Week 2: Computer aided design

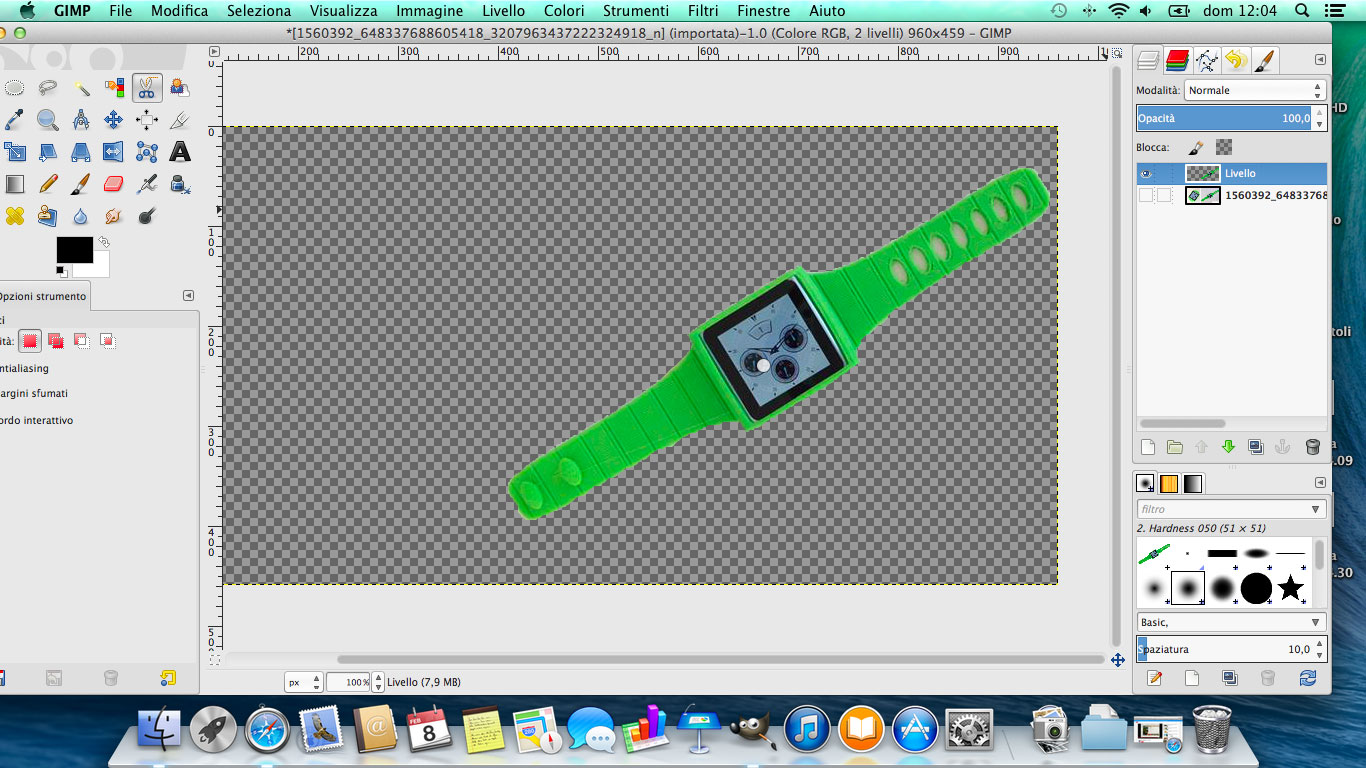

For this assignment I wanted to use the Gimp that I had never used before. I worked some time in the past with Illustrator and I was curious to see the differences. Firt step i cut an image of a watch make with a 3D printer (strap watch is make with pla flex).

I select only the clock and cut it from the background.

