screws, nuts, washers, bearings

Notes and Sketches Archive¶

Gingery Books Influence¶

Gingery books put the means of production in the hands of the people. However you needed to be highly skilled to produce these (Gingery) machines. The Fab Lab, Hackerspaces, and Makerspaces,have combined the idea of Gingery machine building from industrial scraps with digital design and fabrication making it much easier to…put the means of high tech manufacturing in the hands of the workers. Combined with careful design thinking I am to replicate the 3 or 4 core machines used in modern manufacturing. My resources will be Fab Labs & Hackerspaces in Chicago. These core machines will be able to replicate themselves easily in any community that has access to a Fab Lab 1.0 with standard inventory (and possibly without Fab Lab access).

Date: Mid 2019

Title: Sci Bot Rep Rap Project

SciBot Machines¶

Date: Mid 2019

Title: Sci Bot Rep Rap Project

3 Machines can cut & process:

Aluminum

Delrin

Nylon

Brass (free machining)

PETG, ABS, PLA

Acrylic (for proto-plate router templates to machine aluminum plates)

Use machines to make acrylic & HDPE router and drill bushing jigs & fixtures to make Sci Bots. This eliminates the reliance on (large and expensive) machines & speeds up and simplifies mass builds.

Open source the means of production.

Lathe, mill, 3D printer

Called Sci Bot Machines (play on MSI and ORD Bot 3D Printer from Chicago)

Sci Bots of various types are capable of making almost all the parts for these 3 Sci Bot machines.

| Makes! | Does Not Make |

|---|---|

| Spacers | Ball Bearings |

| Wheels | Spindles |

| Gear racks | Motors |

| Circuit boards | Slides |

| Heated Build Plates | Rods |

| Complex Geometry Parts | Hot ends |

| Pinions | Extrusion Drives |

| Bushings | Screws |

| Mounting Plates | Touchscreens |

Sci Mill¶

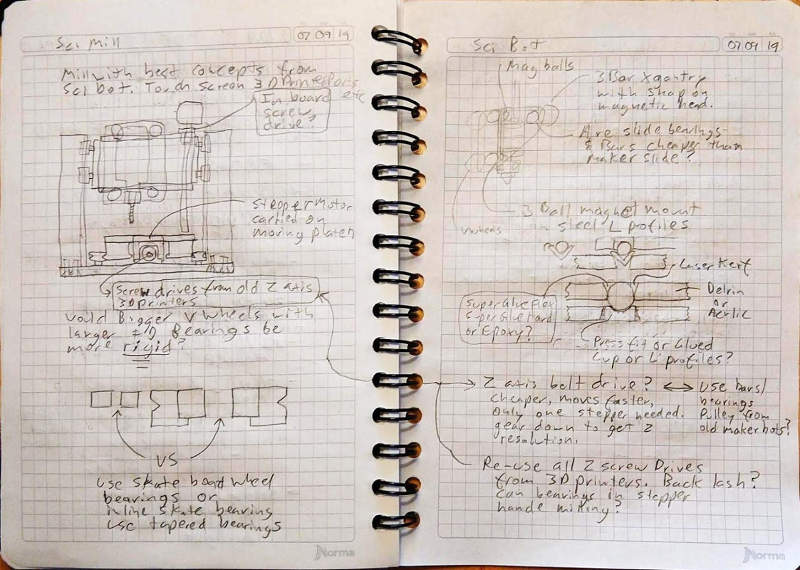

Above: Sci Mill / Sci Bot

Date: September 07 2019

Text from drawing above:

|Sci Mill|SciBot|

|Mill with best concepts from Sci Bot (3D Printer). Touch screen, 3D printed parts, etc.||

Inboard screw drive?

Stepper motor carried on moving platen

Screw drives from old 3D printer axis

Would bigger v wheels with large bearings be more rigid?

Use skateboard wheel or larger bearings. Use tapered bearings.

Title: Sci Bot Mag Ball Mounts 2019

3 Bar x gantry with snap on magnetic head. Are slide bearings & bars cheaper than maker slide?

3 ball magnet mount in steel L profiles

Slide and Bearing Compare

| MakerSlide | Round bars | Belt drive | Screw drive |

|---|---|---|---|

| Have lots of | cheaper long term | moves faster | Simple one stepper Z Drive |

| Expensive long term | Rods from old Makerbots? | Gear down to get z resolution | Re-use all Z screw drives from 3D Printers |

| Backlash | Can harvest from broken machines | Belts from old Makerbots | Backlash |

| One stepper Z drive more complex |

Can bearings in stepper motors handle milling? Or should high forces be transferred into bearings and the stepper floats to reduces strain on them. This would increase complexity and parts count.

Makerbot Harvesting¶

Title: Harvest Makerbot Parts

There are lots of broken makerbots in the Chicago area that are unused. The idea here is to harvest the best parts from them to make more capable Fab Shop machines.

- Gut boards and touchscreens and replace with fully open source controls.

- Sell boards and touchscreens on ebay to raise funds (oem boards are no longer available and fetch a good sum)

- Use stepper with integrated screw for mill and lathes that require slow high force cutting moves and rigidity for machining brass and aluminum.

- Use X & Y pulley rods for single stepper belt drive Z - axis on Fab Shop 3D Printers

- Use wiring harnesses.

- Use extruder, make mag plate that holds makerbot extruder on fab shop machines.

- Use heated build plate from Rep 2x.

- Mount Rep 2 & 2x dual extruders to Fab Shop interchangeable tool head plates.

- Sell makerbots on e-Bay for funds to make scibots

- Sell makerbot motherboards and LCDs on e-Bay

Sci Rota¶

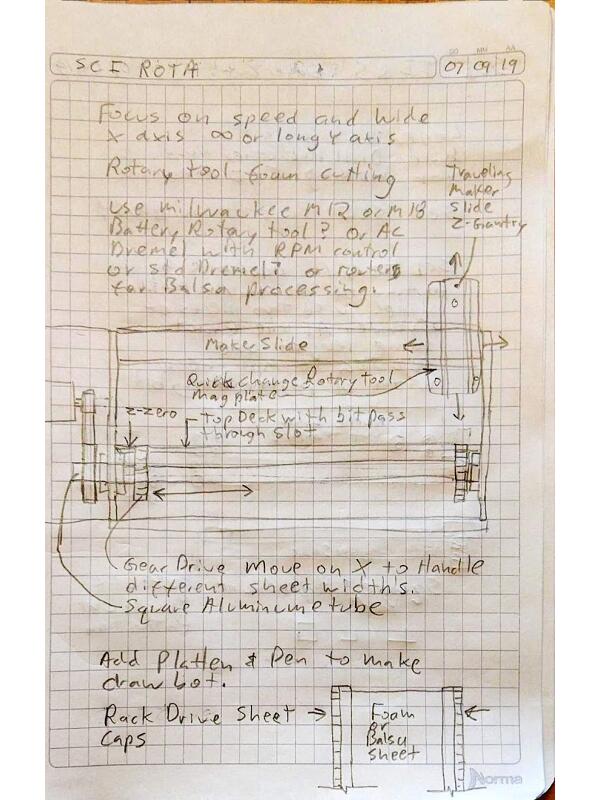

Above: Sci Rota CNC Foam Cutter

Focus on speed and wide x axis infinite or long Y axis (Roller drive)

Rotary tool foam cutting

Use Milwaukee M12 or M18 battery rotary tool on DC. Or AC dremel with rpm speed control or standard dremel? Or router for balsa processing.

Gear drive to move on X to handle different sheet widths. Square aluminum tube drive.

Add platten & Penm to make drawbot.

Rack drive sheet stock end caps.

