What will it do?

Laminar Flow Cabinets create particle-free working environments by projecting air through a filtration system and exhausting it across a work surface in a laminar or uni-directional air stream. They provide an excellent clean air environment for a number of laboratory requirements.

Who's done what beforehand?

I’m coming to this ideas for making mini version of Laminar flow with control heating chamber for sterilization of cutting apparatus. Exiting laminar flow is making big size and their used sprit lamp or gas burner along with ethanol. Sometimes its make accident during works. That’s why I’m try to make desktop size with microcontroller based control of temperature of heating element. The commercial laminar flow cabinet price is higher and big size, here my intension of to reduce prize retain the principle of the mechanism in desktop size. I found some DIY example who try to make this project.

Keeping It Clean: How to Design and Build a Laminar Flow Hood

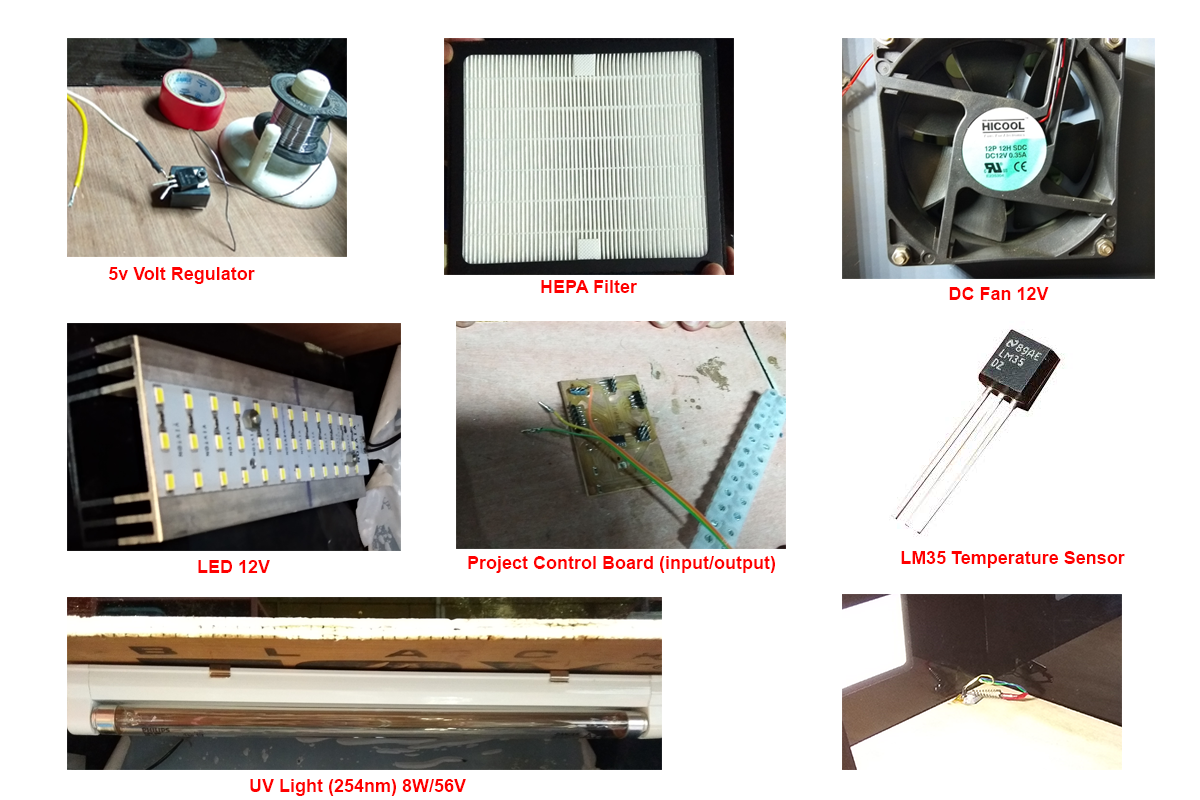

What materials and components will be used?

- 1. Acrylic 6mm/3mm Sheet

- 2. Plyboard 9mm and 12 mm

- 3. Laminar filter with Carbon Activated

- 4. 12 v DC Cooling Fan

- 5. 8W(AC) UV germicidal light (254nm)

- 6. 12V LED light

- 7. Switch / Heat sink

- 8. 12V DC adapter

- 9. LM35 temperature sensor

- 10. 20W DC heating element

- 11. 5V Single Relay board

- 12. Fevi quick glue and some screw

Where will they come from?

- 1. Most of the buying from local market

- 2. Few of things are found from Lab Inventory

For my project most of the component come from local market, the acrylic sheet, plyboard, UV light, led light, dc fan, lm35 sensor, heating coil, relay board all are collect from the local market. Hinge for front door I will make by 3D printer. Some clamp for fixing the back door I will make it by acrylic.

