Principles and practices

Here begin my journey trough the fabacademy program. Week checklist

- Read the Fab Charter

- Sketched your final project idea/s

- Described what it will do and who will use it

For my final project I decided to work on a robot arm joint. More precisely, I want to design and make a very compact robot joint. This joint should be connected to watever prototyping board you use and act like a servomotor. A problem I usually have while prototyping robot is the load the motor can handle. The other common problem is the price of high end actuator. I want to create a precise actuator wich can perform a full rotation whith a bit of torque.

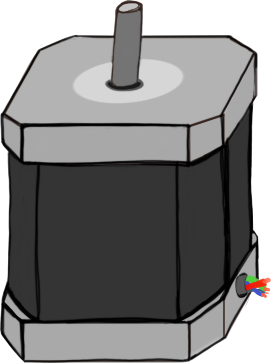

I plan to use stepper motor as the core of the project. Stepper are great to prototype robot since they are powerful and easy to control in term of position. Unlike conventionnal motor they can go from point A to point B step by step (Here is why it is a stepper motor…)

To have more torque with one of these motors I need to print a small gearbox. This wil allow very precise movement while reducing the speed of the system. I theory the stepper may have more torque. Which mean he will be more robust against step loose.

These motor have one little problem… There may be lost if the load is to heavy or after being unpowered. I have to find a way to know there current position somehow…

I have a few ideas about the torque optimization. I will probably use a reducer, but the challenge here is to make it 3D printable. I’ve heard about a cool reducer named “Harmonic drive”

Here is an example of a such reducer :

I want to make this reducer as tiny as possible to facilitate its integration into a robot. In other words, I need a zero/low backlash to be precise while moving from point A to point B.

Strain wave gearing (Harmonic drive)

Strain wave gearing (Also known as harmonic gearing and harmonic drive) is a type of mechanical system that has no backlash, high compactness and lightweight. They also have other advantages such as :

- High torque

- Coaxial input and output shaft

- Gest reduction/ volume ratio of known reducer

Strain gear offer ratio from 30:1 up to 320:1 in the same space in which planetary gears typically only produce a 10:1 ratio

The basic concept of strain wave gearing (SWG) was introduced by C.W. Musser in his 1957 patent.

Here is the main idea. I plan to use a Nema 17 stepper motor as my main actuator. Nema 17 are very common nowadays and cheap thanks to 3D printer manufacturer.

Harmonic gearing are composed of 3 parts :

- The flex spline ( flexible gear )

- The circular spline ( static gear)

- A Wave generator ( eliptic bearing )

The reduction ration can be calculated this way :

Cycloidal gearing

I also want to explore an other kind of reducer named cycloidal gearing. This type of gearing seems easier to make but also weaker… The gearing ratio is lower since it has less teeth. Maybe the solution will be just between cycloidal gearing and harmonic drive.

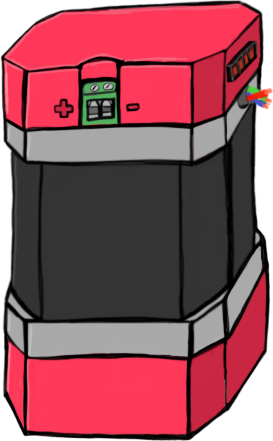

Servo motor

Usually, kid learning robotics may use easy to use actuators. Modelism servomotor are now mainstream and cheap. There are also very simple to use. Want I like with servomotors is how simple it is to control them. You can basically tell them where to go (angular position) and they will to there best to reach the requested position.

The servomotor control il pretty much the same for all prototyping servos. They are using pulse width modulation to be controlled using only 1 command wire.

This may be a cool feature of my final project.

Planning

I will spend a bit of time testing mecanical properties of both reducer and then create a board to control the motor precisely. If the project is going well enough I may prototype a small robot to perform simple picking tasks.

To control the robot I also want to develop a small piece of software connected to the main board of the robot. I like the idea to have a bunch of modular motor that you can control independently or simultaneously.