Week 18

Mechanical Design, Machine Design

Group Assignment

First of all, I would like to introduce the amazing crew of Fablab Iceland, students and instructors: Gísli Snær Guðmundsson, Hafliði Ásgeirsson, Thordur Hjalmarsson, Arnar Daði Þórisson, Vilhjámur Magnússon, Magnús St. Magnusson, Aida González Vicente and Jón Þór Sigurðsson.

This week we met in Fablab Akureyri to work together on our projects and on the machine design and build.

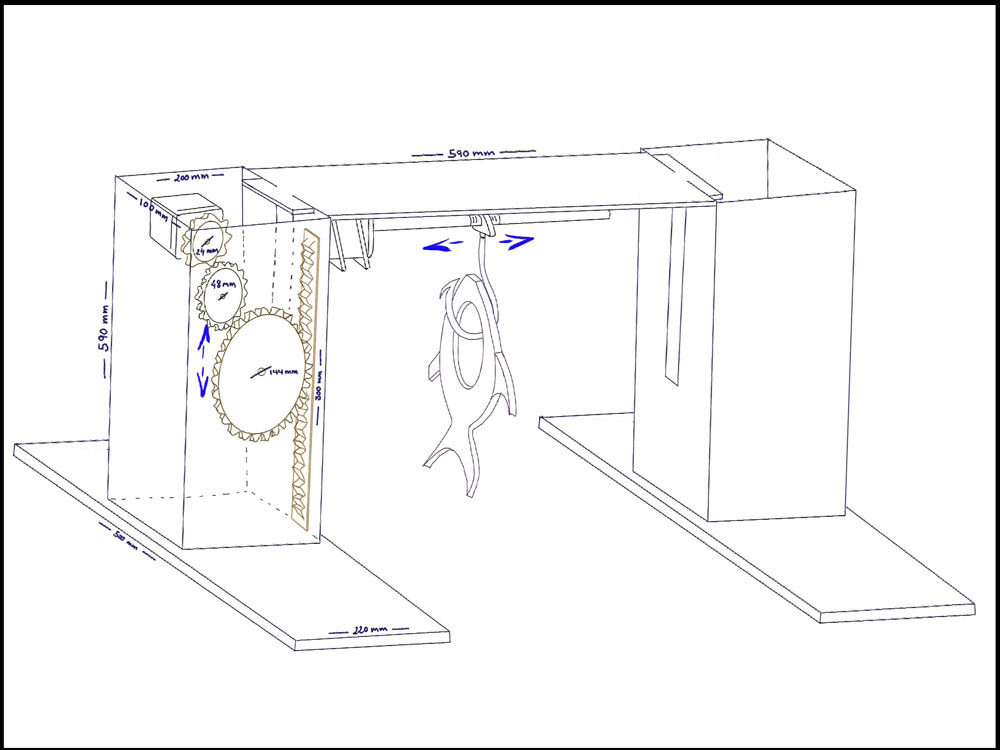

After a brainstorming, we decided to keep it as simple as possible but good and usable for another project’s development. That is a challenge. So, we came up with a preview sketches where you can see a structure is able to up and down with a hook at the middle that is able to move right and left.

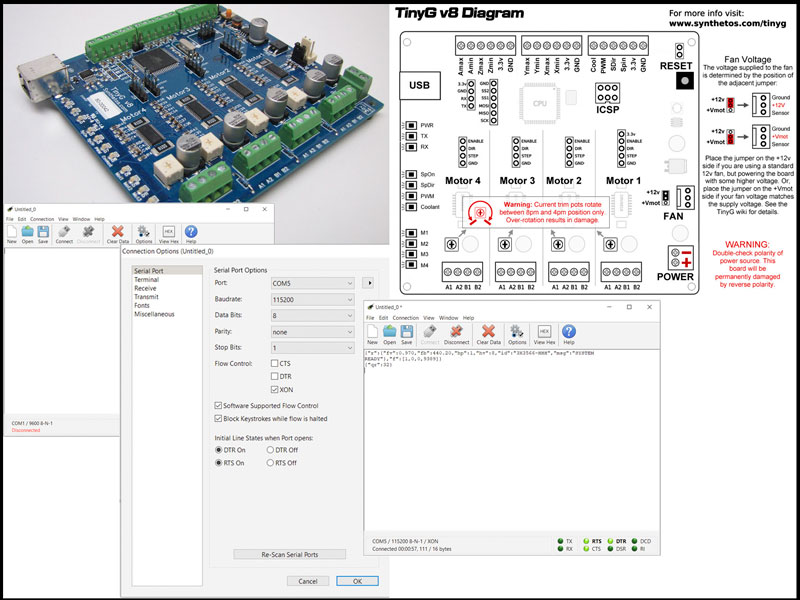

Once the sizes and the material are decided, we divided the work between the four members of the groups. On one hand we have two of us researching about how to use a TinyG, the step motors, the power and the programing.

