Molding and Casting

- 1. Make a mold on Machine milling materials

- 2. After molding then cast it

- 3. Group Assignment: Study on the different milling, molding and casting materials

Molding and Casting

Milling Materials: We have different type of milling materials for making mold negative mold. I'm using machinable milling wax. Other than the wax we have rigid foam(images missing)

Mold Materials: For making mold we have several options, like silicone rubber with hardener, insta-mold, POP, hydrostone etc

Making negative mold by milling:

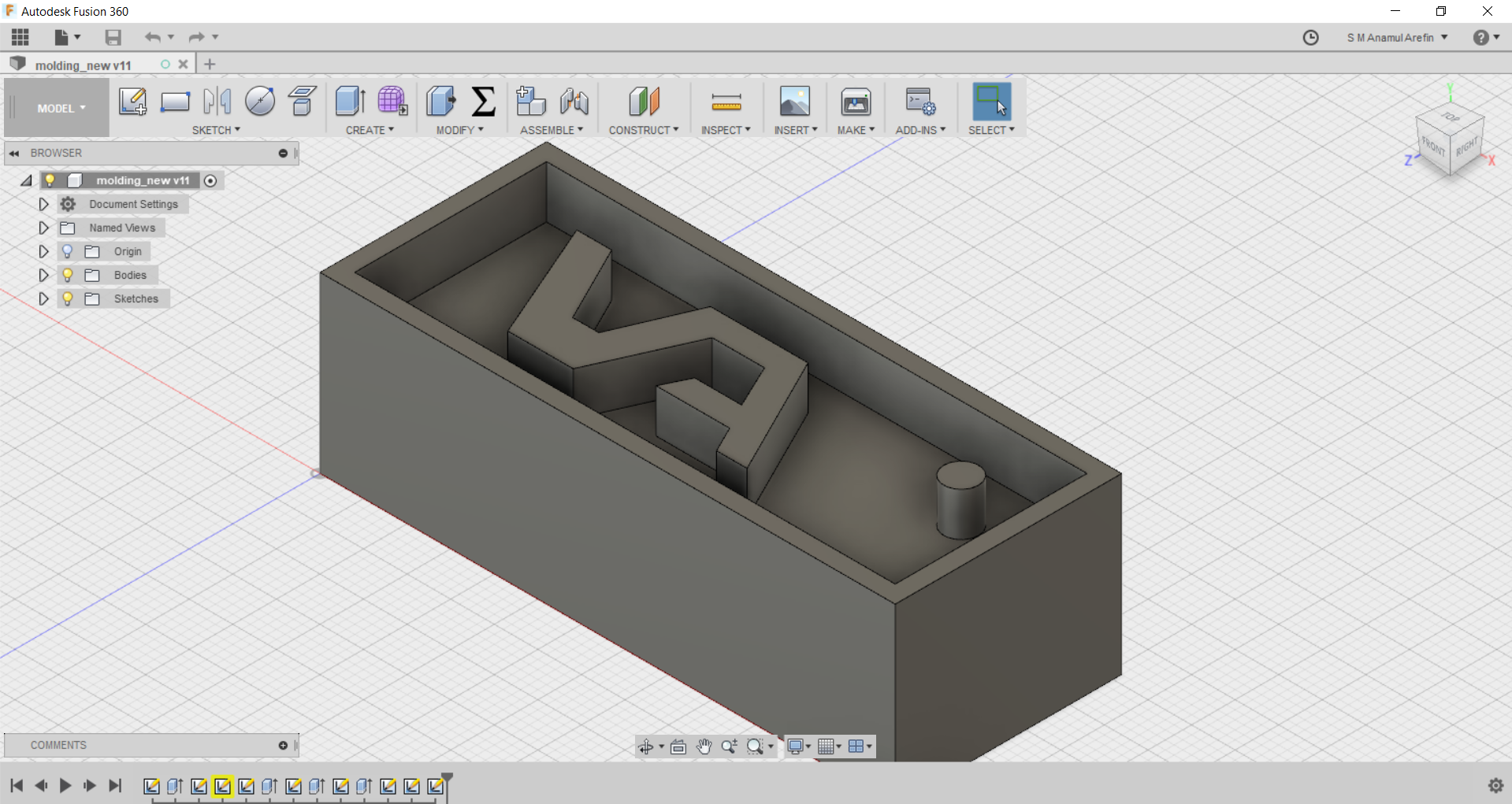

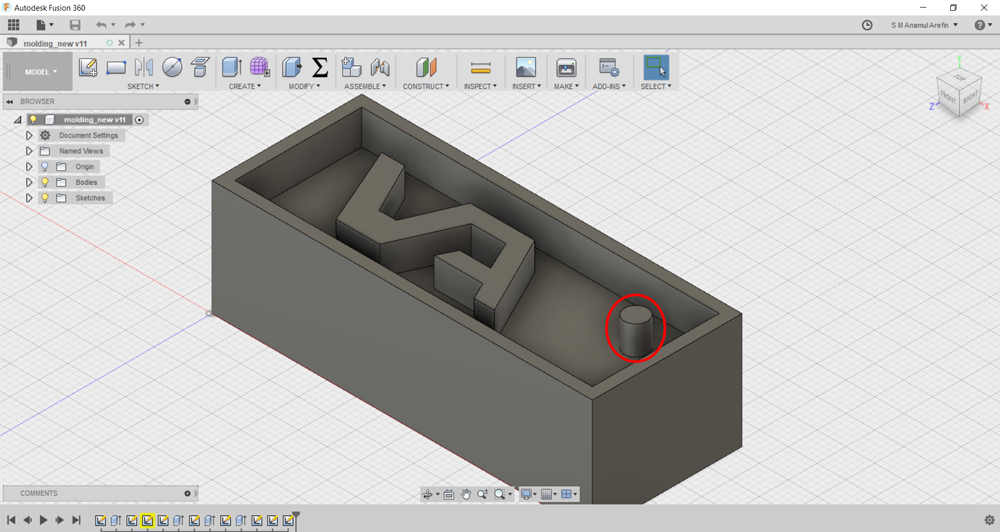

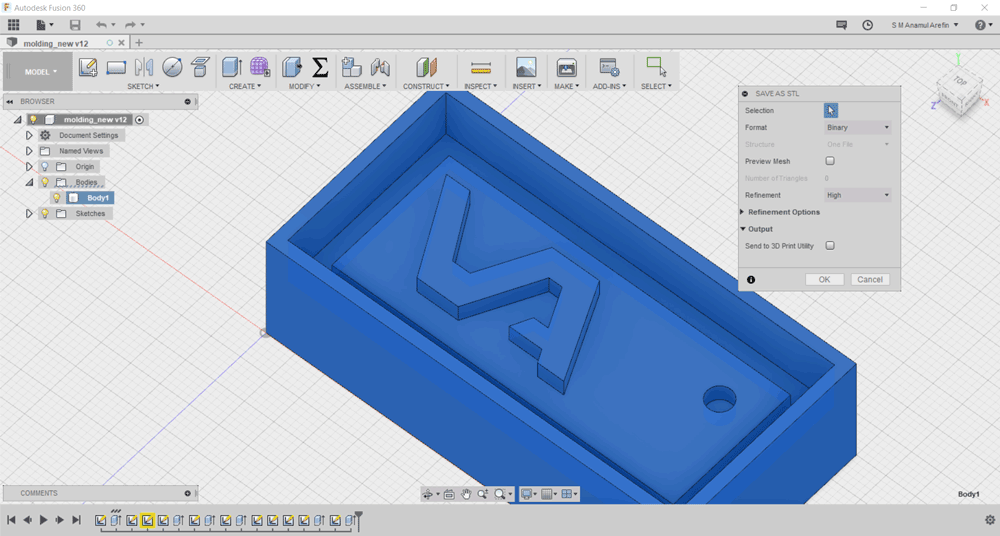

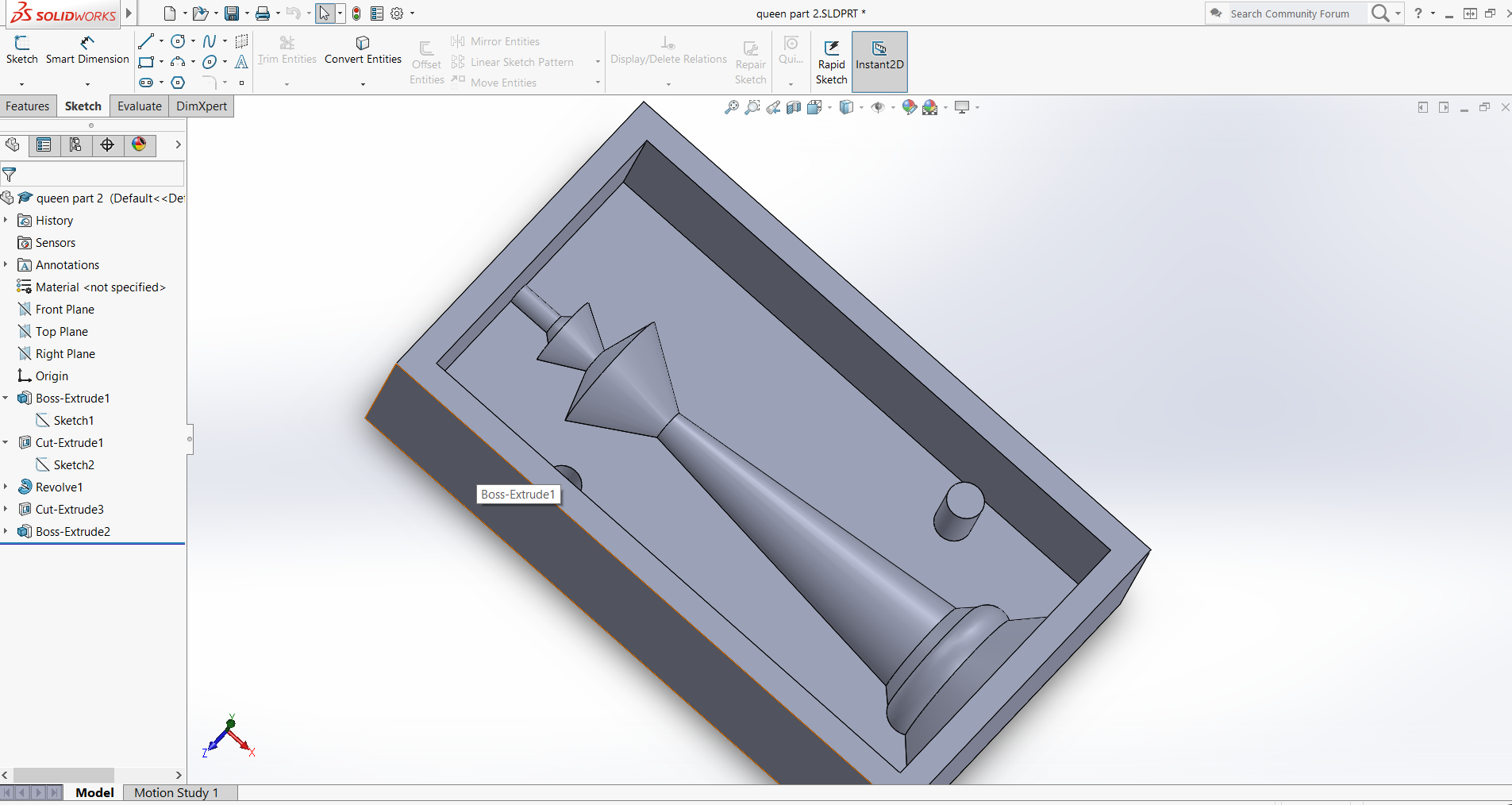

Fig1: 3D Design for milling

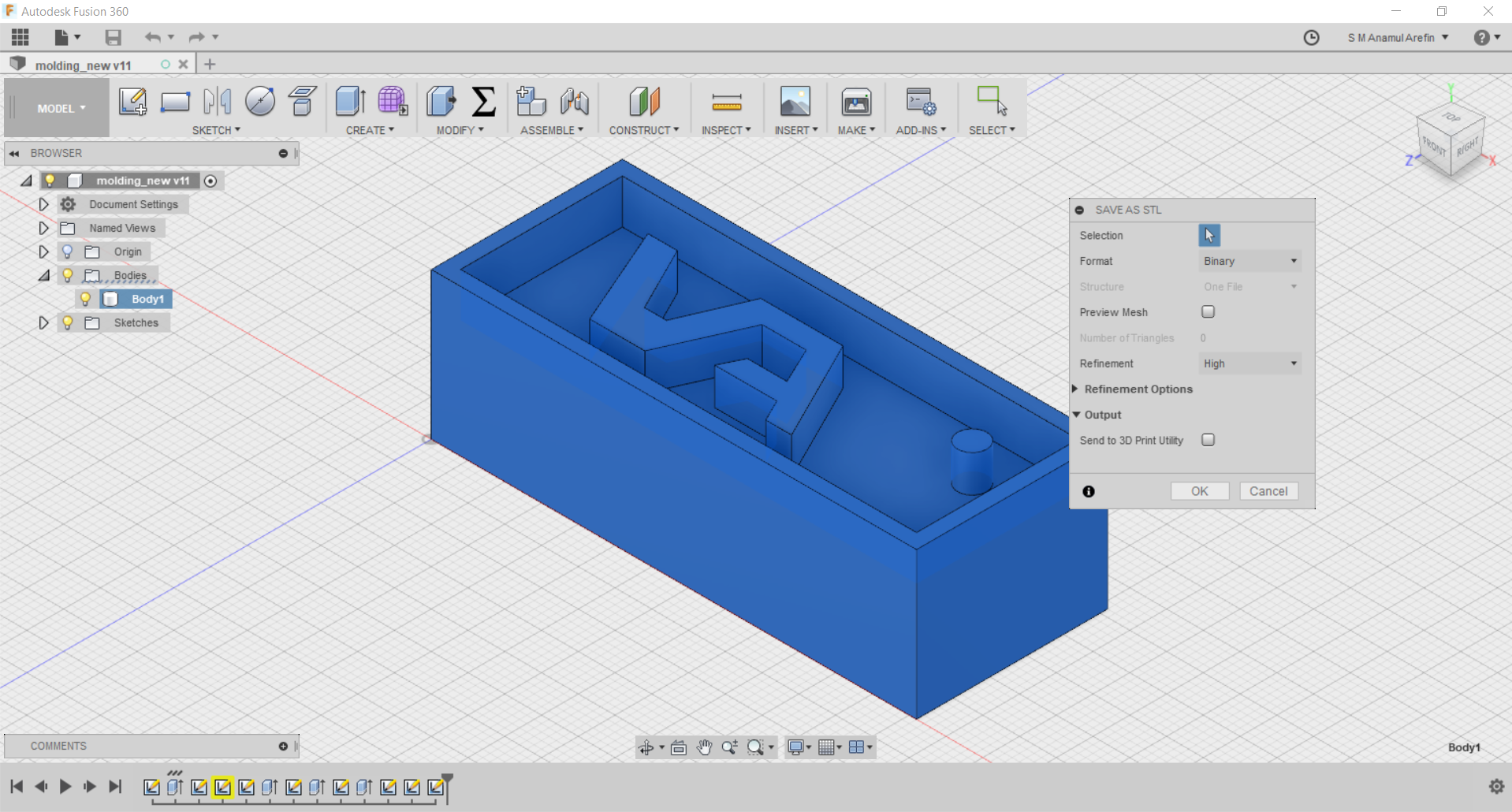

Fig2: Save as .stl format of 3D design for milling

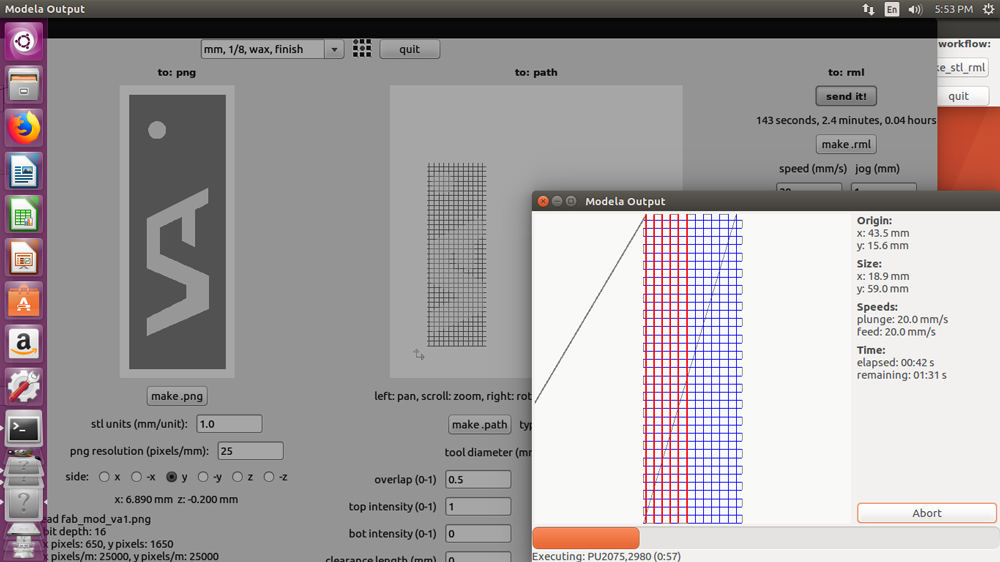

