Week 16

Moulding and Casting

Group assignment

- Review the safety data sheets for each of your molding and casting materials

- Make and compare test casts with each of them

Individual assignment

- Design a 3D mould around the stock and tooling that you'll be using, mill it (rough cut + (at least) three-axis finish cut), and use it to cast parts.

Group assignment

- Review the safety data sheets for each of your molding and casting materials

- Make and compare test casts with each of them

Individual assignment

- Design a 3D mould around the stock and tooling that you'll be using, mill it (rough cut + (at least) three-axis finish cut), and use it to cast parts.

Designing the mould

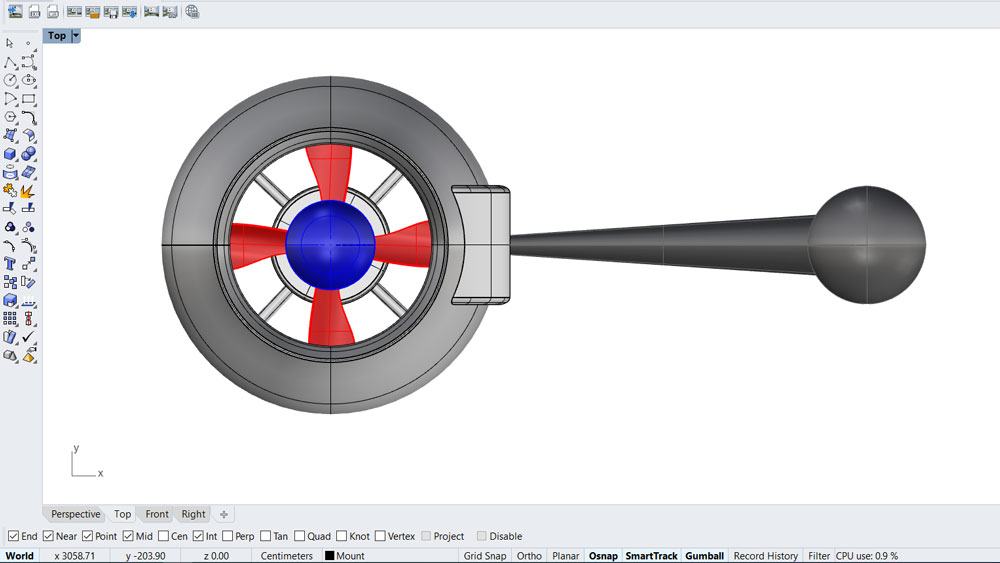

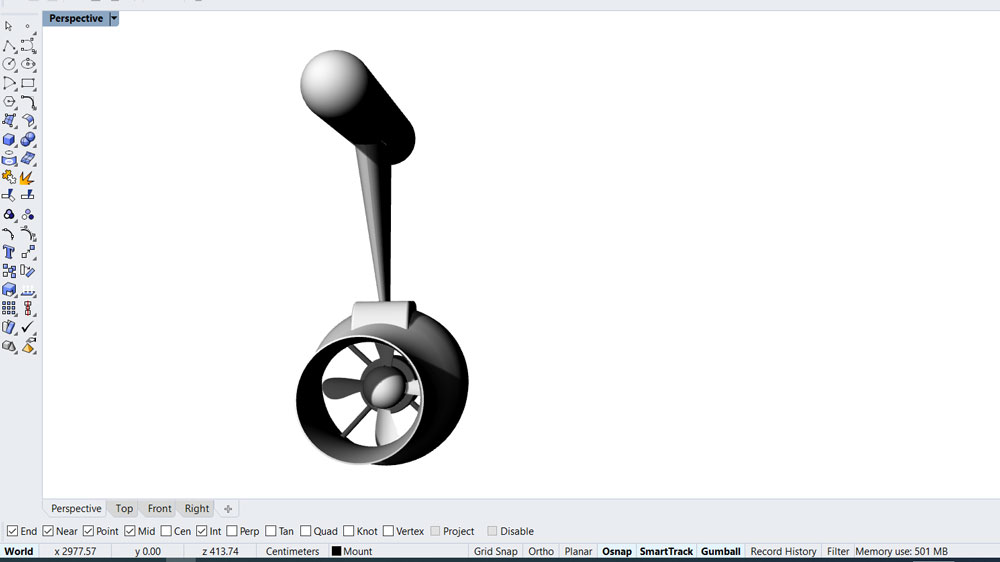

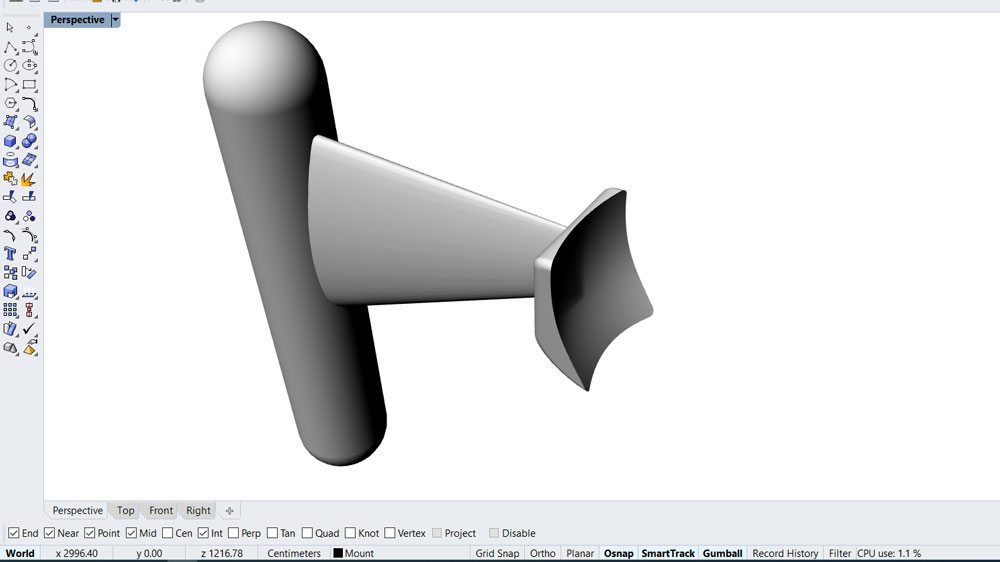

For this week I wanted to design and make a moulding cast that I could use for my Final Project.

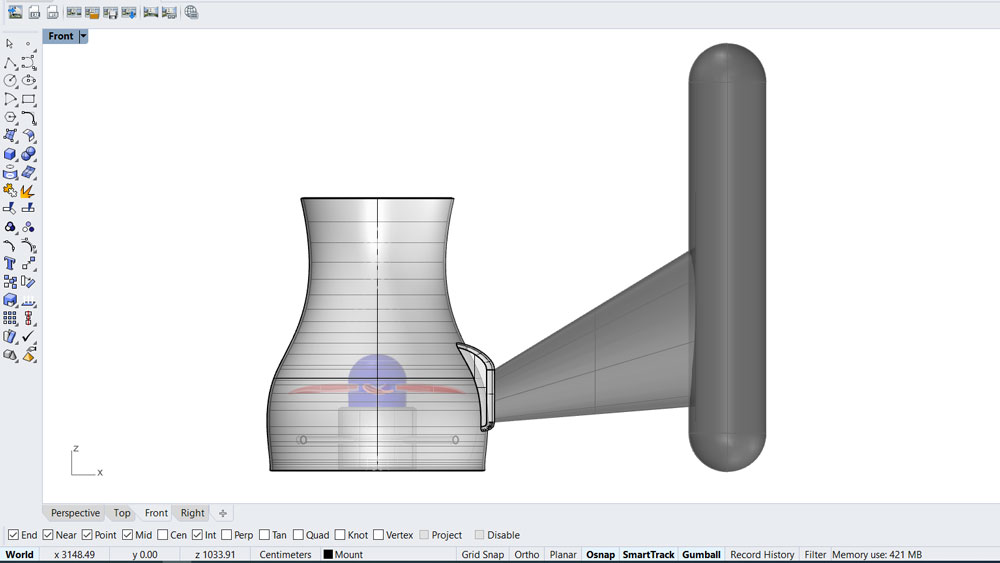

So I decided to make a mount for my Turbine. This item will stear the turbine in line with the current and make it steady under water

