This week assignement was to propose a final project that integrates the range of units covered. The final project was to show individual mastery of all of the skills. Where possible, you should make rather than buy the parts of your project

*All files provided on the navigation menu.

It is intersting how and idea can become greater or poorer with time. Mine i have to confess just got bigger and bigger (not in the fisical form but in the conceptual part), for my final project i will make a Small Parts Storage, with and eletronic interface, or to be more precise with an automated search and inventory system. It will be modular and simple. So it can easialy expandable and anyone can make it (hopefully they will make it and inprove it).

Where is the F***ing 49.5k resistor??

But i think the most important question is why i have decided to make that and why i see that the Small Part Storage can become something important for the FabLab network. First let me tell how i chose to make this for my final project, so i live in Brazil and came to Providence (RI, USA) to participate in the FabAcademy program, my first convern for the project is that it had to be something small or at least that can be easily reproduced in Brazil (or even others parts of the world). The second restriction was to make something envolving most of the units (and skills) covered in FabAcademy (to make it better and even more to better manage the time spent on it). The third concern was to make something usefull for any FabLab around the world (specially in Brazil, because one of my personal gols is to manage or open a FabLab there).

Imagine finding something even in this organized place.

I had another project i wanted to make, but find out that the Small Parts Storage was the one that best capture all elements i want to bring to the final project. And i have that idea that or incoscient make some decision for us without the consient part be totally aware of the motivs, but in somepart we know why. And that said i have to explain why my final project makes so much logic for me and for what i understand a FabLab is and how to improve it.

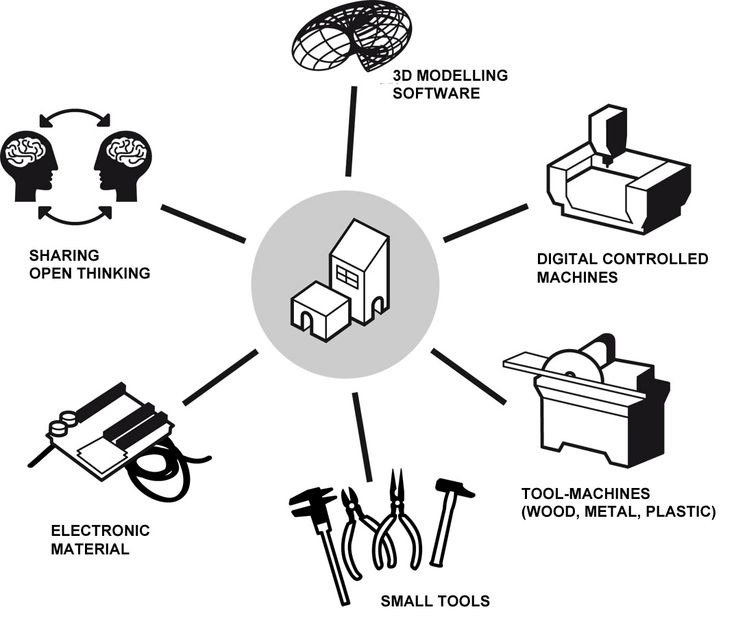

The FabLab "factory" and all its components - source: Neil Gershelfed digital fabrication presentation (http://academy.cba.mit.edu/classes/principles_practices/index.html)