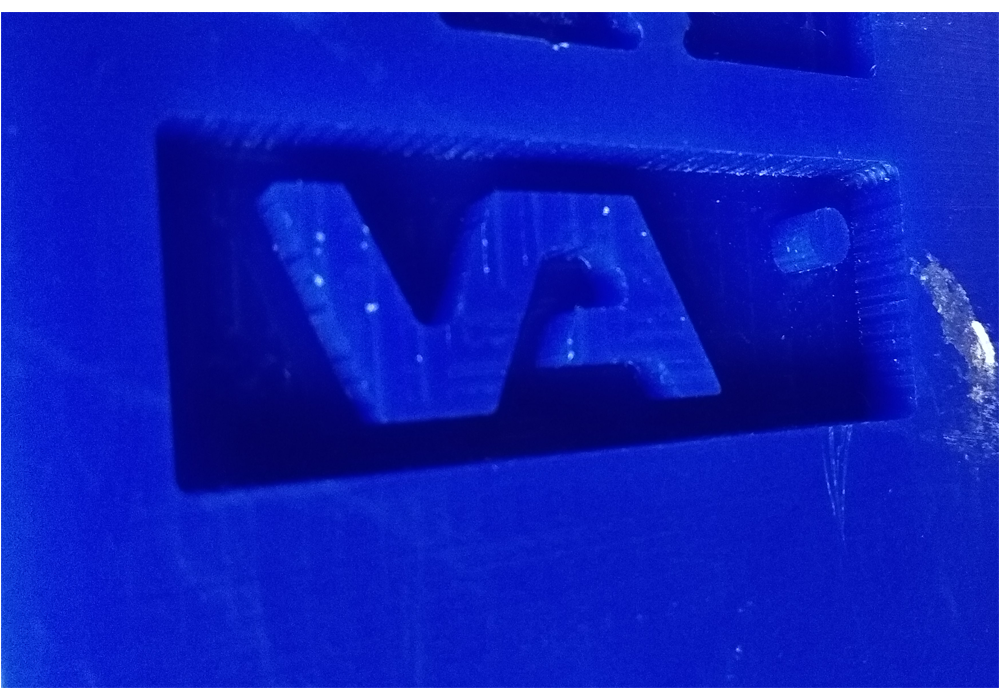

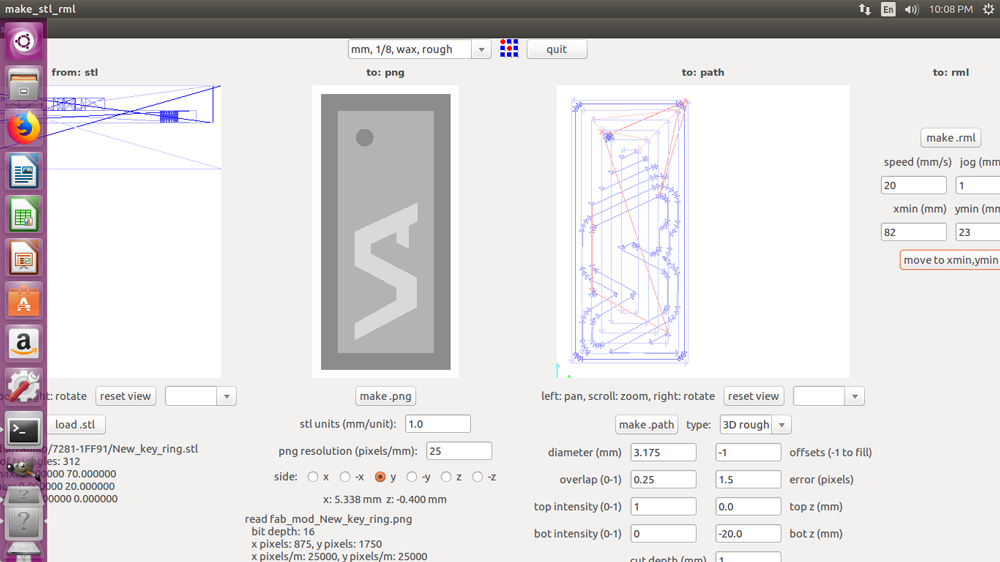

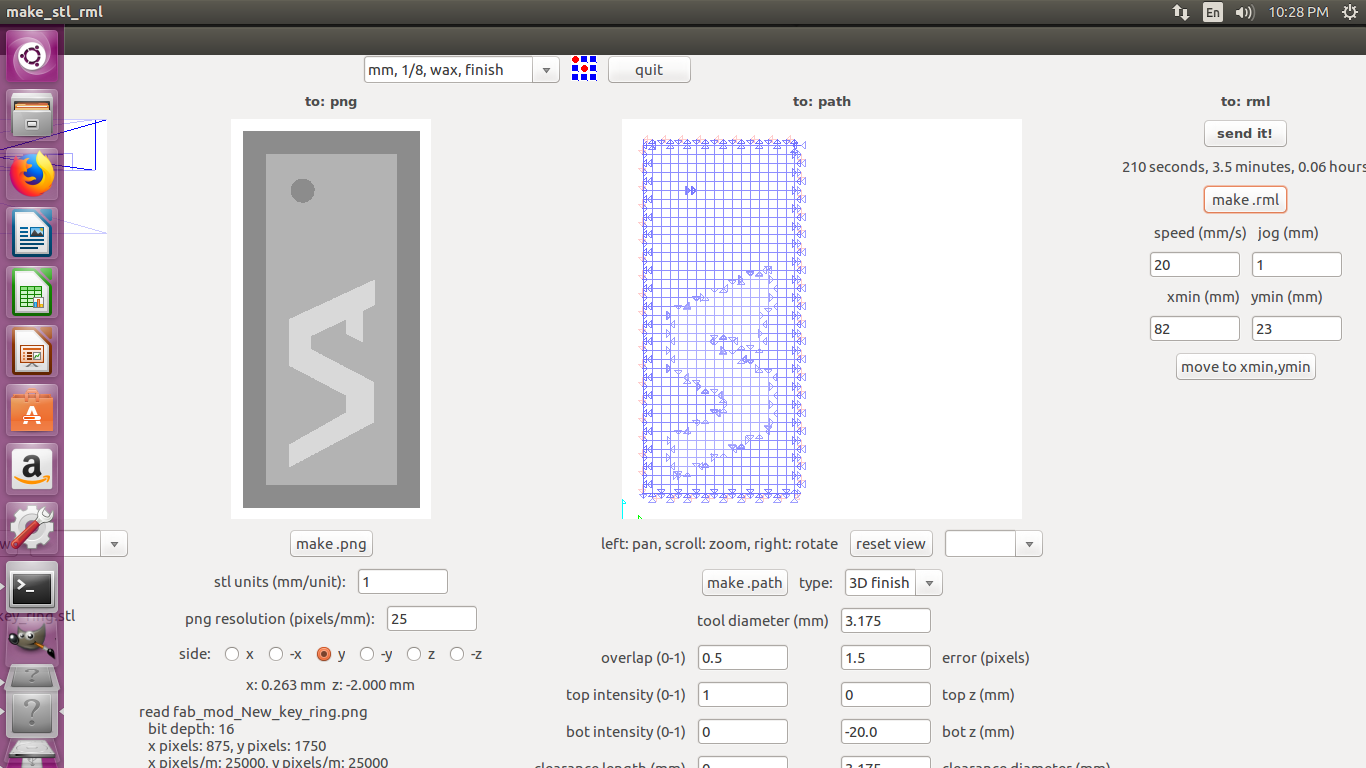

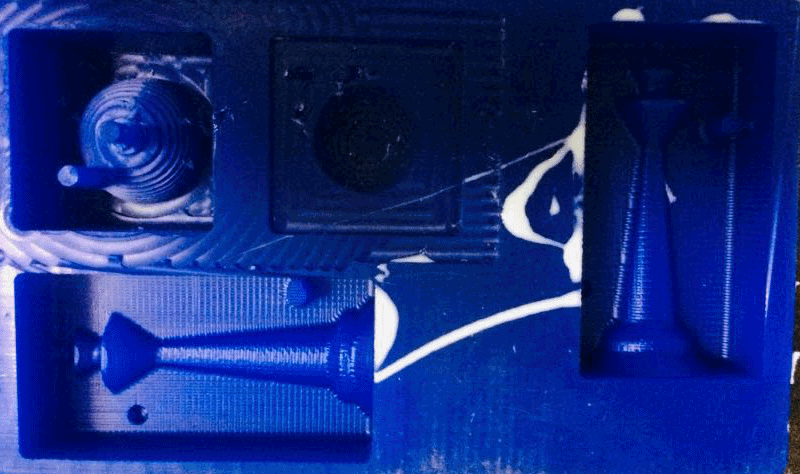

Fig3: Milling by Modella with fabmodule

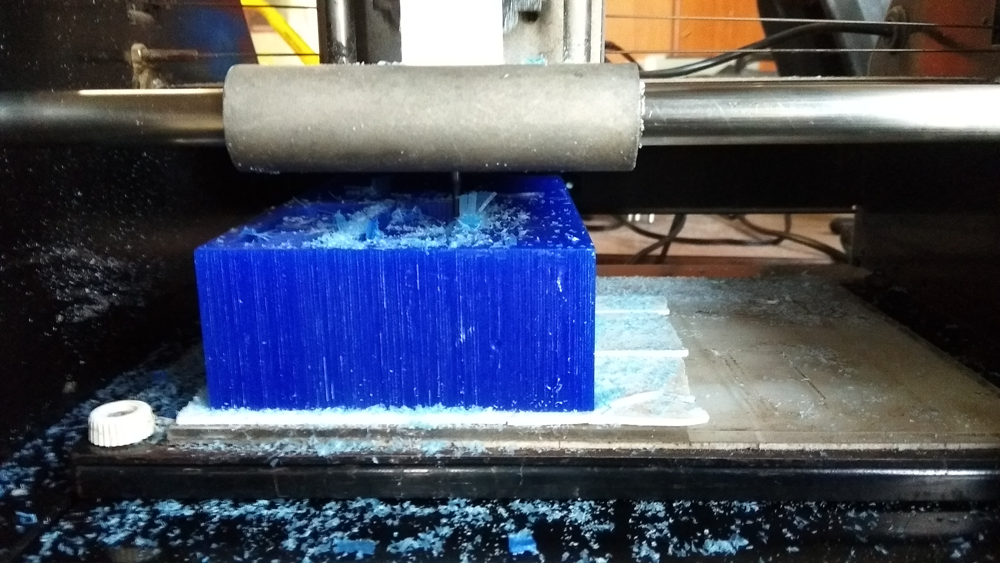

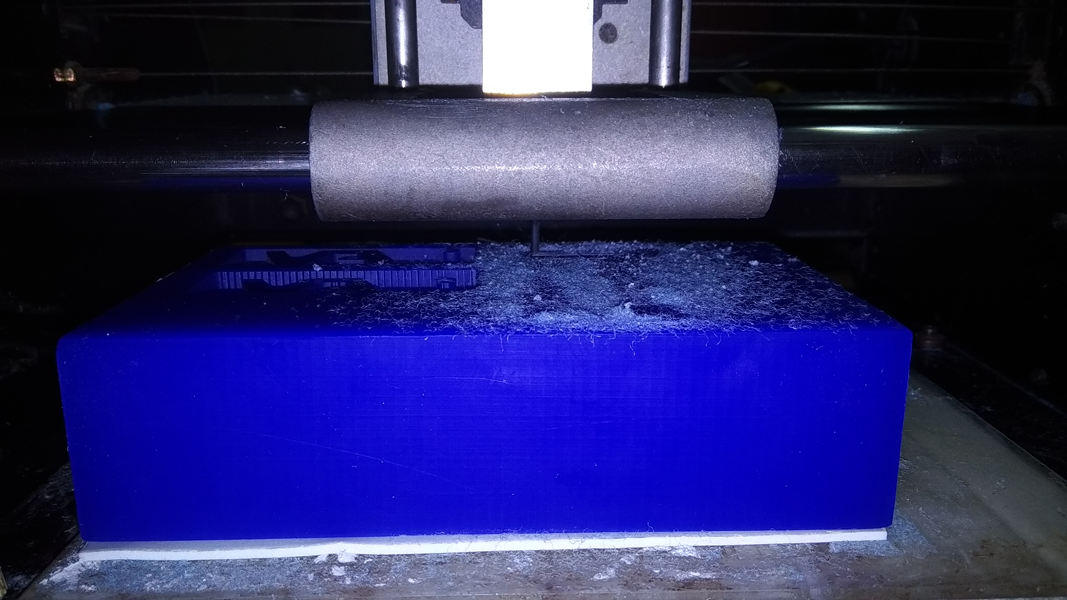

Fig4: Milling process are going

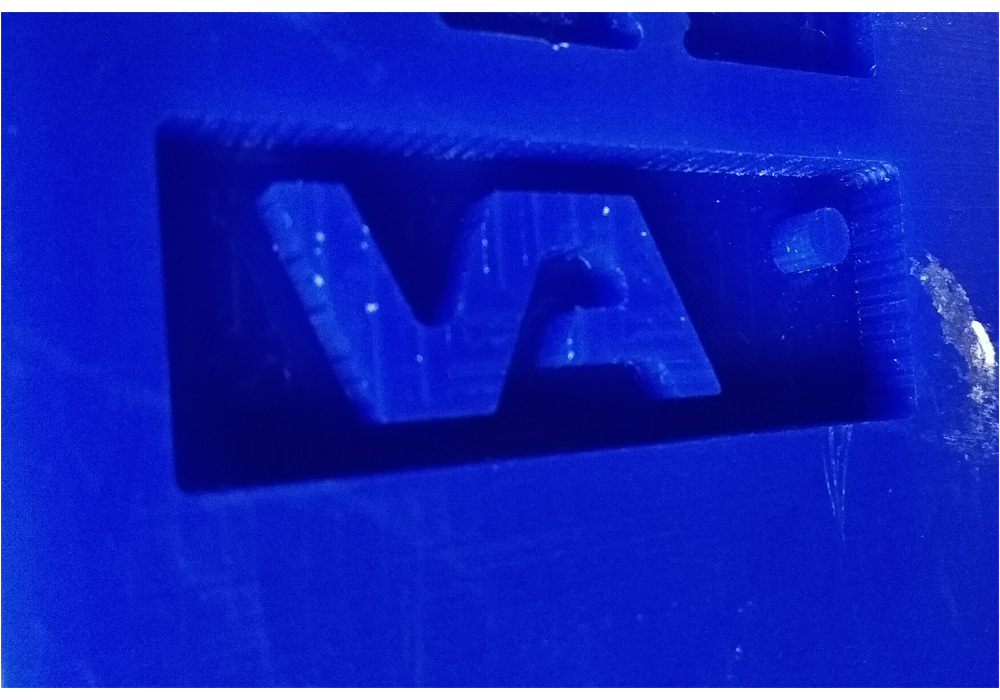

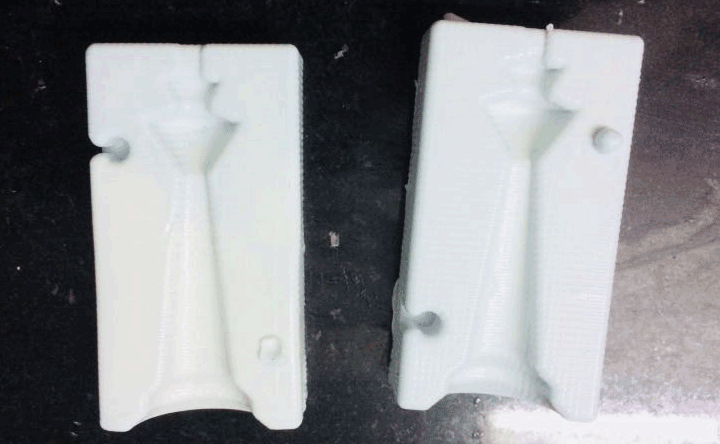

Fig5: Final design after milling