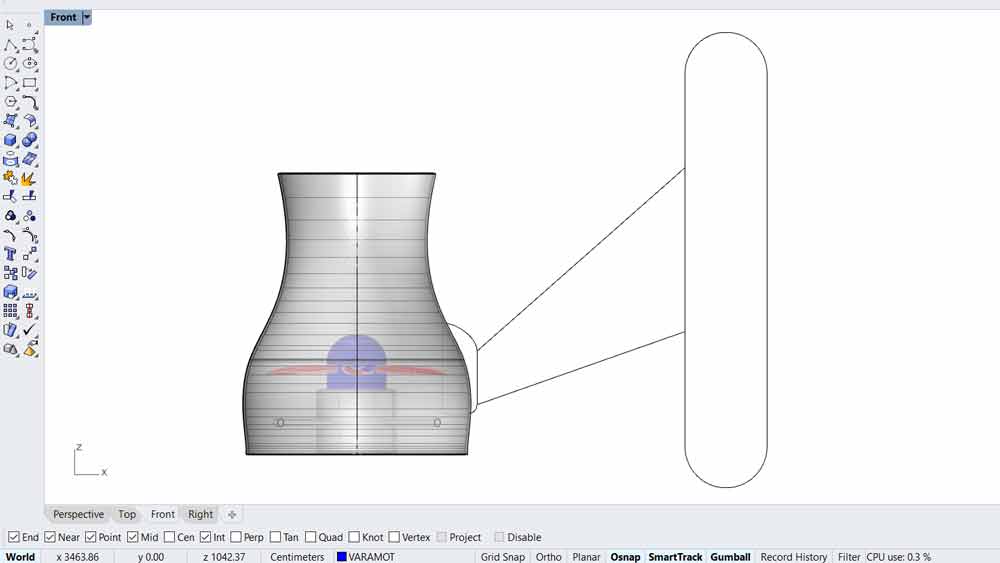

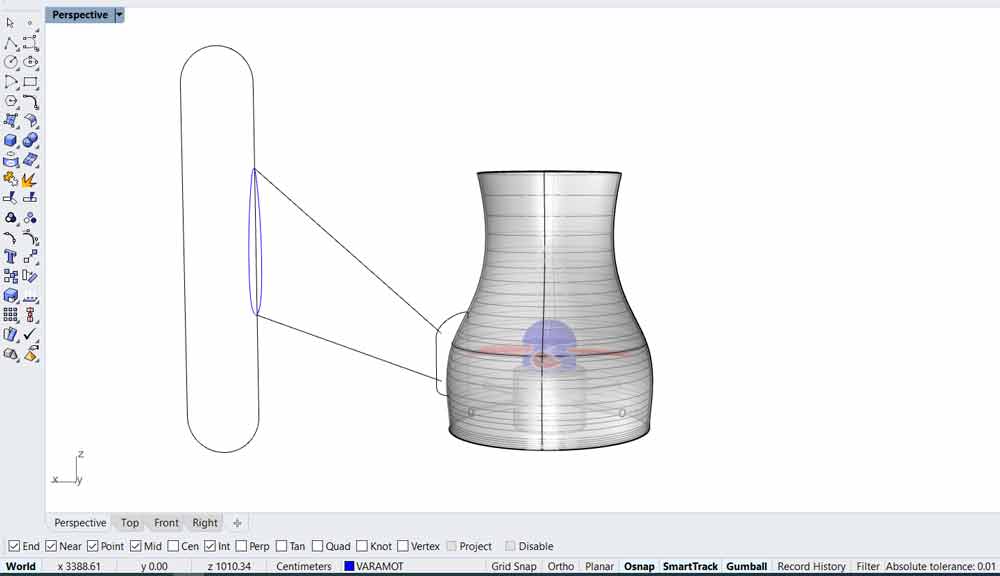

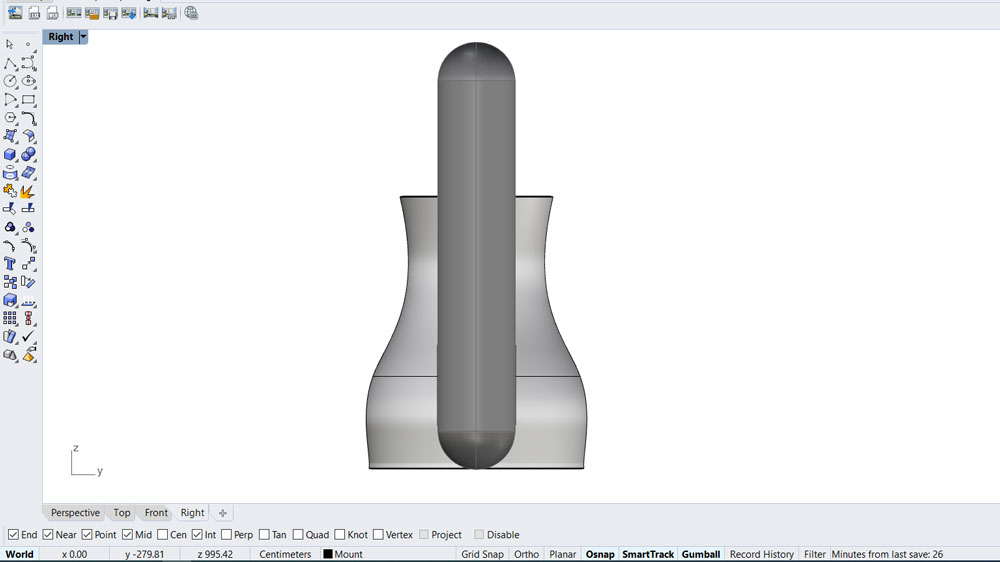

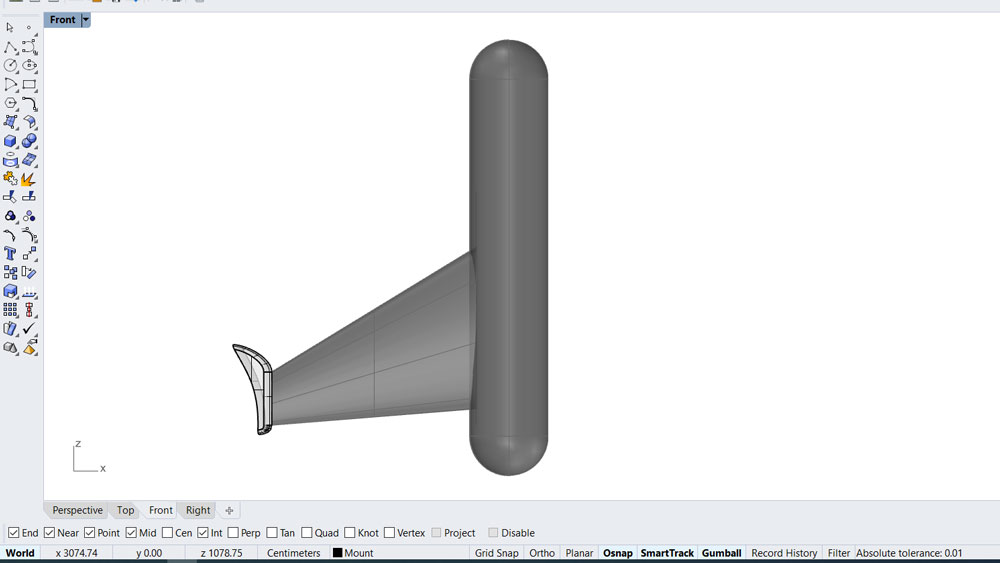

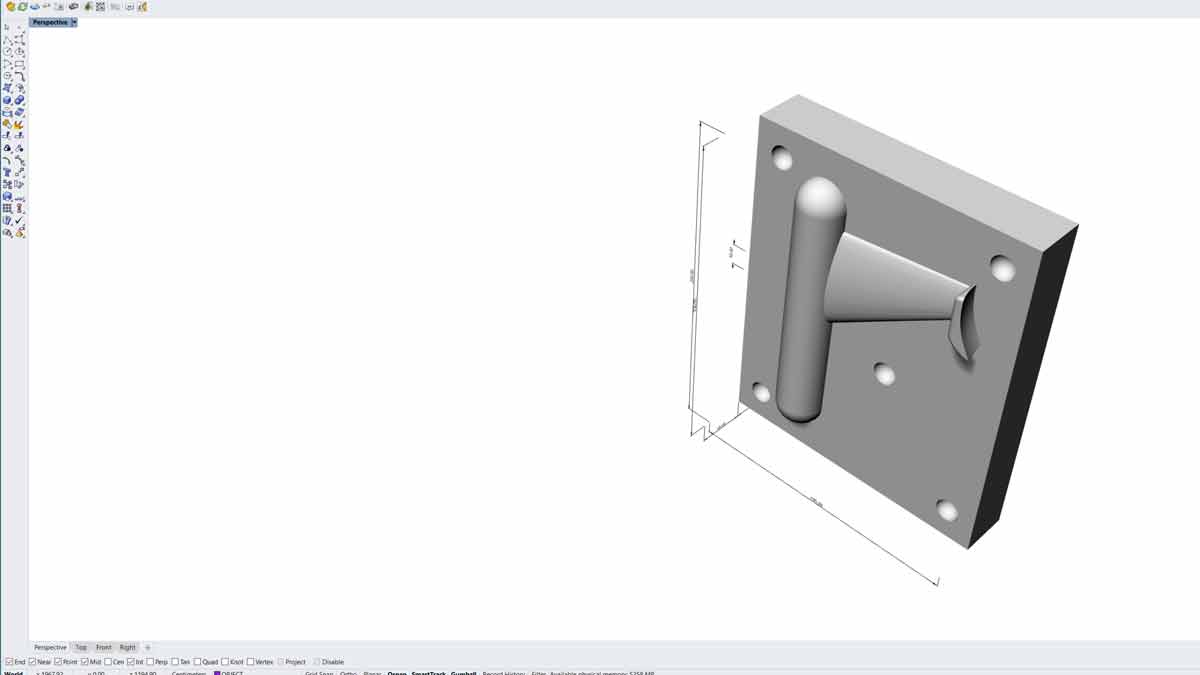

Started by drawing a wireframe of the turbine mount

After drawing the outlines and tweaking them around a bit I got the shape I was happy with and then made a 3d model from the outlines.