Sci Jigs¶

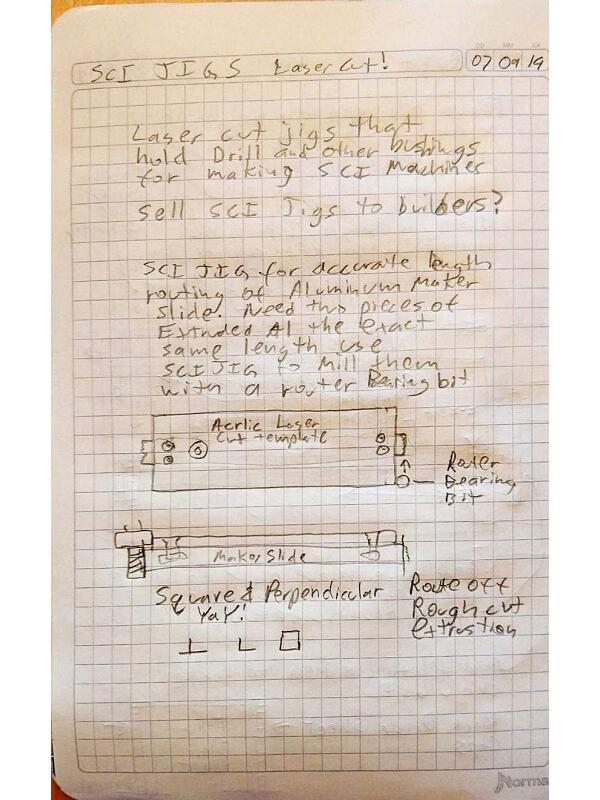

Above: Sci Jigs, Laser Cut!

Laser cut jigs that hold drill and other bushings for making Sci machines.

Sell Sci Jigs to builders?

Sci Jig for accurate length routing of Aluminum Maker Slide. Need two pieces of extruded Al the exact same length use Sci jig to mill them was a router bearing bit.

Date: 2019

Title: Sci Mach Plan

Machine parts for Sci machines on other machines to lower the cost of parts.

Use open source hardware designs as basis for custom machines with major design improvements.

Reference open hardware designs.

Jens Dyvik gear/ rack/ pinion slides

Open Slide

Maker Slide

Rigidify designs above B & C to utilize stock of MakerSlide purchased from Inventables.

Use stock of:

MakerSlide

GRBL Controls

36VDC Spindles

HDPE Sheets

Aluminum Sheets

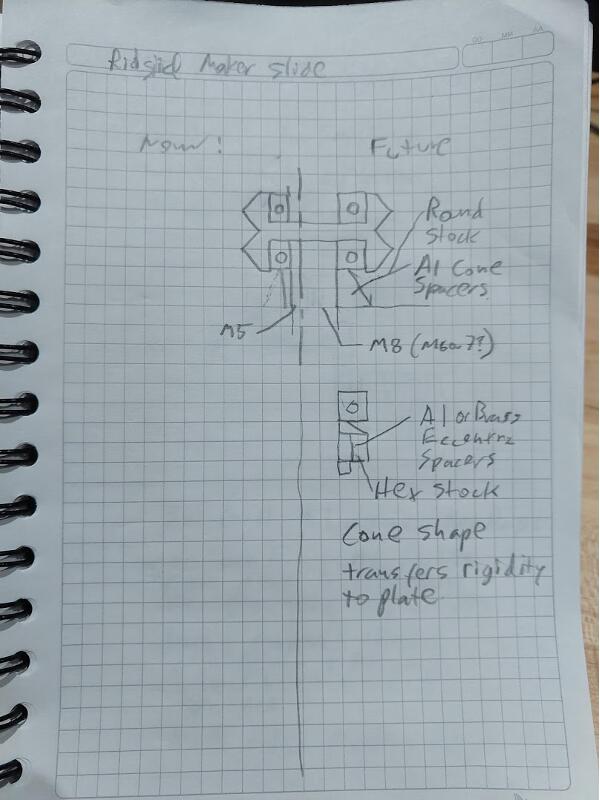

Rigid MakerSlide¶

Above: Rigid MakerSlide: Spacers, Wheels and Axles

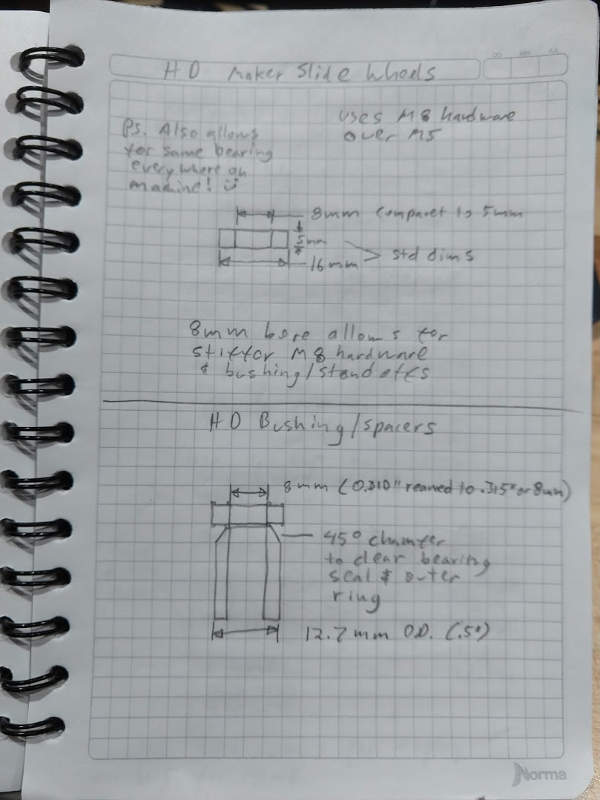

HD MakerSlide Wheels¶

Above: HD Maker Slide Wheels

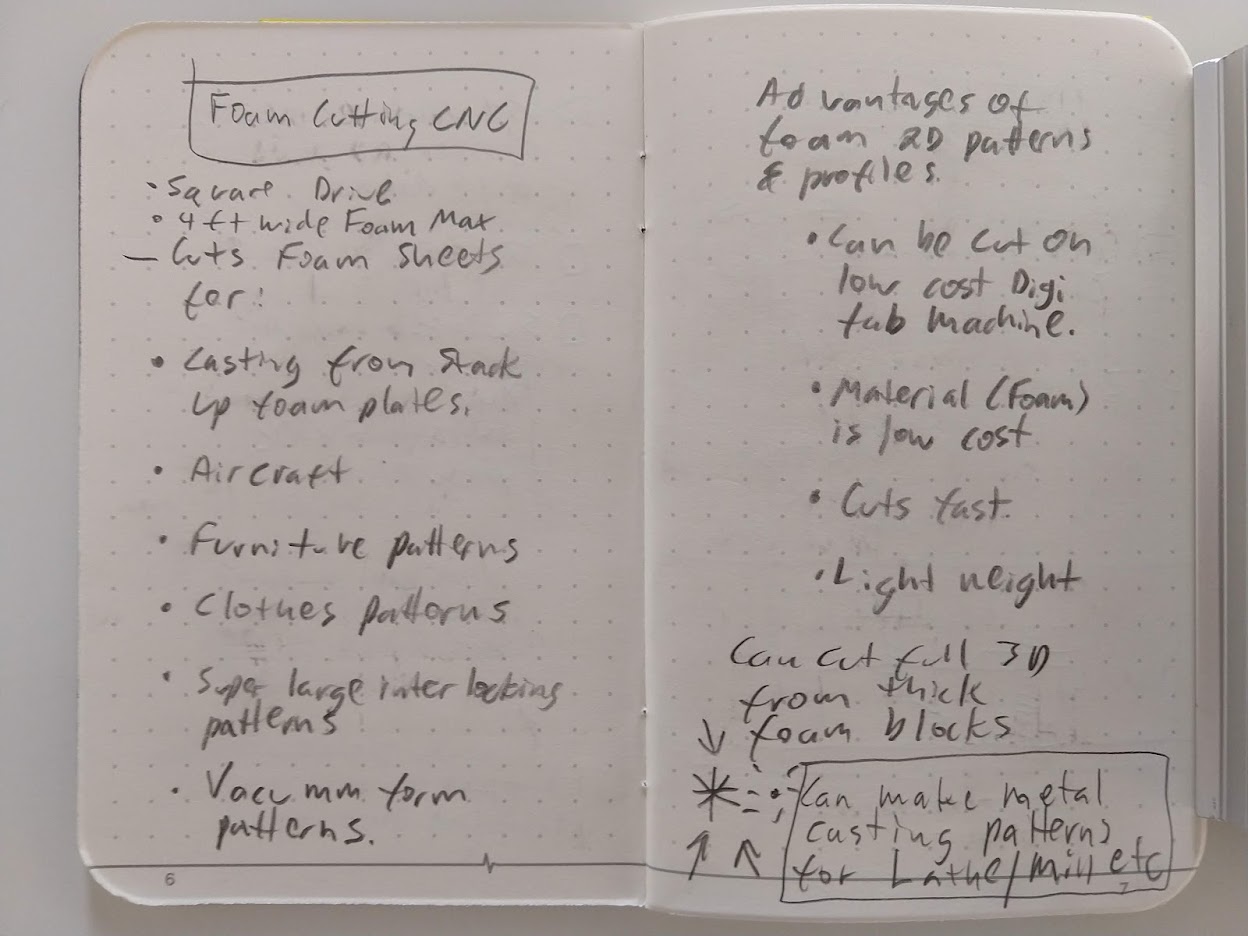

Foam Crawler Concept Sketches¶

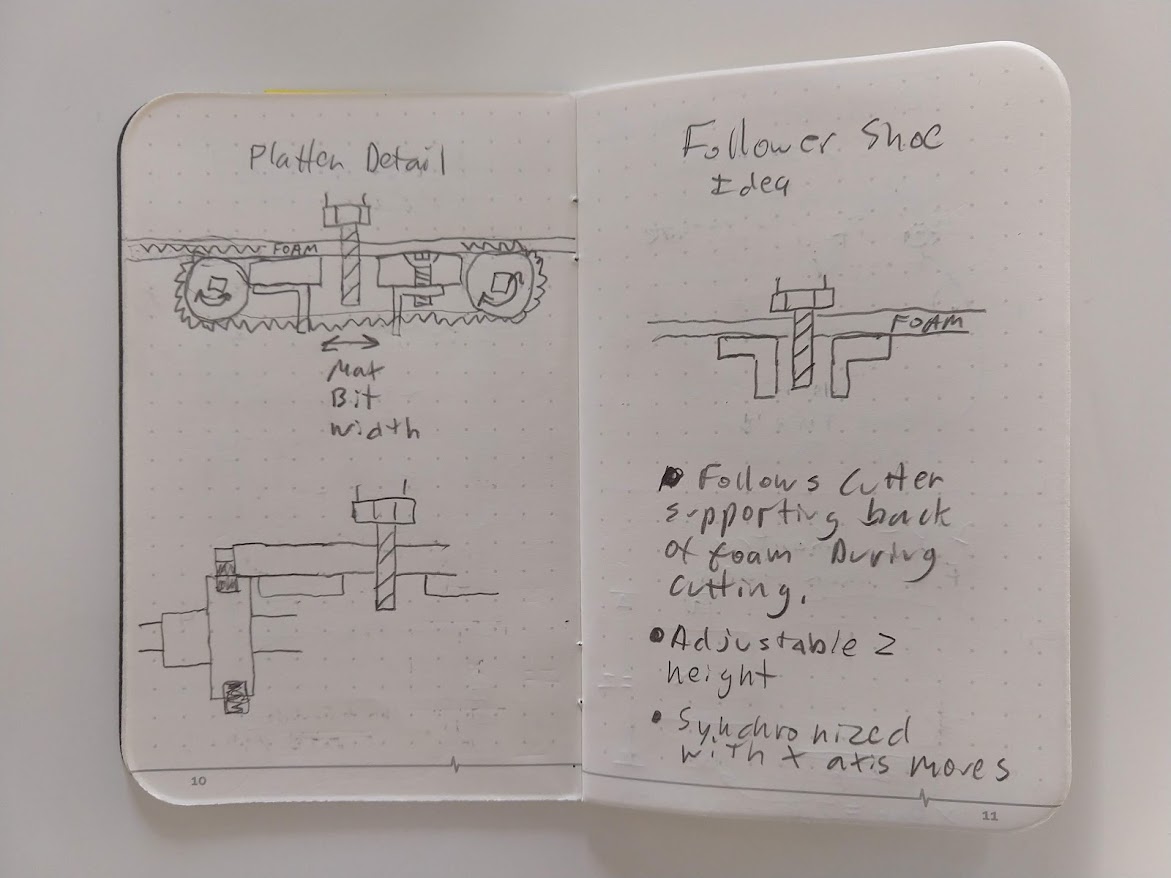

Here are my notes and sketches for designing a new cnc foam cutter:

What can be made on a CNC Foam cutter

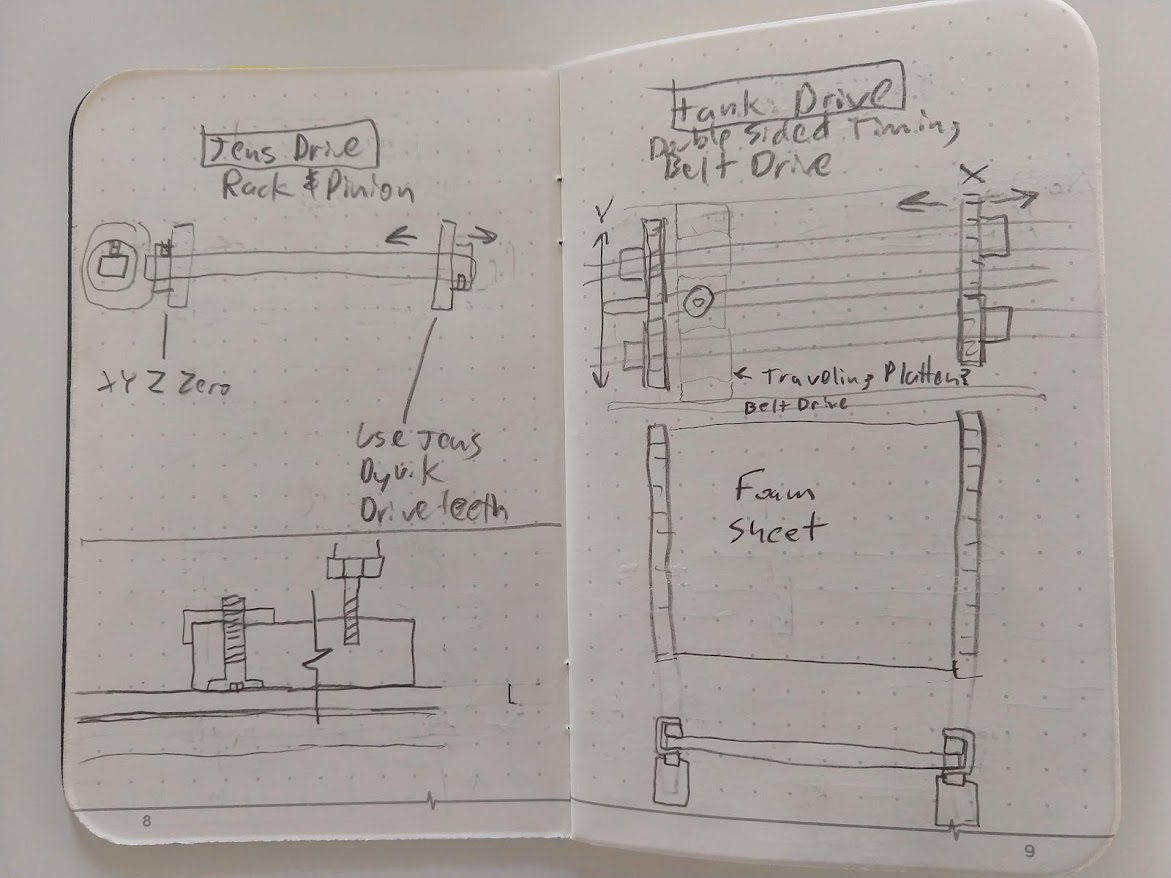

Different foam sheet drive concepts

Different foam sheet drive concepts

TankDrive and cutting follower concepts

TankDrive and cutting follower concepts

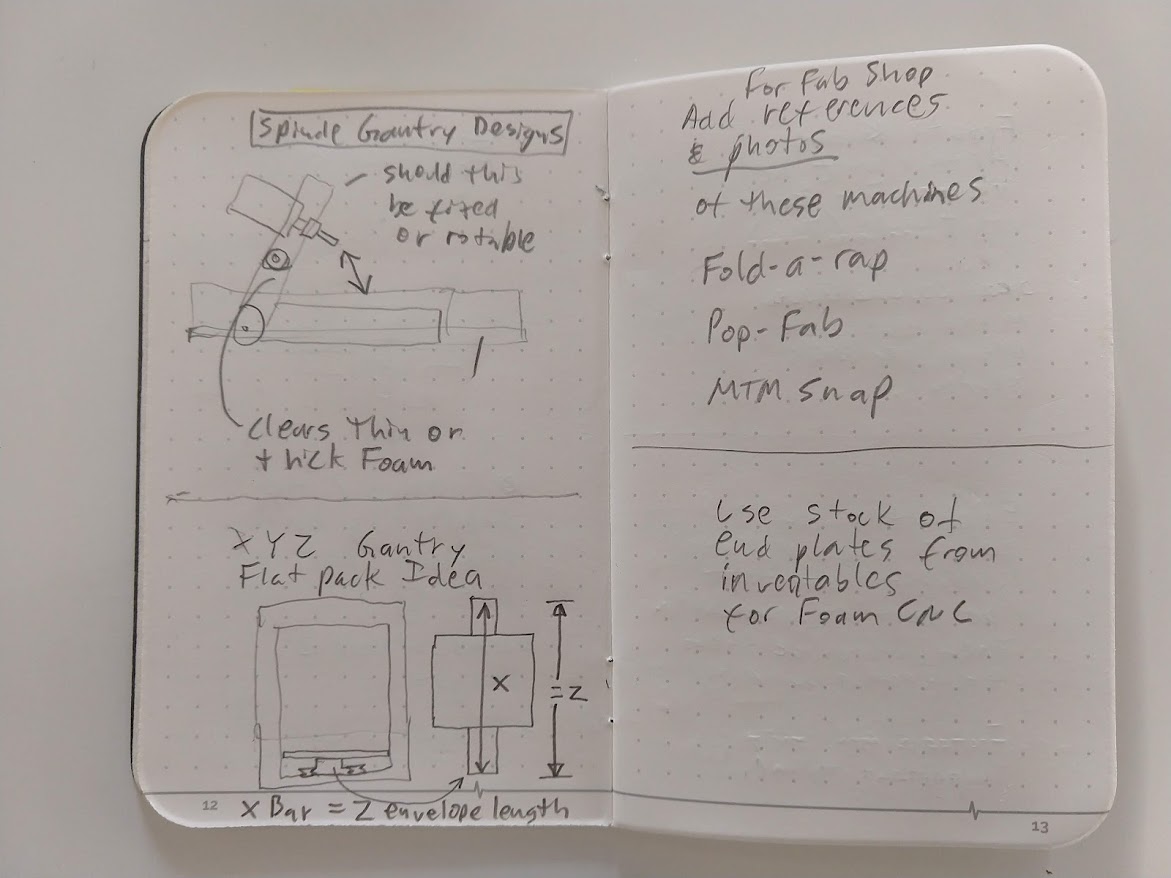

Gantry designs, including folding and flat pack ideas

Gantry designs, including folding and flat pack ideas