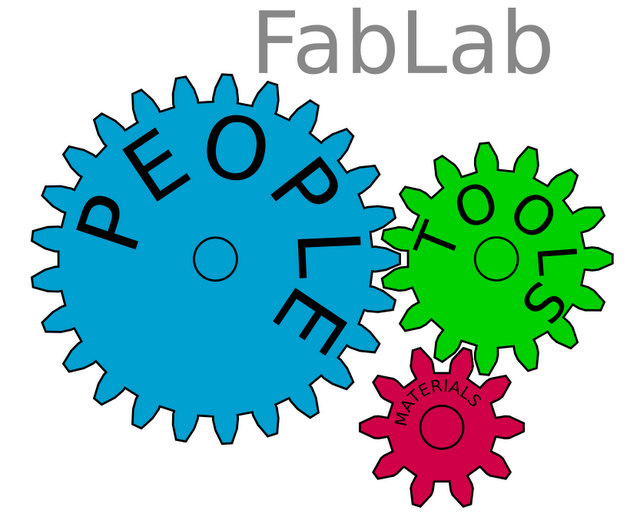

I guess the best part to beggin is from beggining, so that would be what i thing is a FabLab and what is the future of it. The FabLab for me is the connection between people, machines and materials into a network to make almost anything (Neil class spin into the world). People (local or via the fablab world network), machines (digital or analogic, from the inventory or else) and materials (from the inventory, local or specific ones).

Captain Picard from the Star Trek: the next generation series ordering a tea in the replicator (personal fabricator?)

What is the future: a Network with local Personal Fabricators (PF) as discribed by Neil in the FAB book. But from Neil and my perspective the FabLab can be that now, not the small footprint but if you understand the FabLab as a big machine, it is in a way a big personal fabricator, as the computer it was a big room with all modules separated and now it fits on your pocket or many times even smaller.

"Like the earlier transition from mainframes to PCs, the capabilities of machine tools will become accessible to ordinary people in the form of personal fabricators (PFs).""Programmable personal fabricators are not just a prediction, they're a reality. The world of tomorrow can be glimpsed in tools available today." "Just as minicomputer combined components — the processor, the tape drive, the kaypunch, and so forth — that were originally housed in separated cabinets, a fab lab is a collection of coomercially available machines and parts linked by software and processes we developed for making things."

- Neil Gershelfed, FAB. -

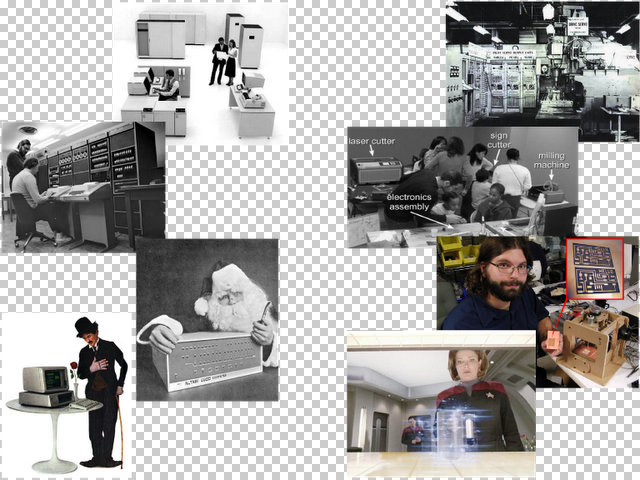

source: Neil Gershelfed digital fabrication presentation (http://academy.cba.mit.edu/classes/principles_practices/index.html)

My idea is to make the FabLab autonomous, of course it is good and even desireable to connect to people inside the fab lab space, but it is a lack of time and motivation to need a person to tell you where are things or even if something is available or not. The energy of the FabMananger, and even the people working on the space should be on ideas and producing things. When everybody was agreed on how things are organized, than they can help mantain the space. Imagine if you had insted of four people on a house, 50, if nobody agrees with what drawer the fork goes than is better to eat the pizza with your hand because you are not going to find it.

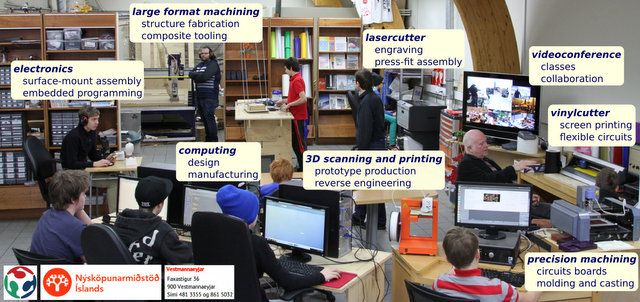

A fablab with all resources (and really organized) source: Neil Gershelfed digital fabrication presentation (http://academy.cba.mit.edu/classes/principles_practices/index.html)

Also it is important to have and inventory of everything on the Lab, and for some parts of the world (like Brazil) it is very, very important to know when things are finishing, because it takes a long time for the shipping to get there.

