Week 12

Link to the class contentOutput Devices

- Group assignment

Measure the power consumption of an output device

- Individual assignments

Add an output device to a microcontroller board you've designed and program it to do something

- Learning outcomes:

Demonstrate workflows used in circuit board design and fabrication. Implement and interpret programming protocols. - Have you:

Described your design and fabrication process using words/images/screenshots, or linked to previous examples. Explained the programming process/es you used and how the microcontroller datasheet helped you. Outlined problems and how you fixed them. Included original design files and code.

Group assignment

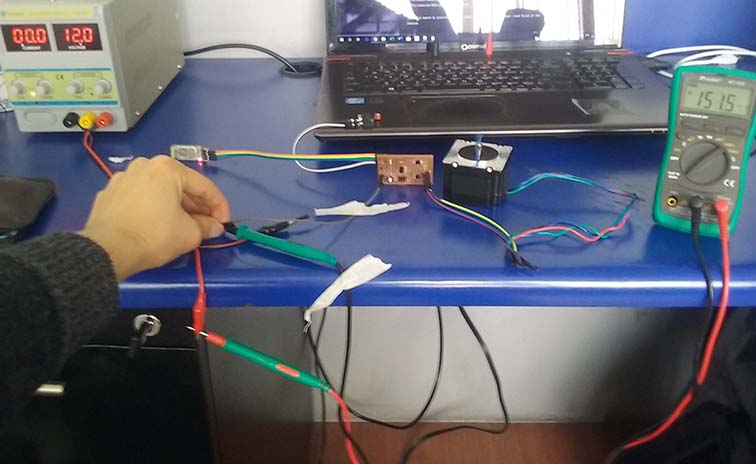

My output device board need 12 Volts to turn on the motor attached to it and also there are another devices attached to it like the bluetooth and the limit switch I measure the current consumed just for my board then my boar with the motor and finally the boar with tall the devices attached.

To do that I had to connect the positive pin from the power supply to the positive pin from the multimeter then the negative pin from the power supply with GND of my board trough a cable after that connect the negative pin of the multimeter with 12V of my board trough a cable.

- Board = 7.36 I

- Board + Motor = 38.79 I

- Board + Motor + Bluetooth + Limit switch = 151.5 I

Current measurement:

- Power = Current X Voltage

- P=IV

- I=151.5 Amps

- V=12 Volts

- P=1812 Watts !

Power consumption of my board with all of the components connected:

Design

Final project

Sketch Plan

For this assignment I design my output devices in relationship with the in-put devices so they can communicate with each other, for that I add the next items:

- Bluetooth: communicate between the circuit board located in one side and the second one at the other side.

- Limit switch: determine the limit position of the shelter.

- Charge module: is about to charge the battery.

- Button: To open and close the shelter.

- Stepper motor (bipolar): Move the shelter from a determined position to another.

You can download the bill of material for the board:

Eagle

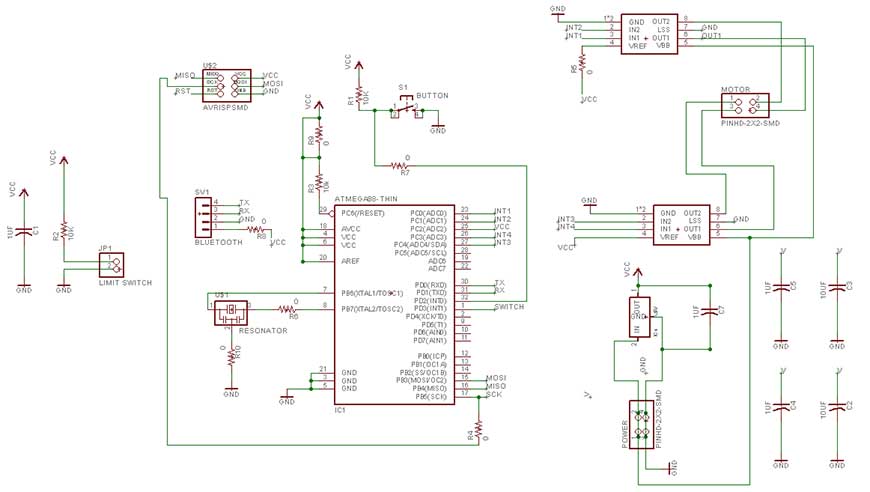

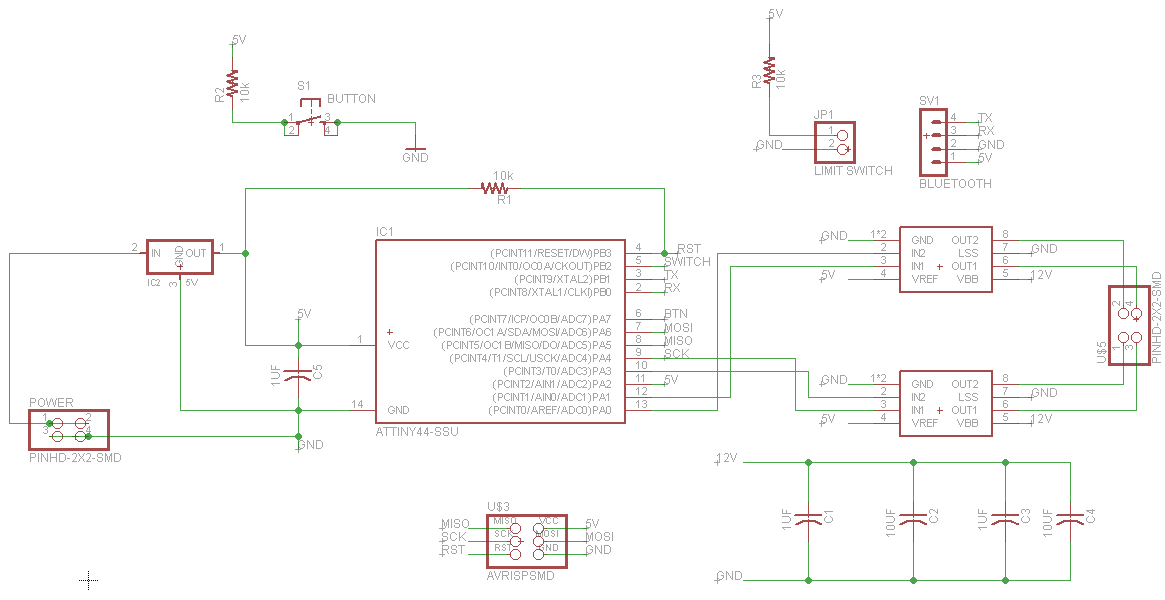

Schematic: this time creating the schematic view was more difficult than the previous times because this time I add more components than before. To know what components I will need for the stepper motor I use Neil's examples board and components as a reference.

For that I did the next process:

- Create a new project called Output.

- Create a new schematic, add the components and organize them.

- Create the connections between them.