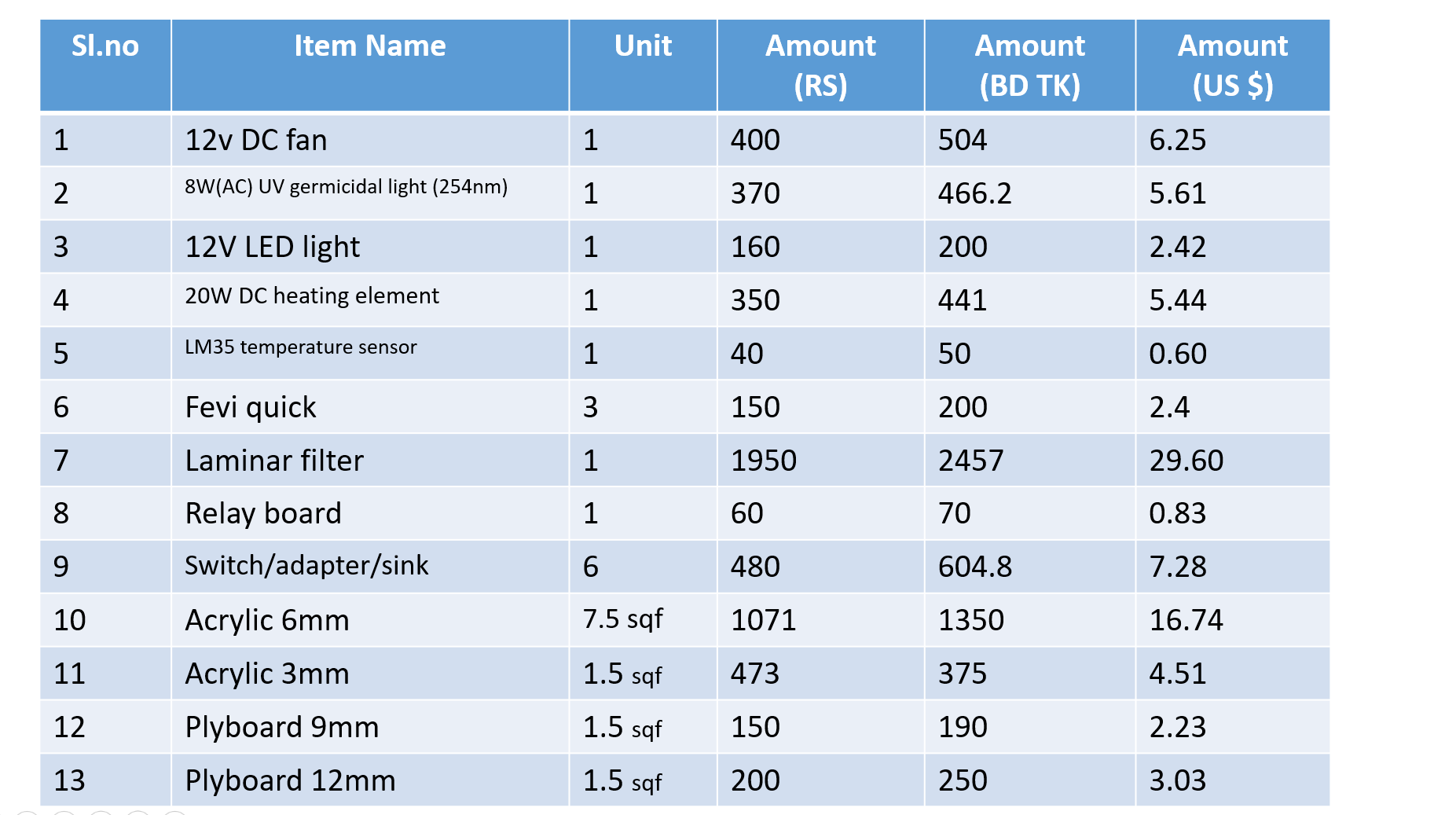

How much will it cost?