Making the mould

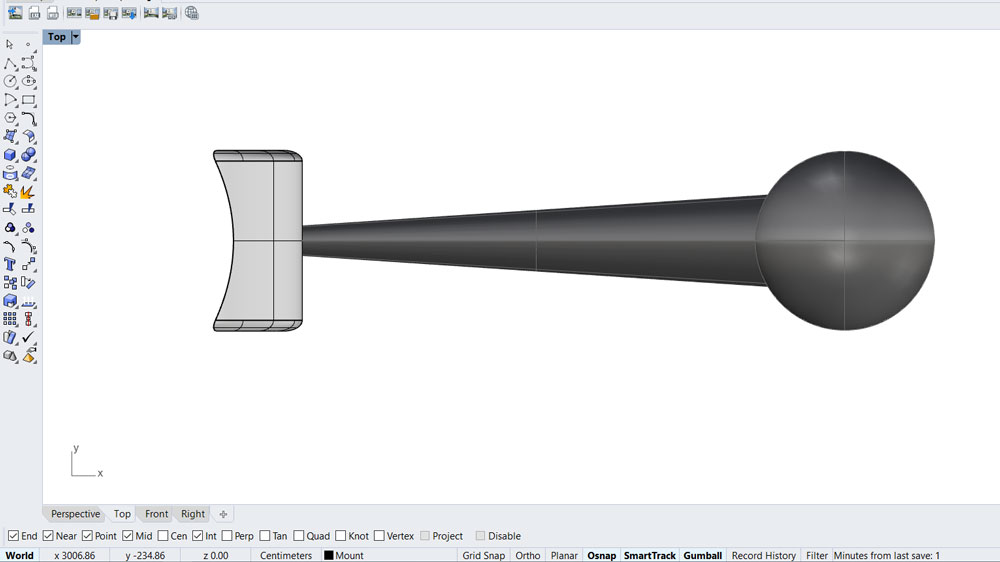

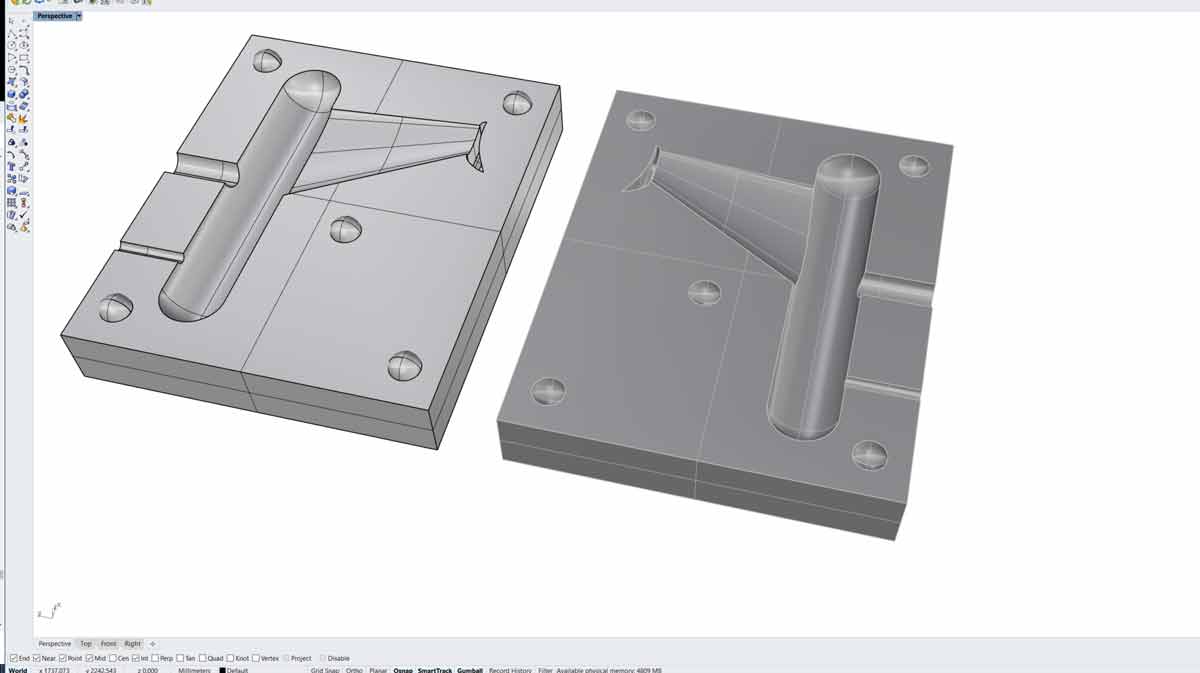

After I finished drawing the bracket that I was going to mount to my Turbine. Then the next step was to make mould around it