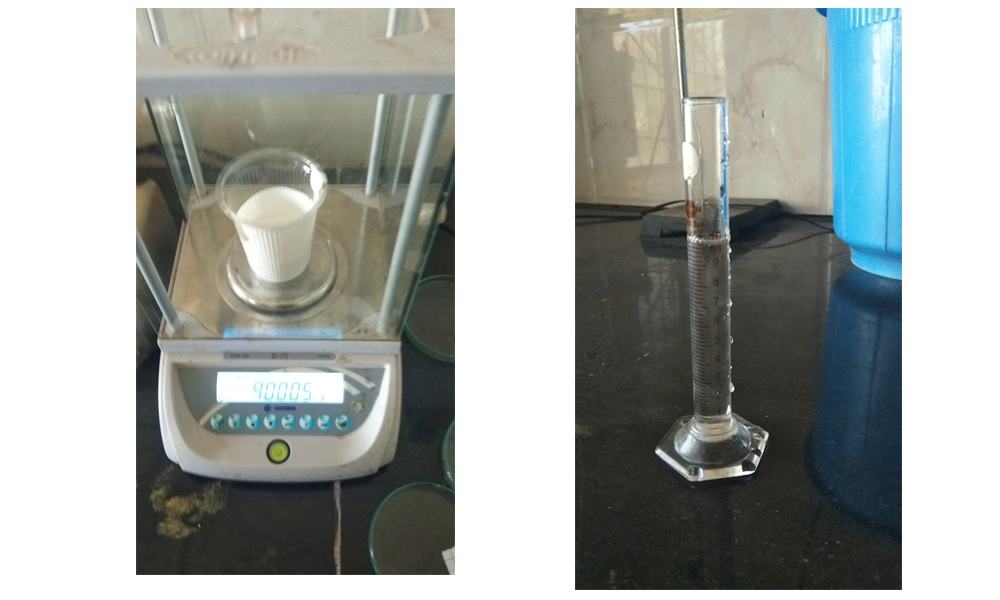

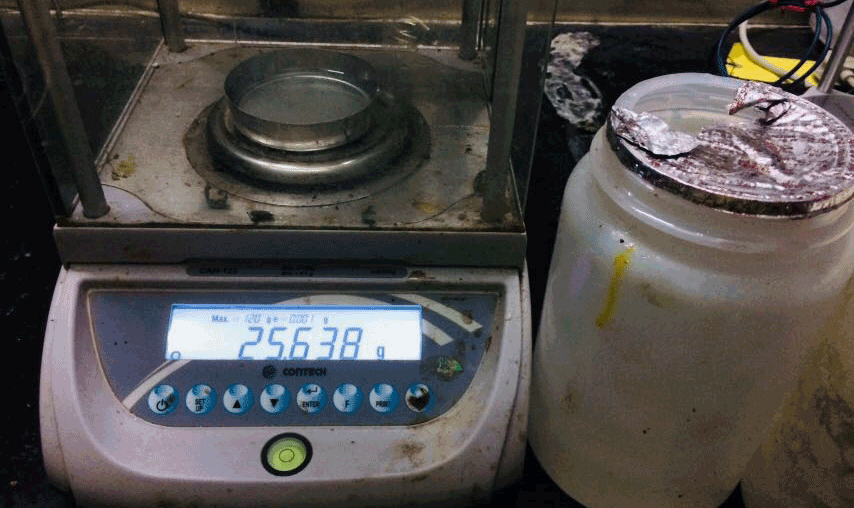

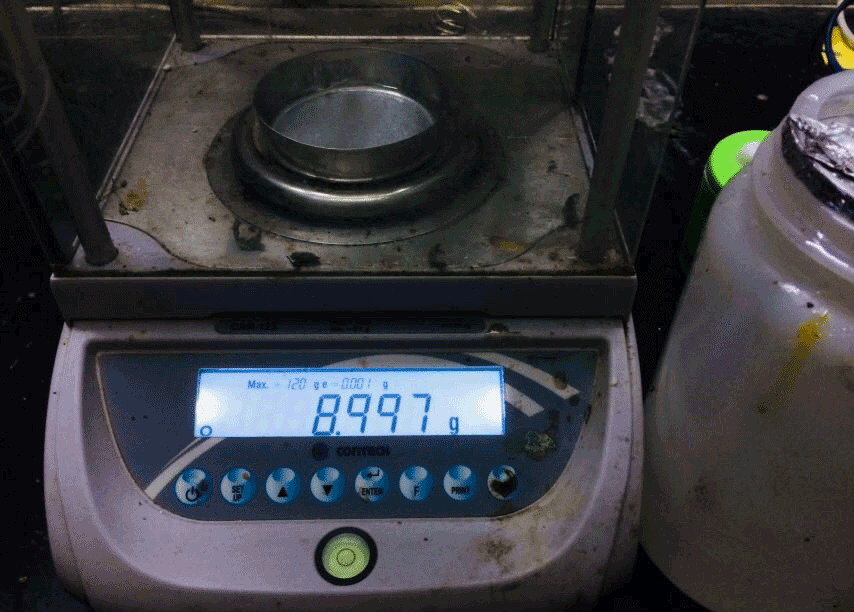

Fig6: Measuring of silicone rubber and hardener

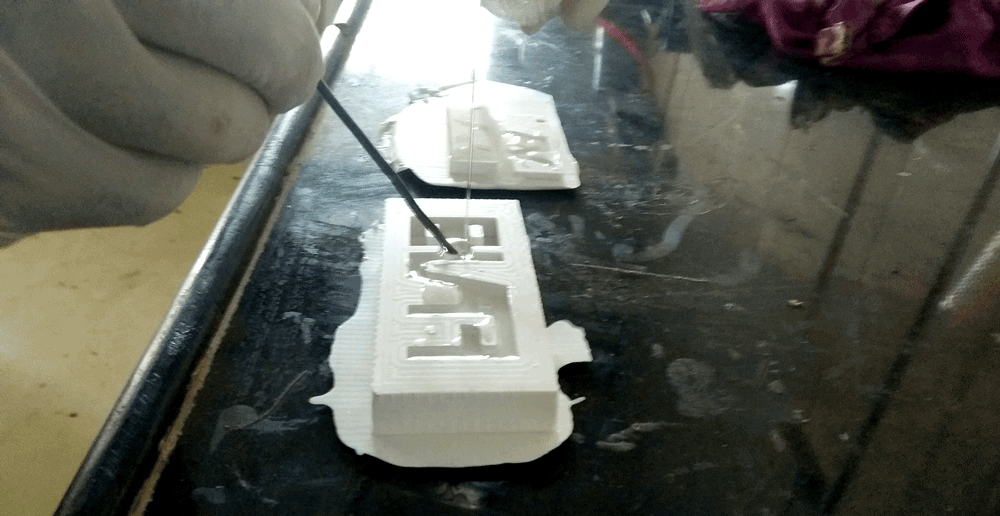

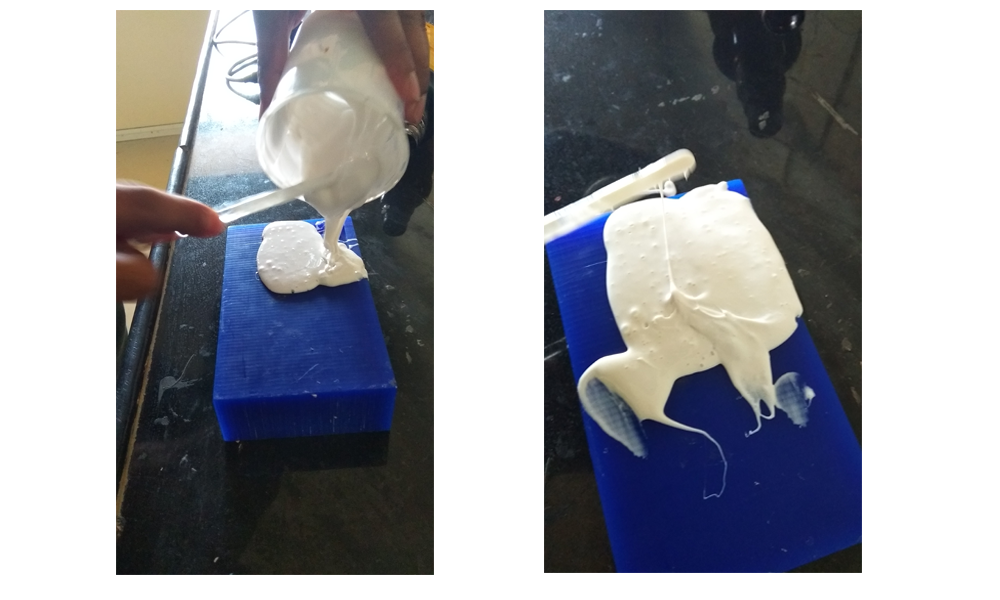

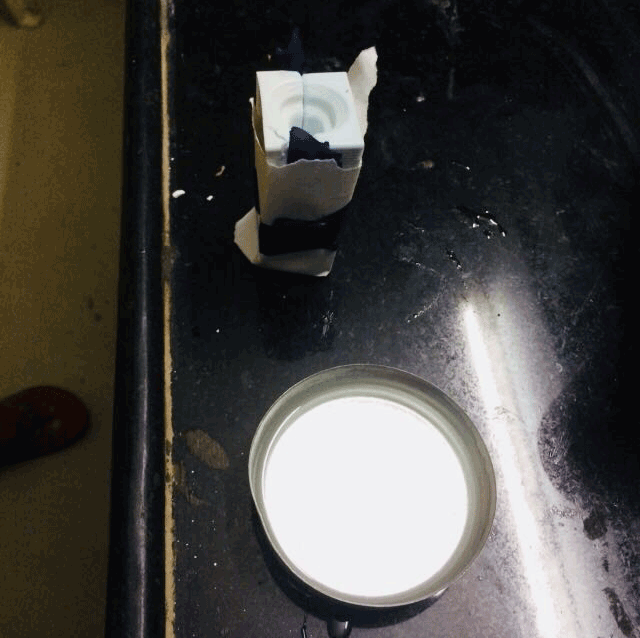

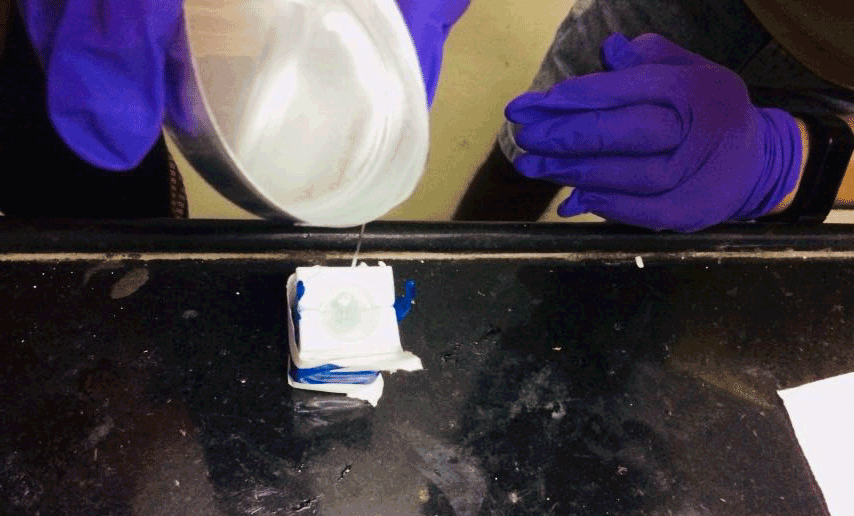

Fig7: Pouring the silicone on the mold

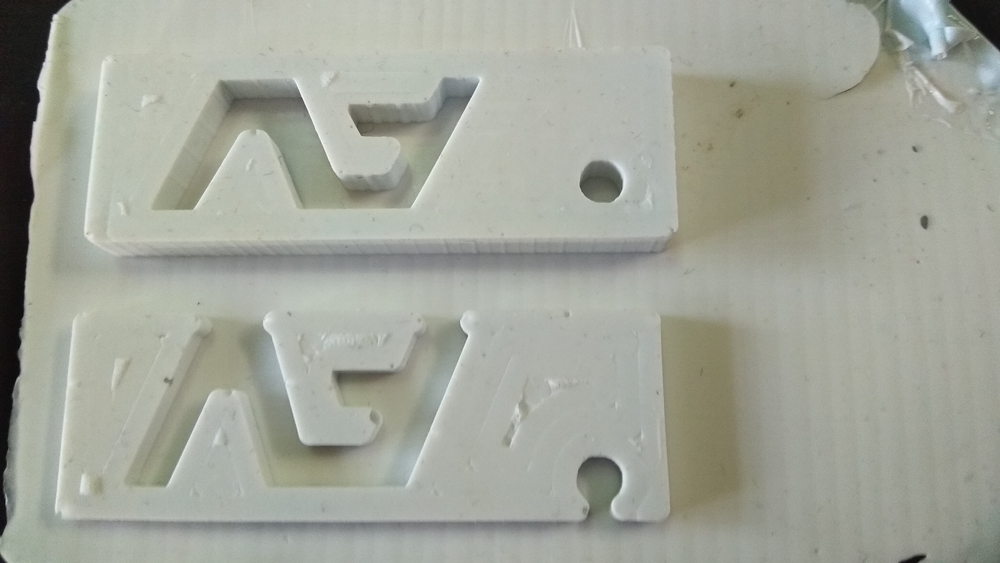