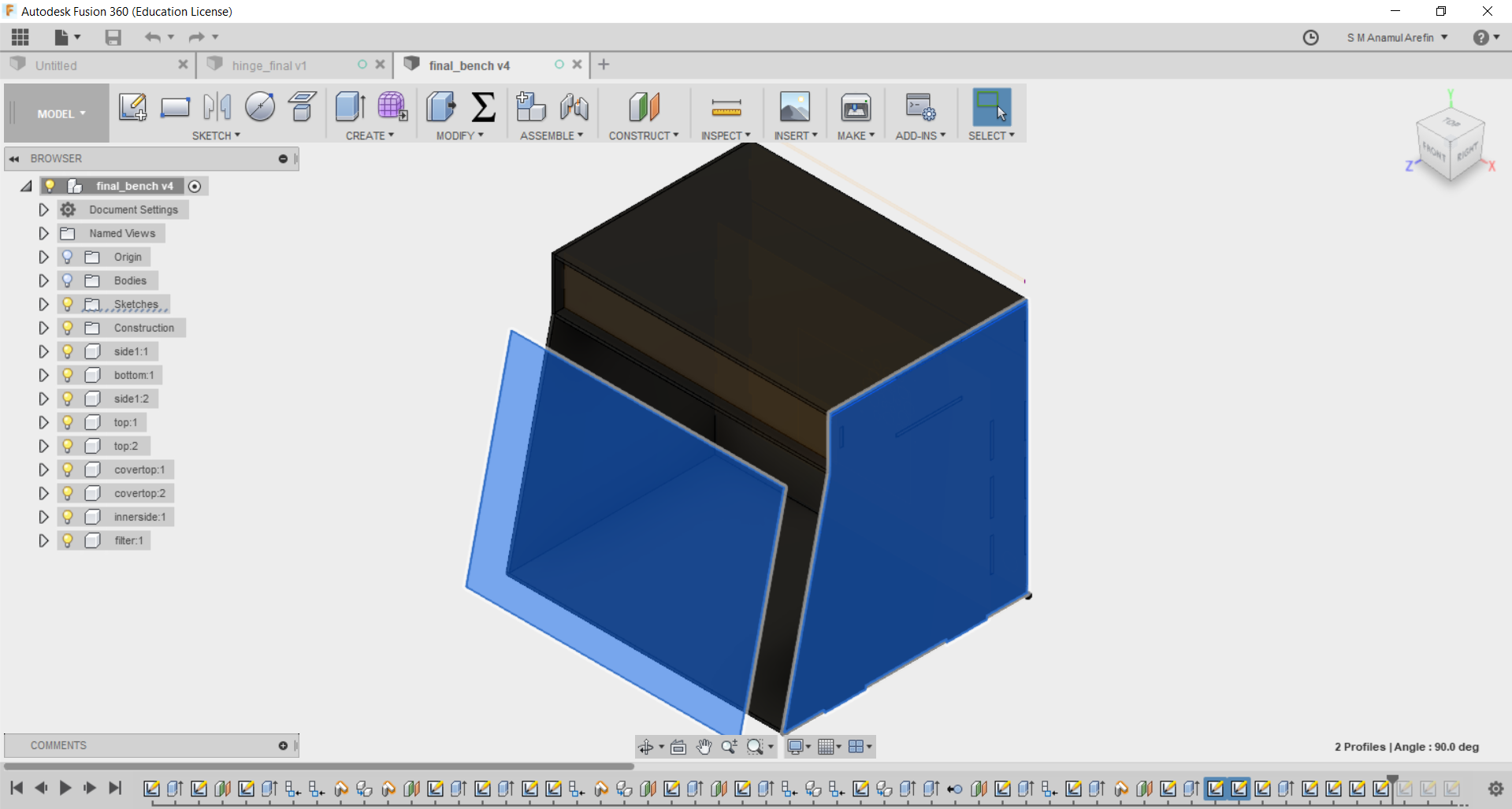

What parts and systems will be made?

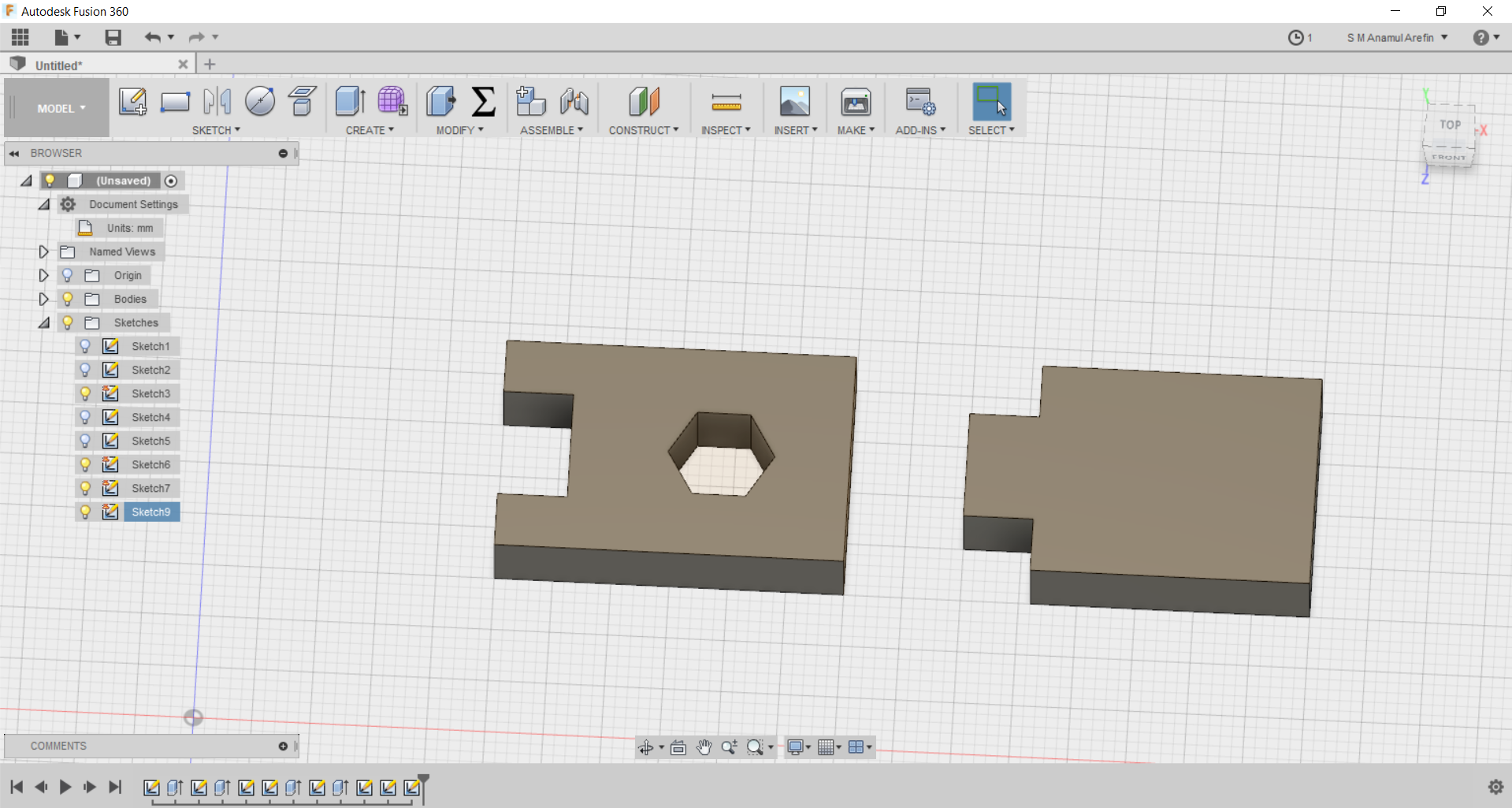

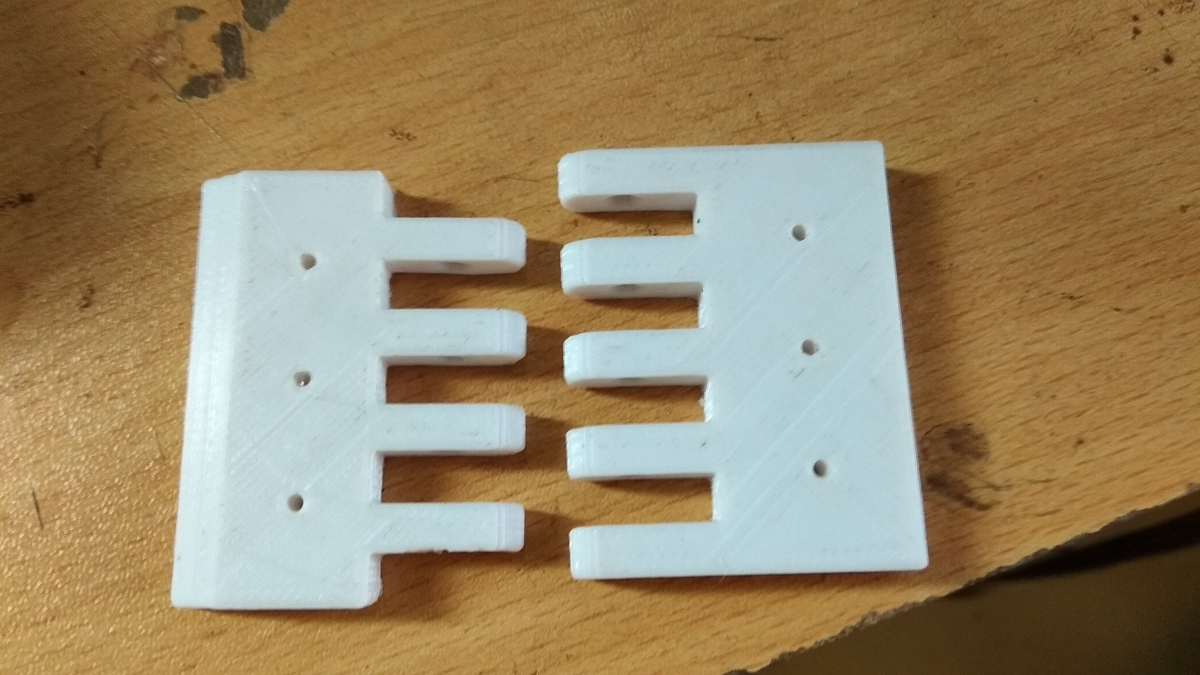

- 1. 3D printed Hinge for front door

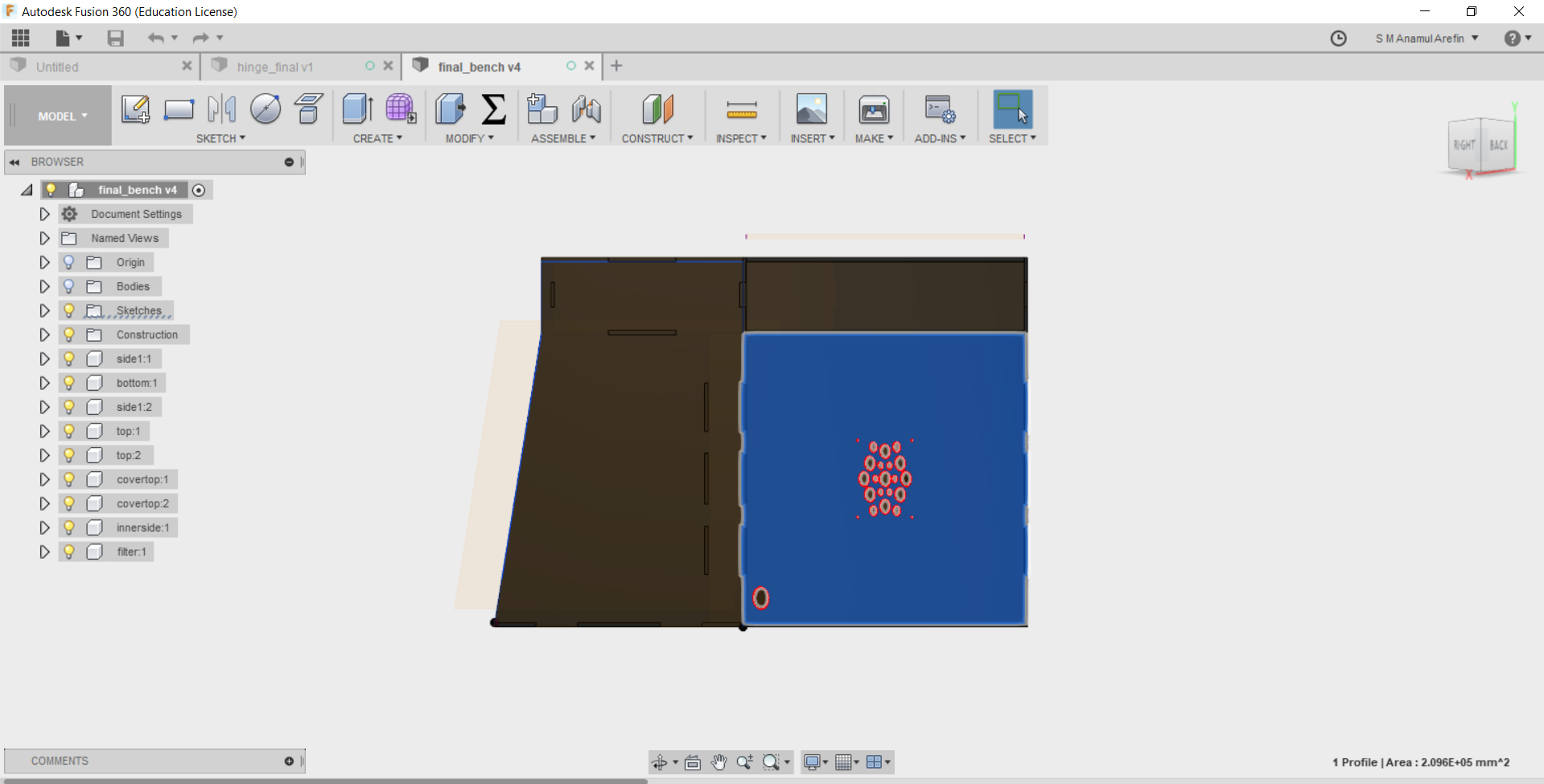

