This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License

Week 17: Applications And Implications

May 25, 2021Summary

This week's assignments

- Propose a final project masterpiece that integrates the range of units covered. Your project should incorporate:

- 2D and 3D design

- Additive and subtractive fabrication processes

- Electronics design and production

- Microcontroller interfacing and programming

- System integration and packaging

- Define the scope of your project and develop a project plan. The answers to the questions below will allow you to create your BOM (Bill Of Materials):

- What will it do? ✔

- Who has done what beforehand? ✔

- What will you design? ✔

- What materials and components will be used? ✔

- Where will they come from? ✔

- How much will they cost? ✔

- What parts and systems will be made? ✔

- What processes will be used? ✔

- What questions need to be answered? ✔

- How will it be evaluated? ✔

My Weekly Schedule

1. What will it do?

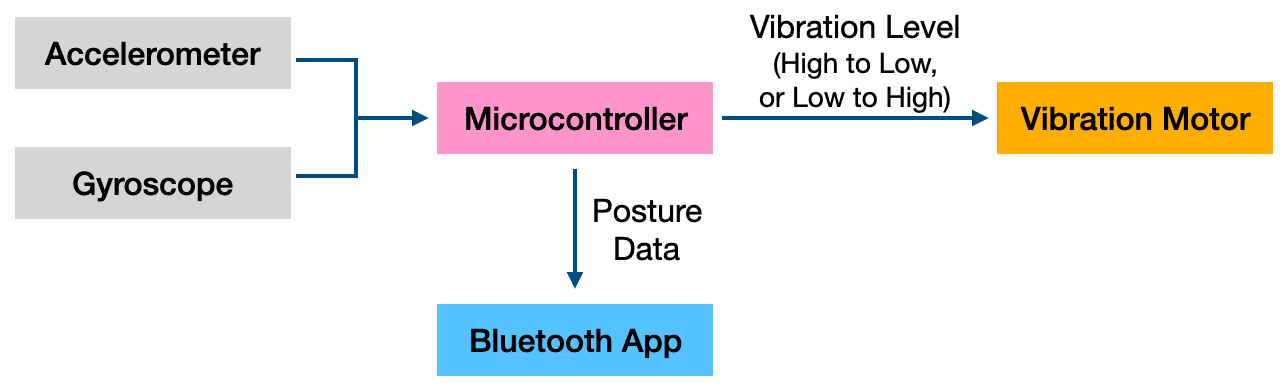

The project is about an interactive dress that responds to the poor posture of the user and cues her through vibration alerts.

2. Who has done what beforehand?

My project was inspired by Wearable X's smart yoga pants which help monitor the right posture of the user during yoga practice.

Here are some prior arts by Fab Academy students:

- Victoria Peredo Robinson: Posturea

- Kiyeon Lee: Posture Nudger

- Carlos Nina Ochoa: Robotic Spiral Brace

3. What will you design?

The designs that will be included in this project are:

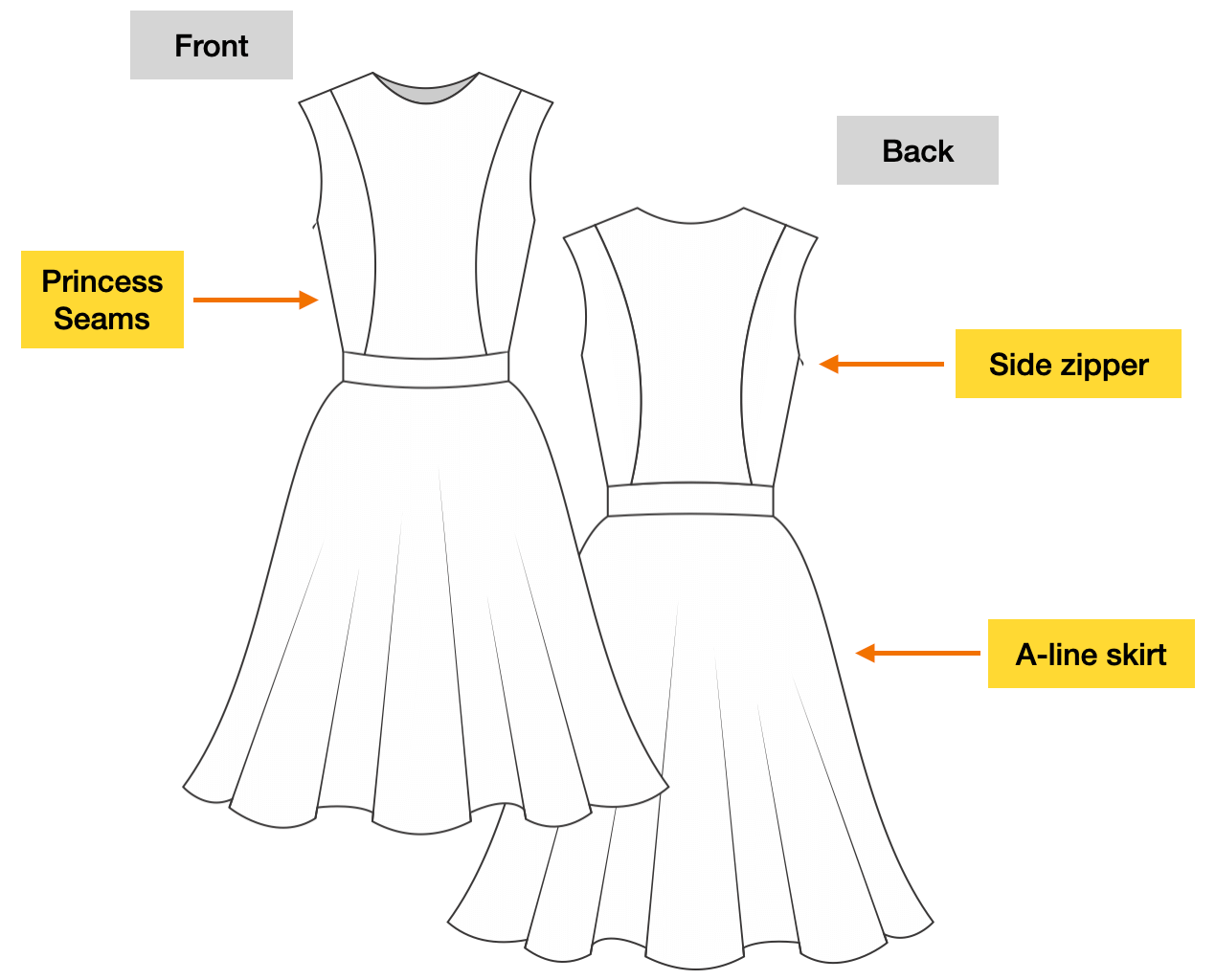

- Dress sewing pattern (2D design and 3D simulation in CLO3D)

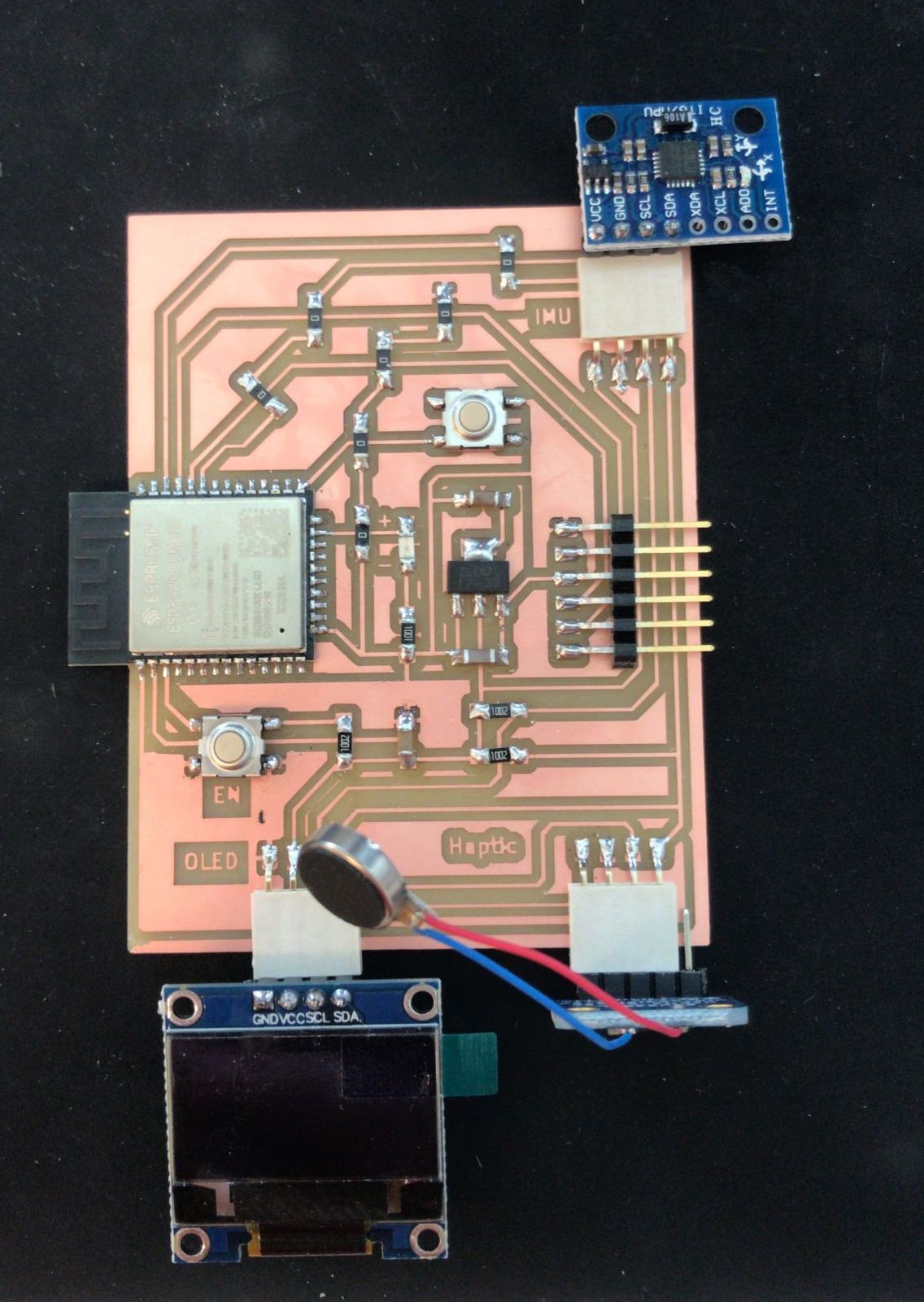

- ESP32 PCB design (KiCad)

- Decoration design for the dress (SOLIDWORKS)

- App design (MIT App Inventor)

4. What materials and components will be used? Where will they come from? How much will they cost?

Note 1: Most of the electronic components will be sourced in 3DExperience Lab (refer to Fab Lab Inventory), however, the MPU6050 and DRV2605 breakout boards, and the vibration motor were sourced from amazon.com.The fabric, thread, and invisible zipper were sourced from local fabric store. Please find the table below for the bill of materials.

Note 2: The 3D printer filament, the FR1 board, the kapton sheet and the copper vinyl sheet will also be sourced from the 3DExperience Lab, however, I will need to consult my instructors and my lab manager for the price.