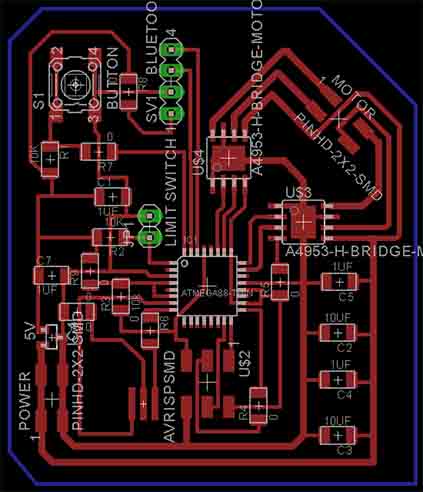

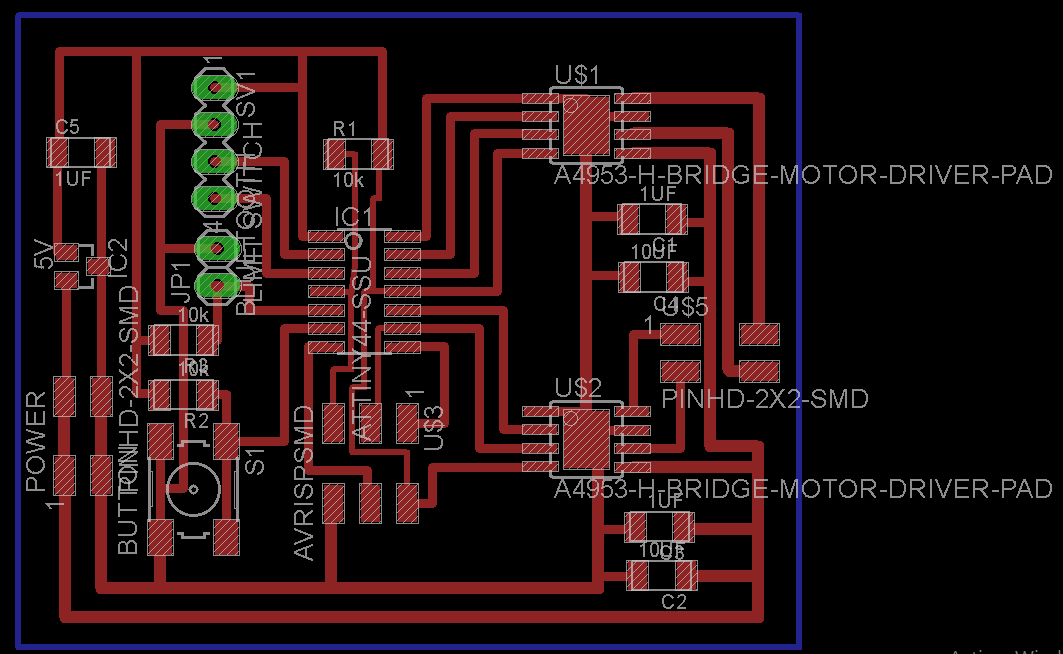

Board: designing the board was easier than before but take me two days to create the connections between the components, because there were to many the most difficult part for me was to connect all of them, for that I returned to the schematic view and add some zero ohm resistor to use them as a bridges.

For that I did the next process:

- Change to the board view.

- Organize all components trying to put the connection of each component near to the micro controller.

- Use the 0 ohm resistor as a bridges.

- Use other layer to create the cut line.

- Export the traces and cut to a PNG file.

You can download the files:

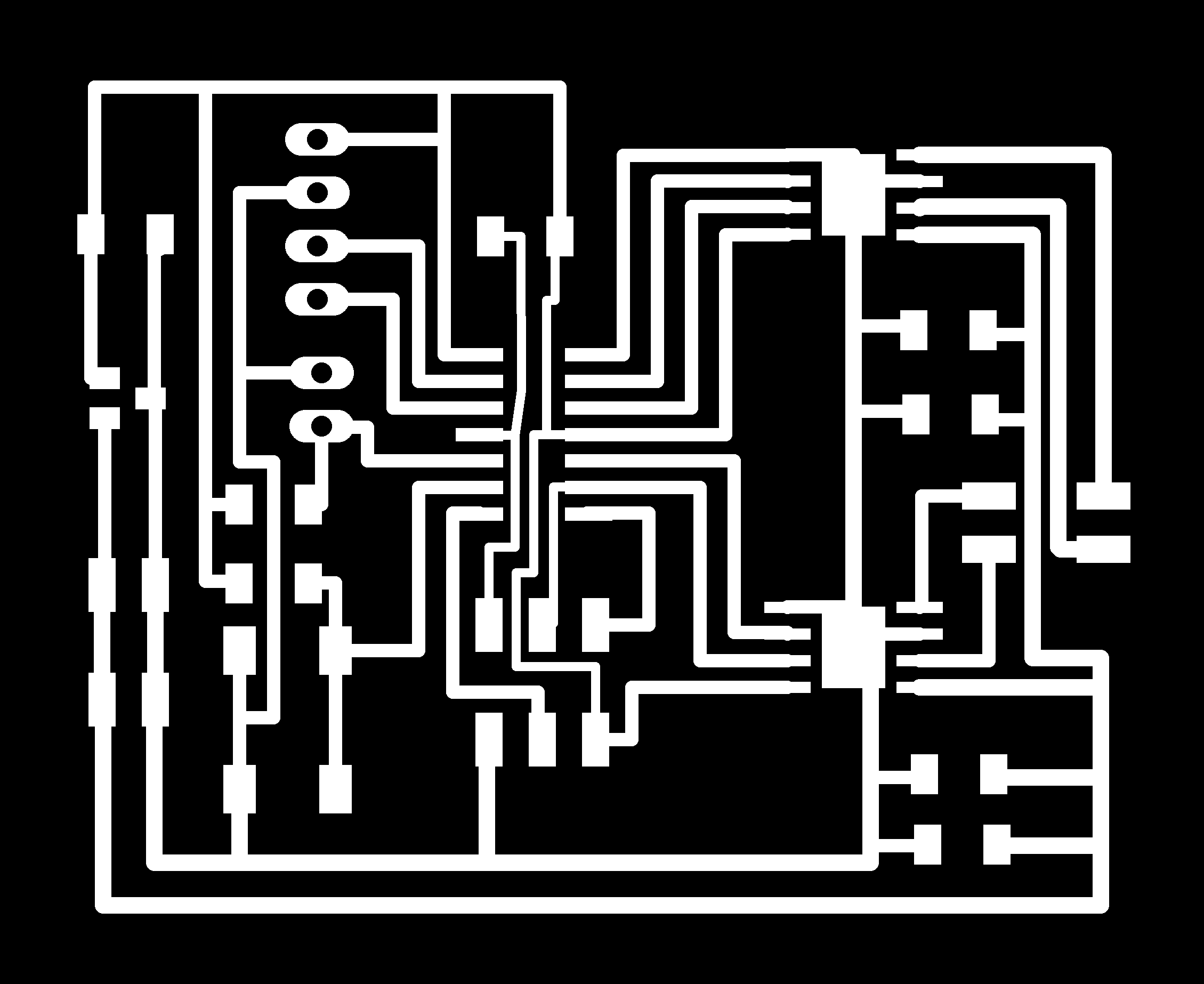

PNG

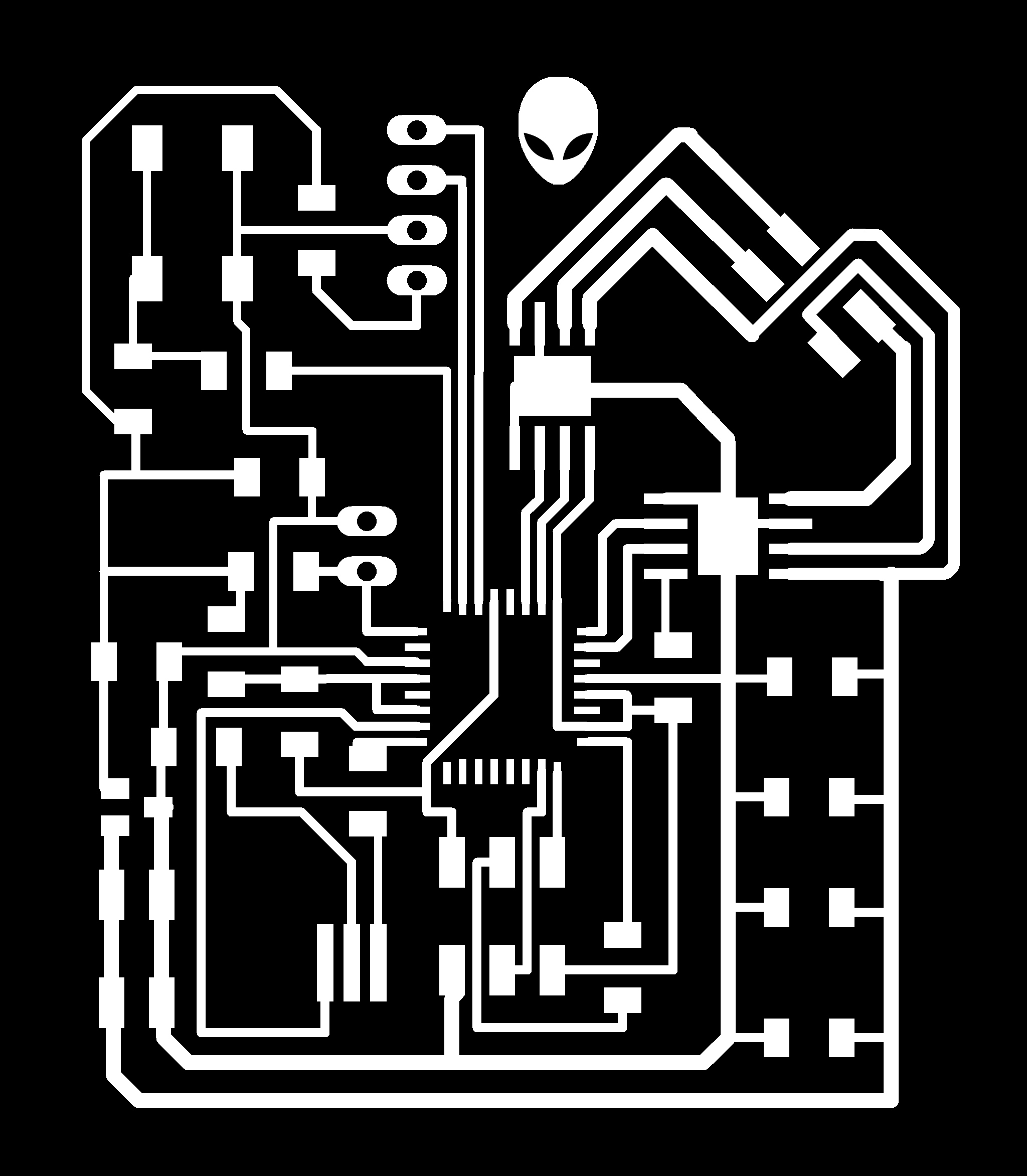

To edit the files I did the next process:

- Open the png files in Illustrator.

- Open Photoshop and create a new empty file setting the file size that correspond to the PNG file.

- Copy the files from illustrator to Photoshop.

- Edit the files and add an alien face.

- Save as PNG.

Mods

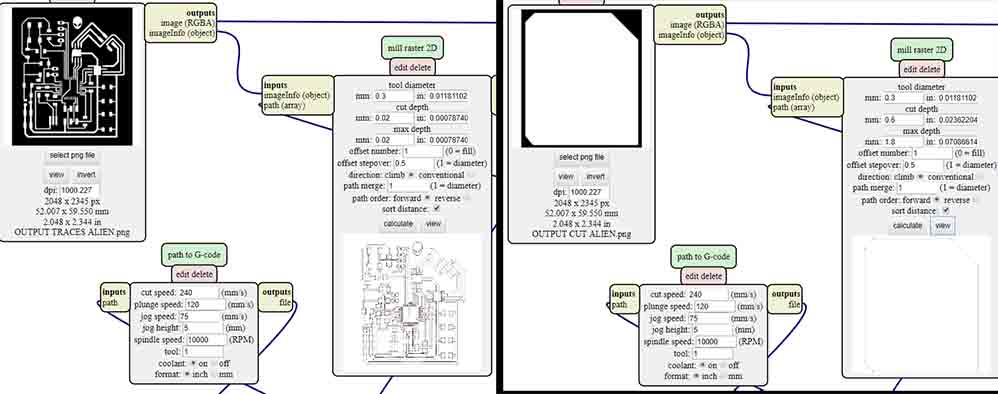

This time I made 3 test before I create the final C-code because the milling cutter with sharp point that we were using breaks before I use it and I had to use a new one with a flat end. For the final C-code I use the next settings:

- Tool diameter : 0.3

- Cut depth: 0.02

- Max depth: 0.02

- Offset number: 1

- Offset stepover: 0.5

- Cut speed:240

- Plunge speed: 120

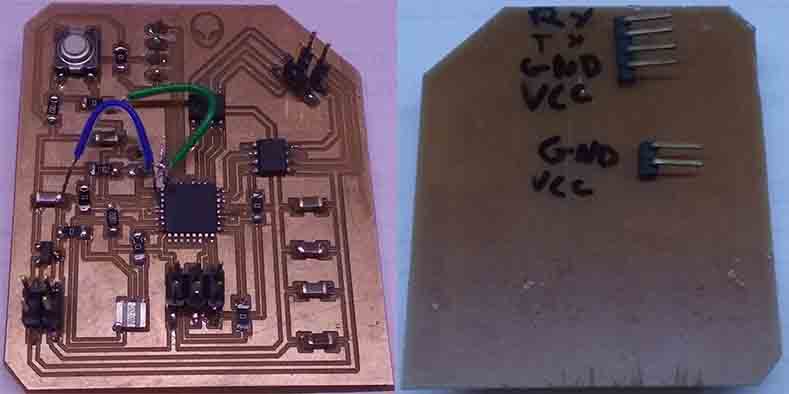

Machining and Soldering

Machining

Before I got my final board I did three test, the fist one with the new milling cutter with the previous configurations that we use but the result was pretty bad most of all the traces disappear, in the second and third attempts I try others milling cutters of 60 degrees that we have in the lab but they didn't work for me because the tip was damaged and the result was rough surface and some traces damaged.

Soldering

In general this process was easier than before at the beginning but when I finish and connect to my programmer the output micro-controller start to overheating so I had to use the multimeter to check if all the connections were ok, I realized that one capacitor was making contact with something that should not as well as some legs of my micro-controller. After debugging that errors my output micro-controller stop overheating.