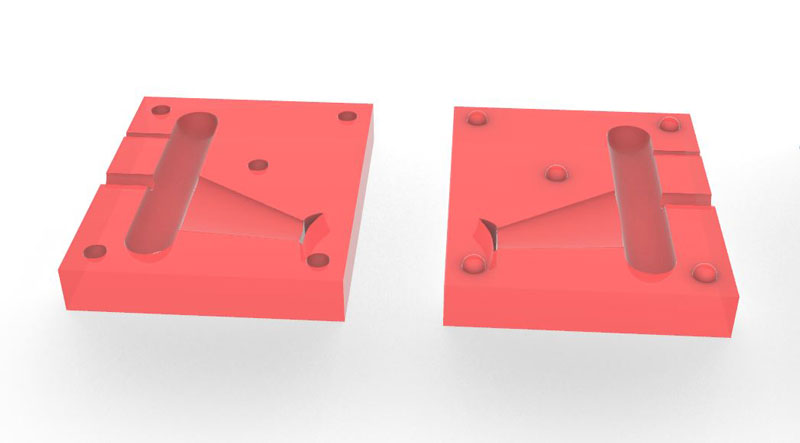

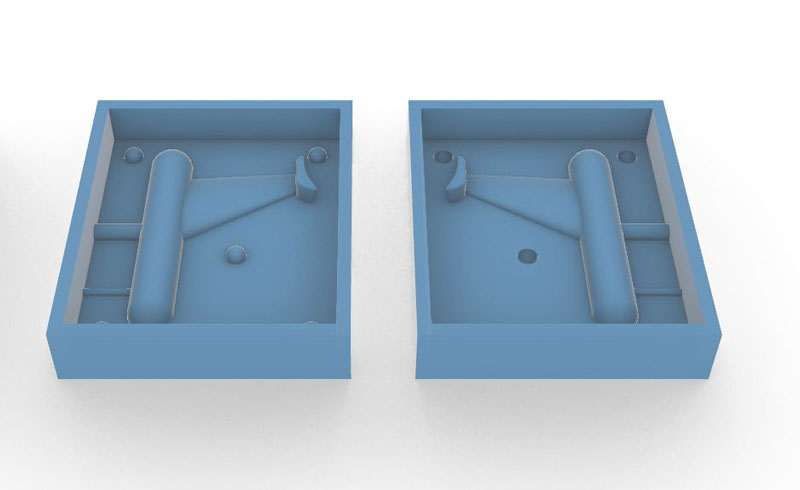

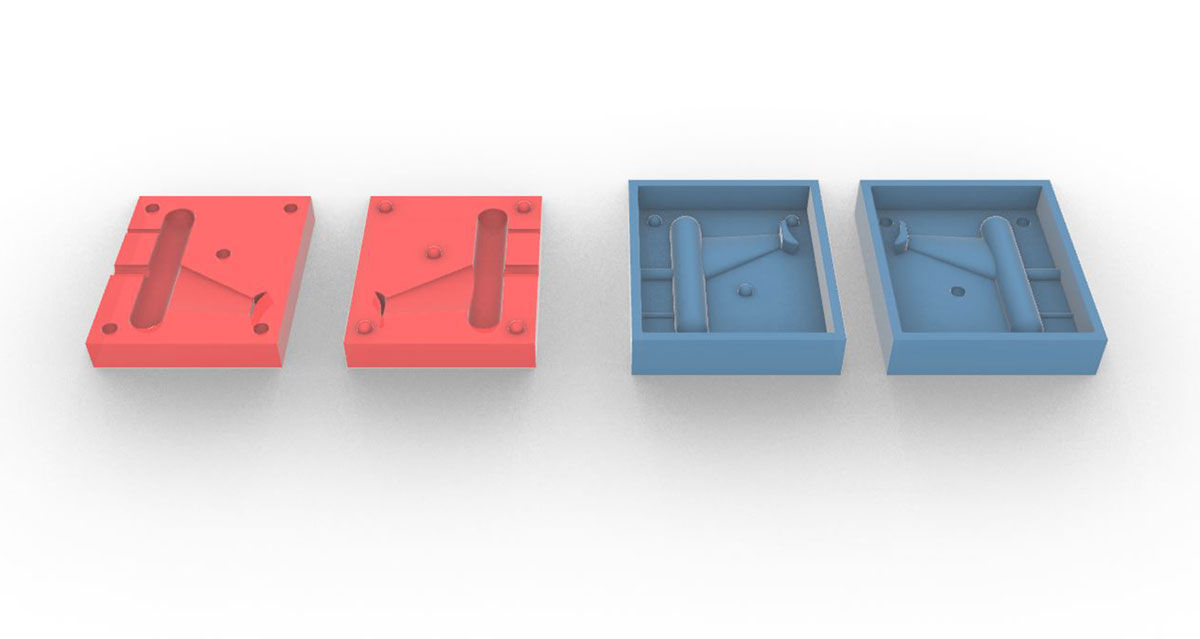

Mould

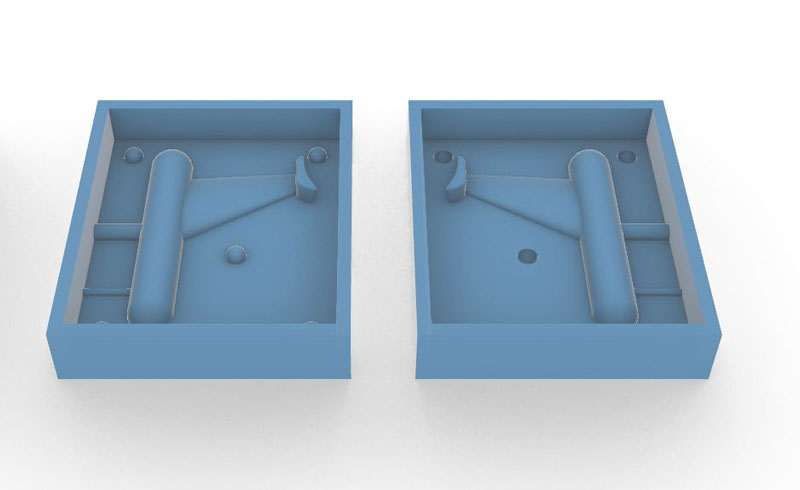

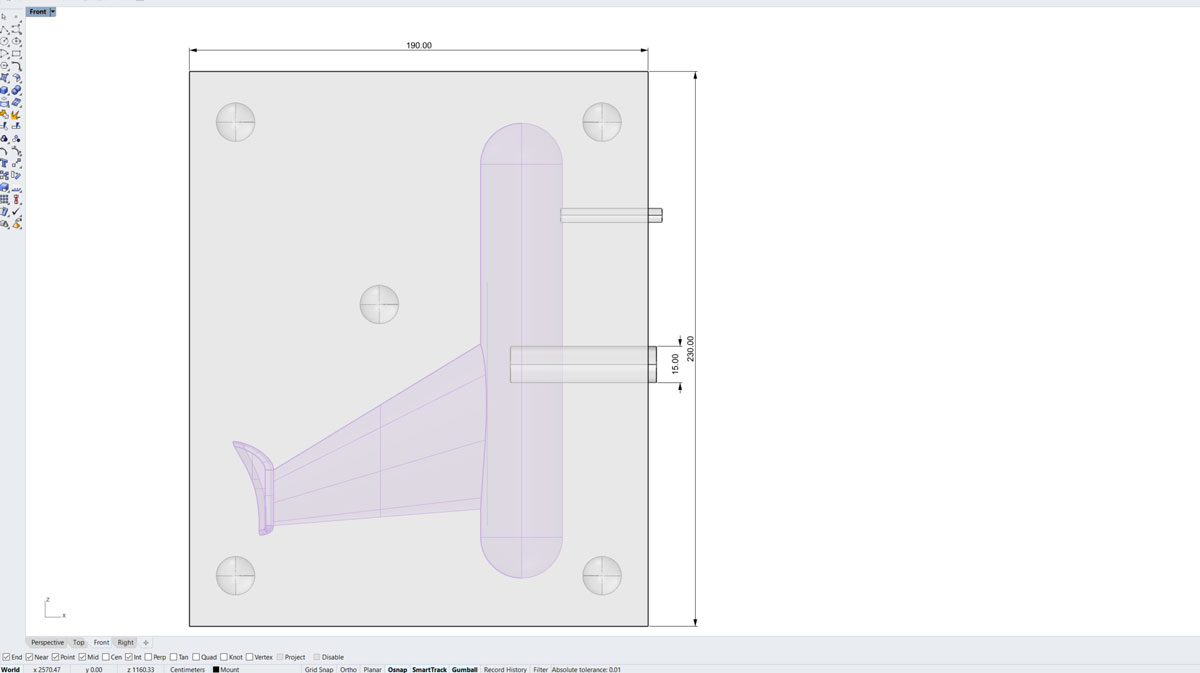

Made a two sided mould with cutouts to stear the two sides correcly in place

Made also one poaring hole 15mm wide and one 6mm air hole to let trapped air out when making the item

Here are both sides of the finished mould

Mould ready for Milling

Was not able to finish my mould this week because I did not have the nessasary materials to work with.

I will travel next week to Fablab Akureyri in North of Iceland to finish my Mould :-)

