11. INPUT DEVICES¶

Goal¶

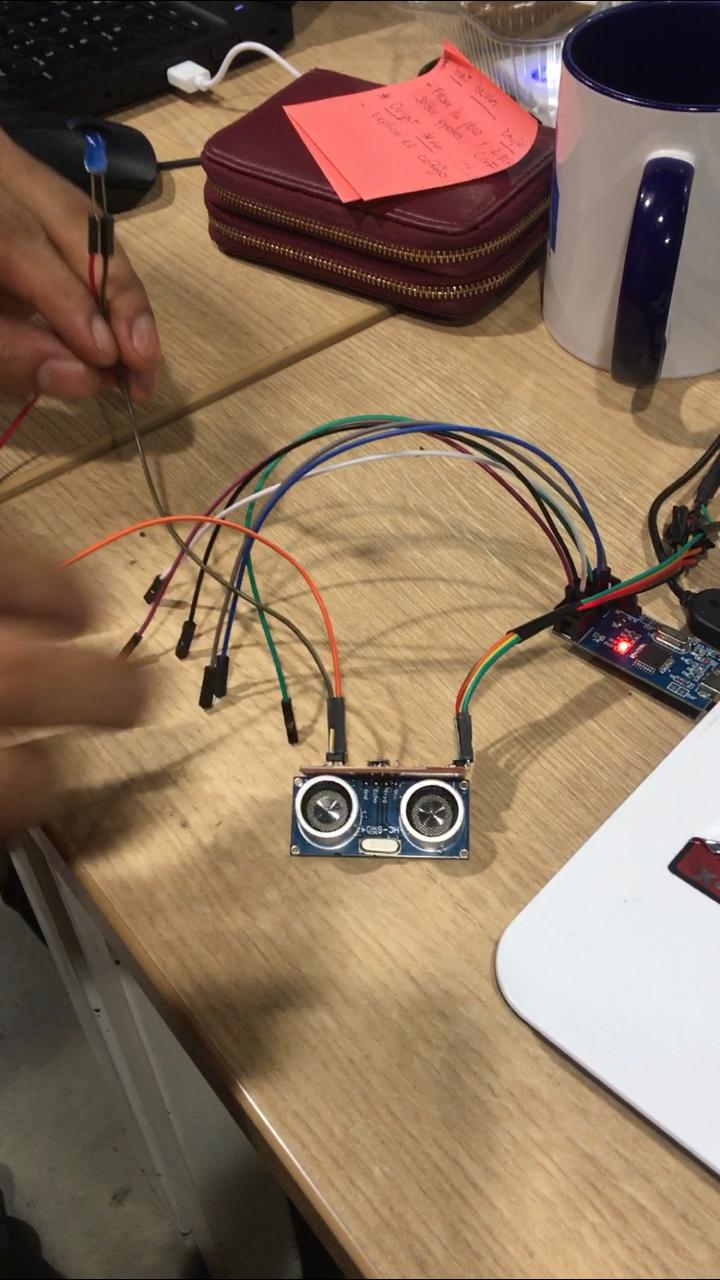

Measure something: add a sensor to a microcontroller board that you have designed and read it

