Assignments

1. Principles and practices

2. Project management

3. Computer Aided design

4. Computer controlled cutting

5. Electronics production

6. 3D Scanning and printing

7. Electronics design

8. Computer controlled machining

9. Embedded programming

10. Mechanical Design

11. Input devices

12. Molding and Casting

13. Output devices

14. Networking and communications

15. Interface and application programming

16. Wildcard week

17. Applications and implications

18. Invention, intellectual property and income

19. Project development

10. Mechanical Design

Assignment:Design a machine that includes mechanism + actuation + automation Build the mechanical parts and operate it manually.

Document the group project

Planning

Link to group page: Here. We actually wanted to make a Pina Colada machine but we quickly realized that this would take very long. As you can see, the Pina Colada needs to be blended and we weren't able to make a design so quickly.

That's why we decided to do a Tequila Sunrise machine, because it doesn't need to be blended and it still looks nice. Here you can see my first draft: I wanted to use tiny measuring jugs that release the fluid via tilting. My plan was using servos and a stabilizing system for the jugs, as well as a big 3D-printed funnel.

We decided to use pumps instead.

Assembling

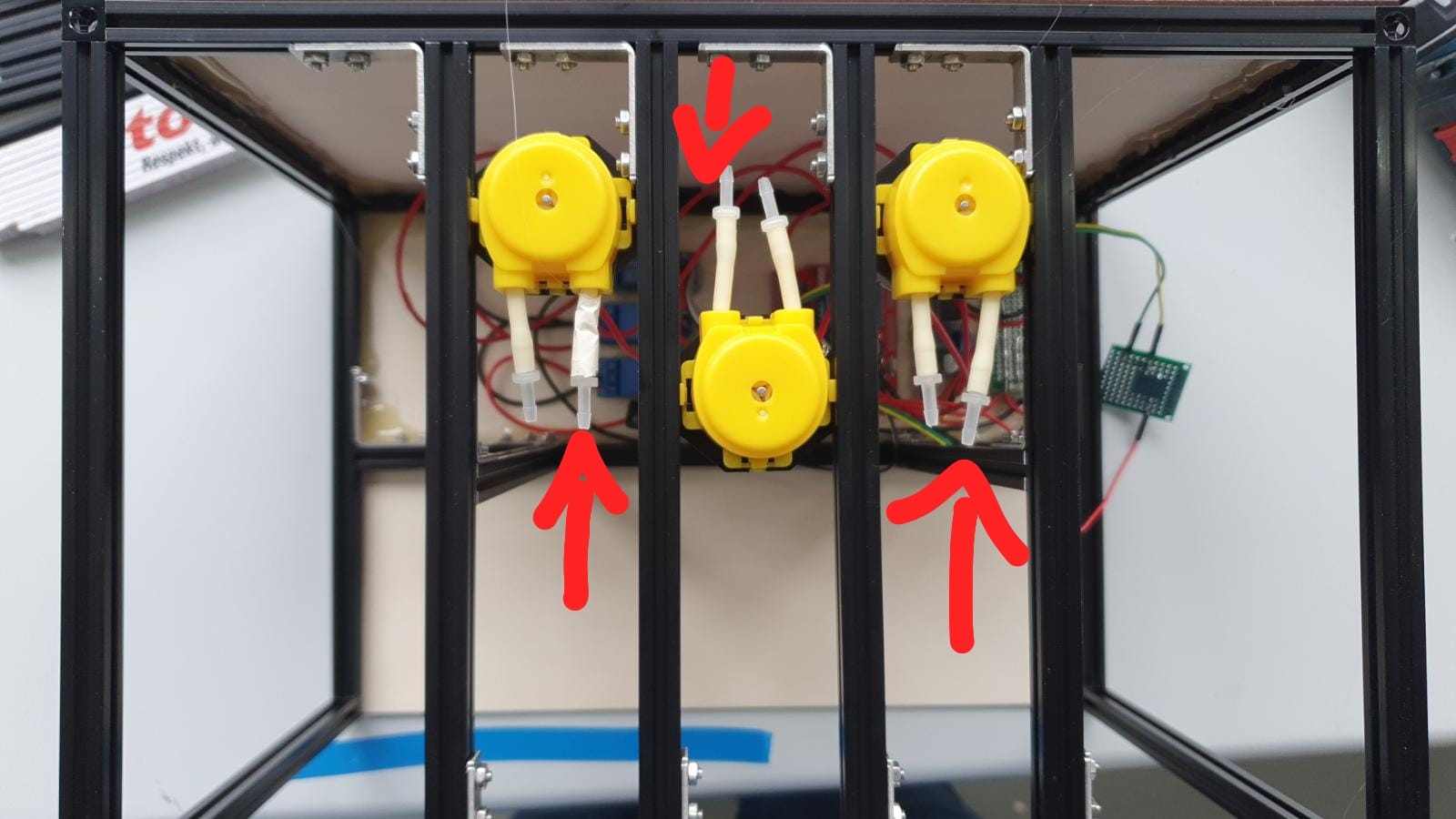