So the final project idea is to help with the the digitalization of the process inside the fab lab, inside the digital fabrication.

One last consideration is how you can manage parts and materials, or even charge for them, and one of the features that can be inserted in future versions of the Small Parts Storage, or in other simliar systems, is to identify te user an with that information make predictions and even feed the new needs of each Fab Lab.

Graphic of a FabLab

Ow and the most important thing! For some obvious motives, the final project it's called Wally (you know, where is Wally? or Waldo for the US). !

So i guess this week is time to sit down, think and rethink what i have proposed for my final project in week One. And anwser the questions: is my first idea valid? what have i done so far related to the project? and what i will do from now on (with the limited time on my hand)?

What have i done and discarted from my first ideia so far? I guess this will be have a couple of links, but i have divided my final project to incorporate as many assignements as i could. I started the program knowing that the most productive (and stress free) way to manage my time was to incorporate my final project to as many assignements that i could, and one of the reasons i chose the Small Parts Storage for my final project is that: It incorporate a lot of assignements, it can be used and reproduced in other parts (as i live in Brazil will be dificult to take many things home with me) and is something that i belive is going to be useful to the FabLab Network.

Let's go to the assignments and the relation with my final project:

Well in my research i found out this project for a eletronics parts storage with a interface that you can talk to and a lot of others systems for organizing and ordering all kind of stuff, but i decided to make my ow based on my needs and hopefully it will be applicable to other FabLab members.

Analogic eletronics parts storageFirst thing the projec will require is a Small Parts Storage, i will make my own, but i'm making mine based on an existing and well adopted plastic system called Akro-Mils. The one i'm making can be made out of acrilyc sheet or MDF. And for the eletronics part i will have an keypad, that i have made but can be bought, an LCD, two eletronics board and a bunch of LEDs and resistor for each drawer.

The system will be projected to fit in the Akro-Mils and my Small Parts Storage will be to be the same size (for the drawers) so the eletronic system can be compatible with both.

The 4x4 plastic cabinet from Akro-Mils

Everything is from the FabLab inventory, so the idea is to be a project that any FabLab can reproduce with ease.

First let me tell you something that startled me, how come a header can cost more than a microcontroller, i just can't understand that! Ok now here is the (incomplete) BOM (Bill of Materials) for the Small Parts Storage.

There will be three main systems, one is the drawers itself, two will be the Master module, with Speaker, SD reader and Wifi and the third will be the control, with the LCD and the keypad, everything connected via i2c protocol.

There will be used laser or Cnc for the drawers (depending on the size desired), milling and soldering for the eletronics parts and molding and casting for the buttons.

There is a lot of programing to be made, but on the hardware part everything is almost ready. For the hardware part what is missing is the LCD to i2c board, the final keypad and to mold a lot of buttons. For the programing i have to make the program to control everything. Most of the programs are working with the different systems separeted, but now i have to integrate all the code. And for extra credit i want it to connect to the internet and upload all the inventory to a google spreadshett or something similar.

If the programs will work, and if they will fit on the 32K memory of the AtMega 328p, i know that i should made all the code in C and not use any library, but i am not confortable and don't think i can learn a new code language.

By the FabAcademy faculty (of course). And for me i think i will be satisfied with the project if it is usefull to somebody else than me (hopefully other FabLabs). I guess the road map for Wally is be a system to help organize and manage materials and hand tools in the FabLab. Making the FabLab a complete machine and automated machine just waiting for imputs from people.

This "Wally" or Eletronic Small Parts Storage is part of a bigger idea. The idea to organize/inventory ALL parts of a FabLab, so it can free people from the laborious task of organizing the space (put things in the right place after you use them is not considered organizing, just education).

For this particularly project to be sucessul it has to be usefull, and for that i has to work fluidy with people of the FabLab. In this moment i thing the ideal system would: Localize parts, atualize inventory, order parts automaticaly and network FabLabs inventories around the world.

Final Project Review Video (my presentation at 47:40)