Doing¶

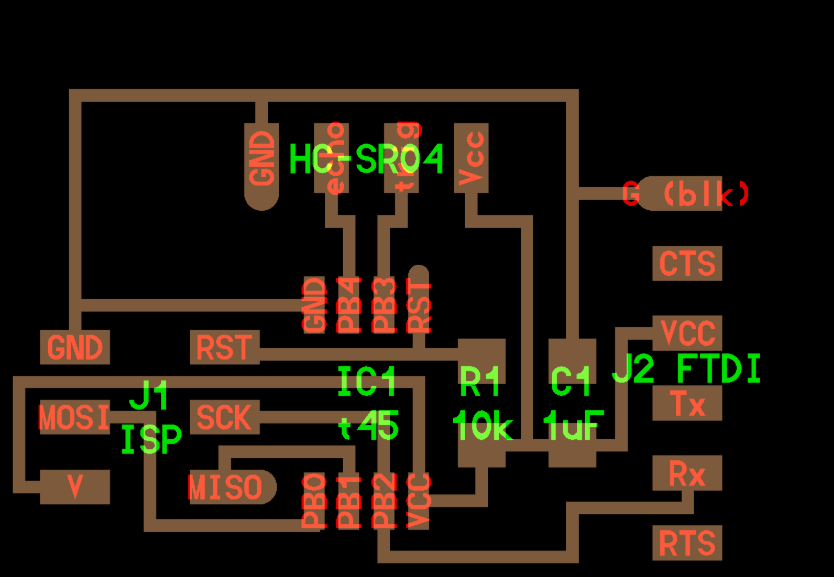

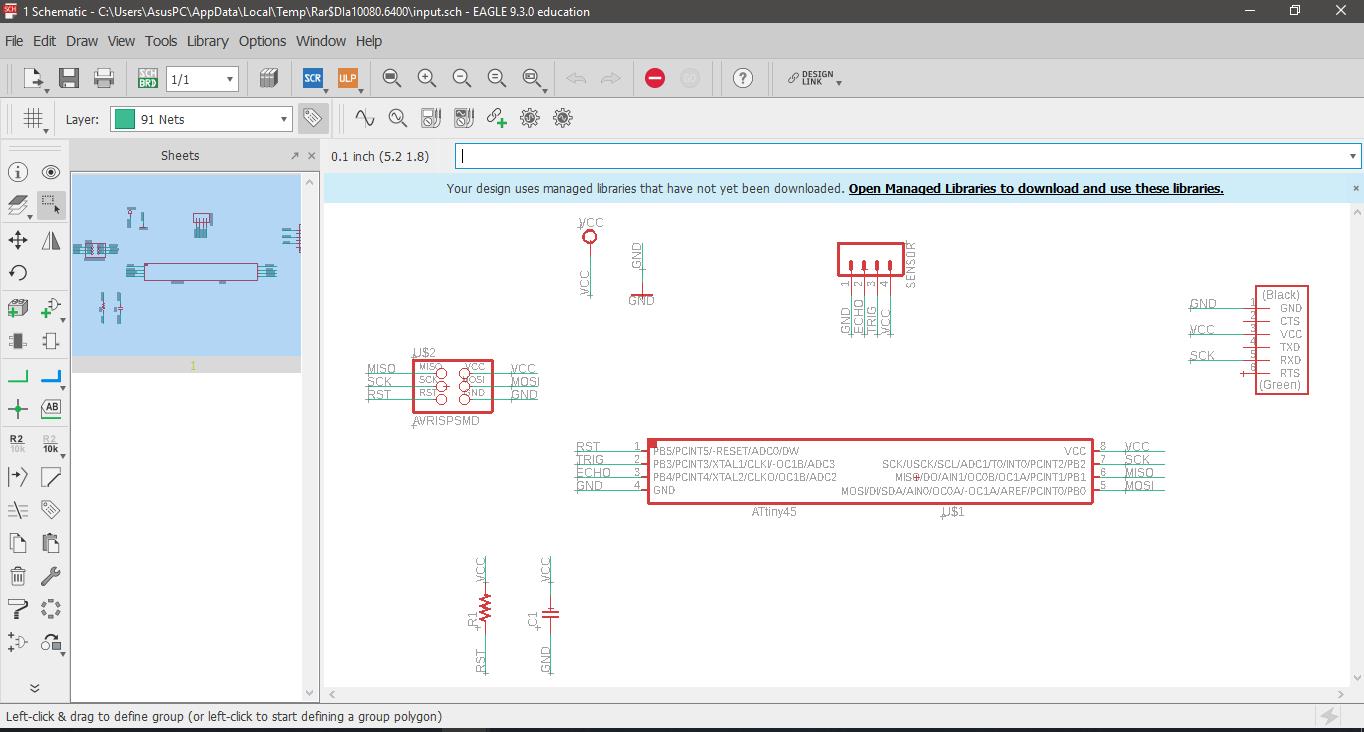

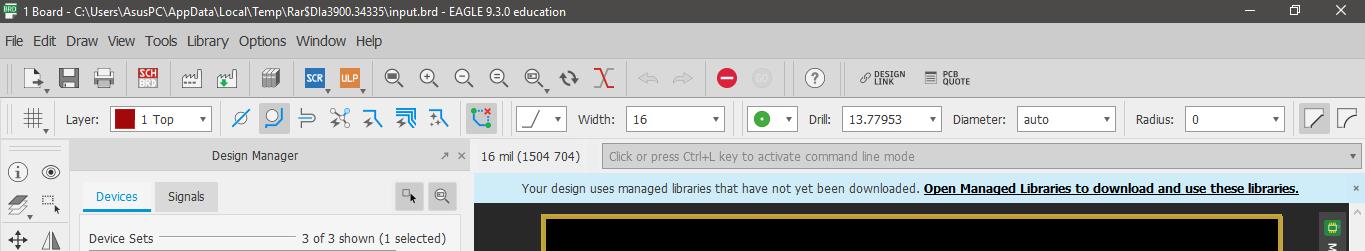

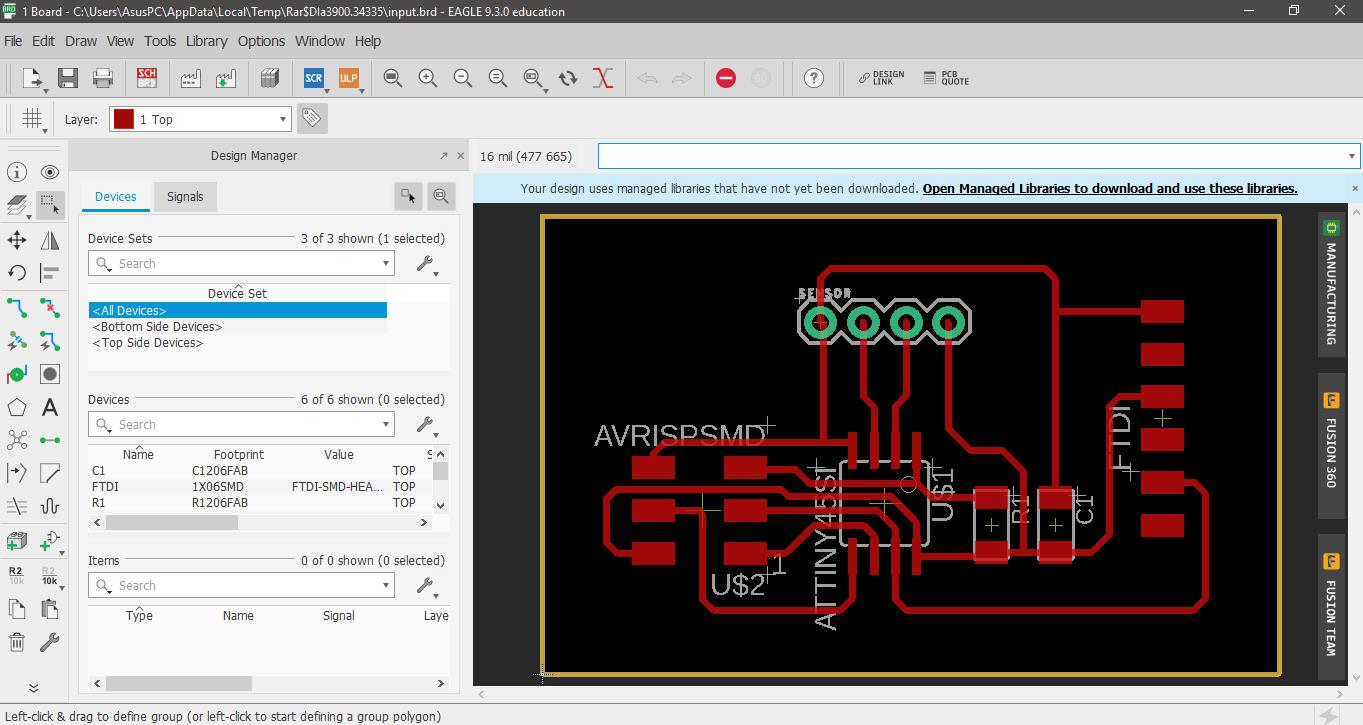

