Wildcard Week- 3D print & cement pen holder

Work for this week

For wildcard week ,first I made a jwerry like RGB light resin for my final project. But I misunderstood the task, I need to produce something with a digital fabrication process, so I redesign a 3D print cement pen holder. And I kept the first manual process in this page.

Meterials

3D print ABS material

cement

sand

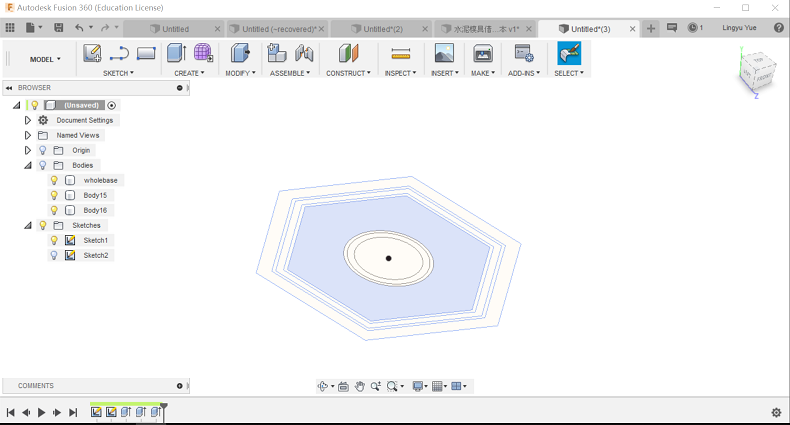

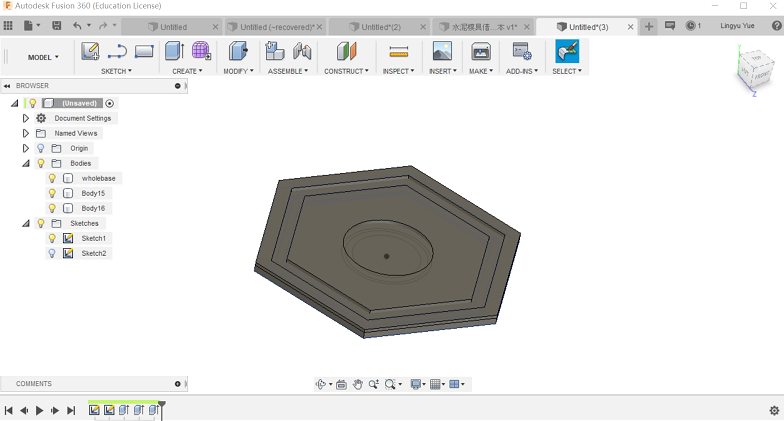

Design the model

First , I drew a hexagon planter. During the sketch , I drew 3 hexagons and a circle and extrude each shape in the proper height.

Base part

Middle part

Side part

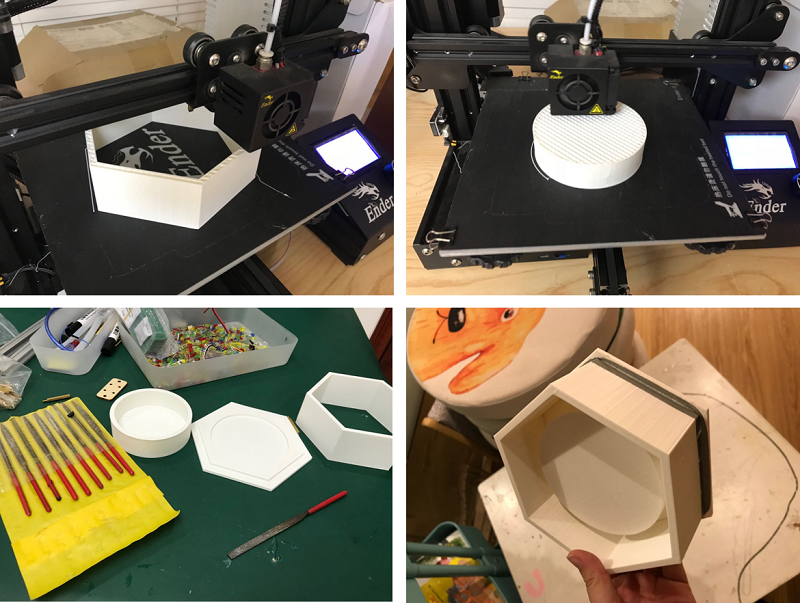

3D Print and Cement Forming

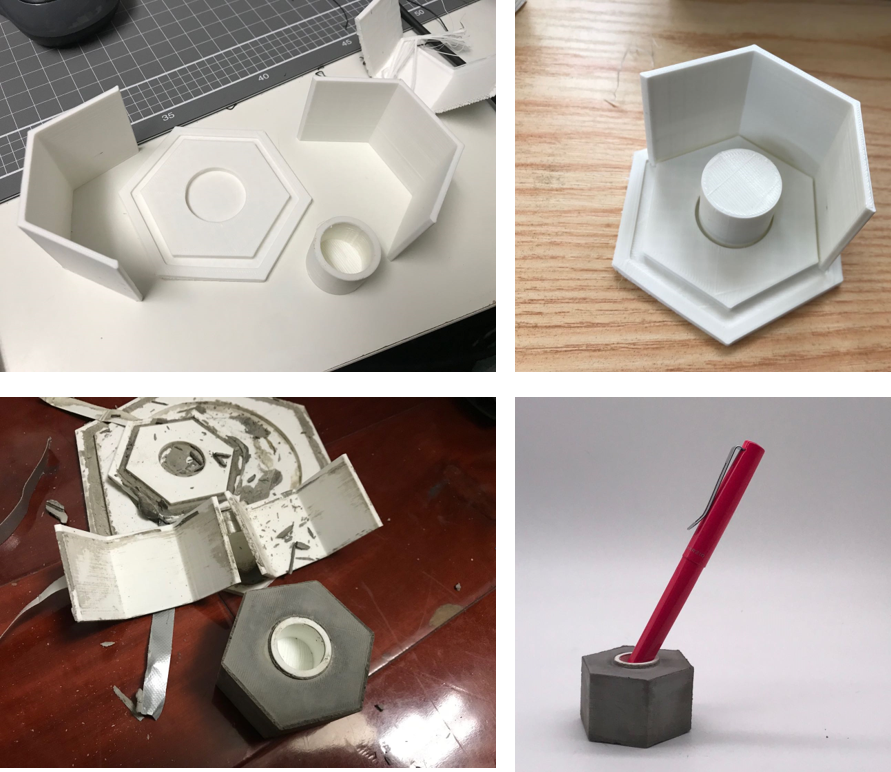

I printed the base , side and middle part and polished them.

Mixed and poured cement in the model. I bought the cement and sand from online Taobao shop I chose the high standard cement and yellow sand.

Waited for the cement to dry, but I didn't think of that I can't take the cement part out. It sticked tightly in the 3D printing model.

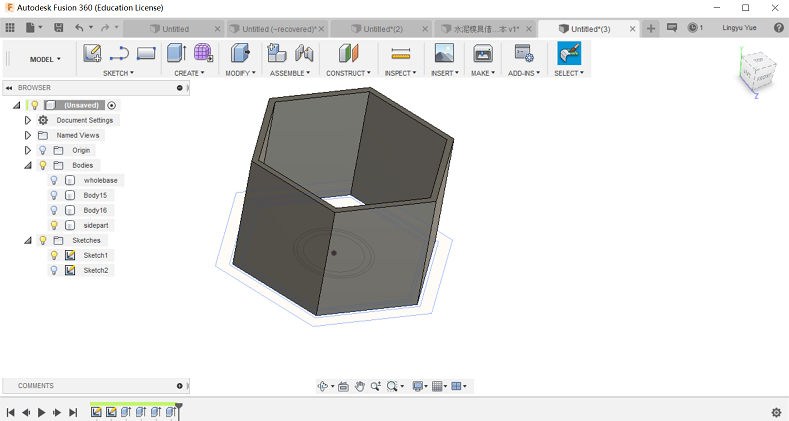

So I started to do my second design , I devided the side part into two parts and adjust the base part to let the side part to insert easily.

The new basepart

The new sidepart

The new middle part

Here's the final pen holder.

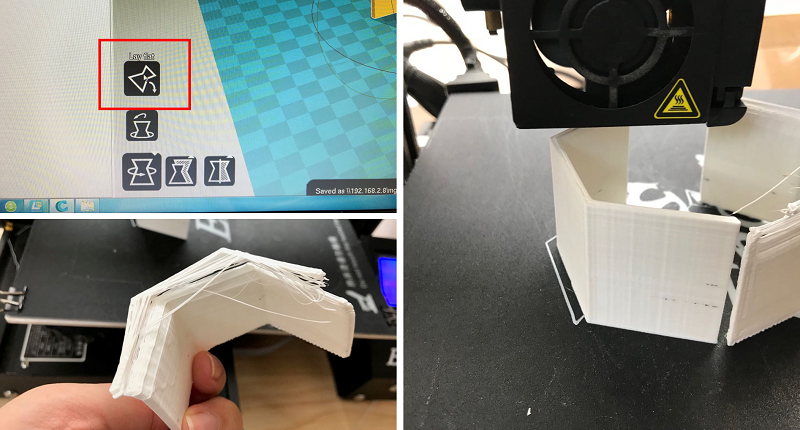

But during the 3D printing process, I failed the first time, cause I didn't put the model flat on the Cura flat.

Do remembet to check the if the object is laid flat.

Files

Here is the RAR-package containing the design and scanning files of the week:

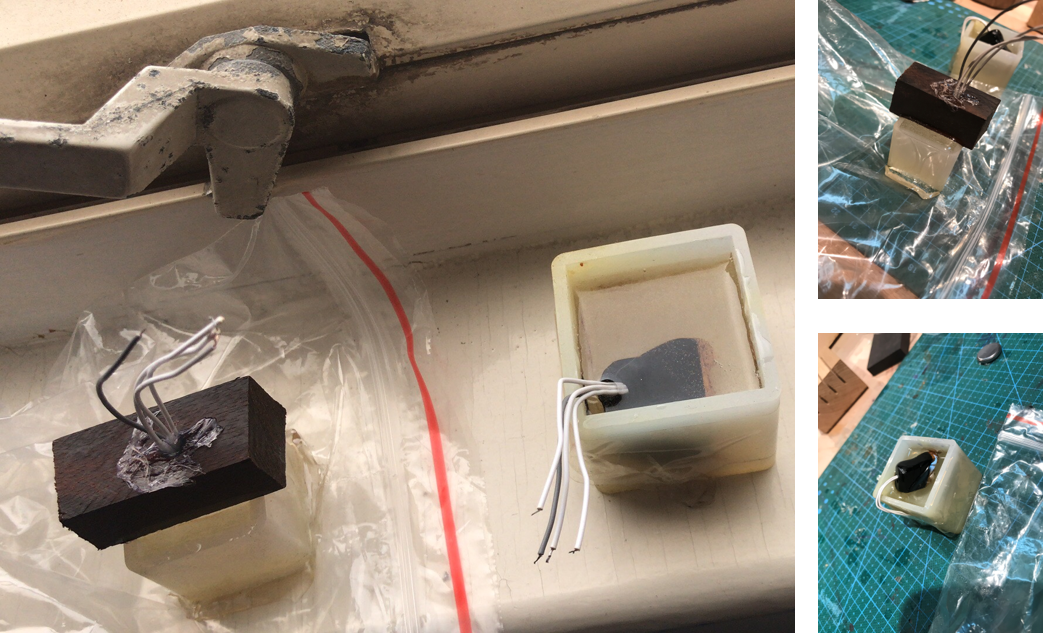

I kept my first try of my RGB resin record below.

Meterials

wood chip collected from the wook-working space

epoxy resin (AB glue)

RGB light

Cut and polish wood blocks

I cut off a piece of wood and use grinding machine to shape it.

During the polishing period, you could put some water to prevent it become too hot.

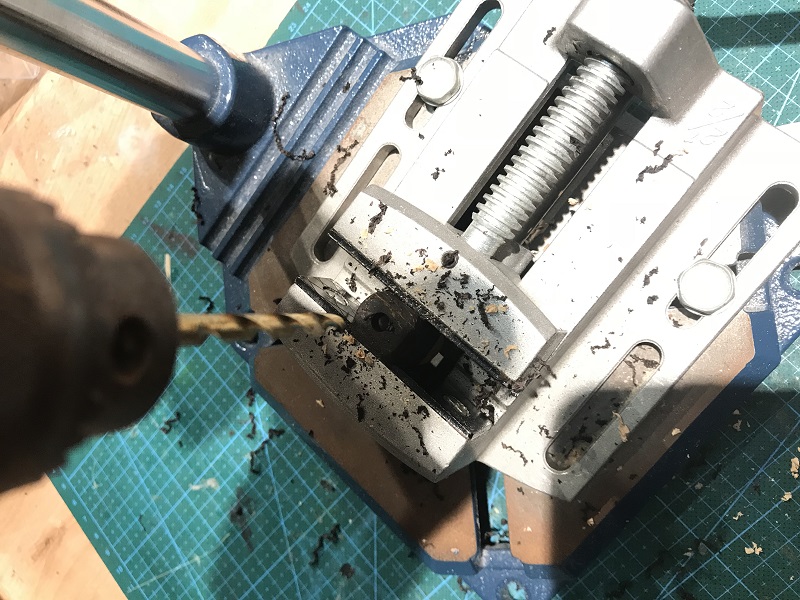

Drill a hole

After get the shape I need , I drill a hole in the wood piece to put the RGB LED inside.

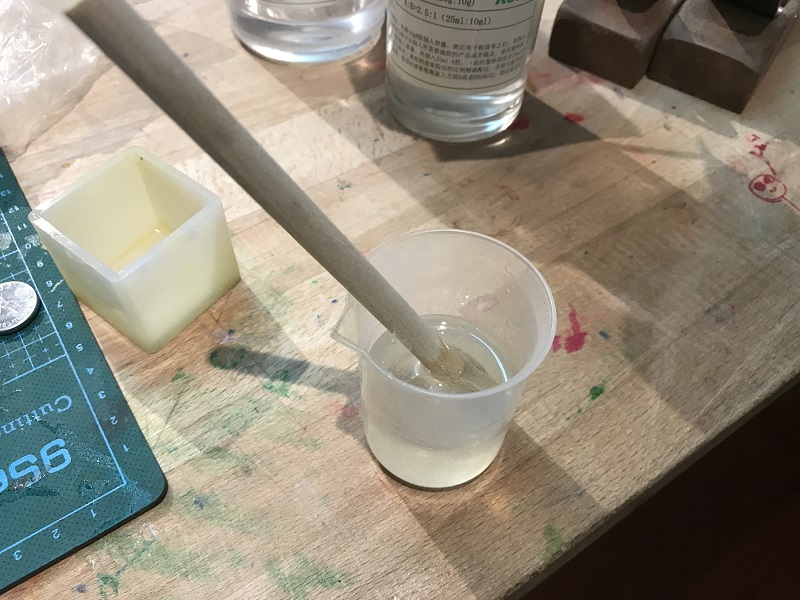

Resin

I use polyester resin to cover the wood and LED. I mix them via the scale instruction. And stired well.

I put them in the room for a whole night.

When I checked them in the morning , I found that the wood one on top didn't sucess, too soft to hold. So I used the one in the middle.

I polished the resin again.

Upload code to it with Arduino

At last, I connect it to Arduino and test to programm it.