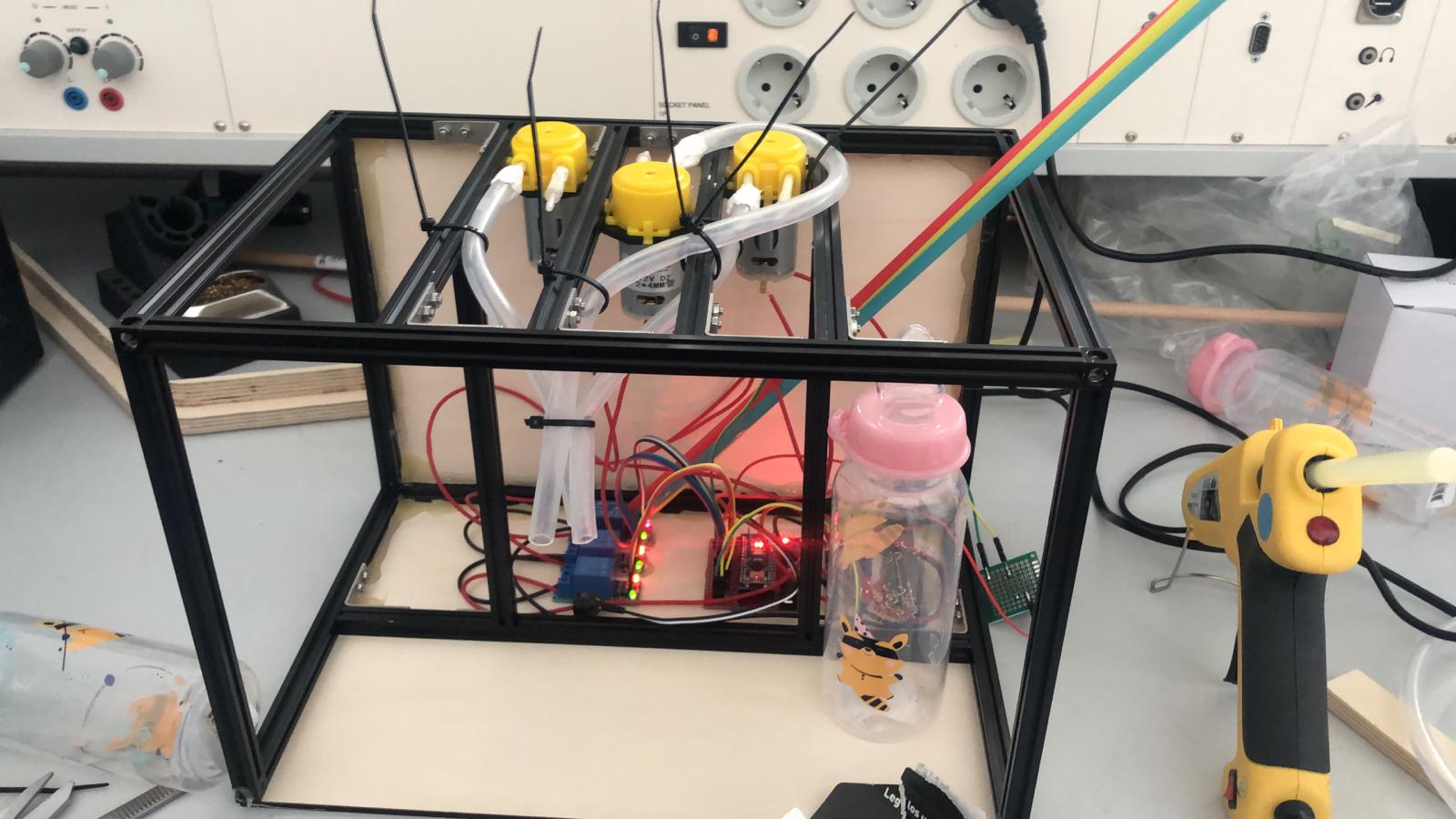

The assembling was a little complicated. So this is what we got: Three pumps and a too wide hose. I really wanted to make it food safe so I was holing back with hot glue. I also needed some bottles which where able to withstand the air pressure from being completely upside down.

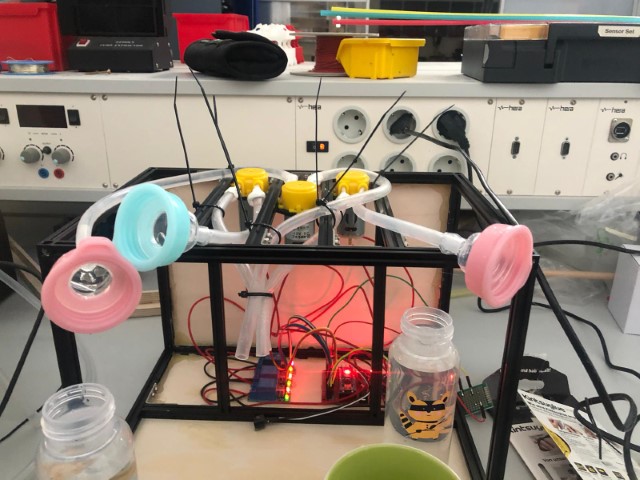

In the left pic you can see the red arrows, those show where the hoses for the fluid that goes into the pump are. And in the right pic you can see how I connected the ones that don't go into the bottles first. There is a sneak peak: I used baby bottles! Why? They withstand the suction from the pumps because the have non-leaking holes in the sides :D.

And this is baby-cthulu! The piping is done!

I used a special rubber glue for sealing. It's called Kintsuglue, after the Japanese word "Kintsugi". Kintsugi is the Japanese art of repairing broken pottery by mending the areas of breakage with lacquer dusted or mixed with powdered gold, silver, or platinum. And the glue can be used for pottery and stuff as well, so it's food safe and leak proof.

Testing and tweaking

As you can see, the timing wasn't perfect and the pumps stopped to quickly. So I tweaked the variables and voila! This is the result (halway sped up because I don't want to waste your time, dear reader);

Sorry we had no fancy glasses in the lab.