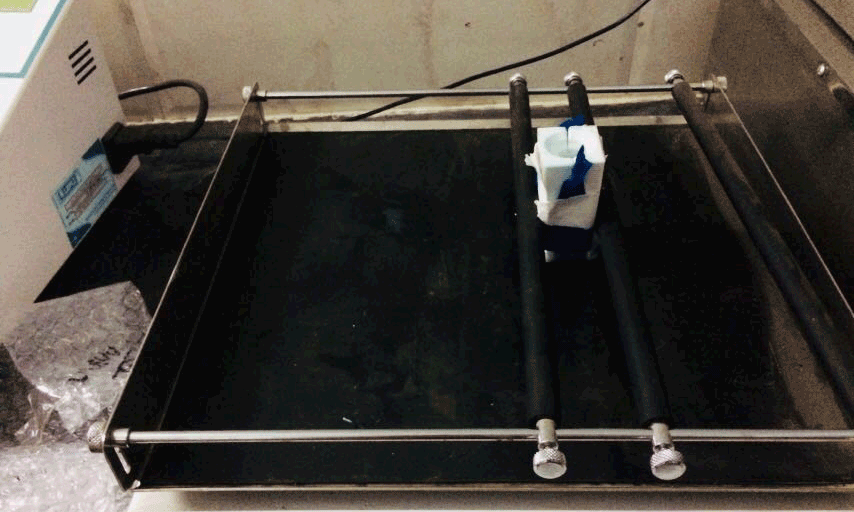

Fig8: After curing of the silicone rubber

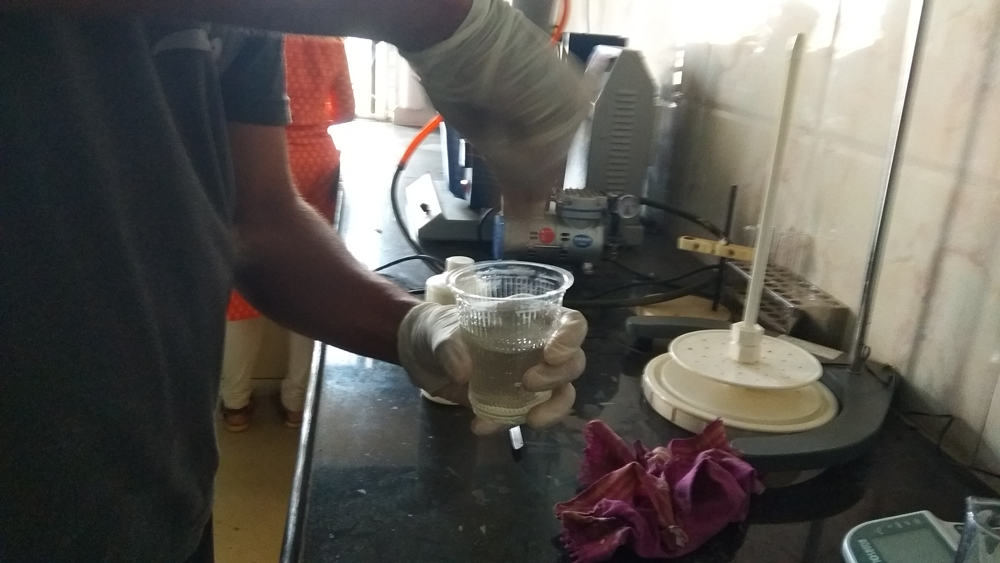

Fig9: Stirr properly epoxy resin and hardener mixer for casting final product

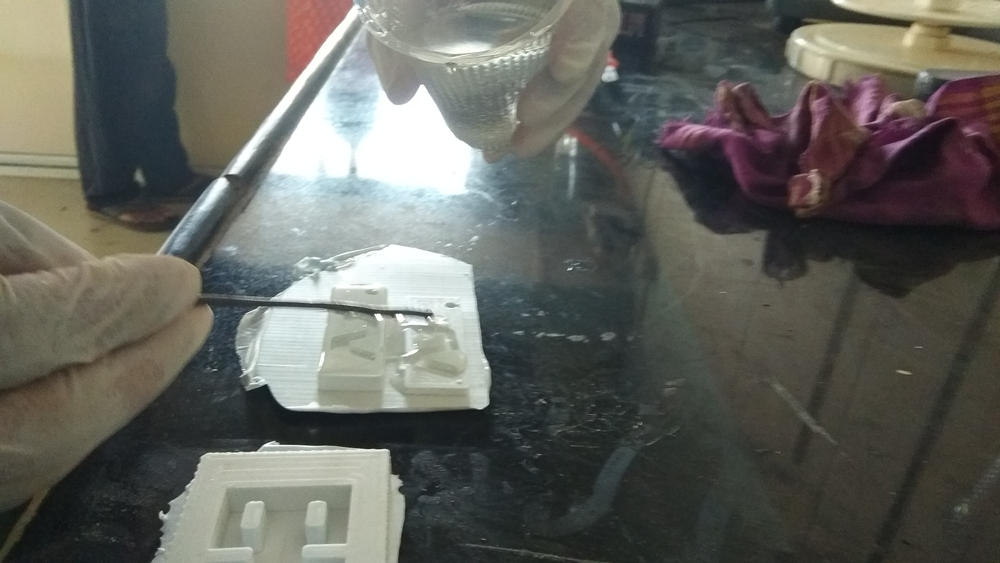

Fig10: Pouring epoxy resin on the silicone mold

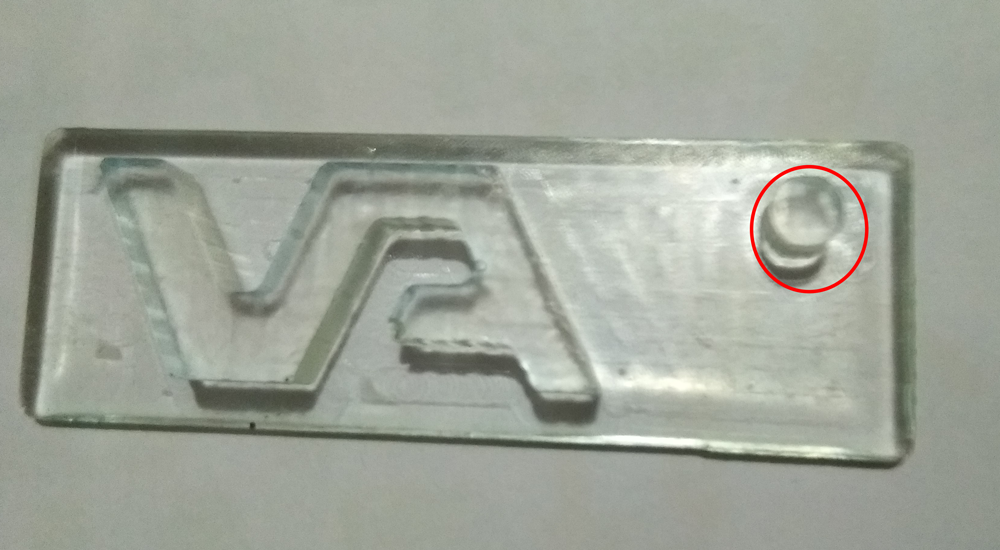

Fig11: Final product after casting

Problem/Mistake in my design: I want to make a key ring, in my design