I then finished also details eliminating imperfections

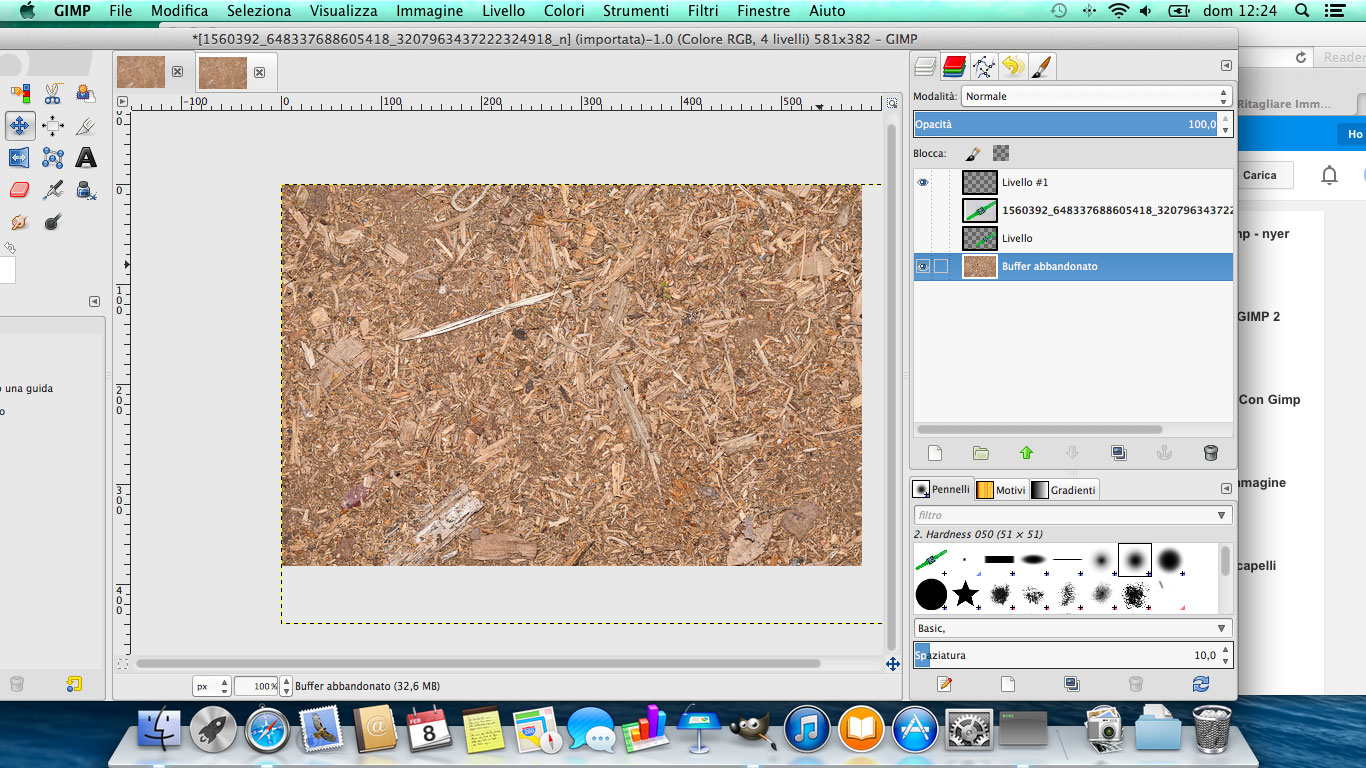

Next step was to choose a new background for my advertising

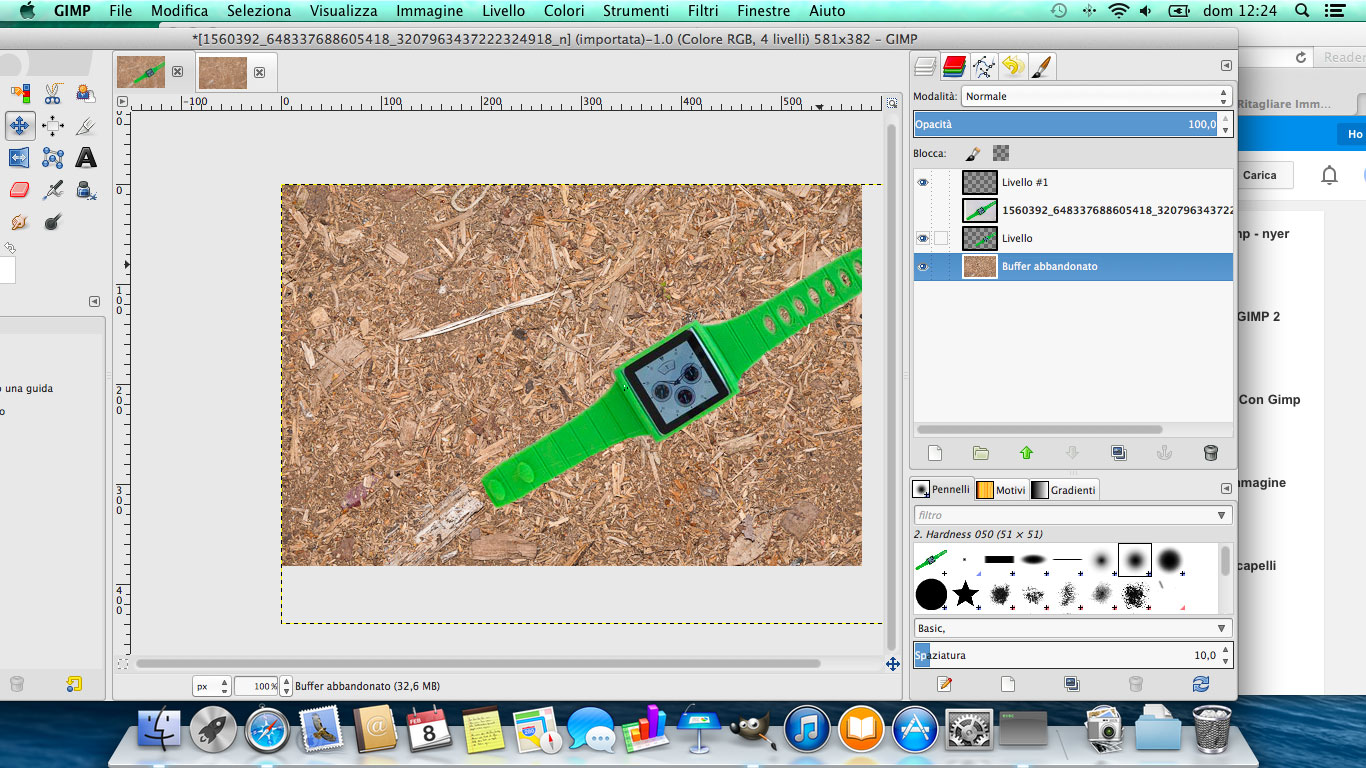

:)

I positioned the clock on the new background and I also included the payoff

The last step was the optimization of light and saturation to make my advertising really pop (file).

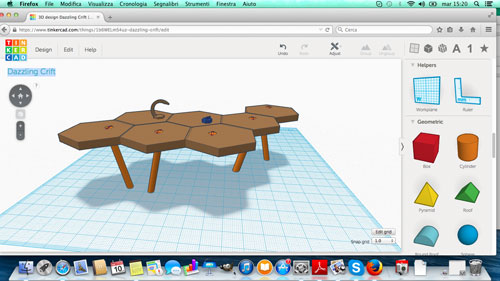

3D Design

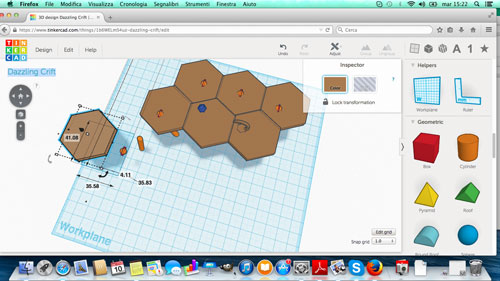

