13. Applications and implications¶

What will I do¶

The answer for this question can be seen in my Final Project Page.

As I have been advancing in the project, I have centered the extrusion to Bio-Materials.

Who has done what before¶

I am going to post links to instagram pages, or thingiverse projects I have been follow, to get ideas of how to design the problems solution:

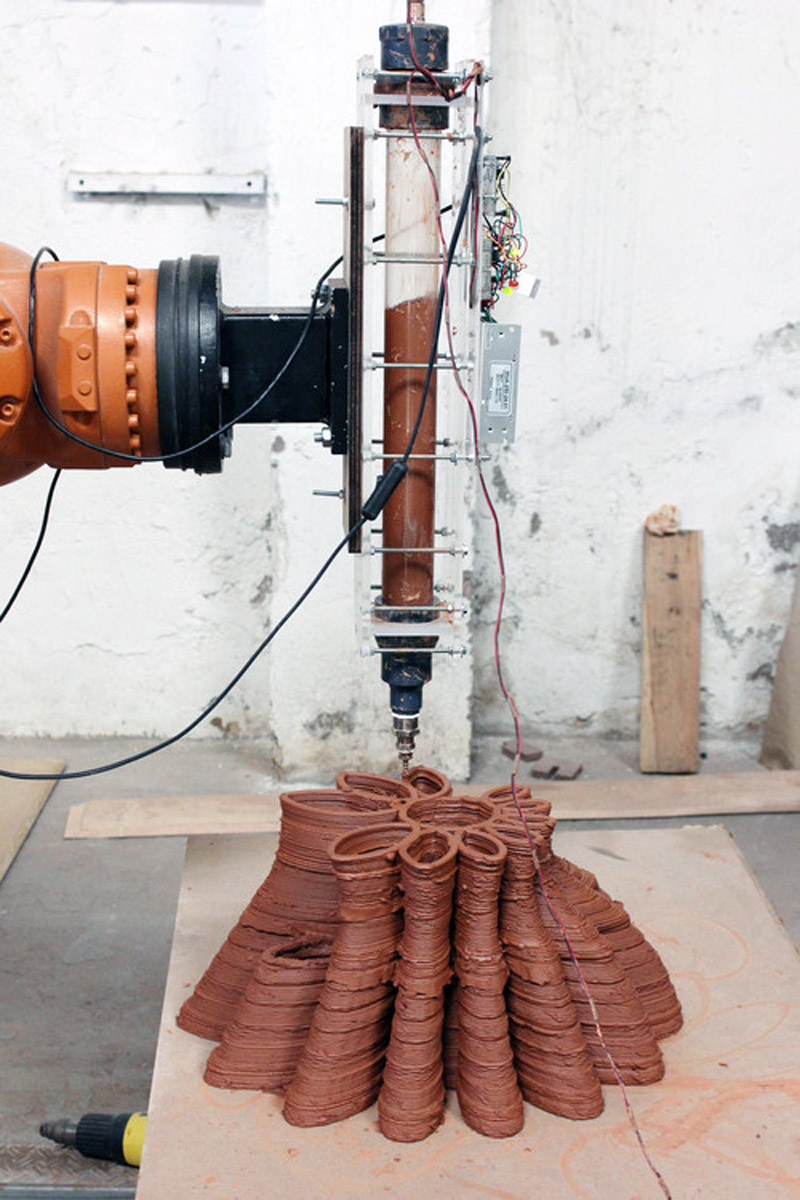

Clay Extrusion¶

3D Printed BioMaterials Receipe¶

Mussel Shell + Sucrose Composite

What will you design¶

The extrusion system:

It consiste of two main subsystems:

The Tank¶

The objective of the tank is to store the material before it is extruded. It also has to apply enough pressure to the material to generate a flow that goes to the extruder, lets remember that most of this materials are viscous, and are suffering of pressure loss.

There are 2 ways of applying this pressure, using a motor (DC or stepper) or using an air pump.

Extruder¶

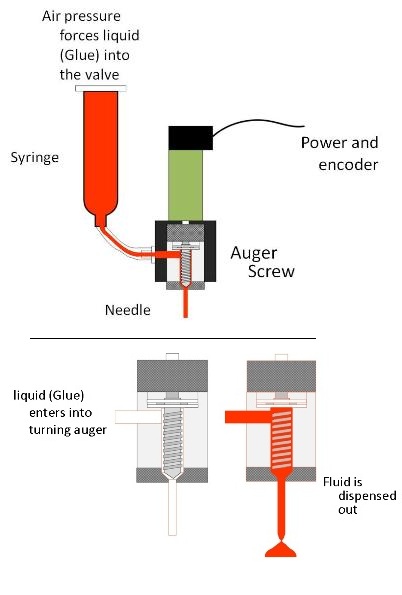

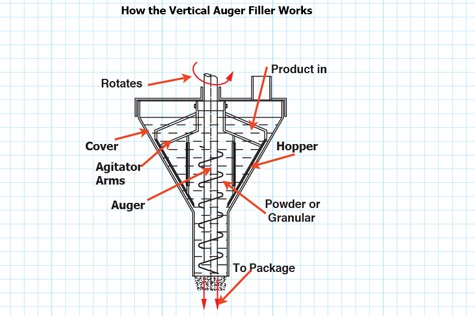

They are different forms to give a more constant flow to the extruded material:

Aplying a constant pressure directly to the material:

2

2

Auger Screw

3

3

I’m working at the moment in a tank + auger screw extrusion system.