First I were guided of this board that is on the page of the fabacademy. I drew the board in Eagle Program

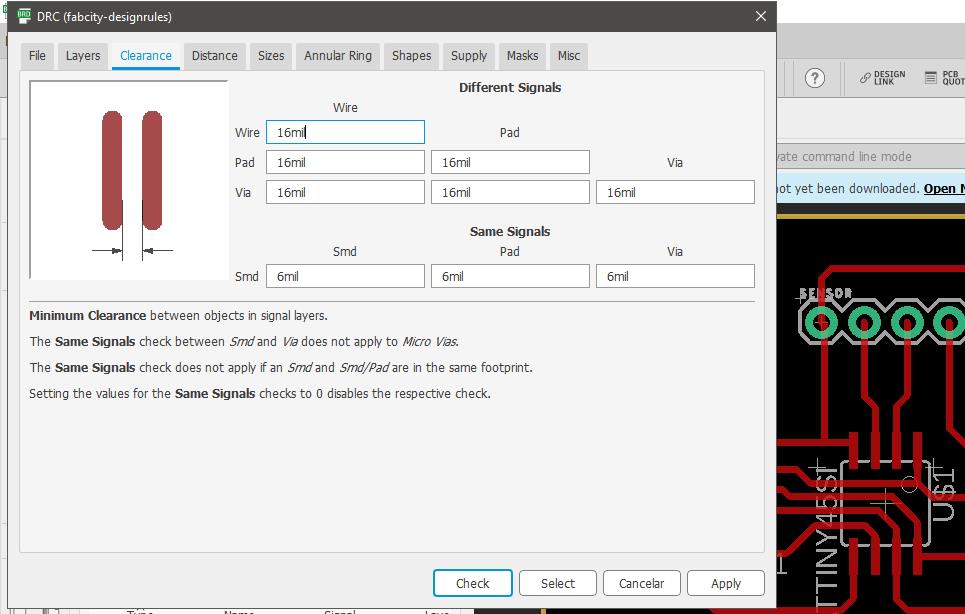

In the clearence option was placed 16 mill, by the reference of the size of wood milling cutter that will be used.

I used the width 16 because it does not use a lot of voltage.

