Do the mechanical design for my final project

I would like to use some local common resources, especially

renewable biomass resources, for my final project. In order to

use the appropriate material in the appropriate component of my

product prototype, I started to research on the material

characteristics and how the material could be applied to the

mechanical components.Rice straw

Rice straw is produced as a by-product from rice cropping, and has thermal, cushioning, and aeration properties. Therefore, it has been used for making various crafts of daily use in Japan. I made the rope of rice straw, and then plan to learn ropework and use the rope as a back support cushion so that we do not hurt our back when we carry a tank of water on the back. I would also like to make a thermal bowl to keep the temperature of warm water even if only slightly.

Photo of me during rice planting last season.

A wisp of rice straw from home in Shinjo, Okayama, Japan.

Photo of me during making rice straw rice straw.

The sample of rice rope we made.

Bamboo

Bamboo has also long been used for fabricating various constructional materials and products of daily use, because of its mechanical properties including flexural strength, toughness and elasticity. Most bamboos have hollow structure, therefore we are able to use it as a material of small container, chute, and tubing.

Thin bamboo from the grove behind my working studio.

The process of working bamboo: from left to right.

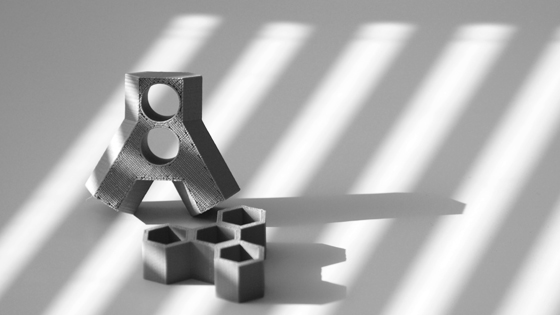

I found the project on the Bamboo and Digital Fabrication by Fab Lab Limerick, Ireland, in the course of research on how to join bamboo. I downloaded the 3D CAD file of some connectors and 3D print it at 1/2 scale.

3D printed plastic connectors, designed by the project of Fab Lab Limerick.

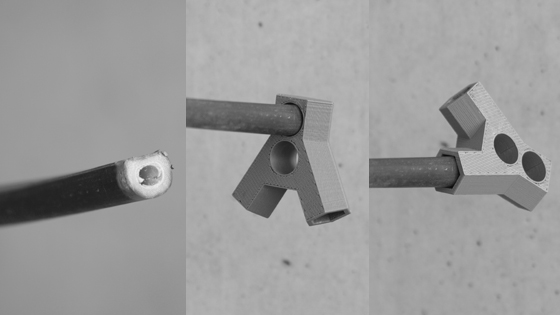

Cross-section shape of thin bamboo (left), fitting into round hole (central) and hexagonal hole (right).

The bamboo is rotated freely when fitting into a round hole, and not rotated when fitting into a hexagonal hole.

Then, I applied a thin bamboo as the rib of the umbrella-like component to collect water, and made connecter that join these ribs by 3D modeling and printing.

Screen capture of Project Shapeshifter, which provides an easy way to create 3D printable models.

3D printed connector, modeled by me.

Ribs joined by the connector I made.