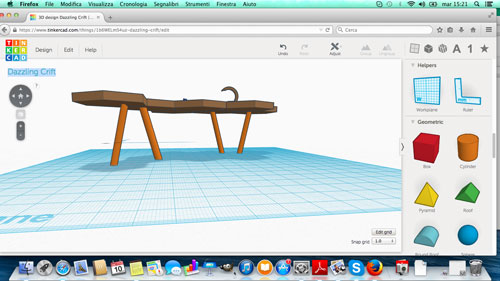

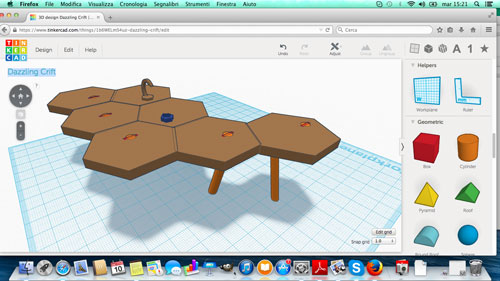

For the first 3d modeling, i thought of using the software Thinkercad. I was around Italy in a series of events and the ability to use it online on different workstation i facilitated the realization of my project. The first step was to model the hexagons that composed my desk, using the solids already present in thinkercad adapting with the size depending on my need with the commands extrusion and sizing.

