Week 12: Composites

To start my assignment related to composites I wanted to explore the use of different materials

i prepared a sandwich of wood with inside cotton fabric, glass fiber and resin epoxy.

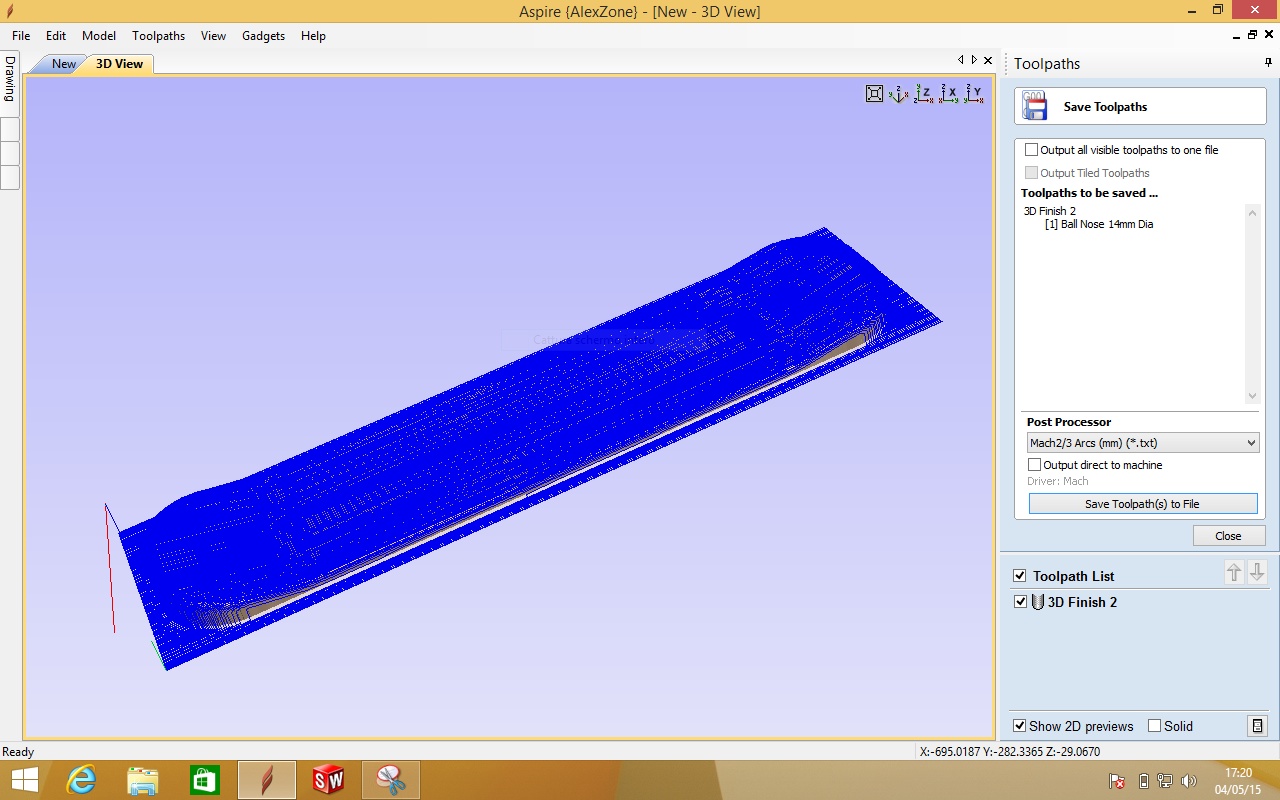

The first step was to design in 3D the basis of my skatebord.

After making the file with Rhinoceros i exported STL in file gcode with Aspire for cnc machine Mache Mate. I use a ball nose 14 mm diameter to work with polystyrene 6 cm thick, ball-mill at 6000mm/min.

The time employed for milling has been of almost 3 hours.

After finishing the milling I polished with sandpaper super fine my profile polystyrene, so that there are no holes.