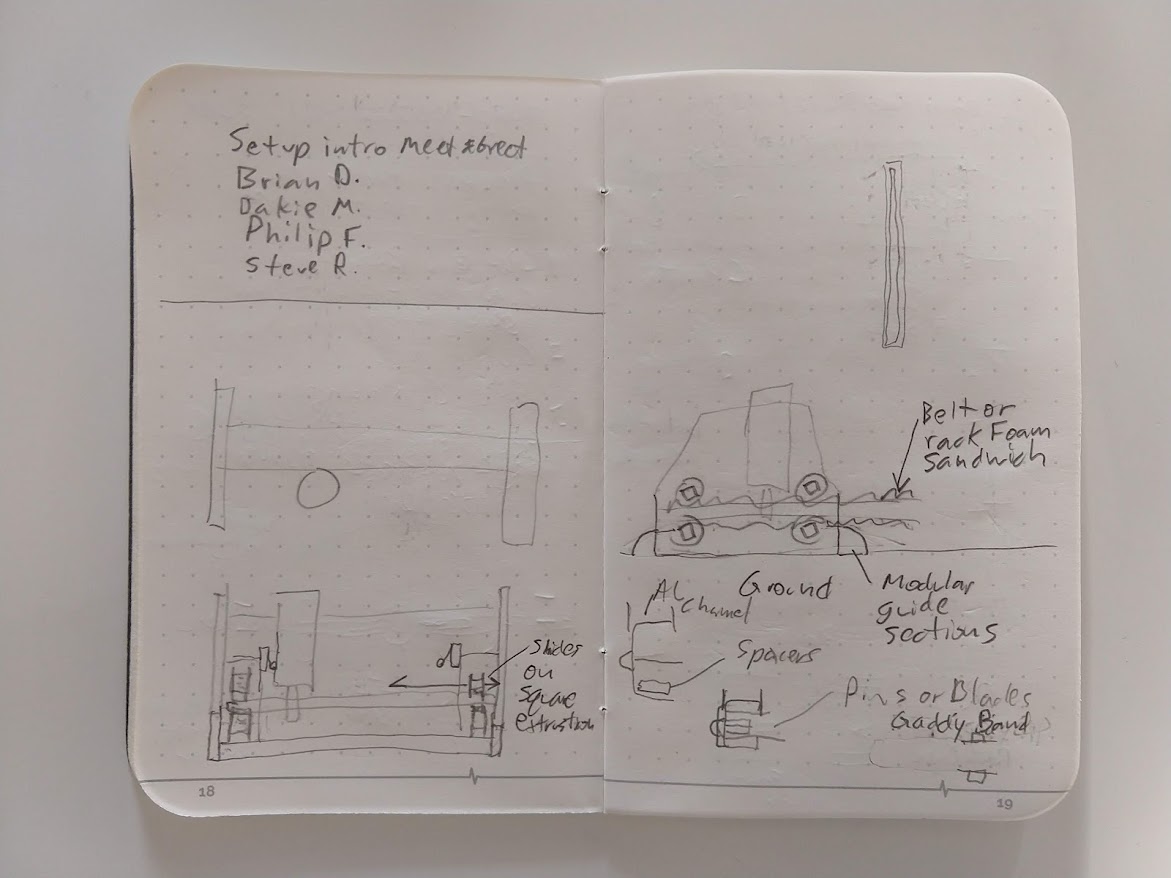

Square tube drive, belt rack attached to foam edge drive

Square tube drive, belt rack attached to foam edge drive

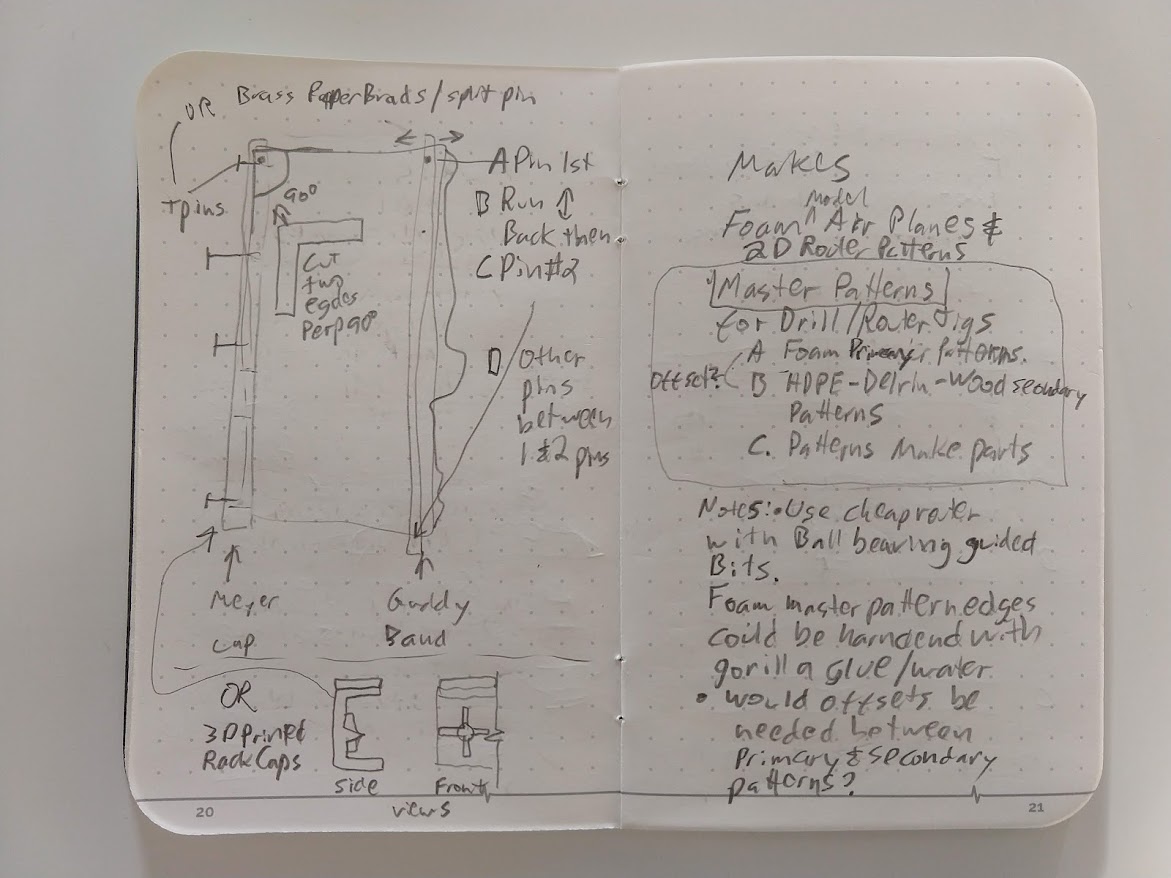

Drive racks pinned to foam sheet edge. More ideas for foam sheet patterns, drill jigs and templates.

Drive racks pinned to foam sheet edge. More ideas for foam sheet patterns, drill jigs and templates.