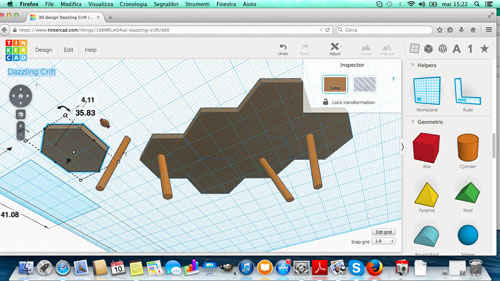

I also created the table legs that will fit through a hole in the hexagonal modules

The hexagonal modules are milled with an additional hole where will insert a device 3D printed.

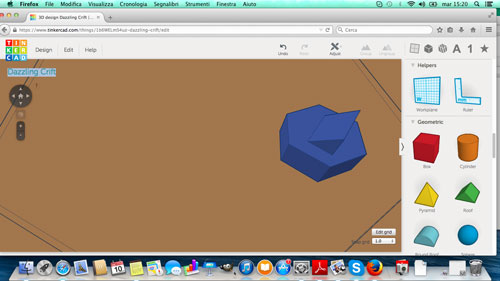

I also designed a lamp that will always be inserted into one of the holes milled, present in hexagonal modules. A lamp that will contain a sensor controlled by an electronic card.

All hexagonal modules are fixed to each other through hooks in wood also their milled. I used the objects already in the software tinkercad as hexagons, cylinders molding them according to my size. It helped me a lot in speed of implementation, and in this stage where I just needed a graphic draft to get an idea of my project was very useful.