where I was kept one circle extrude which is visible as extrude part after milling. But I want a hole so what happen, then I redesign and milling again. I repeat all process as previous. Images in below:

Fig12: Circle extrude part

Fig13: Extrude part show here hole

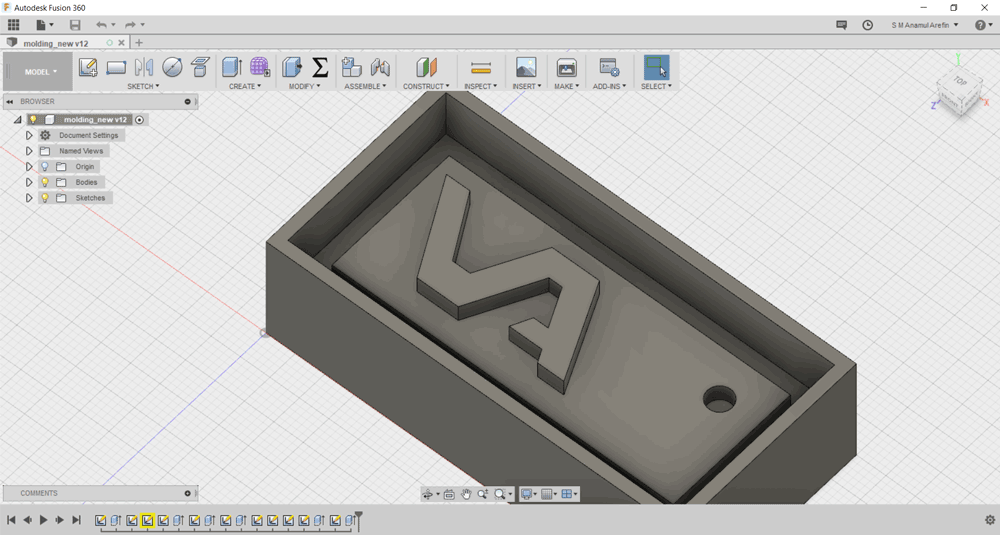

2nd design: After understand the mistake then I redesign the model and milled again and I followed all process as previous.

