Applications and Implications

Assignment: Propose a final project that integrates the range of units covered.

What will it do?

This project idea mainly fulfills our daily requirnment of vegetables without any great pricision. Using these models we can grow our own food in organic way in minimum space requirnments. Its beneficial in economical and health aspects as it gives pesticide free food.

This project idea is mainly devided into two sections ; Moduler design and Electronic part . Inside moduler design we have developed two models of vertical garden; which we can place in Gallery ,parking ,terrace etc. places. This modular designs are integrated with electronics part that contains soil moisture sensor and motor for auto-irrigation.

Who's done what beforehand?

Moduler design part of vertical garden models are not done before but I inspired from AKER to do this;their are various designs available on their site. They designed these as a kit and given installation steps.So I added two more new designs of vertical gardens following them. electronics part is used by different peoples as per application.There are so many links available for soil moisture sensor circuit design and programming;but here I added RF communication and awaring system in my project and its never done before anyone.

Here are some links for electronics design :

Soil moisture link1

Soil moisture link2

What materials and components will be required?

Download project material list from here.

Where will they come from?

All these components are coming from Local electronic market(Pune)and fablab inventory. Those are not available in local market are ordered from different placecs with online source. For vertical garden we required 12mm plywood sheets which gets available at nearby timber market.Pipes, elbows are available at local hardware shops.

Go with this linkfor material, location and cost details.

How much will it cost? Costing table

Costing as per categories:

Material cost:54$

Transport:8$

Electricity :3$

Total:65$

What parts and systems will be made?

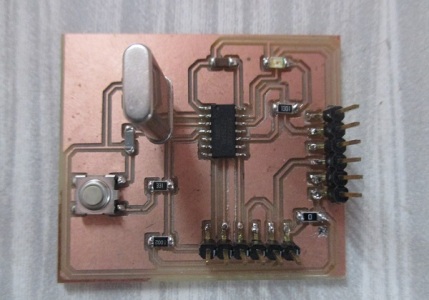

Vertical garden Models: Used 8mm plywood sheet to cut vertical garden design models on shopbot. PCB: Transmitter and receiver circuits designe and printed. Acrylic casing: Casing for project. PVC pipe and Motor

Softwares:

Inkscape Catia Partworks Eagle Dr. Picza

|

|

What processes will be used?

Processes:

-CAD design: Designed vertical garden models inside CATIA software. Also cuts files inside Inkscape.

-Computer controlled cutting:Printed labels on vinyl cutter.

-Electronic design: Designed and printed transmitter and receiver unit boards inside Eagle software.

-Embedded programming:Done programm for transmitter and receiver unit in embedded C language.

-Computer controlled machining: Created toolpaths of cutting files of vertical garden and cutted its on Shopbot.

-Input device: Soil moisture sensor is act as a Input device.

-Output device:Relay, motor and Buzzer are output devices.

- Network and communication:Rf transmitter and receiver pair with 434Mhz frequency used for wireless communication between transmitter and receiver units.

What tasks need to be completed?

-Programming and assembling.

- Test-Water content analysis through soil sensor for different crops.

-Test-Power consumption.

-Test-Pipe assembly and water flow.

-Have to check and set additional feasibility to user.

What questions need to be answered?

1.How these models are feasible?

2.How this controls water content inside soil for different vegetables?

3.How it will benefits directly to the society?

4.What will be a cost for maintanance?

5.Power consumption and What ,when there is power cut-off?

What is the schedule?

May 22-27-Programming

May27-June 2-Assembling

June2 -June8- Making page ready with answered questions.

June 10- final presentation.

How will it be evaluated?

I think if anyone can grow their own food in organic way with little pricision and space; it will be worthy for them.