15. MECHANICAL DESIGN & MACHINE DESIGN¶

For this group project, I was the only member because I´m the only student that is taking the Fab Academy course in Fab Lab Esan

Idea¶

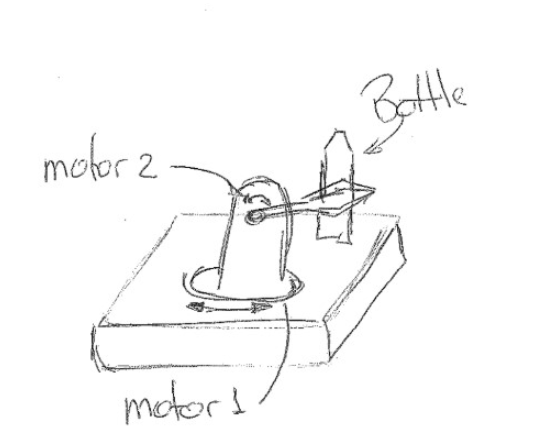

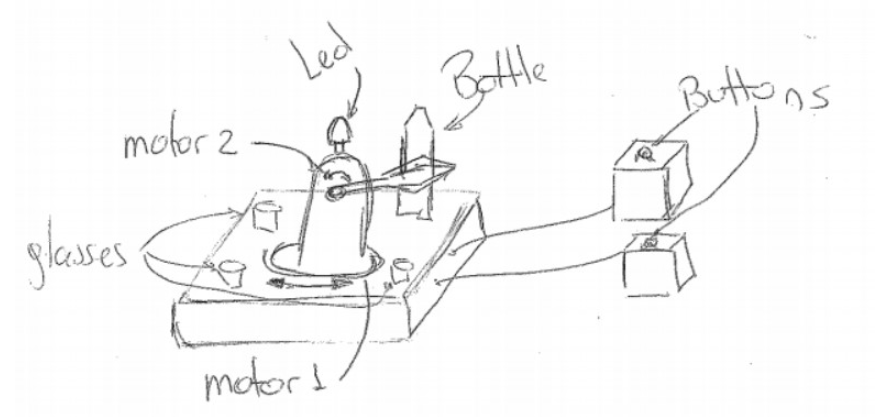

For the grupal project, the current student decided to fabricate the Fab Drinker Machine. It consiste of a 4 player drinking game baed on reaction speed. The game begins when the four players wait for a LED to light up. When it happens, each player have to push their own button. A shot of liqueur is automacticaly pour to the last player to react.

The idea was to make a rectangle platform with a frame in the middle where holder was attach to grab the bottle. For smoothing the movement of the system, a roller bearing was added to joint between the gram and holder. A 3D printed bearing was also introducind between the base and the frame.

For interacting with the machine, I introduced cubes with buttons on their top for each player. also I thought about how to notice the player when to start by adding a LED light on top of the frame.

Mechanical Design¶

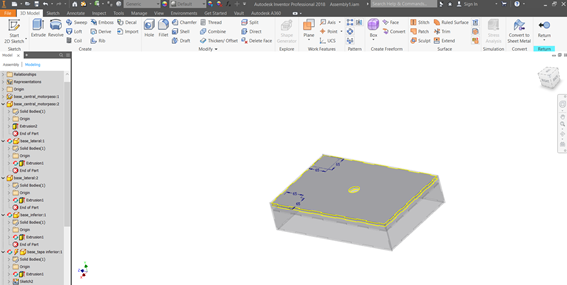

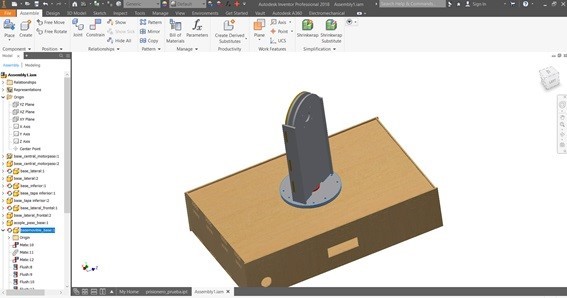

The system with which the “Fab Drinker” works consists use of roller bearing. The system was designed manufactured and built on a rectangular base to which it was attached rotating base with a coupling, which was manufactured in 3D.

Also I designed four coasters, which it will be placed above the rectangular base

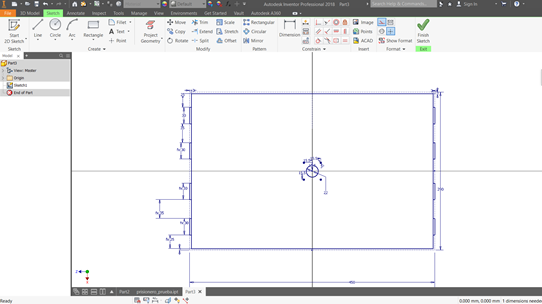

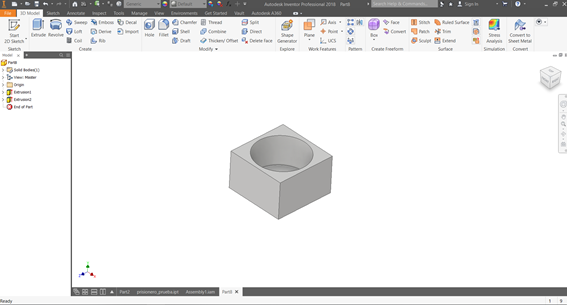

The rotating base and the upper part has a system consisting of roller bearing and a coupling (3D print) that was join to the stepper motor that permit the gyre . The design was realized in Autodesk Inventor, which also served to assemble and verify the mechanism. Both couplings was made in 3d print.

Fabrication¶

This project was made using 100% of Fab Lab Esan machines

Trotec Laser – Laser Cutter¶

We use the Laser Cutter to make The main structure (Rotating base, rectangular base and upper base) and cup holder. The material used was MDF 3mm and 4 mm thickness.

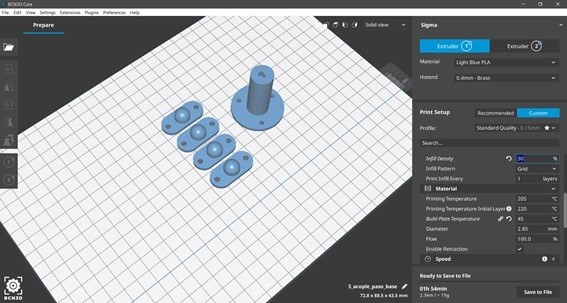

Bcn 3D sigma -3D Printer¶

The prints came out of very good quality. We printed in 3d: The coupling for the motor stepper, and the clamp (which holds the bottle).

Modela-Milling Machine¶

We use the Modela for the Manufacture of the boards for the engines.

Assembly¶

Our Fab Drinker combines the use of all machines available in the Fab Lab Esan. In these images we see the assembly of main structure that contain (Rotating base, rectangular base and upper base) some parts were united with the couplings that was made of PLA.

We sand the mdf pieces so that the press fit will arm without problem. The coupling would be attached to the stepper motor and the roller bearing that permit the gyre.

For the bra of the bottle (made in 3d print with press fit) that was united with the coupling. To avoid friction, we used ball caster wheels that was made in 3d print and were united with the rotating base .For this part, It helped us unite the use of m3 bolts.

You can download the fileS by clicking on the bullets.

You can see the complete documentation on this page, please click on the bullet

You can see the video