Here is the bill of materials:

| Item | Quantity | Source | Unit Price (USD, $) | Total Cost (USD, $) |

|---|---|---|---|---|

| FTDI (1x6 male header connector) | 1X | 3DExperience Lab | 0.60 | 0.60 |

| "I2C connectors" (1x4 female header connector) | 3X | 3DExperience Lab | 0.74 | 2.22 |

| 3.3V 1A Regulator (ZLDO1117G33DICT-ND) | 1X | 3DExperience Lab | 0.34 | 0.34 |

| Capacitor 10uF (587-3007-1-ND) | 1X | 3DExperience Lab | 0.24 | 0.24 |

| Capacitor 1uF (445-1423-1-ND) | 1X | 3DExperience Lab | 0.07 | 0.07 |

| Capacitor 0.11uF (399-4674-1-ND) | 1X | 3DExperience Lab | 0.12 | 0.12 |

| Resistor 10K ohm (311-10.0KFRCT-ND) | 3X | 3DExperience Lab | 0.01 | 0.03 |

| Resistor 1K ohm (311-1.00KFRCT-ND) | 1X | 3DExperience Lab | 0.01 | 0.01 |

| Resistor 0 ohm (311-0.0ERCT-ND) | 7X | 3DExperience Lab | 0.00477 | ~0.03 |

| Red LED (160-1167-1-ND) | 1X | 3DExperience Lab | 0.13 | 0.13 |

| Tact Switch (SW262CT-ND) | 2X | 3DExperience Lab | 0.84 | 1.68 |

| ESP32-WROOM-32E (1965-ESP32-WROOM-32E(8MB)CT-ND) | 1X | 3DExperience Lab | 2.80 | 2.80 |

| MPU6050 Acceleromter/Gyroscope module | 1X | Amazon.com | 5.39 | 5.39 |

| DRV2605 Haptic Controller module | 1X | Amazon.com | 11.44 | 11.44 |

| Vibration Motor | 1X | Amazon.com | 0.866 | 0.866 |

| Linen fabric and lining | 3 yards each | local fabric store | 2.99 per yard | 17.94 |

| Polyester Thread (547 yard per roll) | 2X | local fabric store | 4.99 | 4.99 |

| Invisible zipper | 1X | local fabric store | 0.92 | 0.92 |

| Total | ~50 |

5. What parts and systems will be made? What processes will be used?

The information below is for the "mechanical" system of my project:

- The sewing pattern will be manually cut, reasons:

- the pattern piece is too large for the workarea for the laser cutter

- the fabric I am using is a woven fabric and cutting the fabric on grain is important for woven fabric

- I also cannot cut fabric in fold when using laser cutting as this may reduce the accuracy

- The decoration designs will be laser cut on fabric pattern pieces

- The brooch will be 3D printed

The information below is for the electrical system of my project:

- the non-flex PCB will be produced in Roland SRM-20

- the flex PCB will be produced in Trotec Speedy 400 Flexx fiber laser

6. What questions need to be answered?

Question / Concern: My main concern is that the flexible PCB may not work as expected. If that is the case, I will have to use the FR1 PCB (, which is not as compact) as the electrical system for my project.

Note: Below you can find the spiral development of my final project. Please visit the Project Stage page for more details.

- First Spiral:

- Dress pattern design and cut the pattern on fabric ✔

- laser-cut decoration pattern design ✔

- ESP32 PCB design and mill it on FR1 board ✔

- Test the I/O devices of the ESP32 PCB and make sure the PCB works ✔

- Second Spiral:

- Experiment fiber laser settings for ESP32 flex PCB production + flex PCB design ✔

- Flex PCB production ✔ (accomplished on Jun 1)

- Finalize the networking code for the board (use the I/O devices code as the starting point) ✘

- Bluetooth Application desgin ✘

- Third Spiral:

- brooch design in SOLIDWORKS ✔

- Laser cut and 3D print dress decorations ✘

- Sew the full-scale dress ✘

7. How will it be evaluated?

Here are the evaluation criterior for my project:

- Does the dress have laser cut and/or 3D printed decorations?

- Does the vibration motor buzz at a certain angle? (use phenolic paper or some thinner boards for testing)

- Does the app work?

- Are the electronic components packaged inside the dress well?