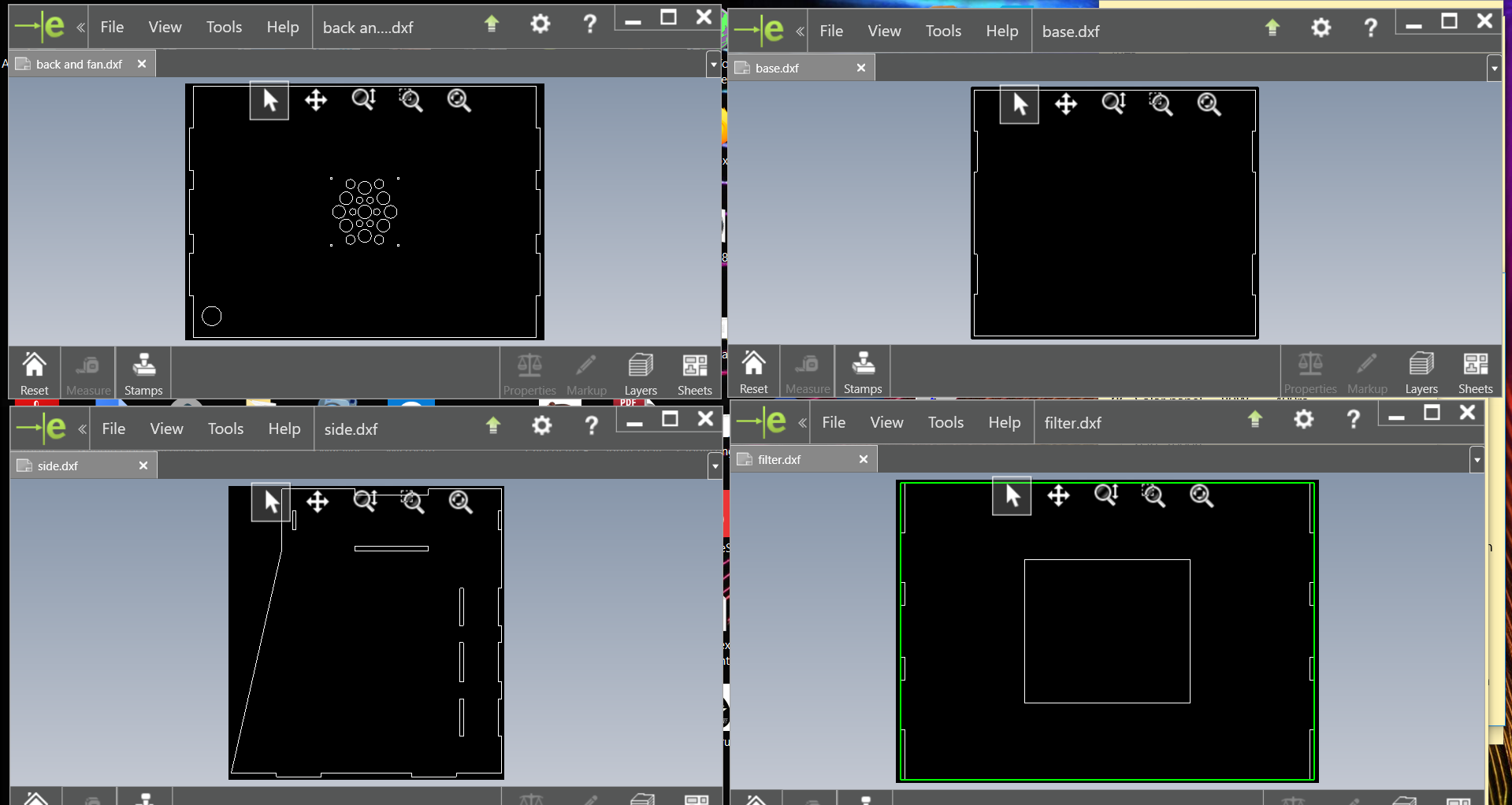

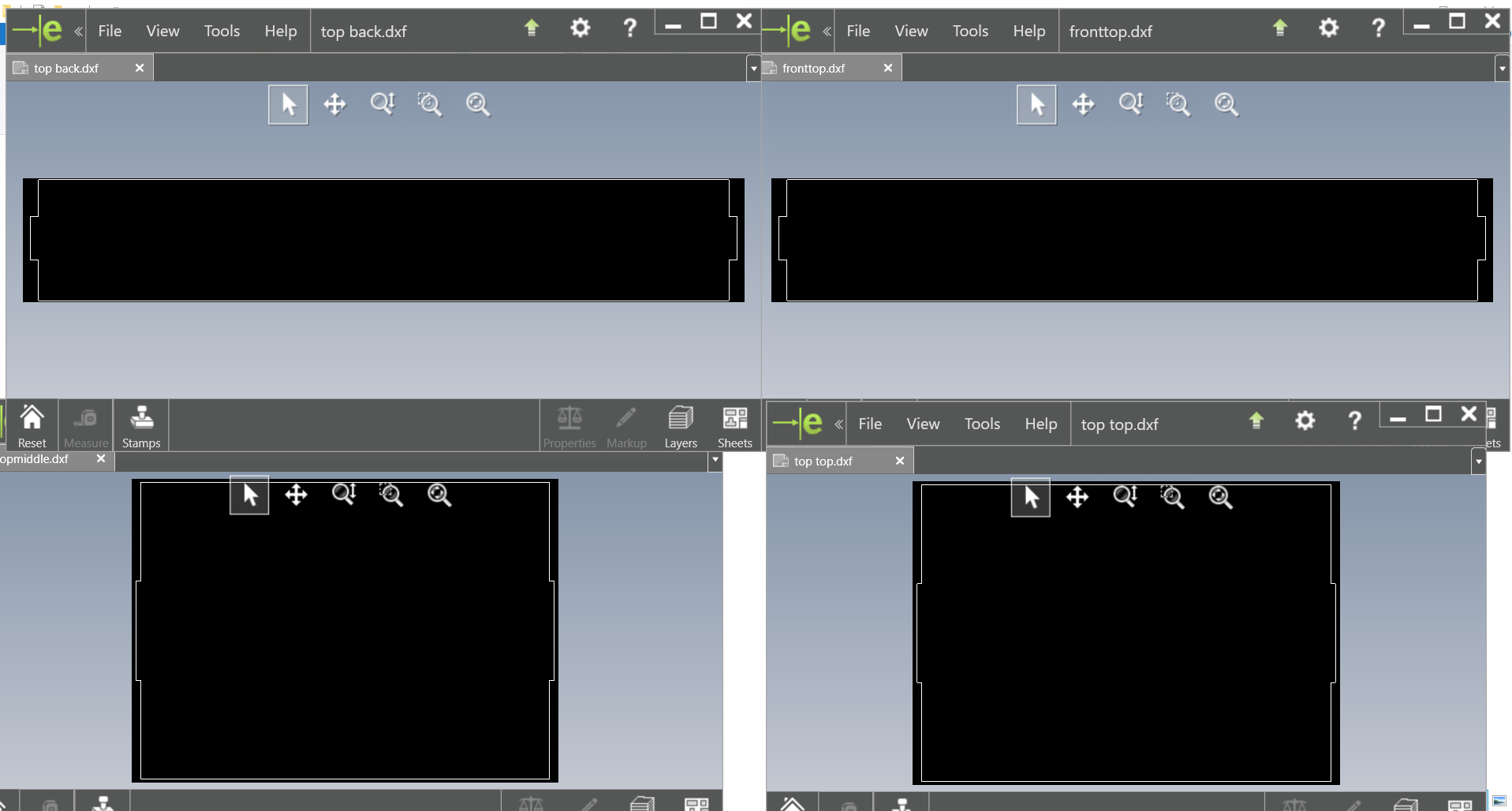

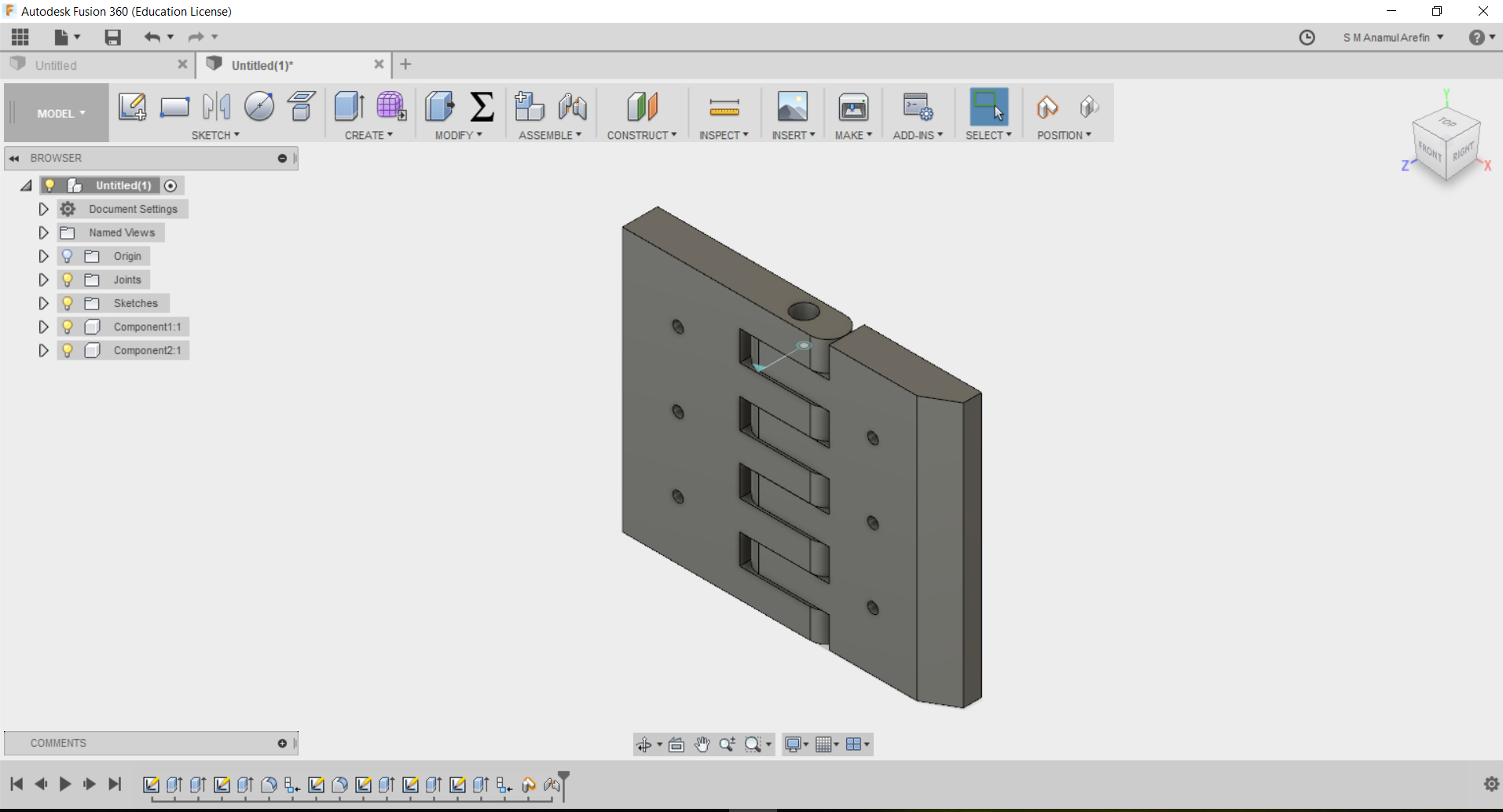

- 2. The whole casing structure design by me in Fusion360

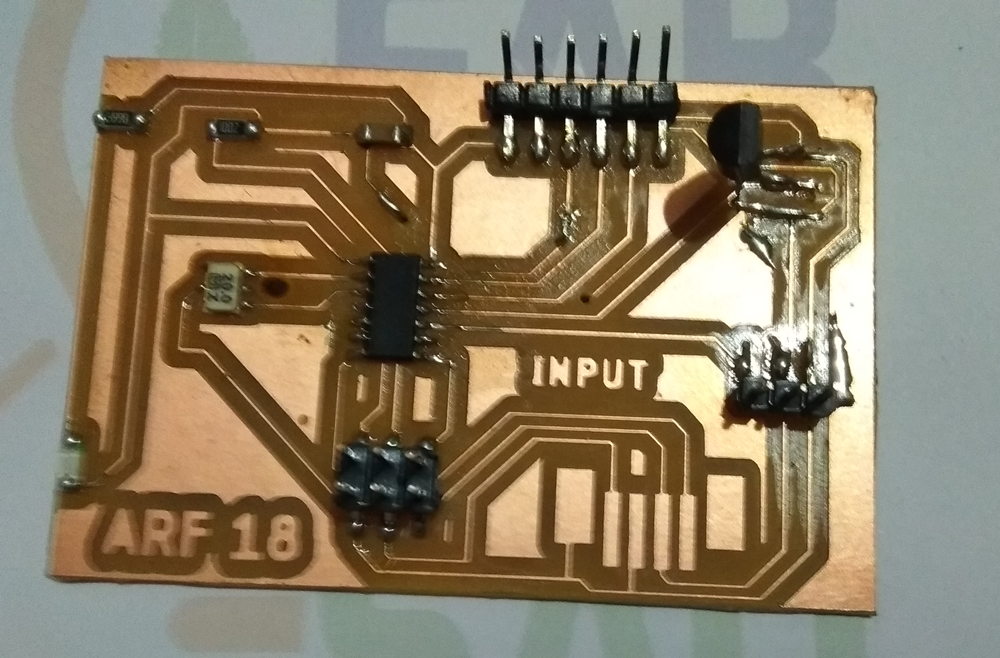

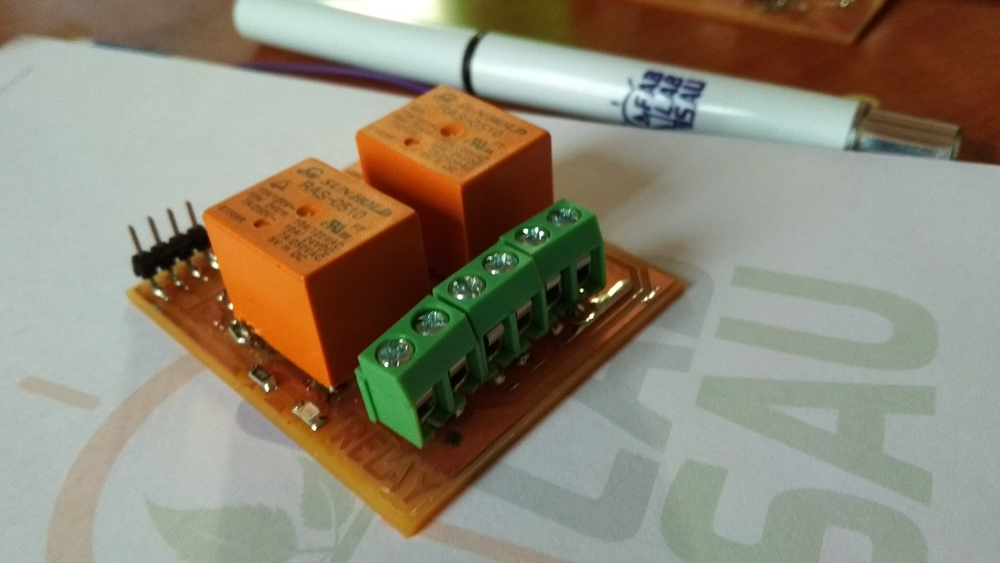

- 3. Heating coil and Sensor control board ( I used my Input board as project board)

- 4. Making switch board

What processes will be used?