The TinyG project is a many-axis motion control system. It is designed for small CNC applications and other applications that require highly controllable motion control. TinyG is meant to be a complete embedded solution for small/medium motor control.

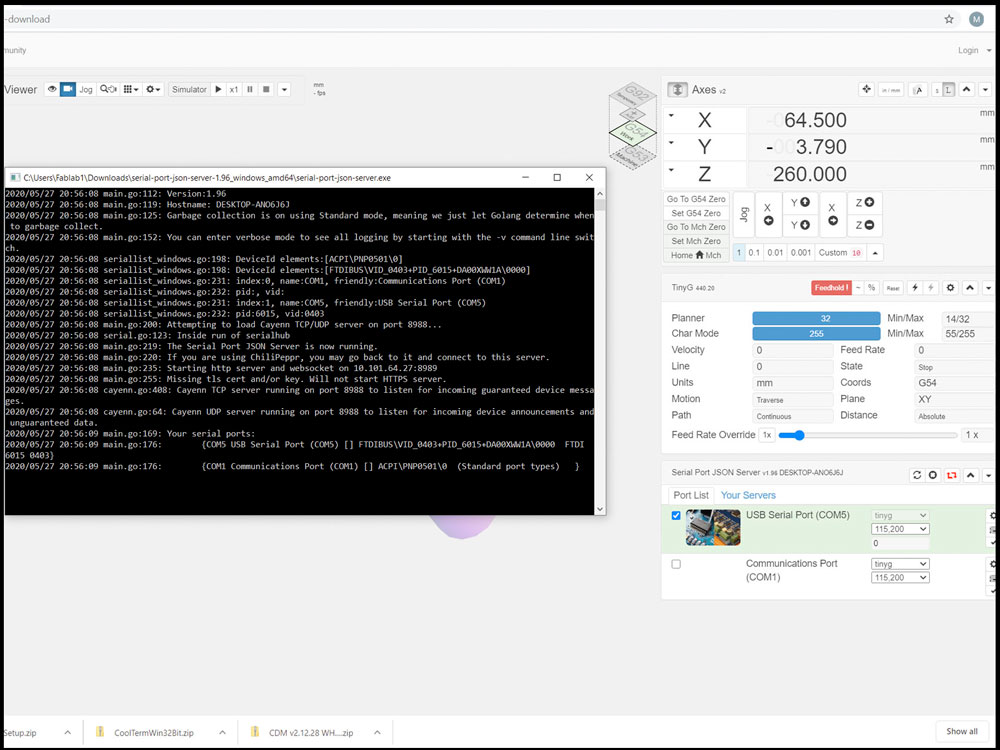

https://synthetos.com/project/tinygThen we programed the TinyG, we need to communicate with it So, to be able to control the movement of the machine with the computer we used a online CNC control program called Chilippepper. Our research for this came from the Icelandic FabAcademy group of 2018

chilipeppr.comThis workspace is a full-blown Gcode sender for your TinyG. The workspace connects to your TinyG via the serial port over the ChiliPeppr Serial Port JSON Server. It lets you view your Gcode in 3D, view the XYZA positions, perform jogging, and see advanced real-time details from the TinyG.

Chillipepper is quite intuitive but it is important to set the port. Once, you connect TinyG and follow the steps, you have the power:

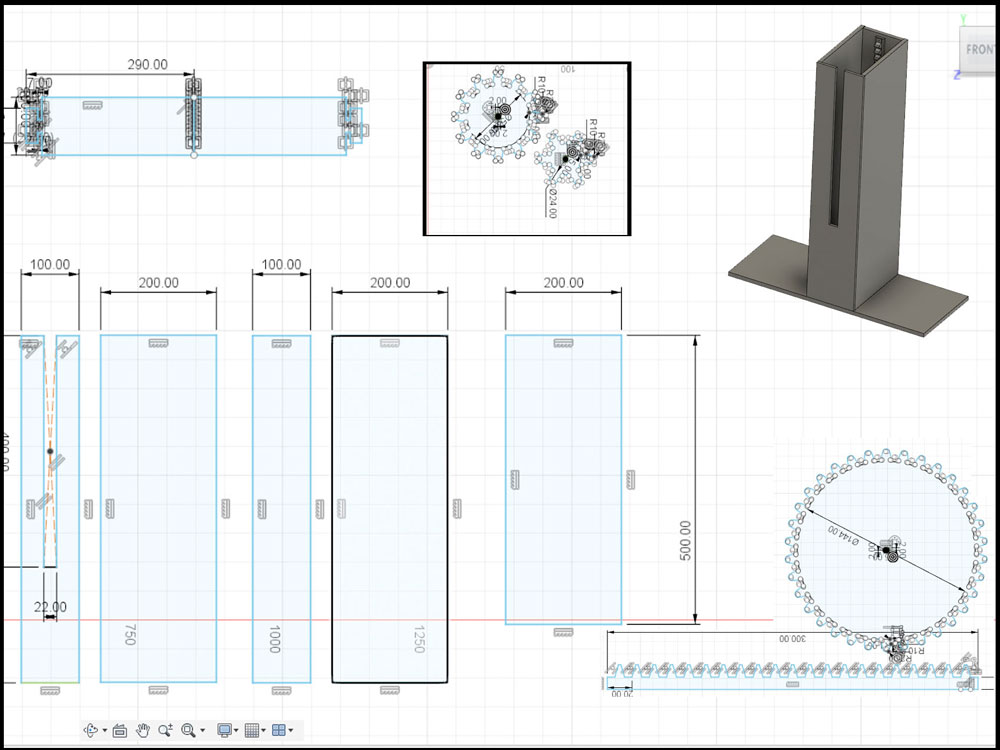

And on the other hand, the other two designing the frame and the gears. We decided to use fusion 360 to be able to see the design on 3D.

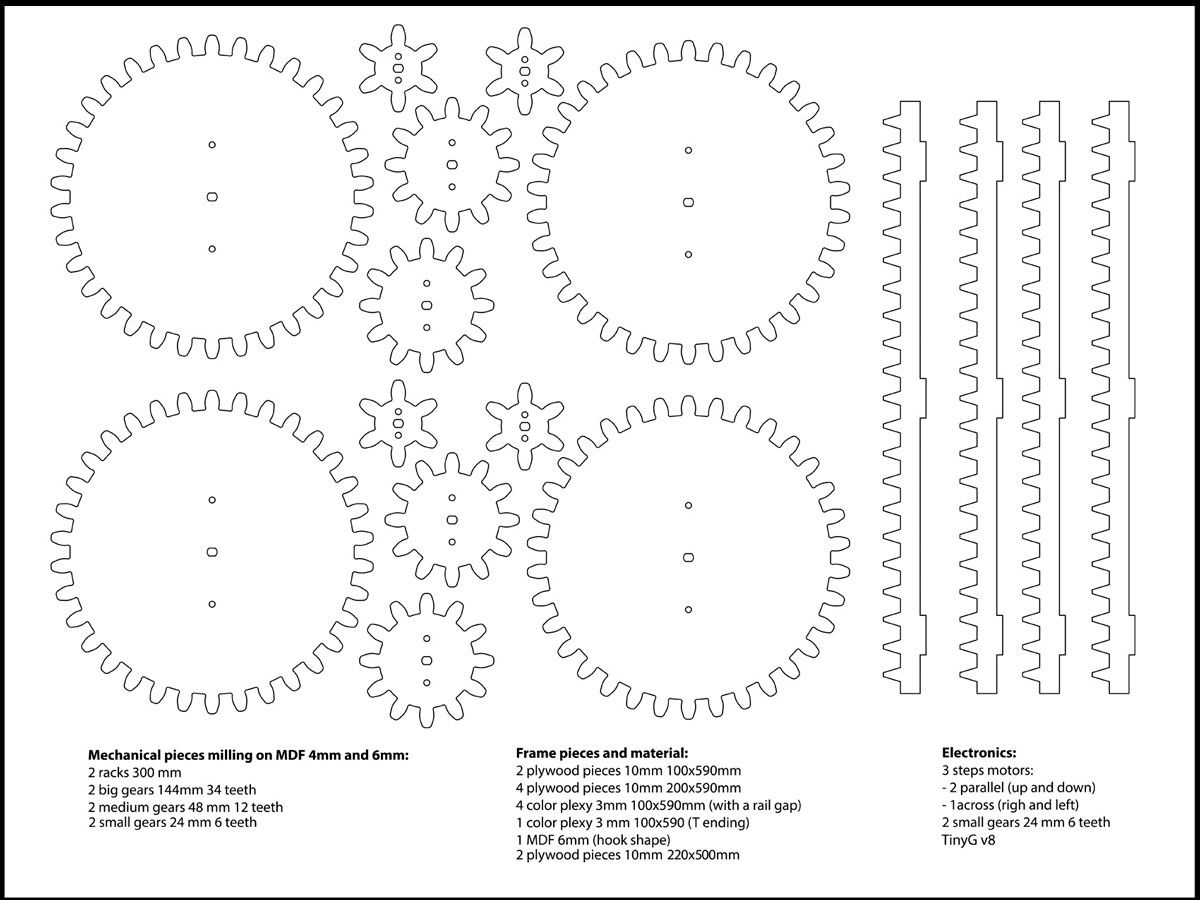

Then, we put our pieces together and split again with other functions. Two of us were building the frame. To save milling time we decided to do it with a material that we can laser cut, glue and screw together without problem and also cutting directly using the old fashion way, handmade. On the picture below is a sum up of the pieces that we used with the last design of the gears and racks.

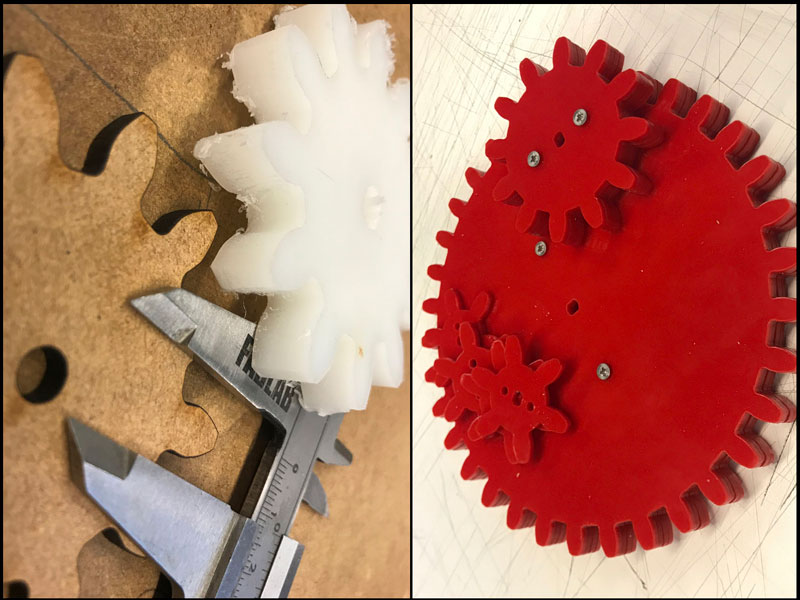

We tested different gears ones milled in MDF and another milled in Plexy because we want to check also the friction that the force can create in addition with the material used.

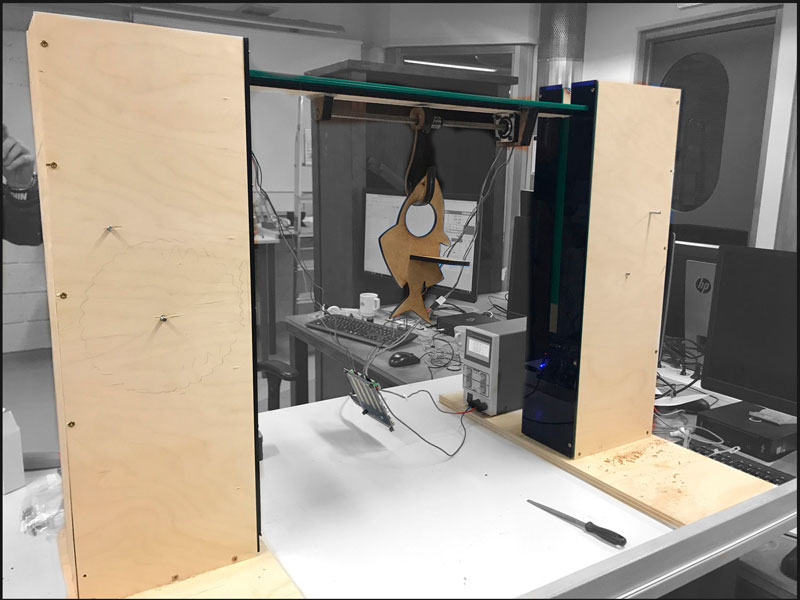

The machine looks like this:

Now, it was the time tested:

On the video we can see how we can control the machine to go down. The mask video shows how the gears and rack work to go up and down shortly.

Magnús St. Magnússon © 2020| v1

Madefor FabAcademy