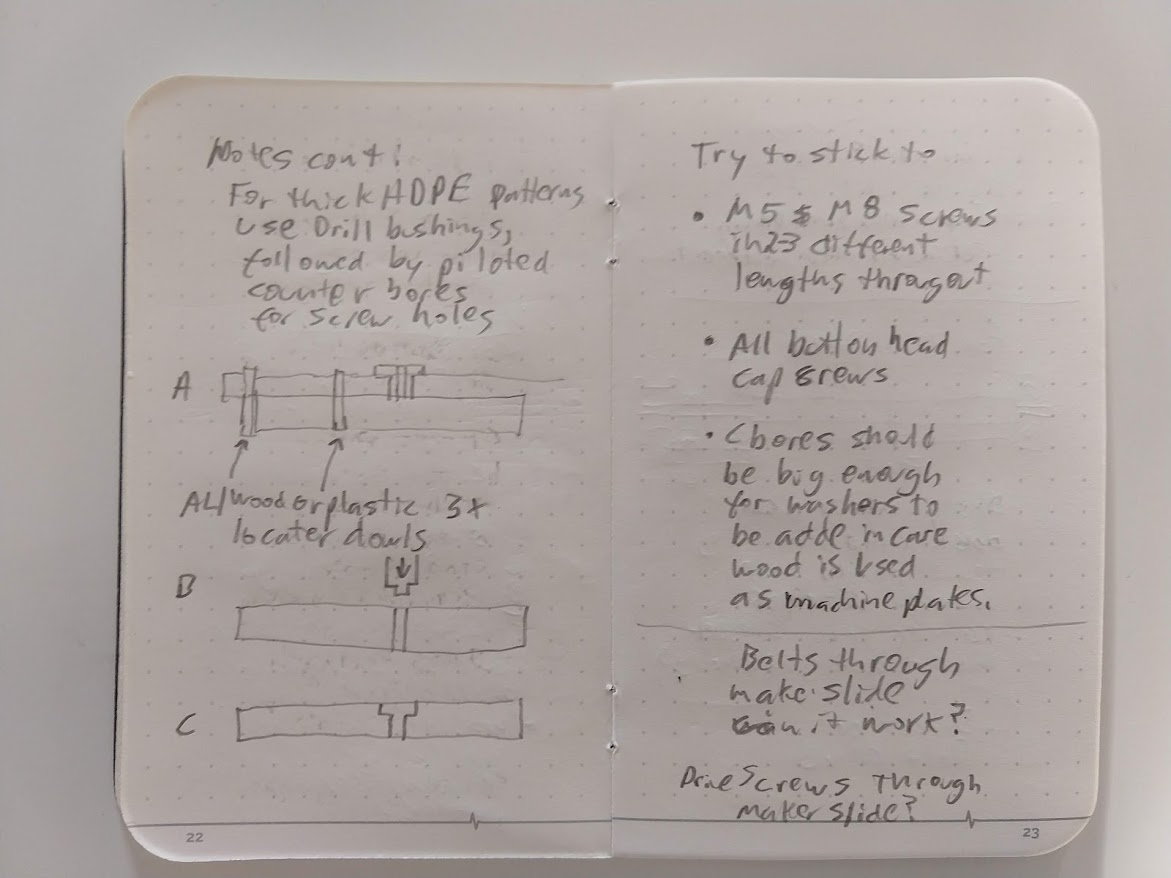

Counterbore drilling of HDPE plates for drive train and machine structure

Counterbore drilling of HDPE plates for drive train and machine structure

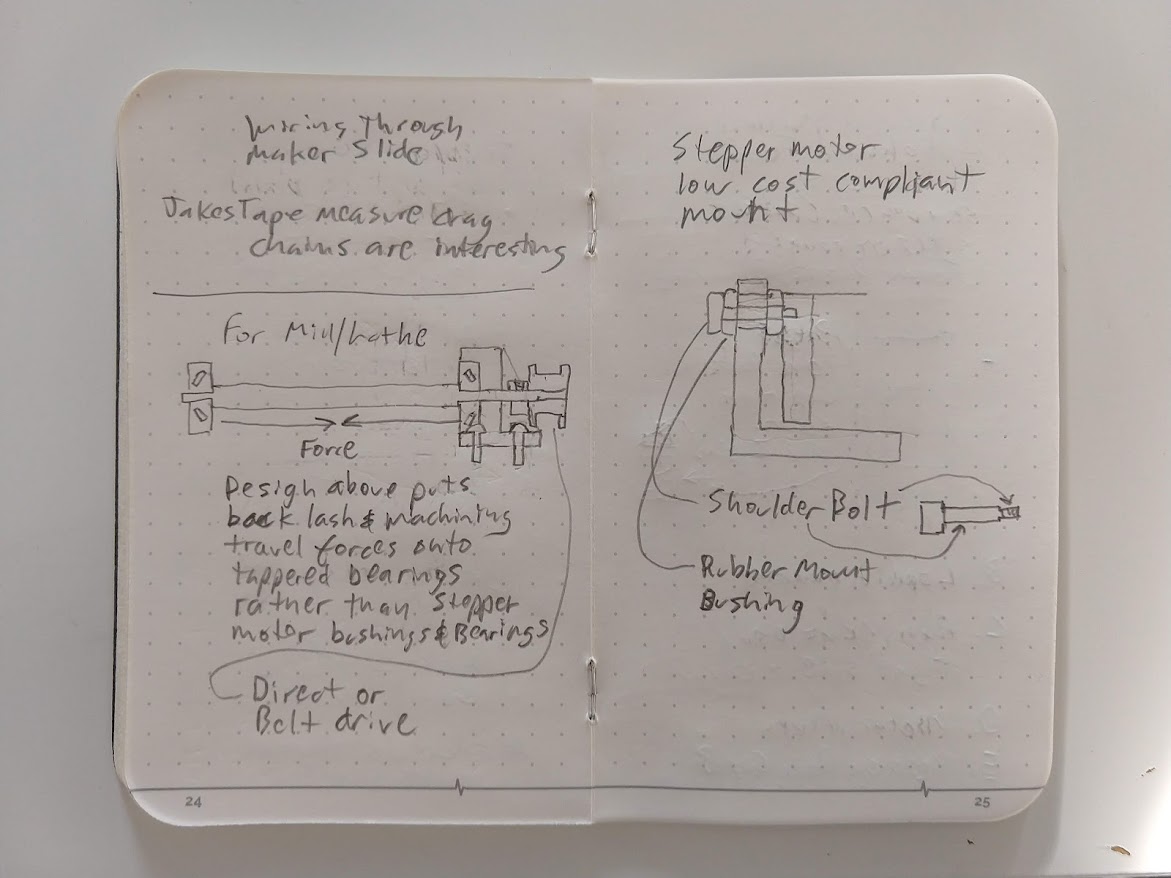

Tapered roller bear concept. Complaint rubber mounted stepper motors.

Tapered roller bear concept. Complaint rubber mounted stepper motors.

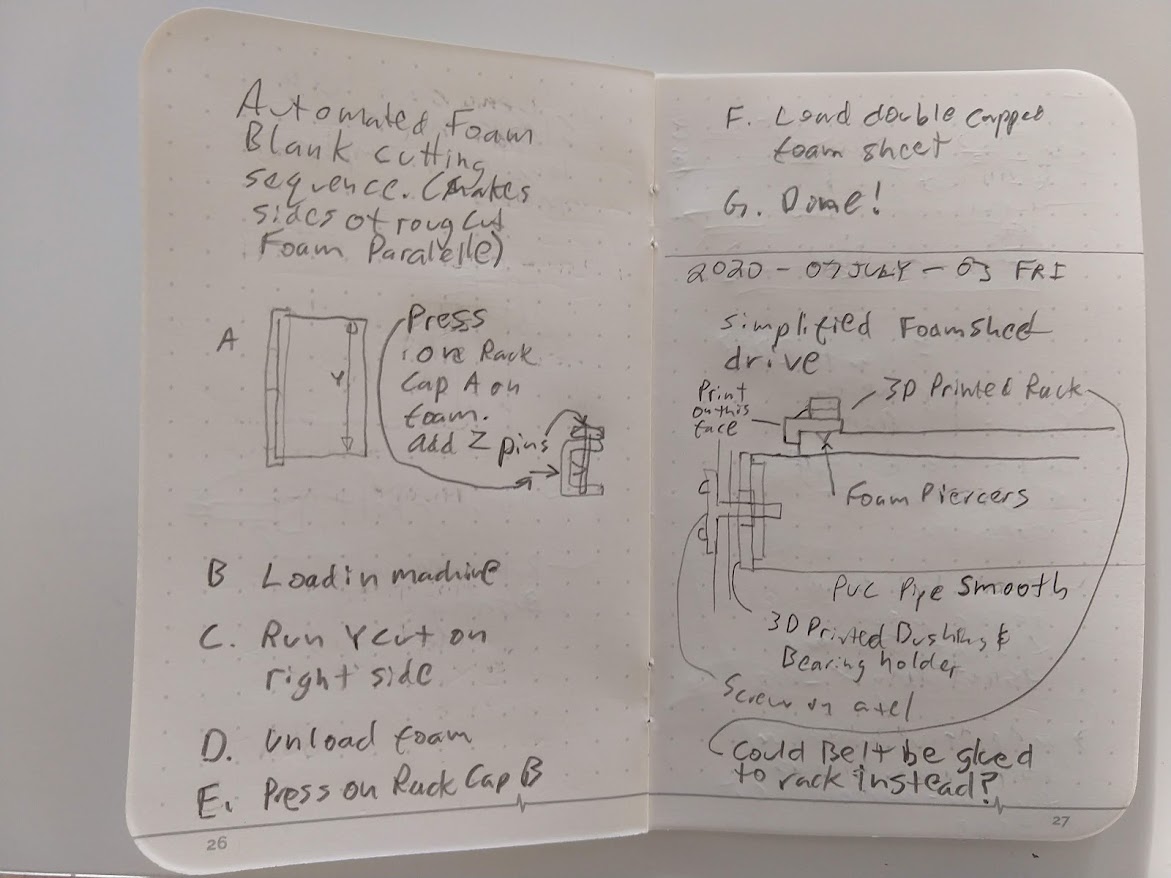

Foam edge rack drive processing sequence.

Foam edge rack drive processing sequence.