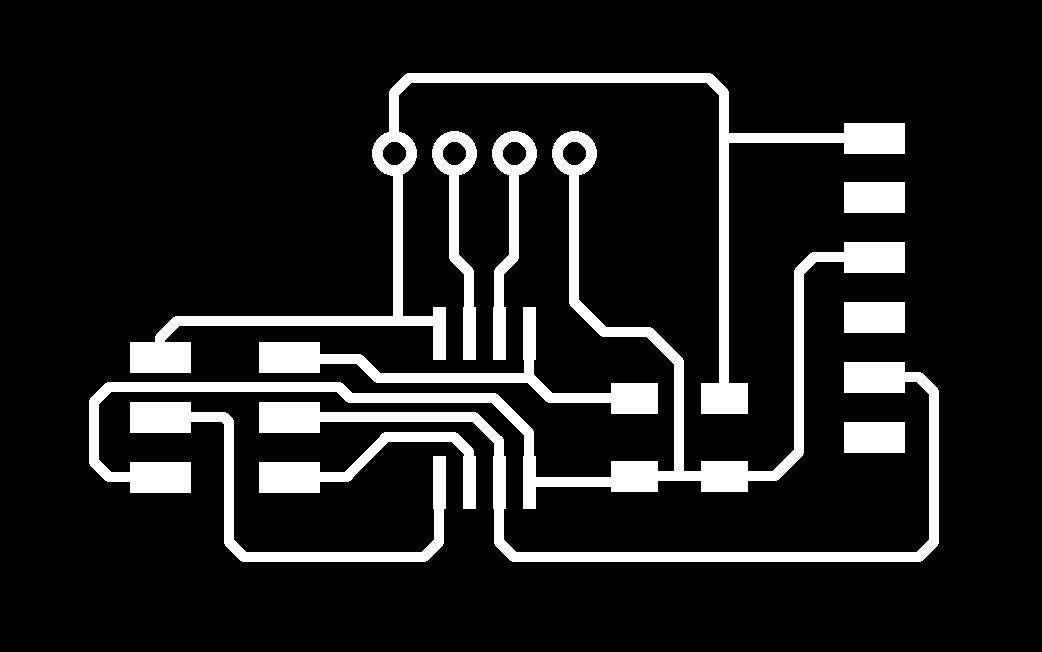

I exported the milling part in png format (600dpi)