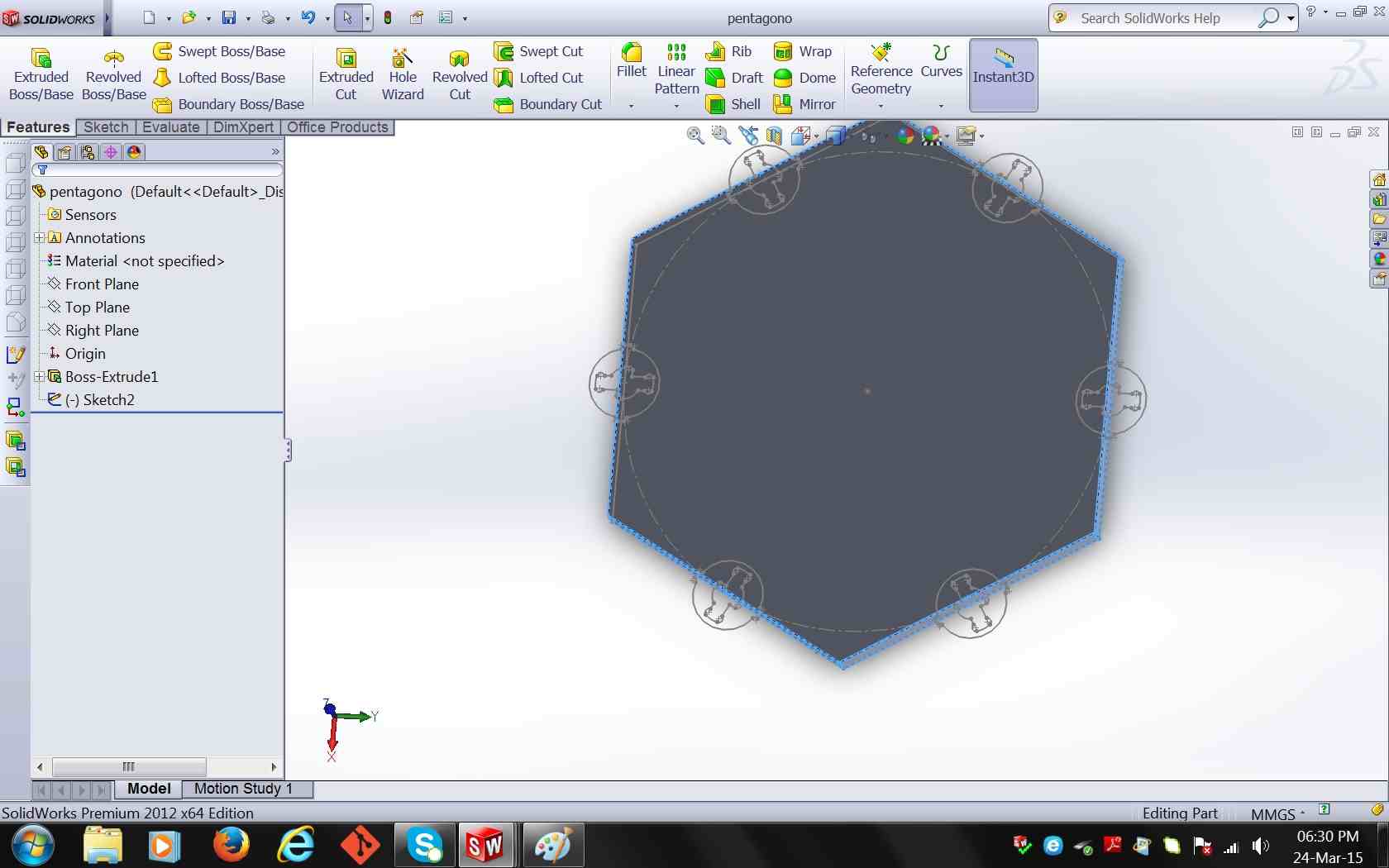

But later in the following week i used, with the help of Lorenzo my tutor, program Solidswork.

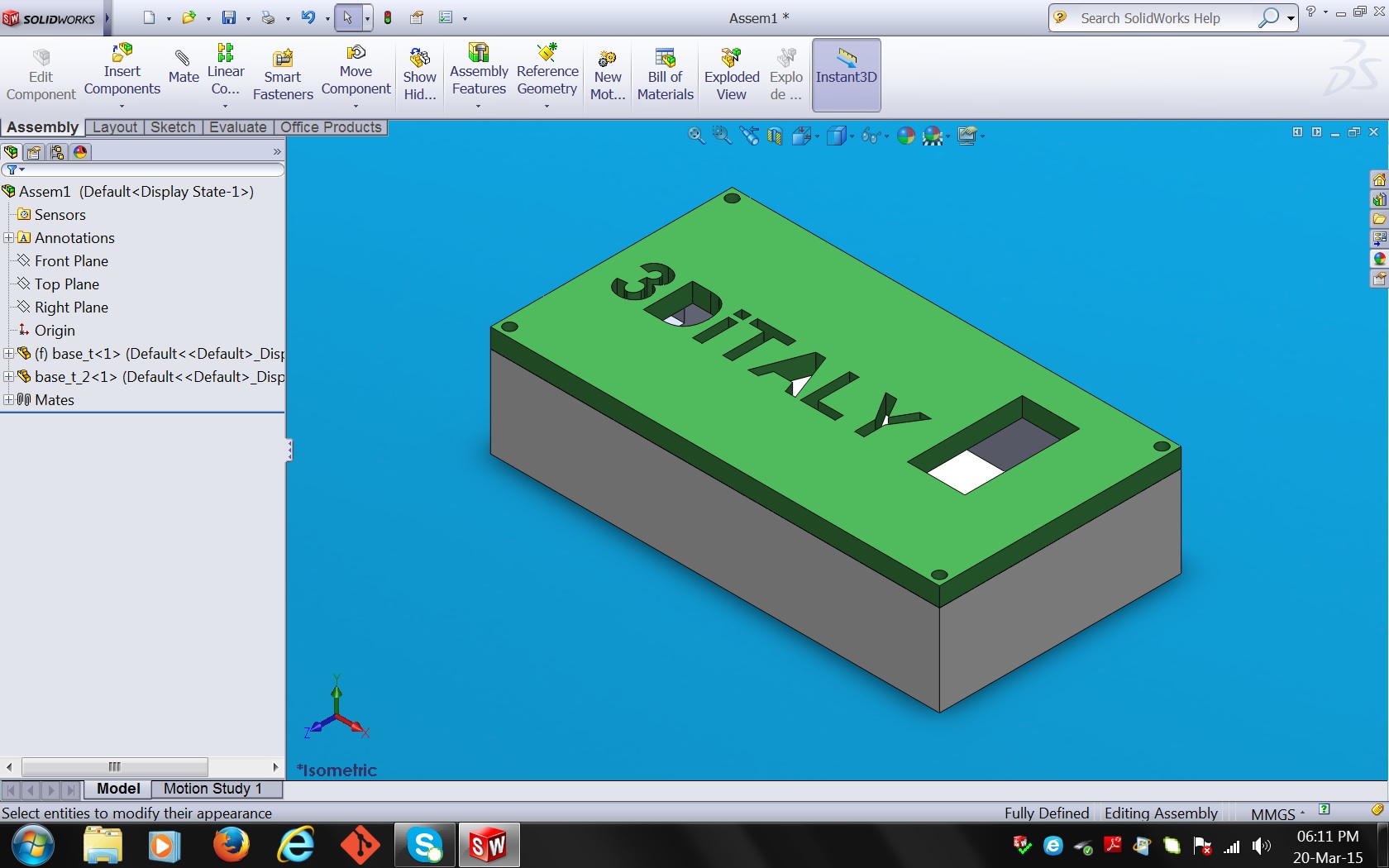

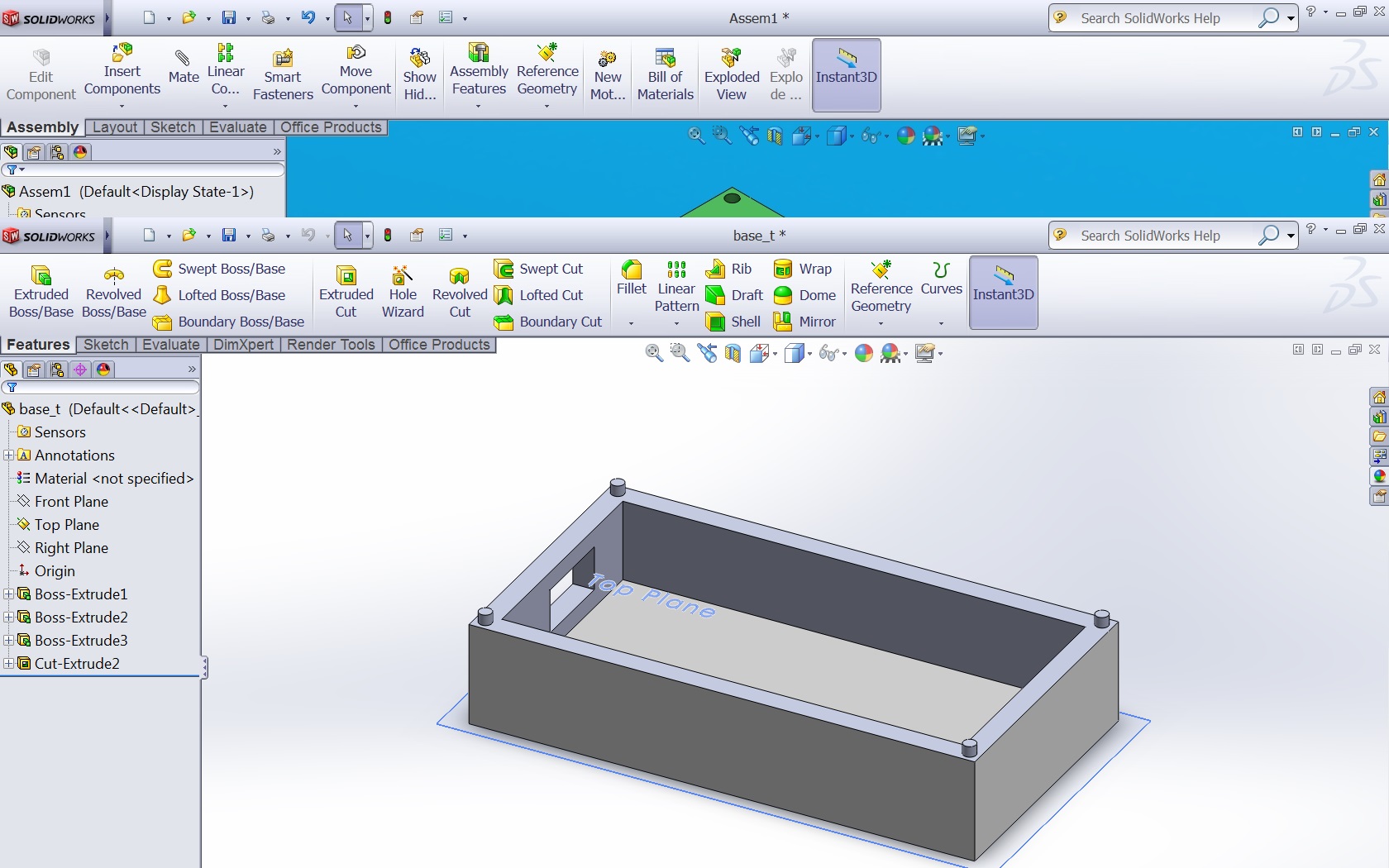

With solidworks following days i also designed the box to my Fabisp (Fabisp box file)

that says my business 3DiTALY and hexagons of the wooden table for my final project.

/>

/>

I realized the project with the software Solidworks and made the first pieces with the cutter machine. The strength of the entire structure is the system of lockable, welding all wood panels and make it such a unique piece modular. I will speak of my final project in the specific page. Hubdesk 3D file

For this form I also modeled in 3d key modules that bind hexes desk.