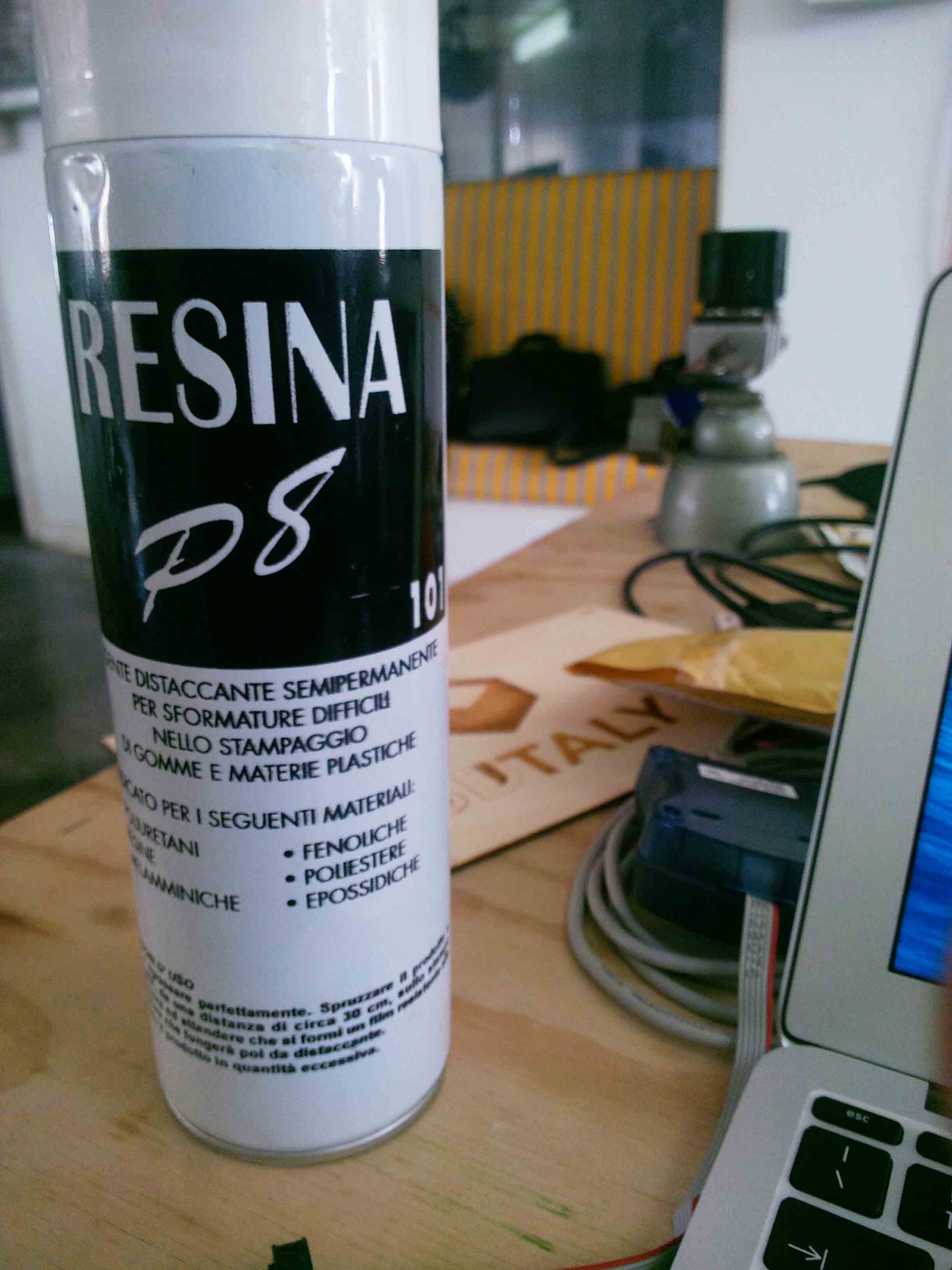

Finally I sprayed release agent to 2 times a distance of 15 min, the drying time. Very important it was to keep a distance of 50 cm spray to scatter the best release.

I thought that if I wanted to do with skateboarding had to create the wood must,

then i tried the wood waste of FabLab a thickness suitable to my needs. I found a panel of poplar wood, thickness 12 mm.

Through the use of the program Aspire I exported only the outer edge of my ironing skatebord that I imported in corel draw to create the vector file for the laser cutting of wood.

I cut two panels and then I also added the logo of my company ;)

I cleaned up the edges of the base and put the release and in the meantime I hand cut with scissors two silhouettes of the codon scatebord and a glass fiber.

Now you have to pass the resin,100g of resins and 60g of catalyst,

on the layer of polystyrene.

Pasting immediately the layer of cotton, immediately after one layer to resin supporting over the layer of glass fiber, resin and even cotton.

Finally, the second panel of wood.

I put all the layers with a vacuum bag and I placed over a bag full of water, in order to give weight and making sure that everything is very compact.

I left everything to dry for two days and finally i opened my table and detached from the base polystyrene, the release did not work was very tiring.

Now clean up the edges with a knife, and the surface of the wood with sandpaper.

And to make everything perfect, eight holes and eight screws holding the rute and the axes of my new skatebord.

Now i'm ready to jump !!

This is the 3D model file and the file Aspire from which i made the layout for laser cutting, by directly entering the program of laser cut the logo of my company.