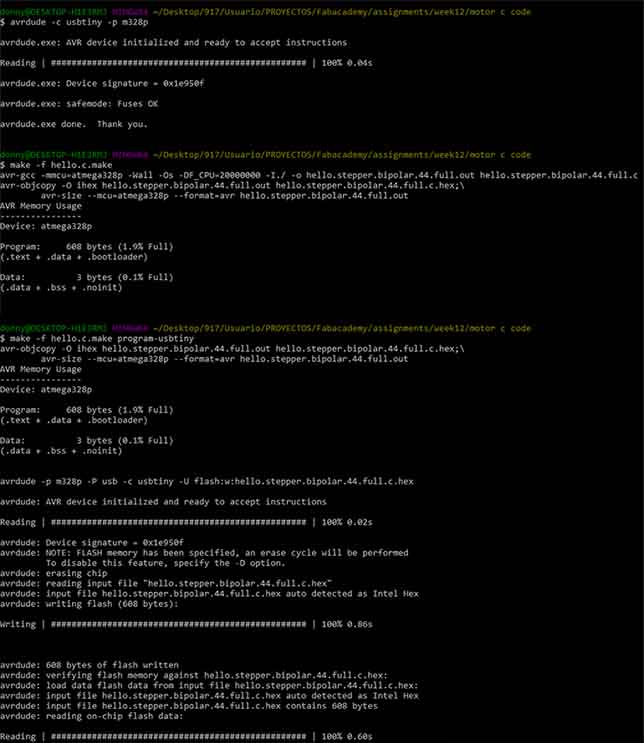

Programing

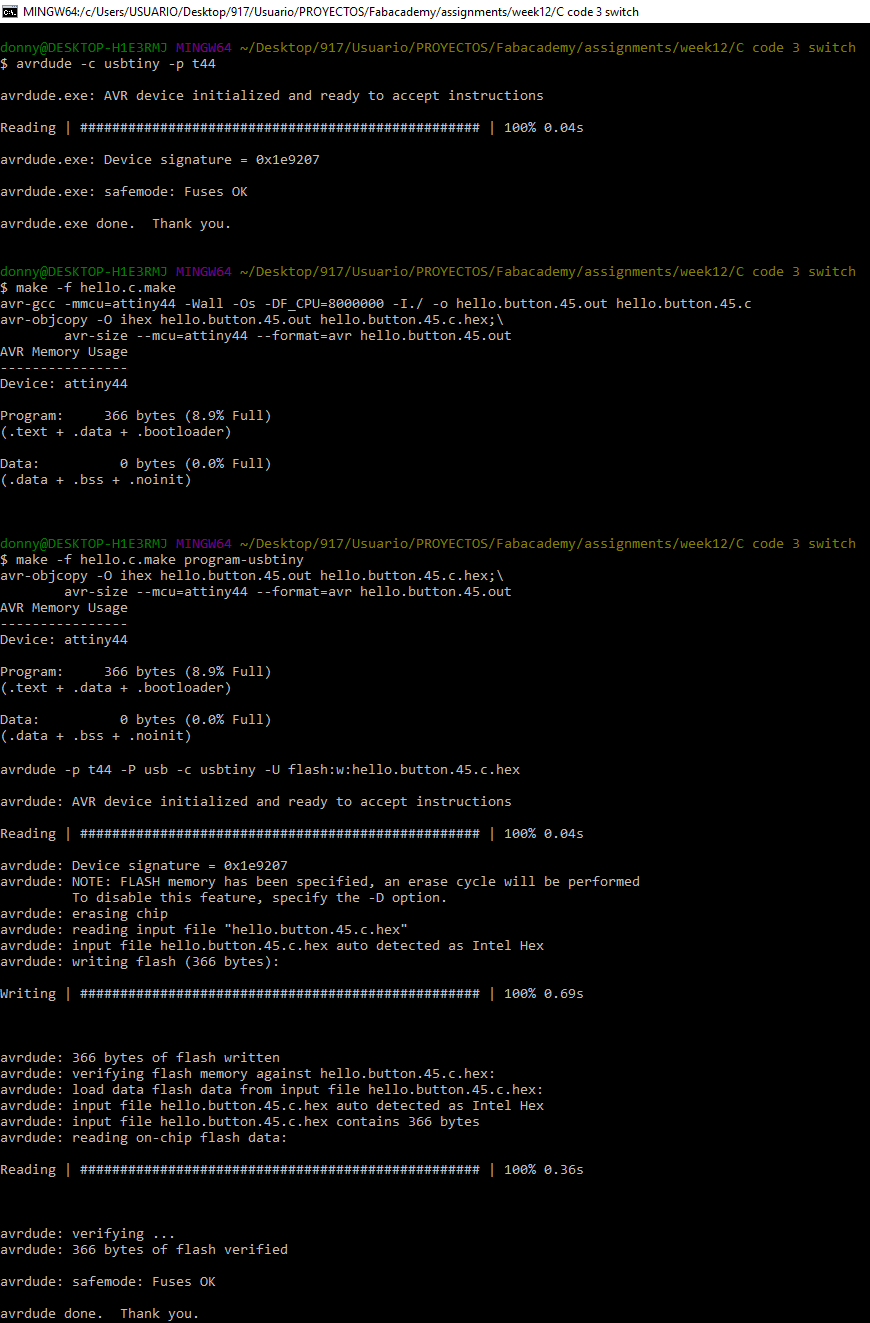

Arduino.

C-Code

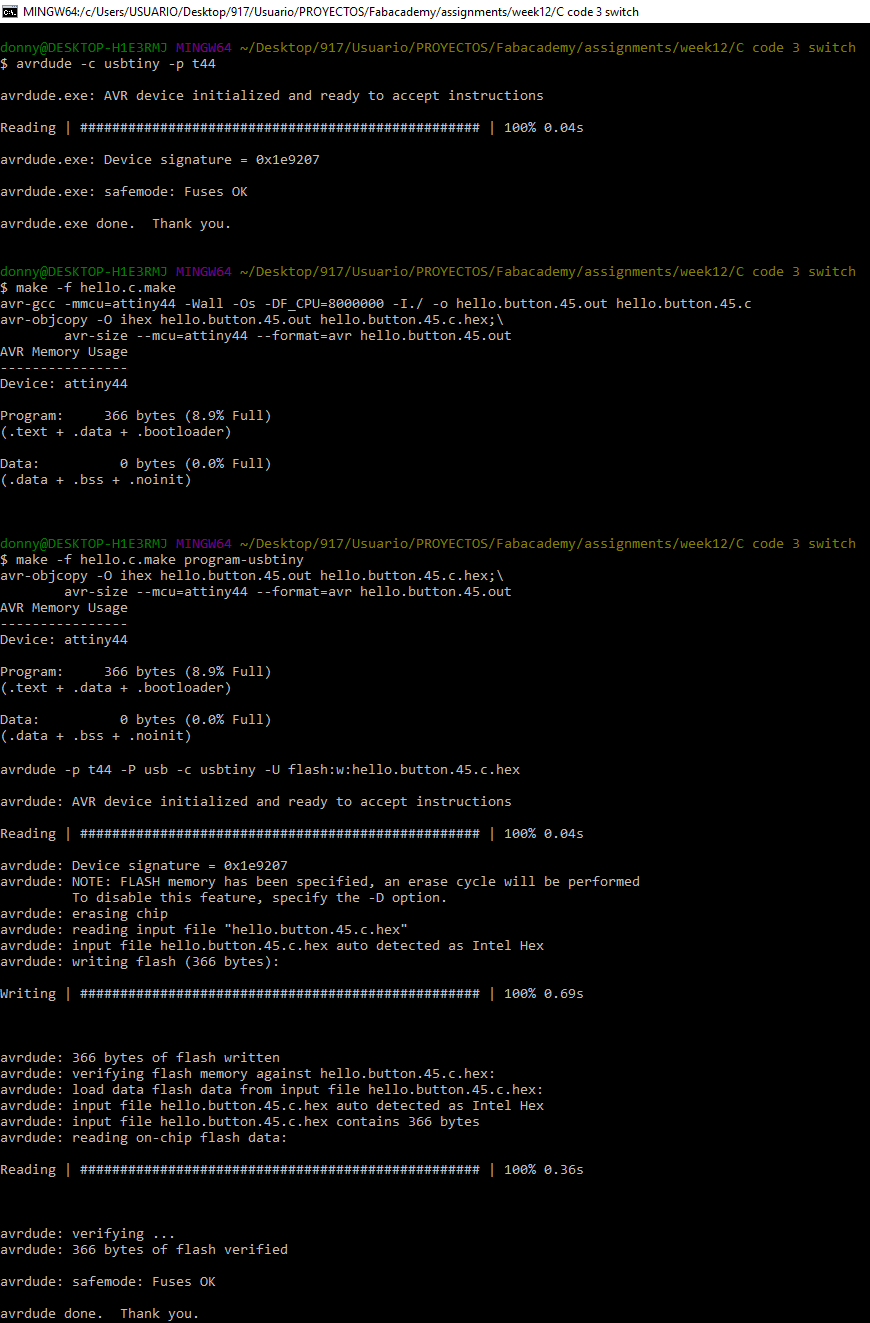

- avrdude -c usbtiny -p m328p

- make -f hello.c.make

- make -f hello.c.make program-usbtiny

You can download the files:

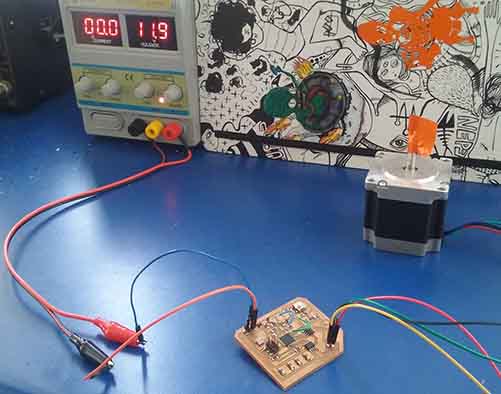

Testing the stepper motor.

Power consumption:

To feed my board with the desired energy to move the stepper motor I need 12 volts and for that I had to use a power supply, and for that I had to adjust the knobs of the positive energy (red) and the negative energy (black) until the display mark 12 volts, It was a little difficult to get exactly that measure so I just achieve 11.9 volts.

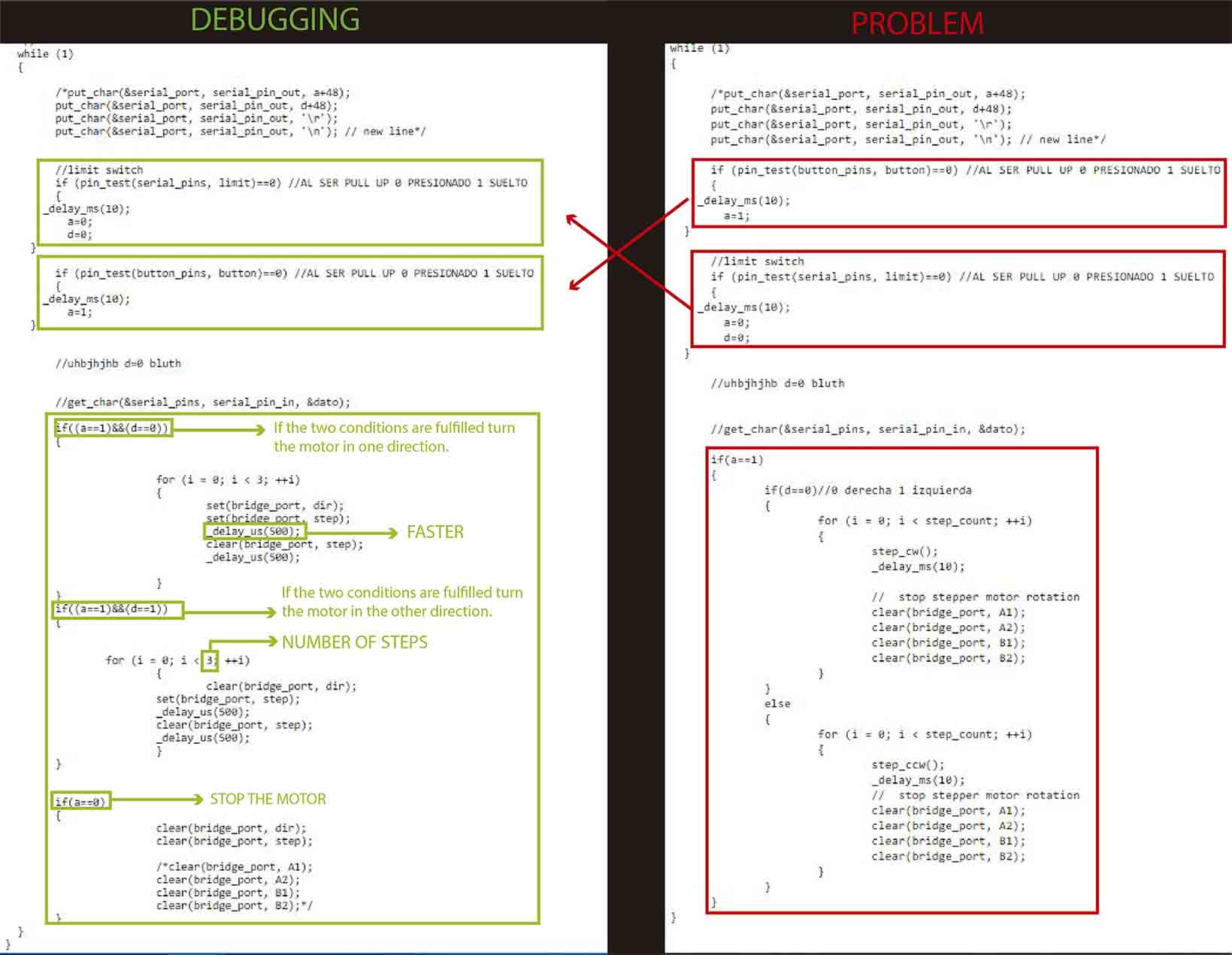

Problem:

The stepper motor didn't respond and also I the microcontroller is overheating slowly.

Debugging:

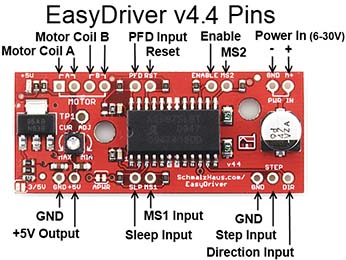

Goal: taking advantage of the creation of a new board for the week14 "networking and communications" I design a board that include both devices the stepper motor and a bluetooth and save time killing two birds with one shot.

Design: This time I decided to take as reference the hello.stepper.bipolar.44.board and also the board of Stéphane Muller who can achieve move the stepper motor in the regional review.

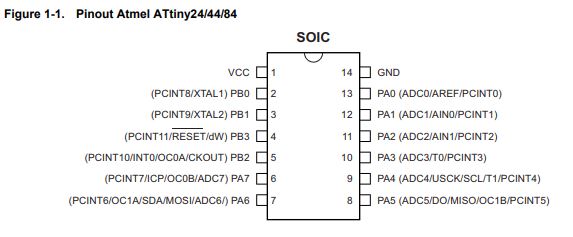

This time I'm using a ATtiny44A

PIN configuration.

PIN configuration.

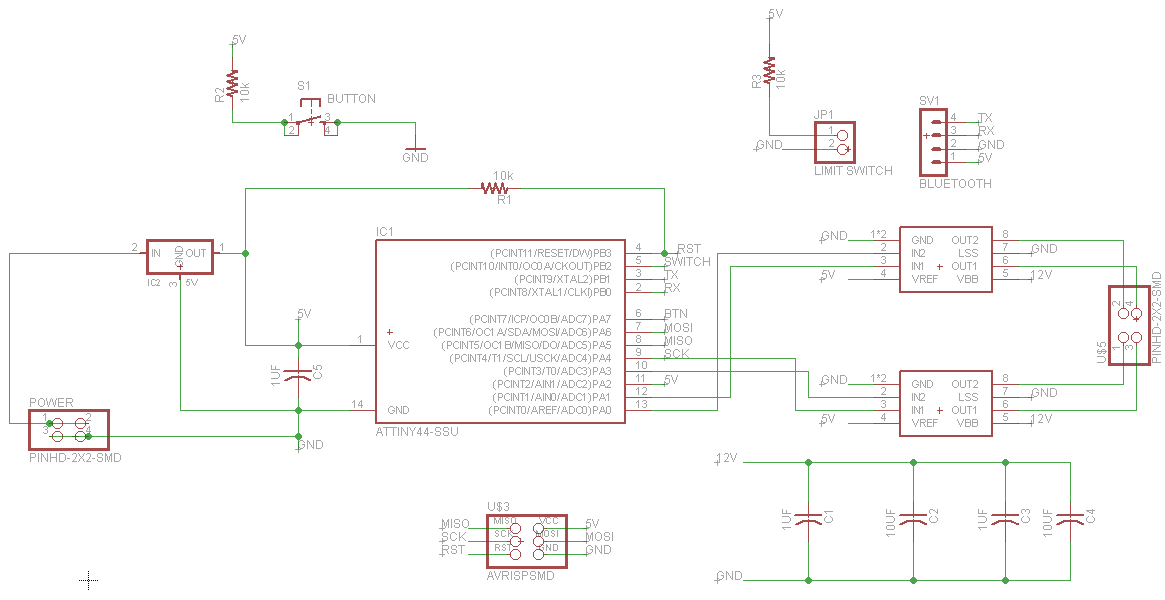

Schematic:

- Add all the components.

