Bioplastic and soft robots

Bioplastic

For the wildcard week I’ve decided to explore two things: bioplastic and soft robots.

Here informations about bioplastic from fabtextiles website:

https://fabtextiles.org/the-secrets-of-bioplastic/

I wanted to try completely vegan recipy, becouse of that I used the following ingredients:

- agaragar 15g (instead of gelatine)

- vegetable gliceryne 22g

- water 200ml

- spirulina for color

One have to mix ingredients and heat them up while stiring (warm temperature but without cooking) until water evaporate, and one will get liquid-gelly structure.

We were experimenting with more or less amount of glicerine in the mixture (we made three tries). Glicerine is responsible for flexability, so the more you will add the more elastic it should be after drying.

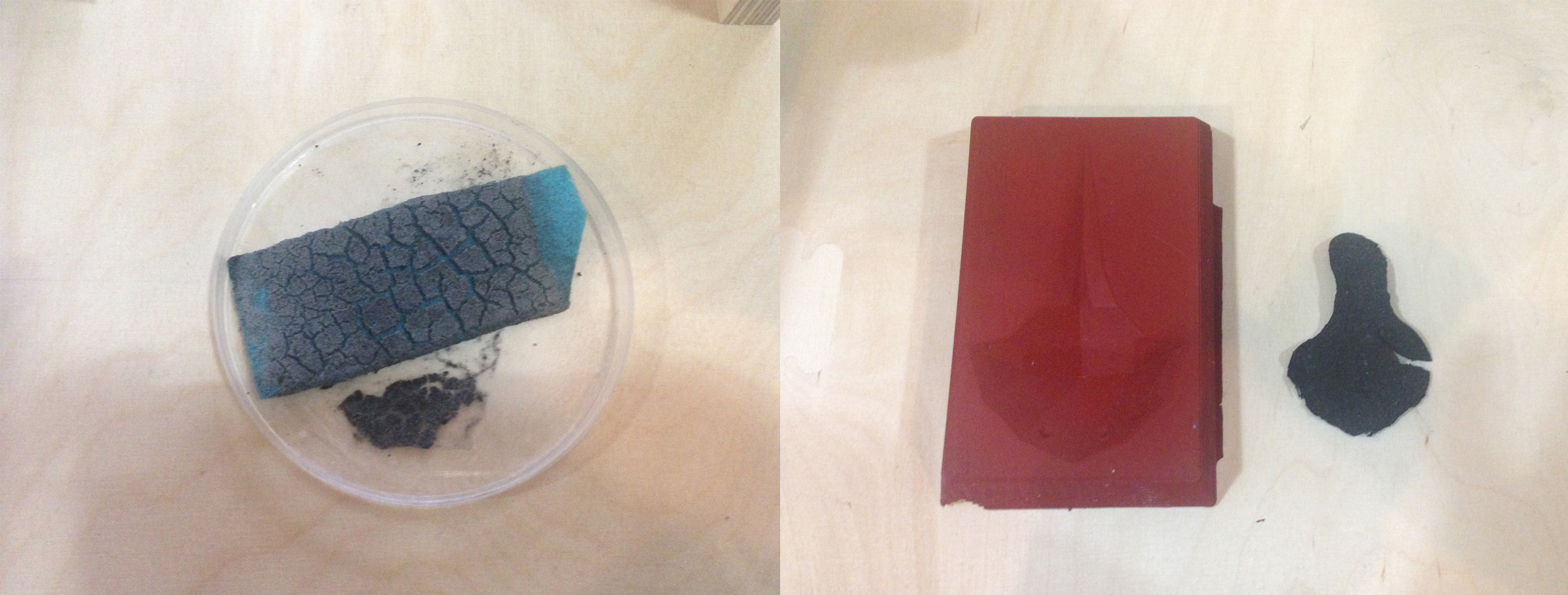

With a friend we wereinterested if it’s possible to make a conductive bio-plastic (we are researching conductive mateials for the ise in final project). Thus we decided to mix active carbon (powdered) into the mixture. I casted my flat-fish form from molding and casting assignment, plus soaked a stripe of felt to see if I could meke it conductive.

The experiment was not so succesfull at the end…conductiveness was very tiny, not enough to play a role of the sensor. On top of that my molded form shrinked like four times the size and cracked a bit. This probably becouse the actibe carbon was absorbing more water than it was predicted. The substance also didn’t integrated well with the felt stripe, dried and cracked on the surface.

One could iterate more and more on the proportions of the recipy, though I understood that in this point I’m not going to dive deeper in this topic.

It can also happen easily that the bioplastic will mold, if the drying process wouldnt take place in clear conditions.

I learnt later that the mold can appear mostly becouse of presence of spiruline.

Before experimenting with bioplastic I was thinking that one could use it a s resin in compositing (instead of very toxic epoxy).I learned though that it needs access to the air in drying process, thus one can not close it in the vacum table.