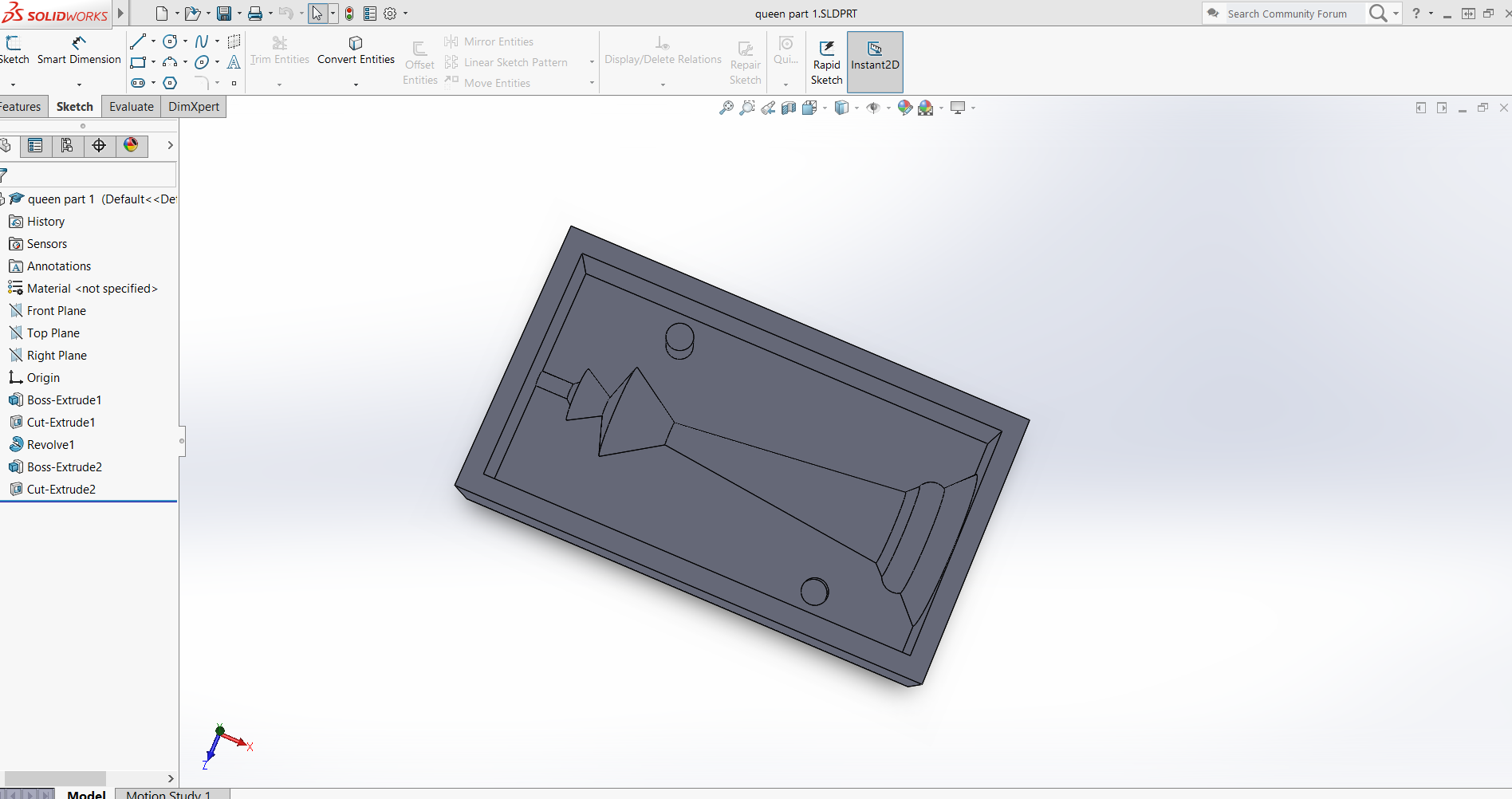

Fig14: 3D Design for milling (2nd)

Fig15: Save as .stl format of 3D design for milling

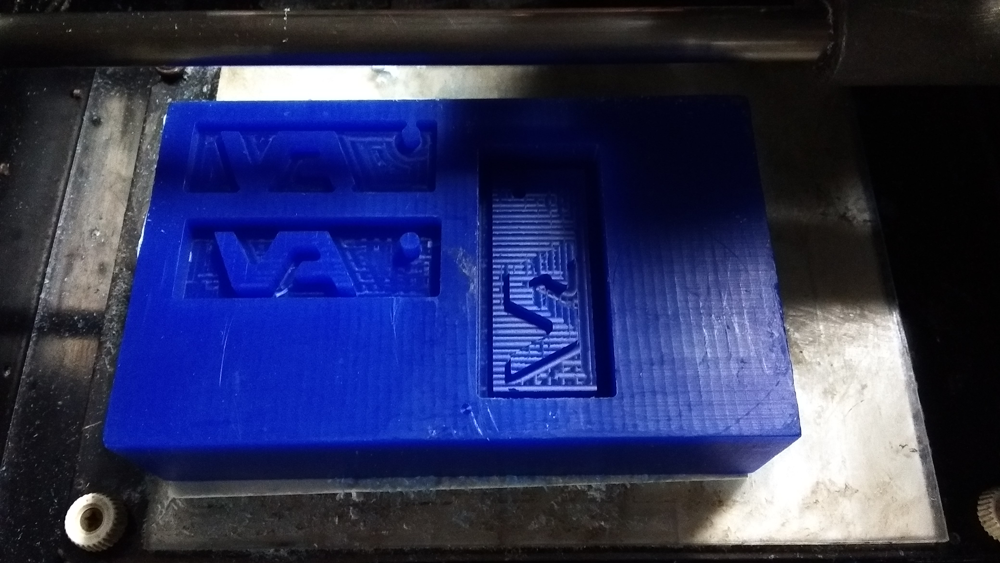

Fig16: Milling by Modella with fabmodule in rough cut

Fig17: Milling by Modella with fabmodule in finish cut

Difference between Rough cut and Finish cut: In rough cut the endmill paths are goes in deep according to the design and cut it first base structure, second is finish cut are make more path in zigzag pattern for cut the smooth layer by same endmill. So in rough cut the path is lesh but cut it in deep and finish the doing same thing but in more path.

Fig18: Milling process are going

Fig19: Final design after milling

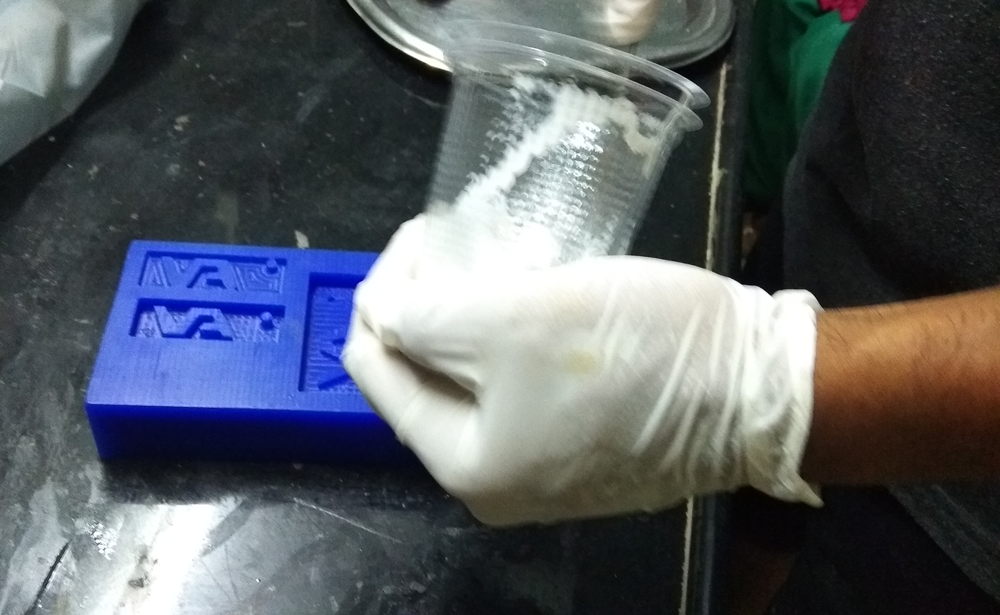

Fig20: Pouring the silicone on the mold

Fig21: After curing of the silicone rubber

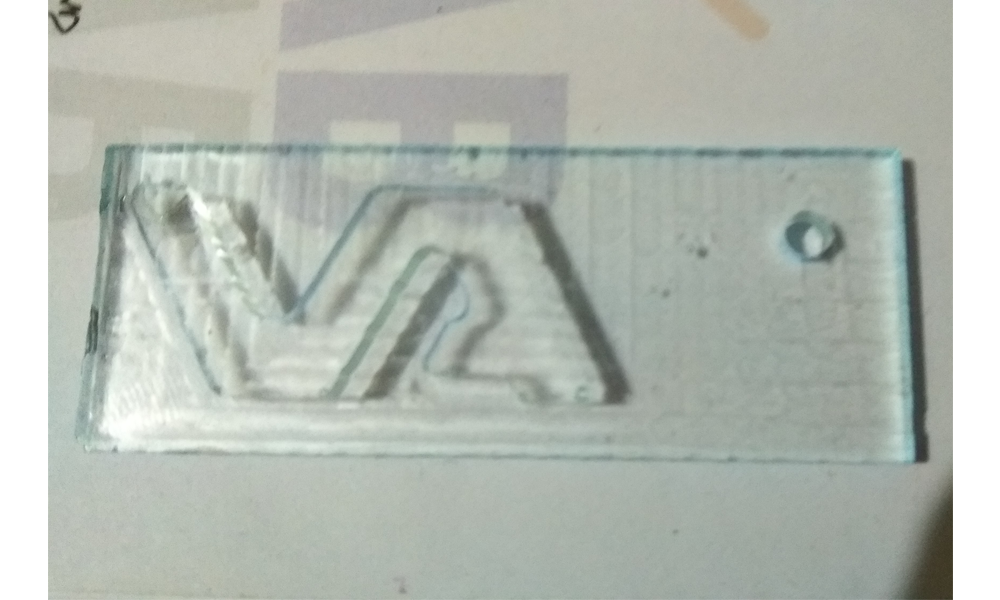

Fig22: Final product after casting

I will again making 3d double sided molding when i will get the SRM 20 in my LAB, it take around end of the july 2018.

I my Lab still i need to wait for SRM20, that's i have no option to make any machinable mold after that use other chemical materials

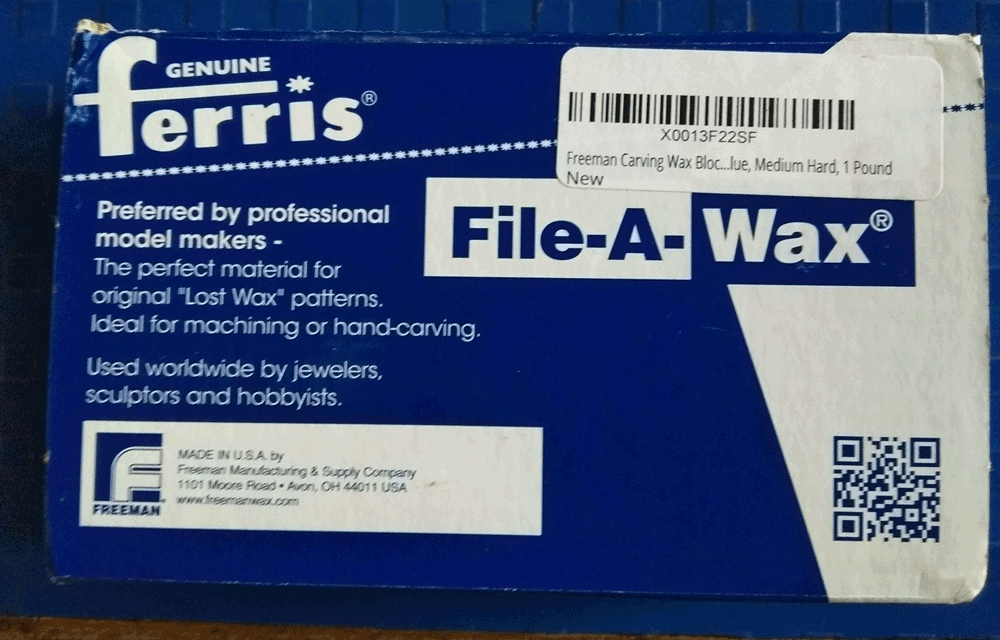

Ferris-WAX: A machinable was for milling here for making mold by milling the machinable wax is one of the most used materials for that. We also use this materials for making mold by milling. also figure out the physical, chemical compound and health hazard, safety during used etc. for more read this doc. Click here for Datasheet

Rigid Foam: For making there is another materials which is used for making design by milling. This is good source for making mold by low investment. Click here for Datasheet

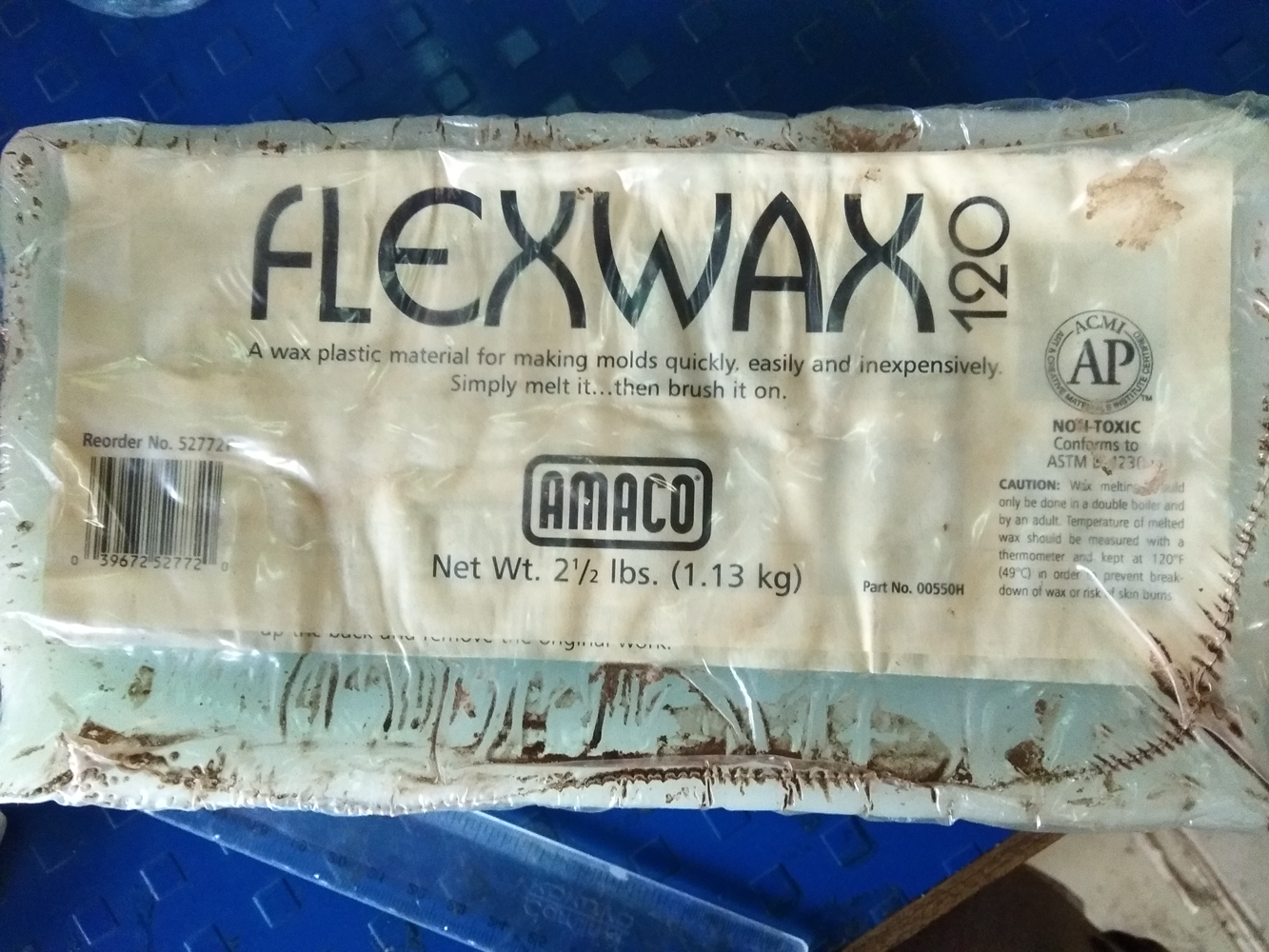

Flex Wax Making mold by this first you need to melting it and make your mold as you like. Physical data are in the link Click here for Datasheet

Paraffin: Making mold by this first you need to melting it and make your mold as you like. Physical data are in the linkClick here for Datasheet

Silicone Rubber and Hardener for making positive mold we used silicone rubber with hardener. Please check the link for more info.Click here for Datasheet

Hydro-Stone gypsum cement: Hydrostone is one of the hardest and strongest gypsum-cement. We are using for casting which produces extremely hard surface. The important thing, always add powder to the water, never the reverse. (Sprinkle the powder into water slowly and evenly.) Mix with a 1750rpm drill and mixing blade. Pouring should be smooth and steady into the center of the base of the mold. DRYING- All casts should be dried as quickly as is safely.We read the instruction on the box which explained how much quantity and time required for the material. Specification:

Insta mold: This is another materials for making mold, please visit the link.Click here for Datasheet

POP: This is another materials for making mold, please visit the link.Click here for Datasheet

Epoxy and hardener: This is materials for casting to your final product as you mold. Epoxy resin and hardener used for making this solution and pour it in the mold. Check the link for moreClick here for Datasheet

Solder bar and aluminum : This is materials for casting to your final product as you mold. First you need to melt it by required temperature use by a graphite pot for melting. Check the link for more