- Create the connections between the components and the microcontroller.

- Run the error checker and correct them.

- Switch to the board view.

Schematic

Schematic

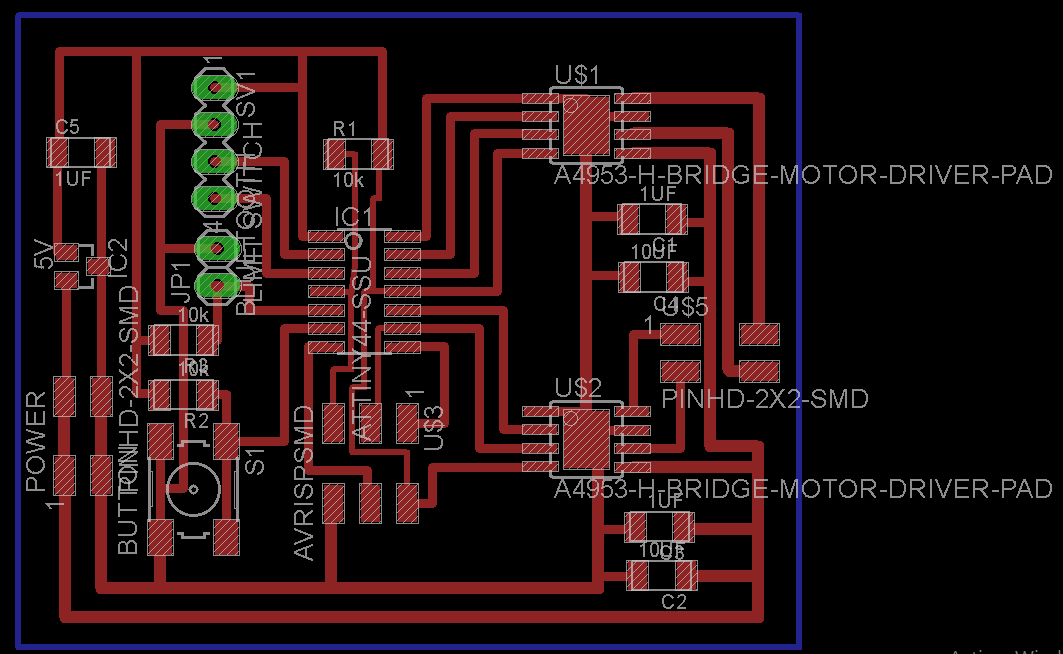

Board:This time I spend a lot of time making sure everything is all right and doing a good design.

Board

Board

You can download the files:

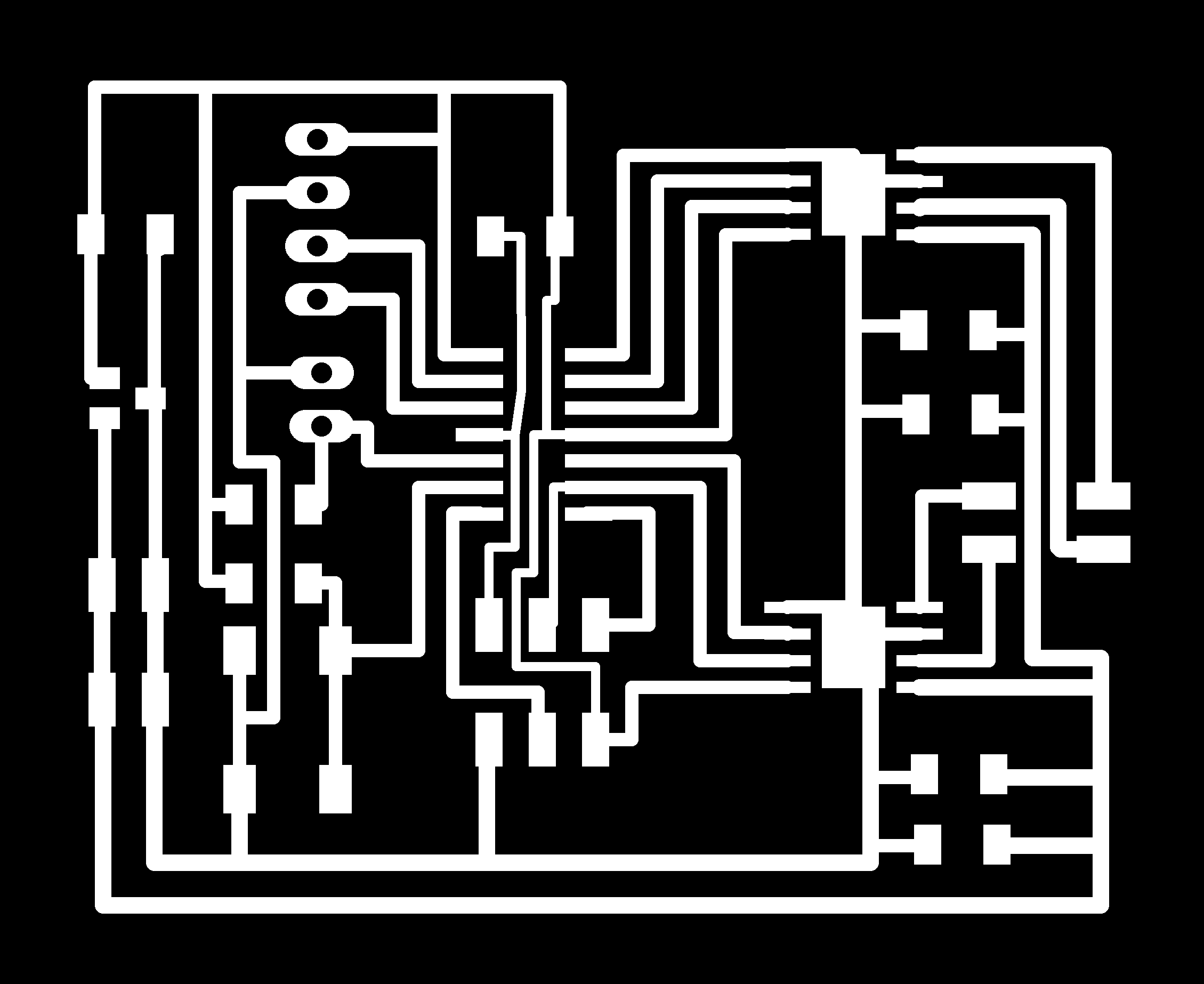

PNG:

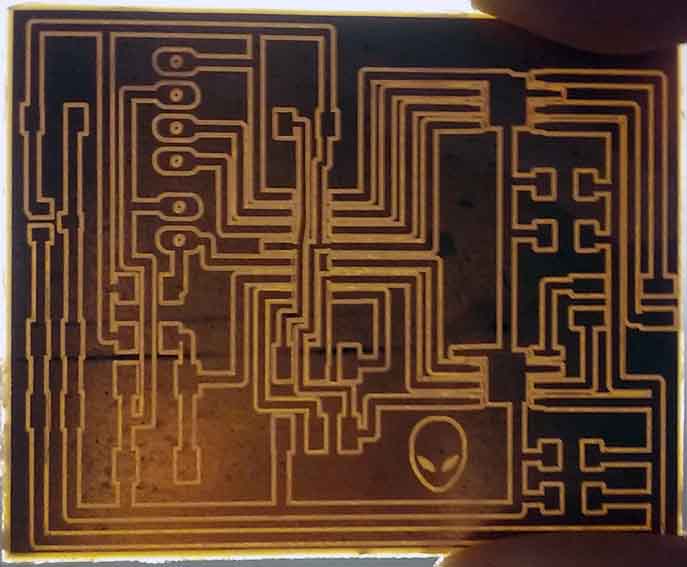

Traces

Traces

Cut

Cut

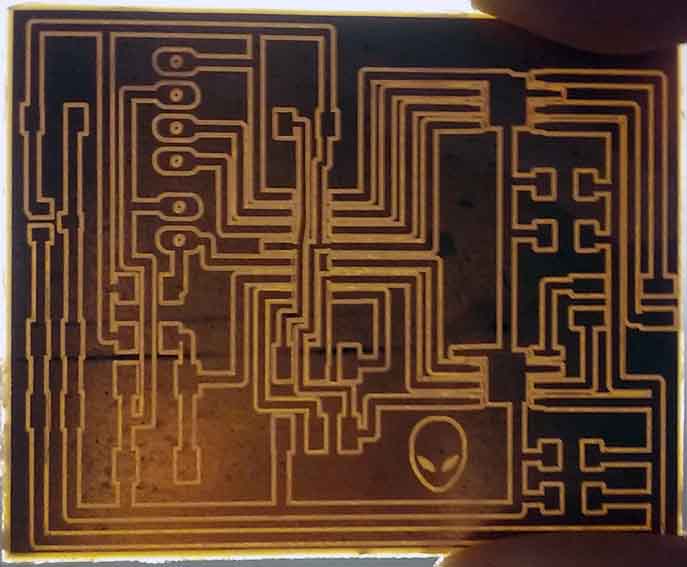

MODS: In the milling process I use a new milling cutter tool so I did two tests the fist one with a cut depth=0.06 and the second one with a cut depth=0.1 this two PCBs help me to set up the machine PCB for the machine design week where I use a cut depth=0.05 and the result was really good.

Traces / Cut

Traces / Cut

PCB

PCB

You can download the files:

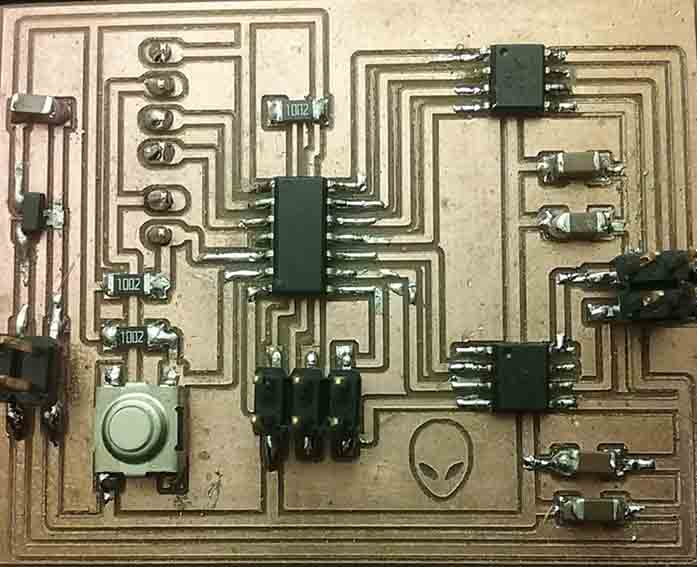

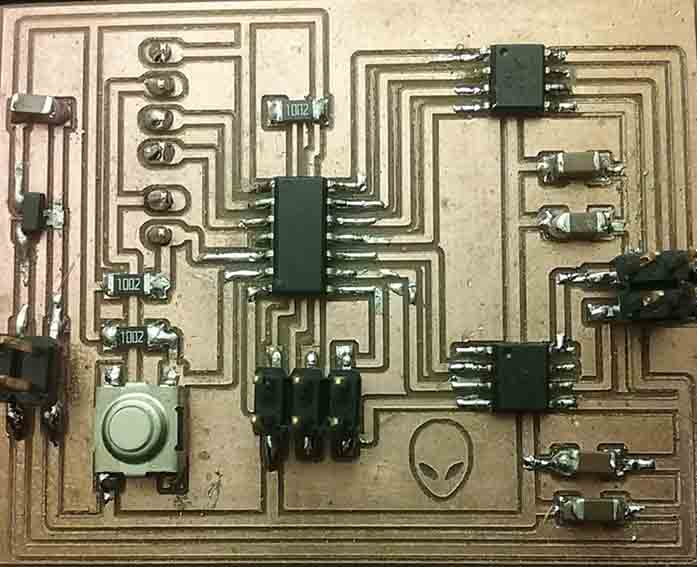

Solder: This part take me all the day soldering the components more difficut to solder were the drivers because the bottom side need to be solder to the ground for that I use a heat gun and also the regulator because of the size.

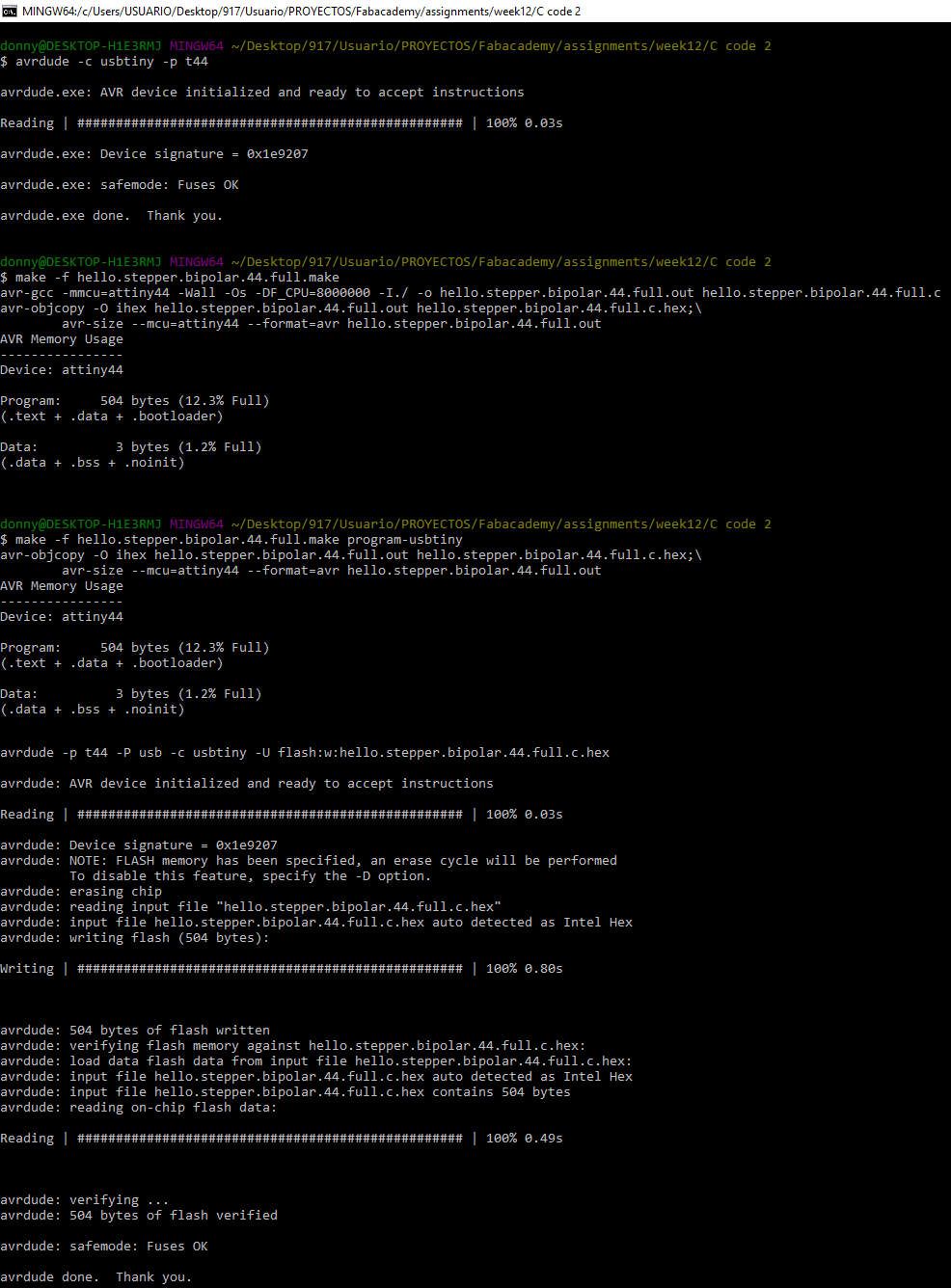

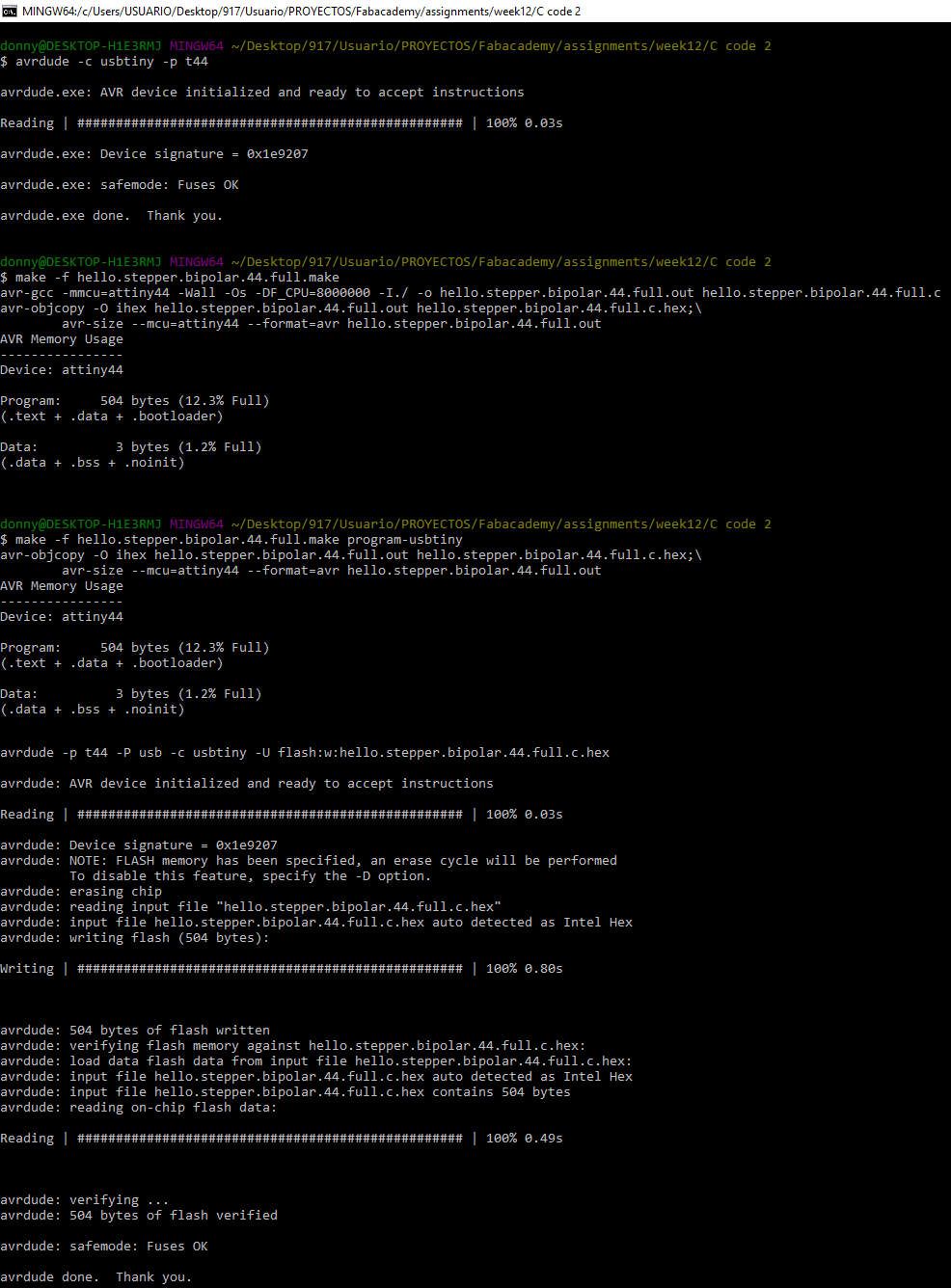

Programing with the hello stepper bipolar 44 code: For this attempt I'm using the same code of Neil example and the board programed without any problem.

You can download the files:

Testing the stepper motor

I connect the stepper motor to my board and also the power supply and the voltage go down and the current go up I try for three times, the first one I see a sparkle and the last one a little smoke appear so I disconnect intermediately. I try to figure what's happening and connect my programmer to upload another code and I realized that the 5V regulator was overheating when it was connected to my PC trough the programmer.

After that I desolder the regulator and test if there are any wrong connection or even if VCC was connected to GND or if any component wast wrong connected after that I programed my board with another code.

Programing with the hello button code: I change some parts of the code that I use for the input devices week to test if the microprocessor is still working and after that I upload it. After that I solder again the regulator and is still overheating. Just to know if the code was working correctly I opened the arduino software and also the serial monitor and when I star to push the switch give us the desired answer.

Goal: taking advantage of the creation of a new board for the week14 "networking and communications" I design a board that include both devices the stepper motor and a bluetooth and save time killing two birds with one shot.

Design: This time I decided to take as reference the hello.stepper.bipolar.44.board and also the board of Stéphane Muller who can achieve move the stepper motor in the regional review.

This time I'm using a ATtiny44A

Schematic:

- Add all the components.

- Create the connections between the components and the microcontroller.

- Run the error checker and correct them.

- Switch to the board view.

Board:This time I spend a lot of time making sure everything is all right and doing a good design.

You can download the files:

PNG:

MODS: In the milling process I use a new milling cutter tool so I did two tests the fist one with a cut depth=0.06 and the second one with a cut depth=0.1 this two PCBs help me to set up the machine PCB for the machine design week where I use a cut depth=0.05 and the result was really good.

You can download the files:

Solder: This part take me all the day soldering the components more difficut to solder were the drivers because the bottom side need to be solder to the ground for that I use a heat gun and also the regulator because of the size.

Programing with the hello stepper bipolar 44 code: For this attempt I'm using the same code of Neil example and the board programed without any problem.

You can download the files:

Testing the stepper motor

I connect the stepper motor to my board and also the power supply and the voltage go down and the current go up I try for three times, the first one I see a sparkle and the last one a little smoke appear so I disconnect intermediately. I try to figure what's happening and connect my programmer to upload another code and I realized that the 5V regulator was overheating when it was connected to my PC trough the programmer.

After that I desolder the regulator and test if there are any wrong connection or even if VCC was connected to GND or if any component wast wrong connected after that I programed my board with another code.

Programing with the hello button code: I change some parts of the code that I use for the input devices week to test if the microprocessor is still working and after that I upload it. After that I solder again the regulator and is still overheating. Just to know if the code was working correctly I opened the arduino software and also the serial monitor and when I star to push the switch give us the desired answer.