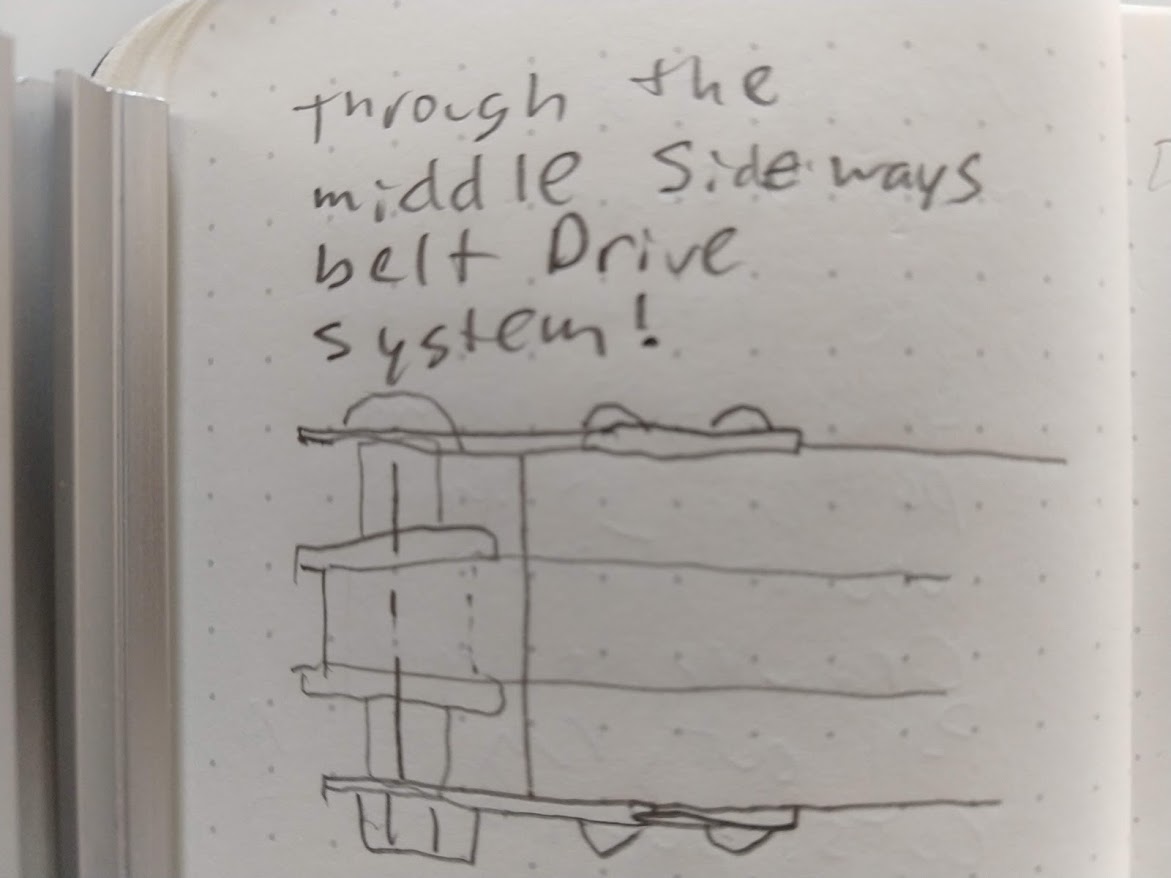

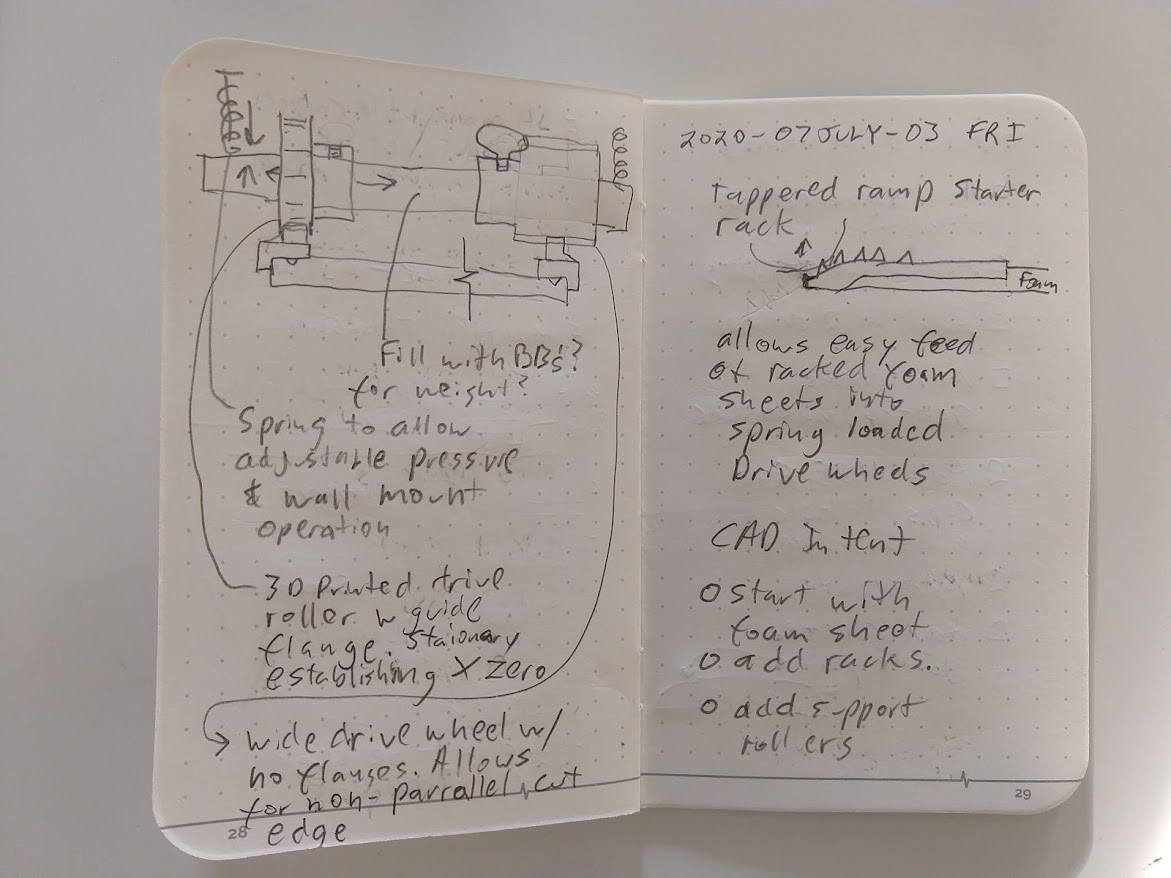

Spring loaded top rollers for belt rack or 3D printer rack drive

Spring loaded top rollers for belt rack or 3D printer rack drive

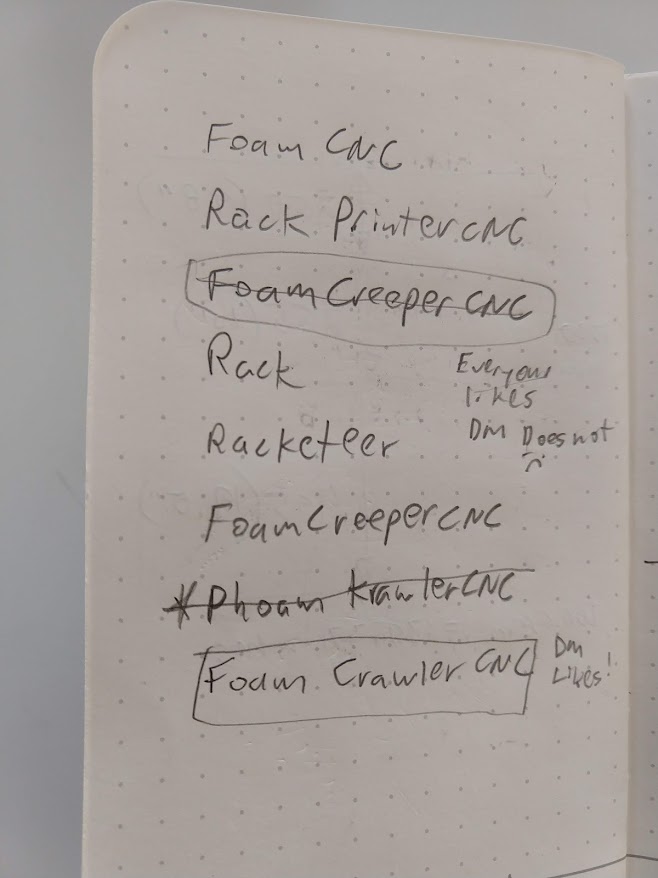

Various names for the new foam cutting CNC

Various names for the new foam cutting CNC

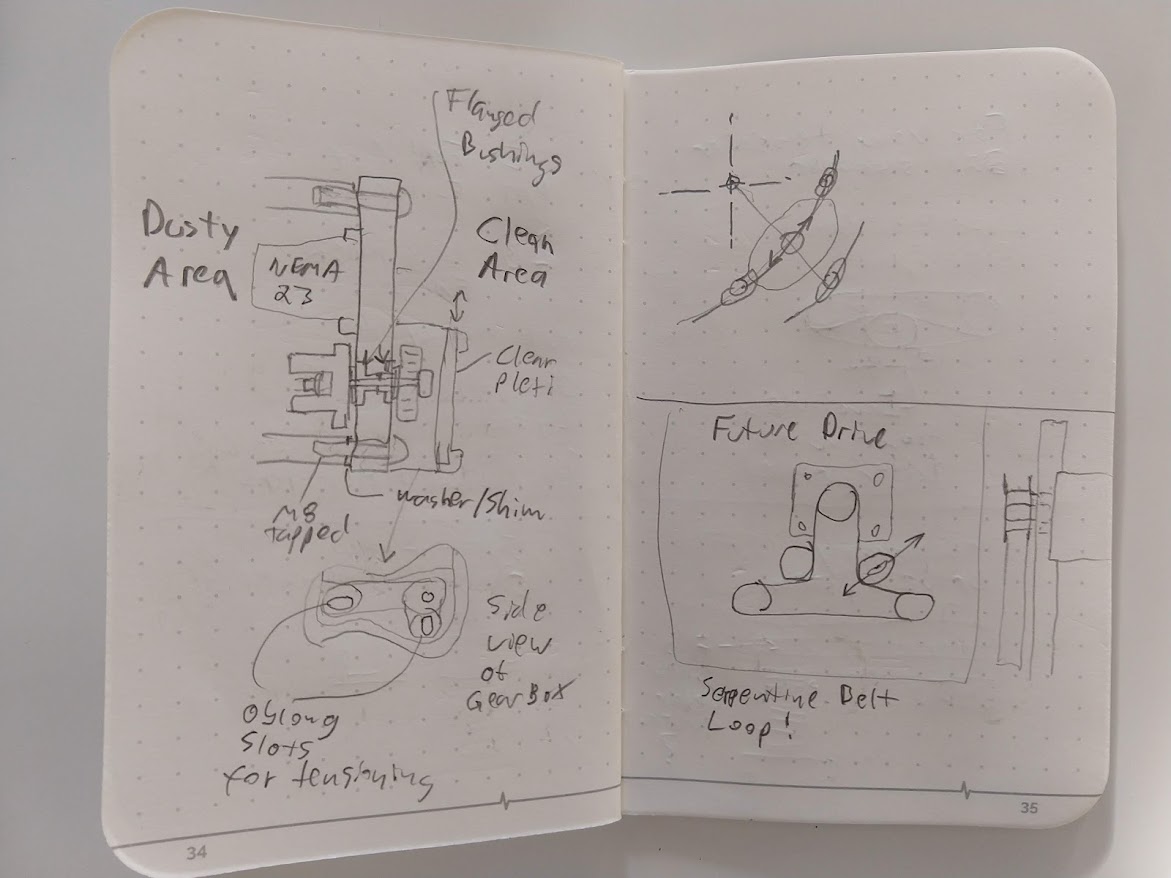

Drive train plate concept, housing with plexiglass window to see gearing. Drive belt ideas

Drive train plate concept, housing with plexiglass window to see gearing. Drive belt ideas

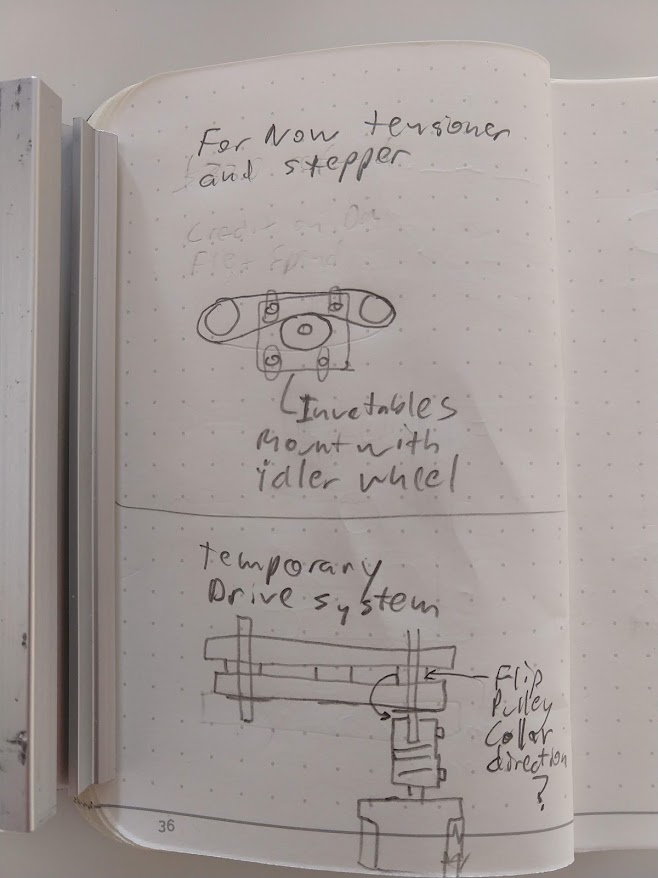

Tensioner idea

Tensioner idea

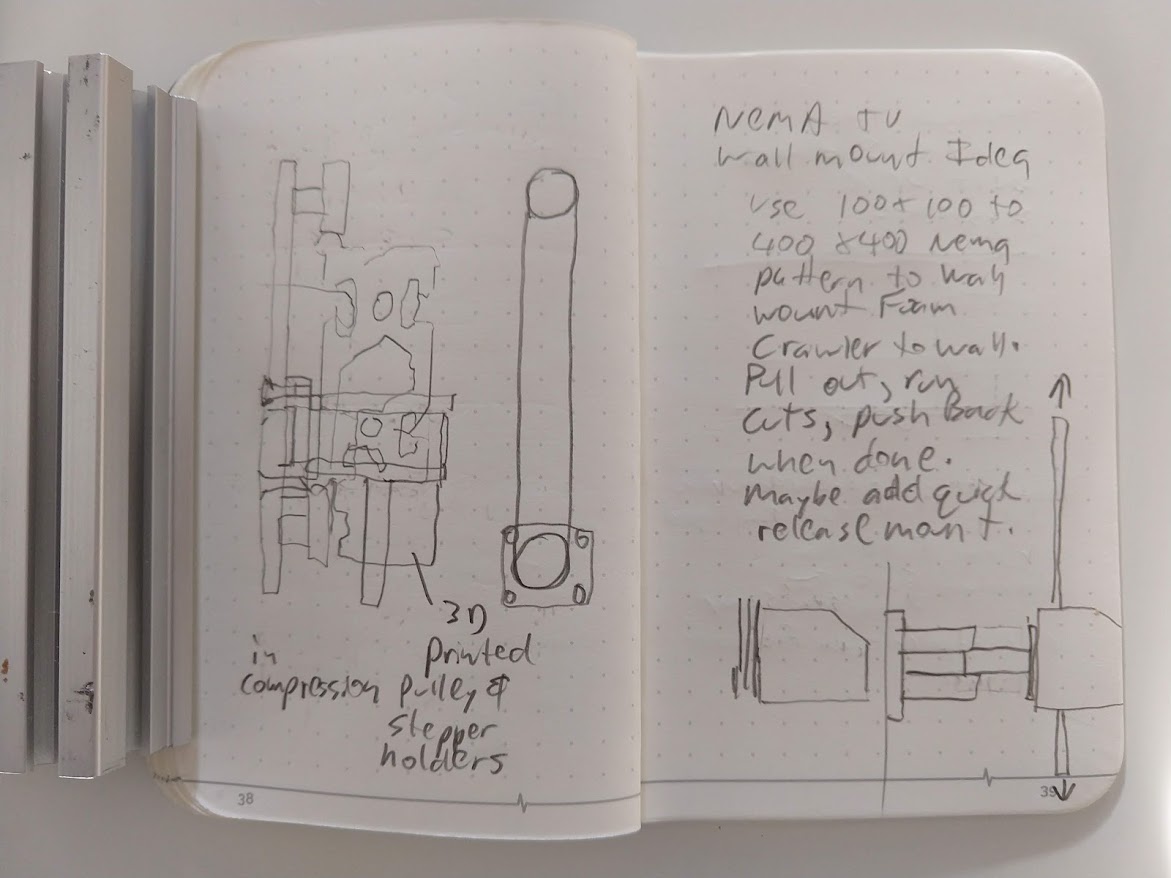

Wall mounted machine concepts, one uses a NEMA screw pattern TV wall mount.

Wall mounted machine concepts, one uses a NEMA screw pattern TV wall mount.

Pulley mount that allows belt to routed inside MakerSlide extrusion.

Pulley mount that allows belt to routed inside MakerSlide extrusion.