Milling¶

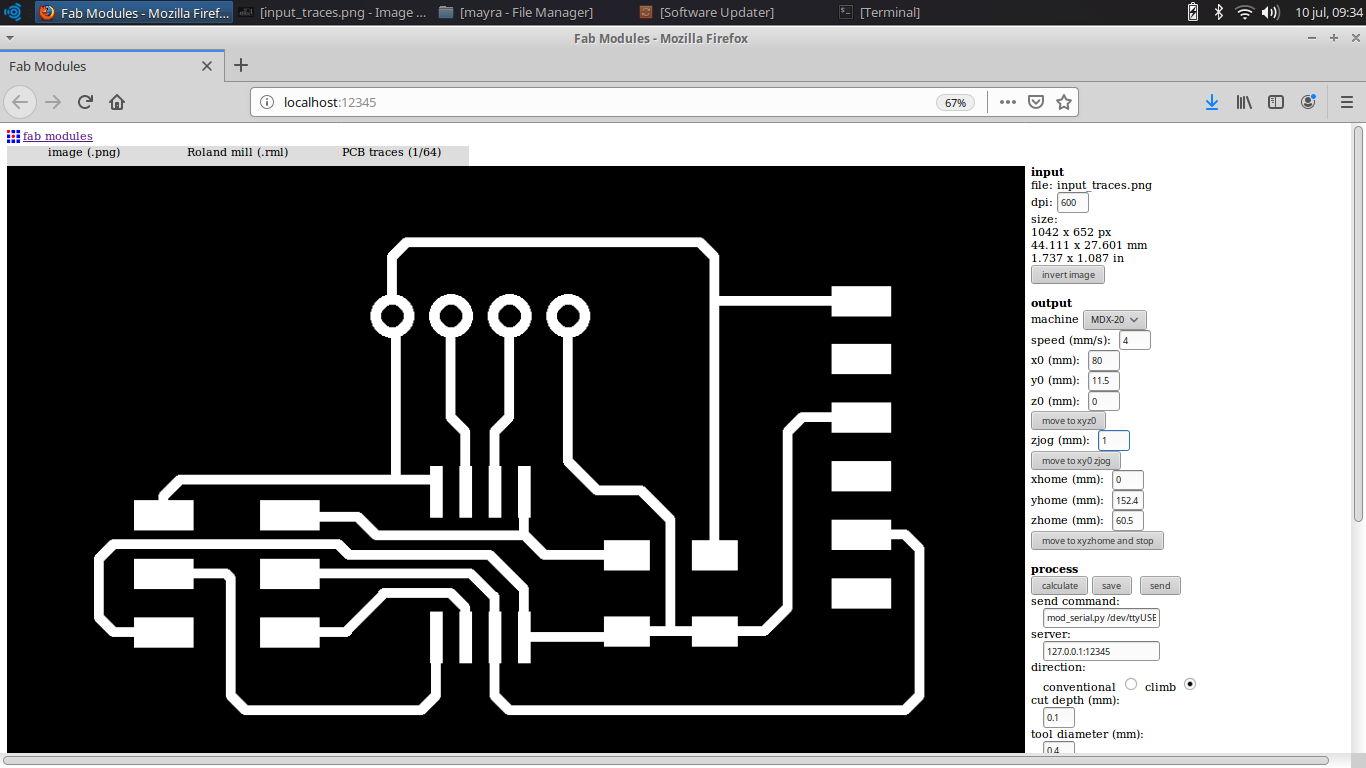

Also to be able to milling the plate, I used of the Roland Modela Machine

Then, I opened the PNG file, in the software of the MODELA, opened the terminal and mill the design on a copper blad board.

Before, I put the parameters in the Fab Modules to have a good milling. I opened the Fab Modules I chose the process of mill (.rml) in which input is image (.png)

I started with the rough (traces 1/64),.It is important to modify the parameter of Path error (pixel) which by default is 1.1 and it is changed to 0.1

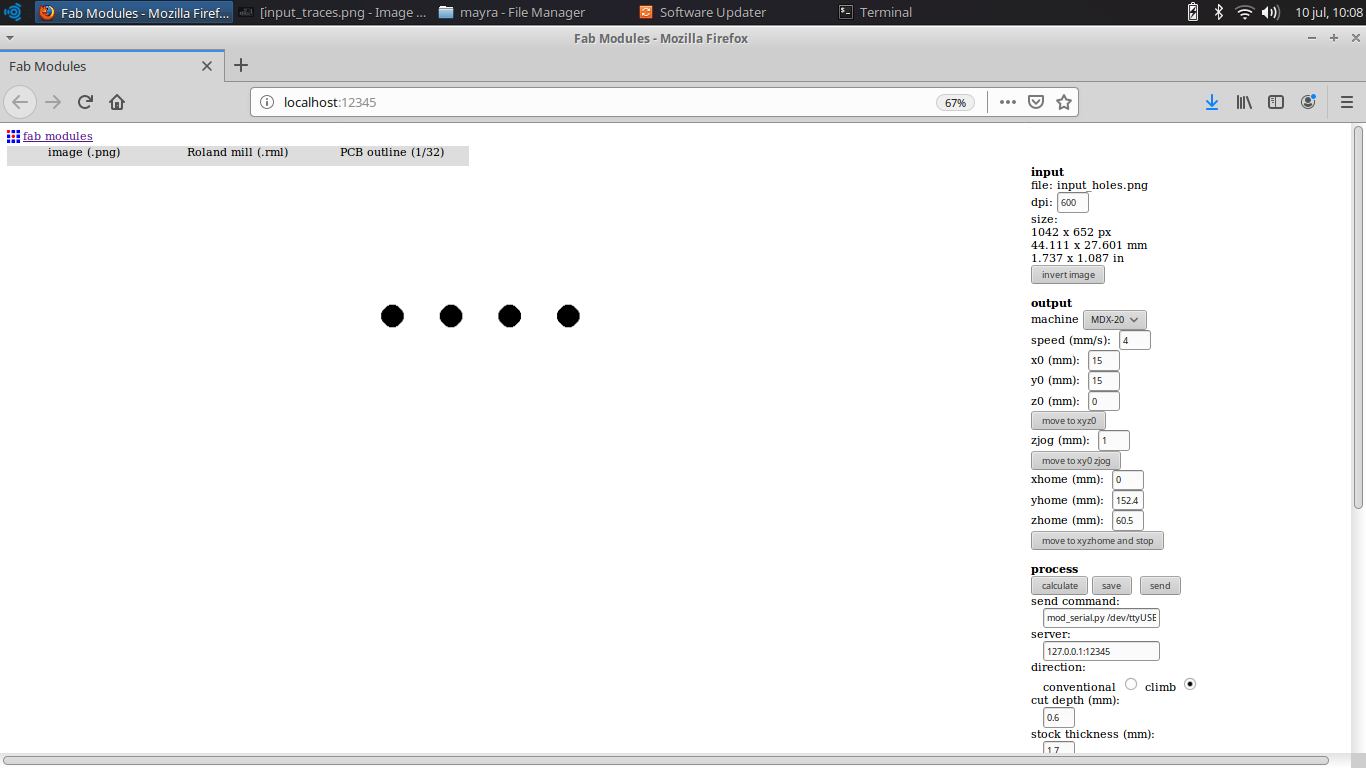

I continued with the finish process (outline 1/32)

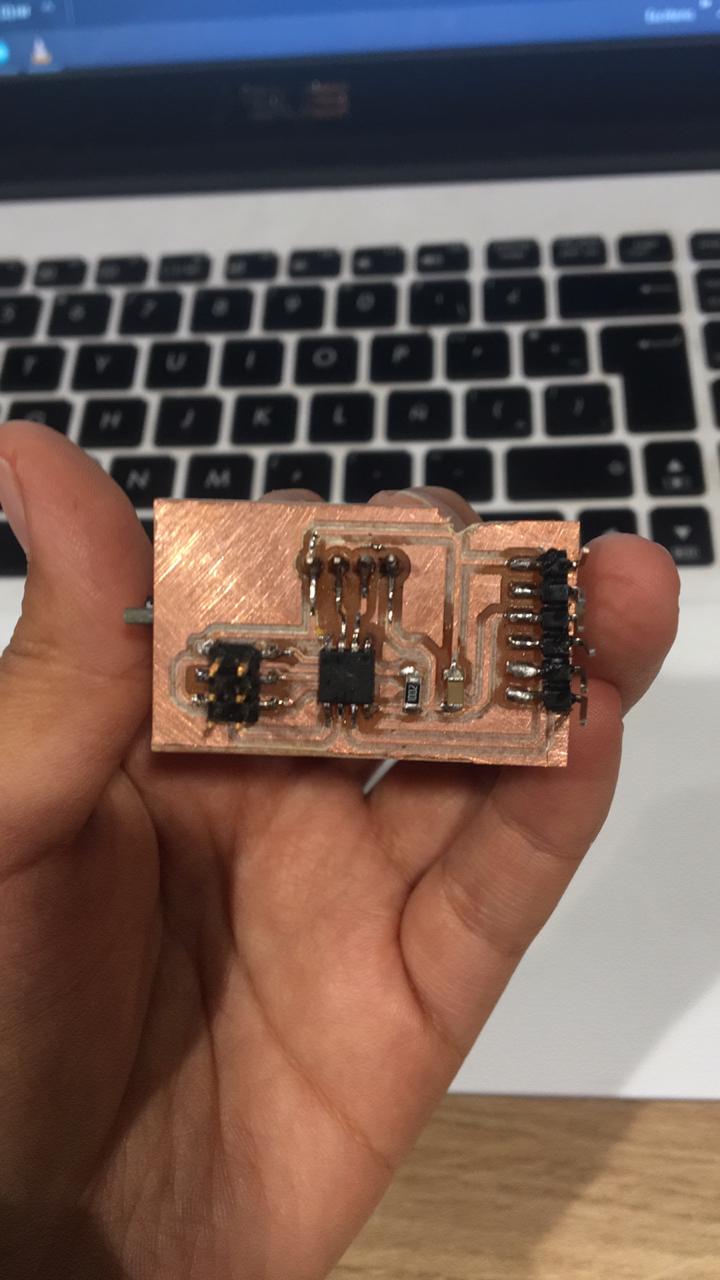

We can see the milling of the board

Then I soldered the board with the materials provided by the Fab Lab Esan.

Programming¶

To burn the bootloader, I need to identify the port in wich the FTDI cable was pluged,

Then in the tool tab, begin to set the information, board, processor, port.

Also, For this assignment I used the USBasp recorder because my isp recorder did not work

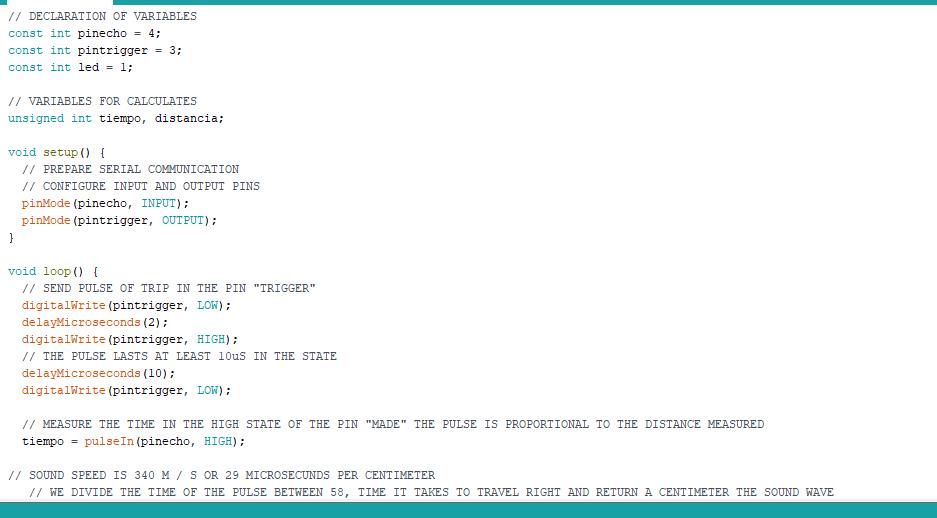

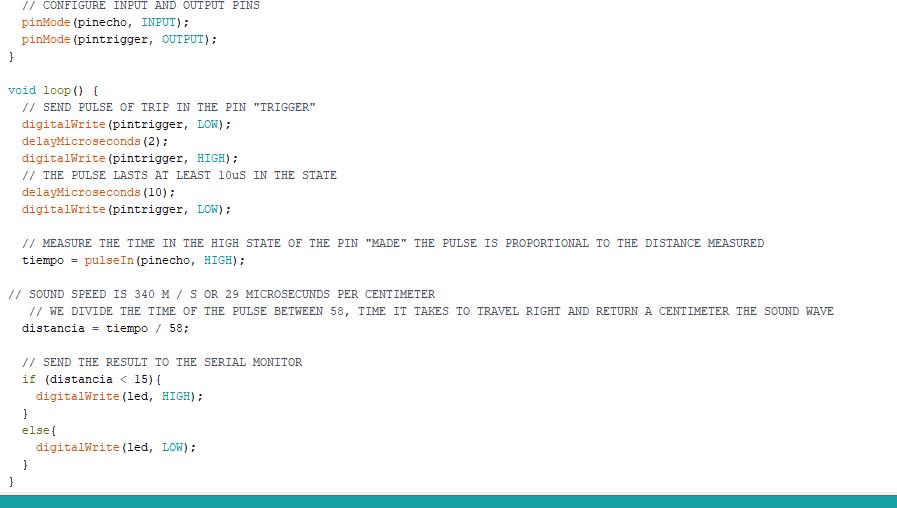

I did this programming because my board could not transmit serial communication in the Arduino, so I used a led to activate communication

which consisted,the ultrasound detects an obstacle in less than 15 cm, it activates the led, otherwise it goes out

Explaining the code¶

)

)

)

)

You can see the video

You can download the files by clicking on the bullets point.