Here below is the file that I made in Rhino

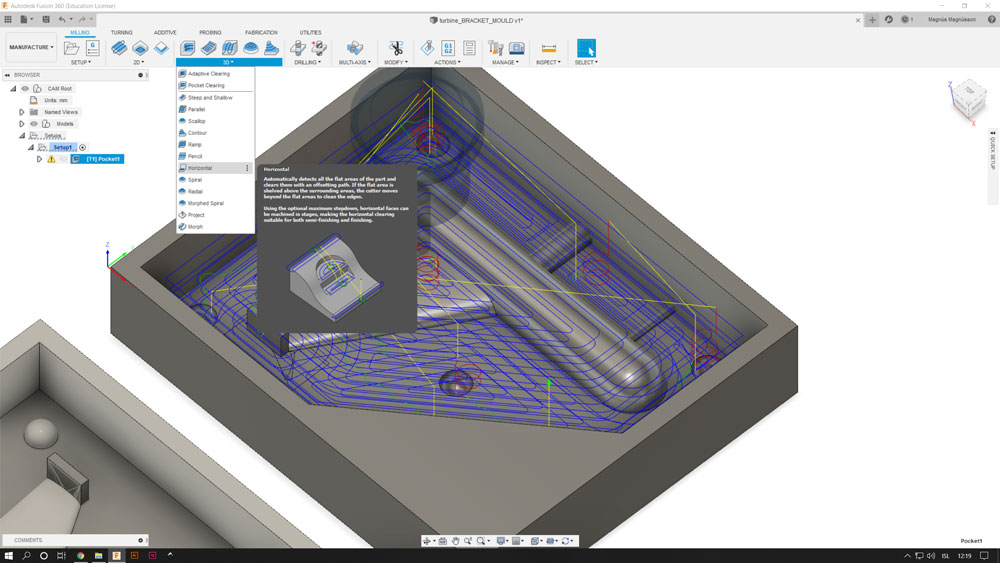

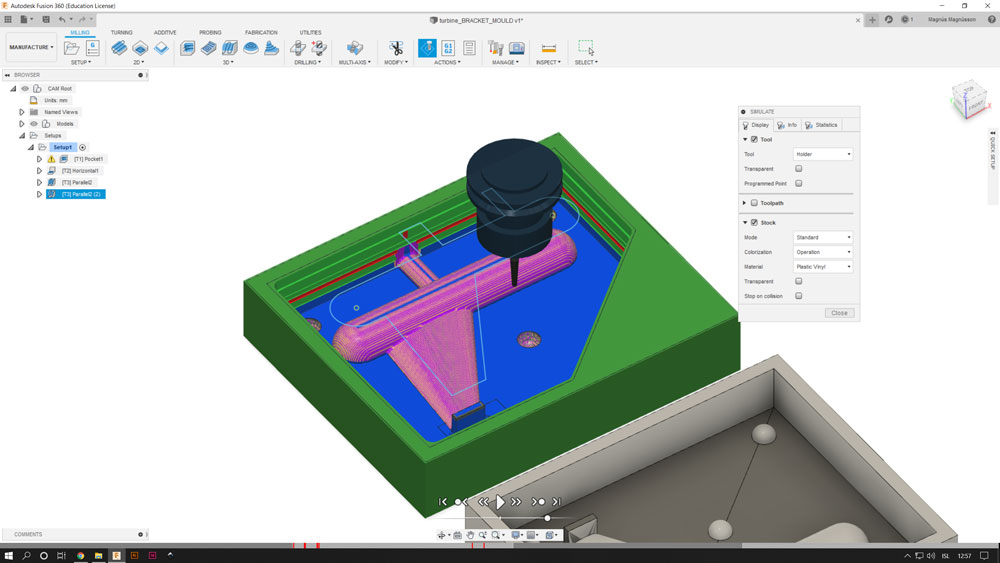

turbine Bracket Mould.3dm /Prepearing to CNC the mould in Fusion

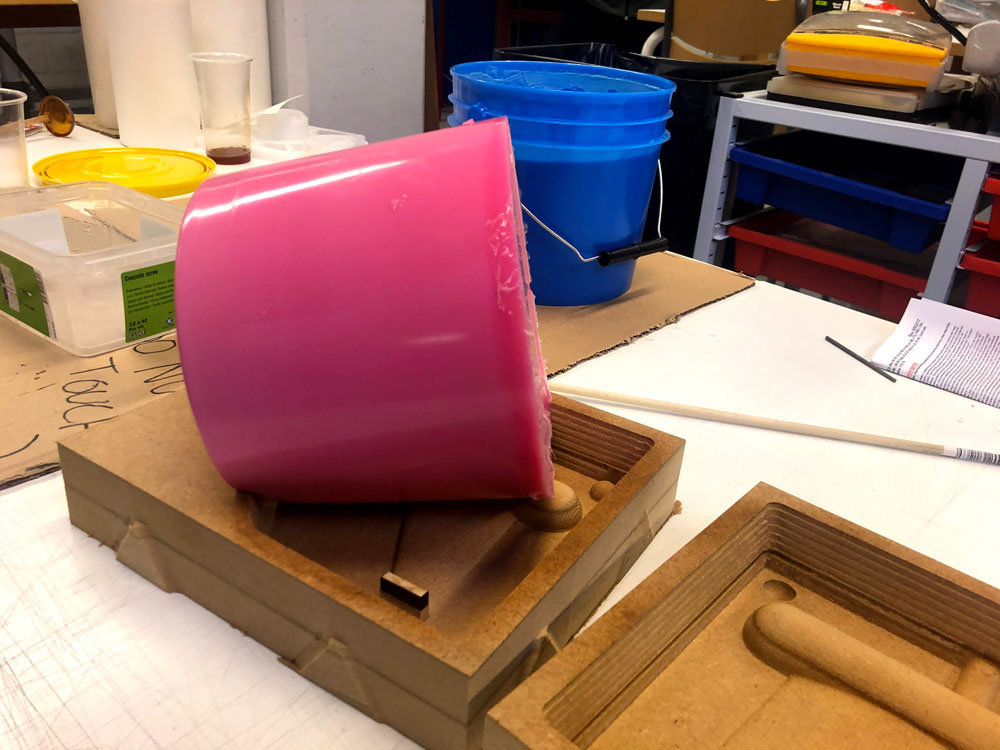

Moulding

The moulding material was kind of old and i could not use it

Waiting for more material to finish

Magnús St. Magnússon © 2020| v1

Madefor FabAcademy