What materials and components will be used?¶

I am not completly sure of how the project will look at the end of the hole process, but this is the listof materials I expect to use: - EcoFlex for molds

-

3D printer filament

-

Stepper motor Nema 23 and 17

-

Motor coupling

-

Auger Screw

-

Linear Bearings

-

Ball Bearings

-

Linear Axis

Where will they come from?¶

This question is answered in the following two questions.

How much will they cost?¶

| Qty | Description | Price | Link | Notes |

|---|---|---|---|---|

| 2 | LM8UU Linear Bearings | 1.00 $ | https://www.amazon.com/gp/product/B0711SNV4N?pf_rd_p=1581d9f4-062f-453c-b69e-0f3e00ba2652&pf_rd_r=R9JVPX22R85X7FW7D5QV | Order many, as those packages are more convinient than the unit price. |

| 2 | Chrome Linear Guides | 6.00 $ | https://www.amazon.com/dp/B07H9HDNYP/?coliid=I3FH7XXY9FZOZL&colid=IKZOWO2NXR68&psc=0&ref_=lv_ov_lig_dp_it | |

| 1 | Nema 23 Steel Mounting Support | 6.59 $ | https://www.amazon.com/Stepper-Bracket-Support-Mounting-Engraving/dp/B075L92Y6B/ref=sr_1_1?keywords=nema+23+base&qid=1553722704&s=gateway&sr=8-1 | |

| 1 | Nema 23 Lead Screw | 112.49 $ | https://www.amazon.com/STEPPERONLINE-Precision-Actuator-External-1-5875mm/dp/B07PTZ8JN4/ref=sr_1_5?crid=2S7PKB6A38INJ&keywords=nema+23+lead+screw&qid=1553722758&s=gateway&sprefix=nema23+lead%2Caps%2C135&sr=8-5 | |

| 1 | Ball Bearing | 6.97 $ | https://www.amazon.com/ABI-Enduro-cartridge-bearing-9-5x22-2x7/dp/B001GSKOB0/ref=sr_1_18?keywords=ball+bearing+9.5mm&qid=1553723200&s=gateway&sr=8-18 | This one is expensive, but you just need it to fit your lead screw from the motor. |

| 2 | O’Ring | 1.52 $ | https://www.amazon.com/uxcell-Rings-Nitrile-Rubber-Diameter/dp/B07HRRTRP9/ref=sr_1_13?keywords=o+ring+50mm&qid=1553723371&s=gateway&sr=8-13 | I used a 50mm diam with a 3mm thickness |

| 1 | Thread Seal | 1.2 $ | https://www.amazon.com/Everflow-811-5-Thread-Plumbers-White/dp/B00538ITFW/ref=sr_1_2?keywords=teflon&qid=1553723450&s=gateway&sr=8-2 | |

| 1 | Ultimaker Filament | 75 $ | https://www.amazon.com/Ultimaker-2-PLA-Filament-Blue/dp/B00NLK1DF2/ref=sr_1_1?keywords=ultimaker+filament&qid=1557012734&s=gateway&sr=8-1 | |

| 1 | EcoFLex | 39 $ | https://www.amazon.com/Ecoflex-00-30-Super-Platinum-Silicone/dp/B00CA5VY3U/ref=sr_1_2?keywords=ecoflex&qid=1557012799&s=gateway&sr=8-2 | |

| 1 | Nema 17 | 14 $ | https://www.amazon.com/JoyNano-Stepper-Bipolar-Holding-2-Phase/dp/B07DPFD22K/ref=sr_1_fkmrnull_1_sspa?keywords=nema+17+jameco&qid=1557012860&s=gateway&sr=8-1-fkmrnull-spons&psc=1 | |

| 1 | Nema 17 Motor coupling | 7.86 $ | https://www.amazon.com/OctagonStar-Flexible-Couplings-Printer-Machine%EF%BC%882PCS%EF%BC%89/dp/B01HBPHSII/ref=sr_1_5?crid=25O74Q4U4EBDL&keywords=flexible+couplings+5mm+to+8mm+nema+17+shaft&qid=1557012921&s=gateway&sprefix=coupling+nema+%2Caps%2C126&sr=8-5 | Its a pack of 2 coupling |

*This costs are an estimation and could vary through the finnal project development.

What part or systems will be made?¶

From the tank:

In case it is motor based:

The whole piston system, and the parts that ataches the system to the machine.

A first version has already been developed, you can see it in this link

In case I use the air system:

I will buy a syringe that will act as a tank, so I will build the closure, and seals for the air system.

From the extruder:

I will build the whole system, with the expception of the motor.

This includes:

- Auger Screw

- Auger Chamber

- Motor Base

- Motor Coupling

- Nozzle

- Seal

What process will I use?¶

- 3D printing

- Laser cutting

- Molding and casting

What question needs to be answered?¶

In the case of the BioMtaterial 3D printing, the main challenge I will face is the capacity that this material has to be 3D printed. It has to fullfil two requierments:

- Having a low enough viscosity to enable the material to flow through the tank and extruder.

- Sustain itself in order to make a layer based part.

In case the material fails, I am going to test the system using clay, a material that has been proven to work.

How will it be evaluated?¶

The competence of the 3D printer extruder to work with a viscous material.