Bioplastic is still and experiment not used on a bigger scale. It’s weaknesses are that is getting slimy when soaked in water, and can meltin higher temperatires. And mold easily.

Though is a beautiful experiment and I hope will be developed further!

Soft robots

I always wanted to play around with inflatable robots! Looks like one can reach really smooth, nature-like movements only by controlling the air flow. Also the strength with which soft robots can e.g. grab the object is pretty impressing. Plus the pressure that the robot will put on object can be perfectly adjusted and gentle. Seems there are some advantages over electronic arms!

There are two ways of creating the soft robots (for beginners):

- using vinyl PU+PET film and a heat-press

- making the double side mold by usingeco-flex silicone rubber

Since unfortunatelly it’spretty tight with time I’m deciding to work with vinyl and 2D design.

I want to redesign my flat-fish design and give the object biological moves. To make an inflatable shape one needs:

- two pieces of vinyl

- piece of baking paper

- heat press

Pay attention - just one side of the vinyl is sticky!

One can see the structure of the glue which is reflecting the light differently.

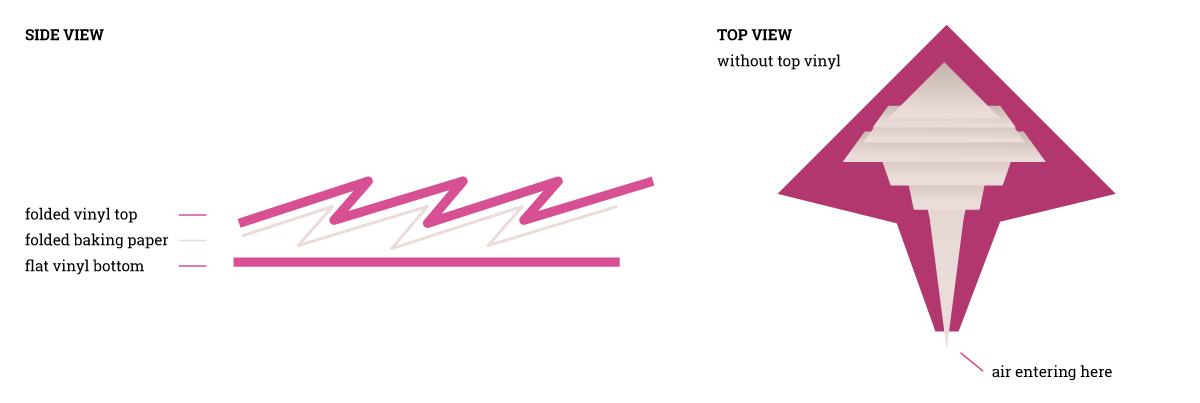

Accordeon folding

First I wanted to try to make a shape which bends itself inside, like kind of a worm which is rolling itself inside or bending finger.

I learnt that to reach this kind of motorics ohe have to fold the baking paper and the top part of the vinyl, so while pumped with air it will undold itself.

While designing the paper shape one has to rememberto keep the channel for letting the air be pumped in. In my case it was a tale of the fish.

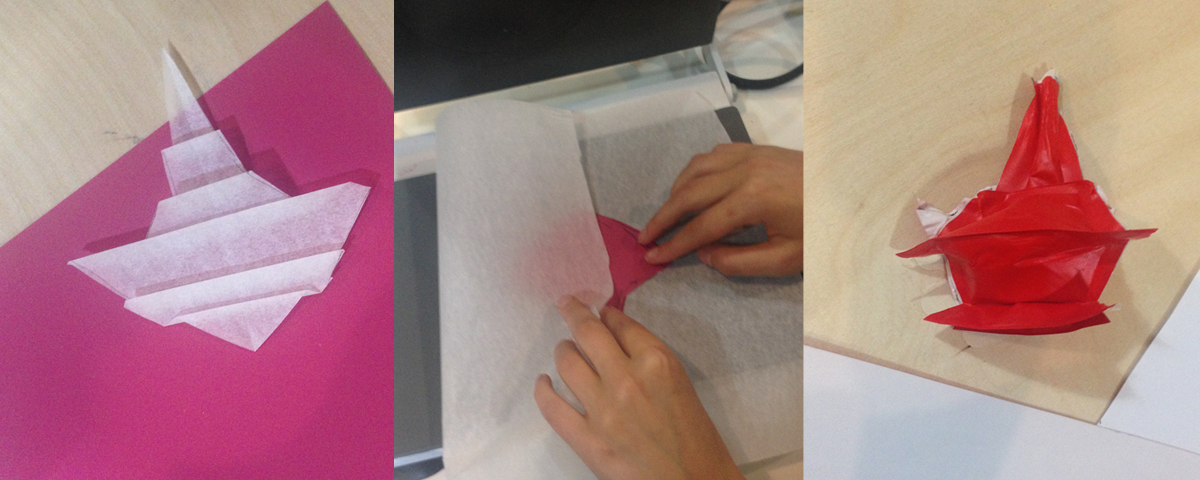

Bending the top layer is pretty hard since the PET film is hard to bend and is constantly jumping back to the flatshape. After some struggle I’ve managed to do it, and than still presiing I’ve placed it in the open heatpress. A friednd put the flat metal flat knife on top of the fold so I could remove my hand. And than we parallely closed the press and slide out the knife. The probablilty that the layers didn’t moved was 50:50.