- 1. Computer Aided Design

- 2. Computer controlled cutting (Laser)

- 3. 3D Printing

- 4. Embedded programming

- 5. Input Device

- Output Device (Relay control)

What questions need to be answered?

- 1. How to control fan and which direction are flow the air ?

- 2. How to control sensor and relay board ?

- 3. How to maintain UV light from human ?

- 4. How much temperature are producing ?

- 5. Is it good for sterilization as such temperature?

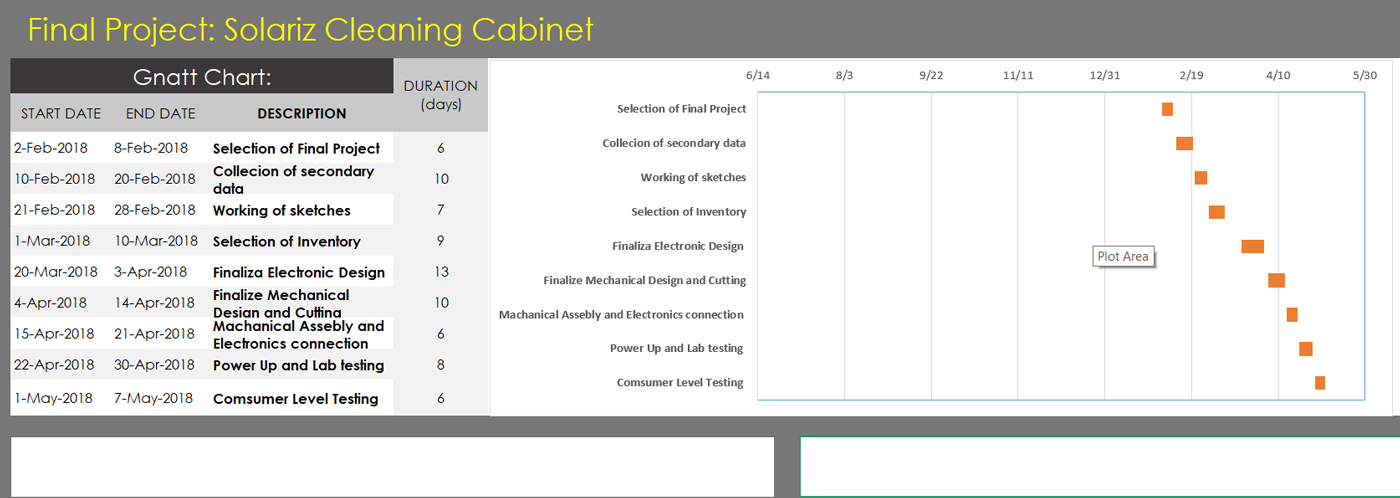

What is the schedule?

How will it be evaluated?

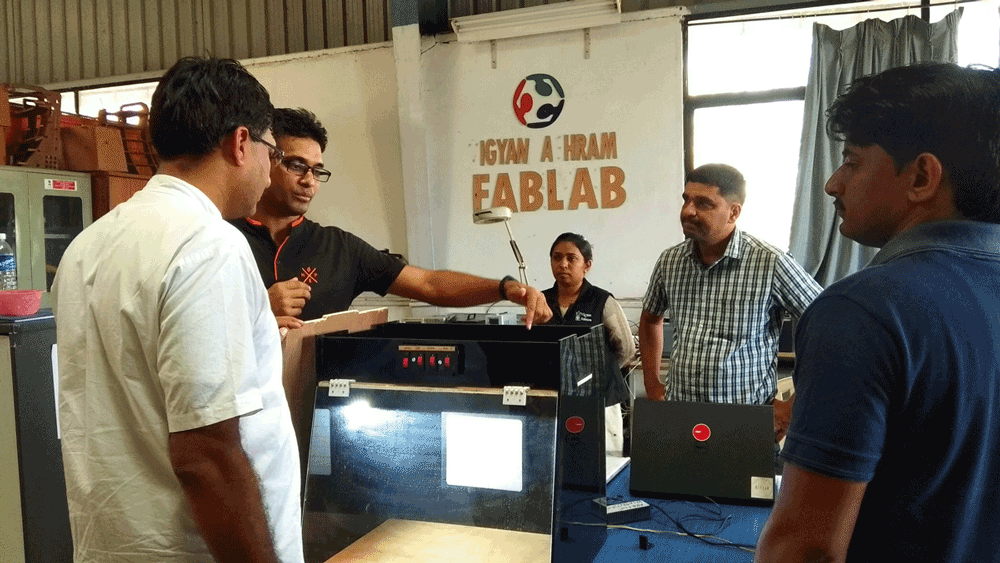

I check several times whether is working or not, I presented it to my mentor DR. Arun Dixit sir, Dr. Yogesh Kulkarni Sir and My Instructor Suhas Labede, so they said every thing is okay, they will use it in their soil lab.