Design a 3D mold, machine it, and cast parts from it

I tried to make a dry confectionery made of Wasanbon toh.

Photo of dry confectioneries (kind of cast objects) I made.

Wasanbon toh is a fine-grained Japanese sugar, which made from sugar cane plants grown locally in Kagawa and Tokushima prefecture, Japan. I backordered Awa Wasanbon toh from Okada Sugar Manufacturer in Tokushima immediately. The process of making wasanbon toh is here.

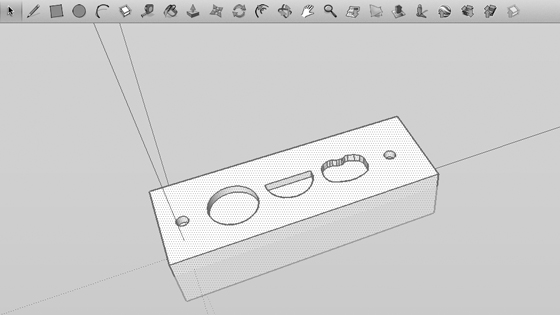

I designed a simple mold in the motif of rouded patterns which I have used in the previous assignment.

Screen capture of SketchUp. 3D model of mold.

Then I made the wooden mold based on the model by CNC router engraving.

Prototype of wooden mold for dry confectionery.

I referred to the blog (written in Japanese) for information on how making dry confectionery. I cast the Wasanbon sugar into the wooden mold and turn it upside down on the tray.

The process of making dry confectionery.

Finished dry confectionery, for now.

Generally, the wooden mold which can make a rounded form is composed of two parts. In future I will try to make a dry confectionery with more complicated shapes.