In the heatpress one have to keep the pieces for ca 15 seconds, at a temperature between 150-160 Celsius degrees. Afterwards keep the shape flat until it will cool down and gently remove the PET film.

Unfortunatelly the shape didnt worked out so well…some corners get sticked together since the shape was unregular. Looks like for this approach it’s better to work with symetric folding.

The “fish” was still bending a bit though…but in that point I’ve noticed that this is not the movement I would like to have, so I switched to another approach.

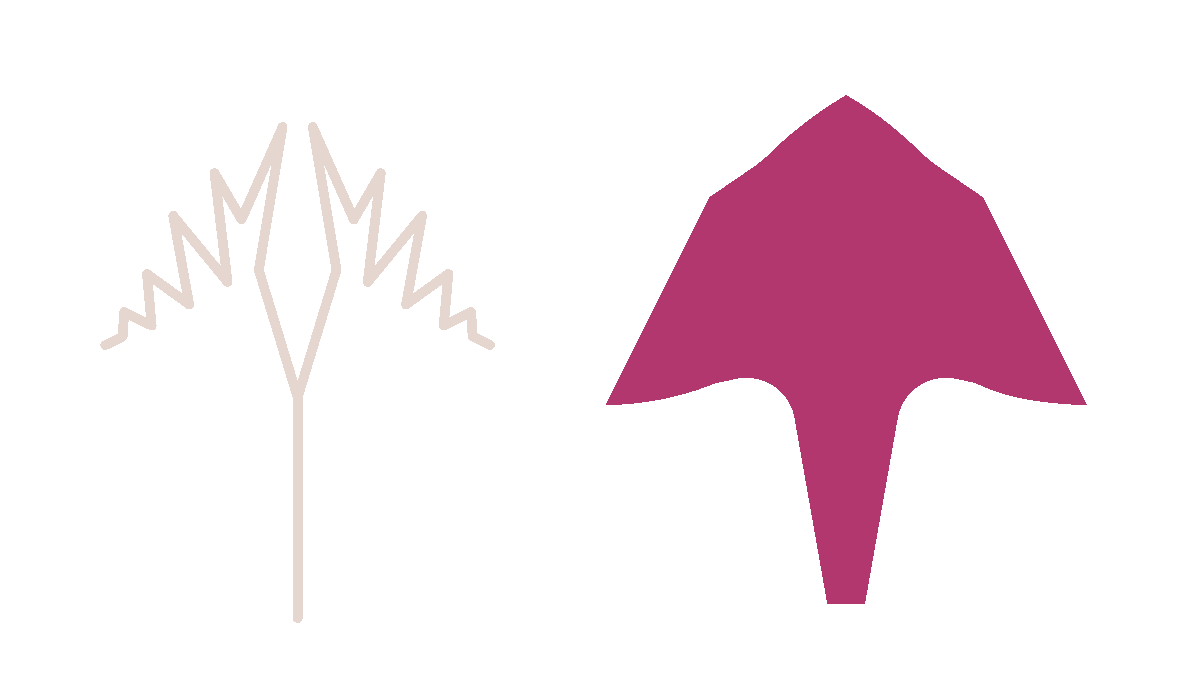

Air vines

Other approach is based on contracted movement - the air which is being pumped in stretches some parts of the shape which coses contraction of other parts.

I think by using this approach I can reach more flying/swimming like movement of my fish. First I’ve cut out the parts from paper to see if everything is fitting. After few iterations I’ve decided to roughly cut outthe shapes from the baking paper and vinyl and make a try with heat-press. Seems like this time it’s working out better!

For cutting the shapes on the vinyl or laser cutter I perepared two files: for air channels and for shape (this one I will cut twice for top and bottom layer).

I wanted to cut the pieceson the vinyl cutter. After few tries with baking paper, and baking paper taped to the sheet of regular paper I’ve noticed that this doesn’t make senseand I would have to cut it on the laser. I’ve tried the Vinyl sheet few times but seemed like it was a bit to hard and the blade was not cutting through smoothly, just making scraggy holeson the line of a cut.

With laser it went better and after few tests I’ve found the right settings:

Baking paper:

Power: 6.00

Speed: 0.9

PPI: 1000Hz

PU+PETvinyl:

Power: 20.00

Speed: 0.9

PPI: 1000Hz

I had to make the vines thicker since baking paper was folding and behiving unpredictably. The edges of the vinyl sticked a bit to the cardboard which I’ve put underneath of the sheets, but it was easy to rip out.

I’ve assambled everything together and put into the heatpress…and voila! Flat fish is alive and moving in pretty natural way!

Files made during this assignment: