09 - Computer-Controlled Machining

CNC Router

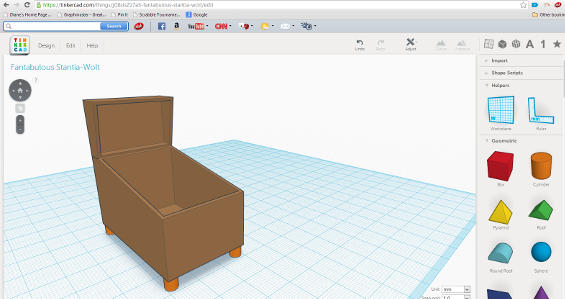

The goal this week was to make something big. I made a cabinet for my future tabletop-sized pinball emulator. It will use an approximately 22" monitor as the "playing field" and have flipper buttons and a coin slot wired in for authenticity.

Here is a model of what it will look like:

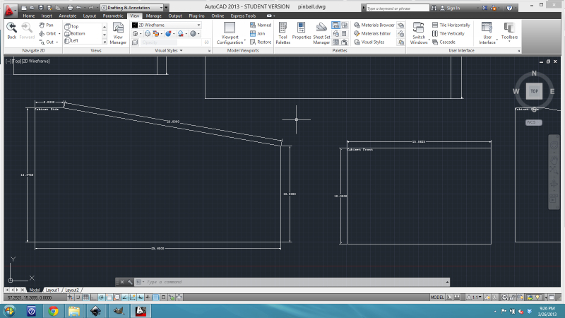

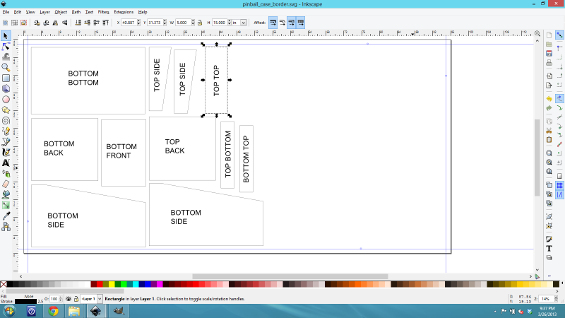

I first tried drawing the pieces in AutoCAD, but once I learned that Inkscape worked well, I used that.

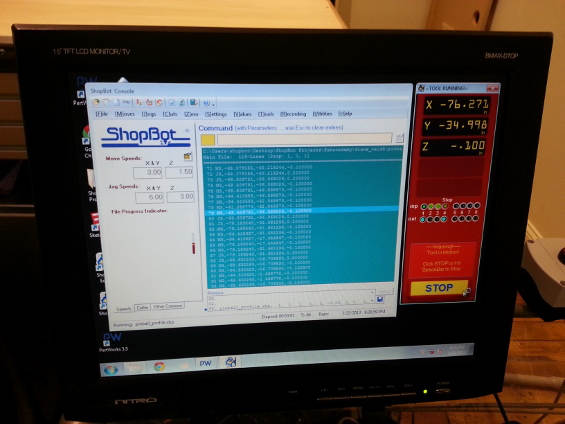

When I imported the pdf from Inkscape into PartWorks, some of the rectangles looked like they had double-walls, so those were deleted and redrawn directly using the CAD features of PartWorks.

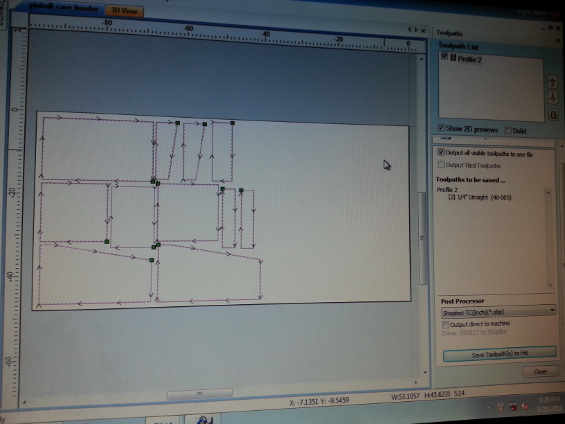

The toolpaths were created in Partworks....

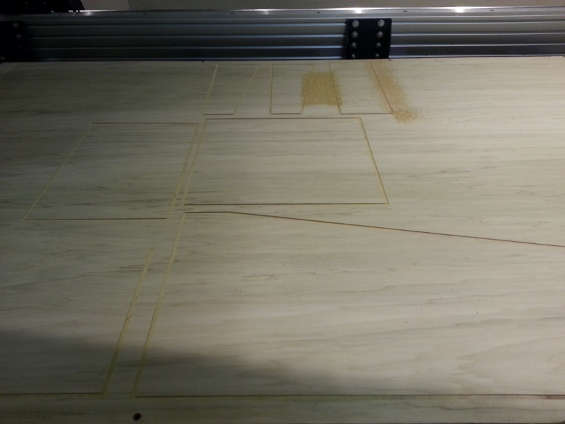

Then the router worked its magic! Since the parts were fairly close together, I did a marking pass first, then placed some screws in the areas that looked like they could use some extra securing.

You can see some of the supplemental screws in this picture:

Here is the computer running the job:

The parts have almost finished cutting. I used a 1/4" downcut bit and no tabs. Since the downcut bit drives the chips downward, there was enough material packed around the edges to keep the pieces from moving while being cut.

A close-up view of the packed chips around the cut pieces. They were easy to pry out using a screwdriver.

The extraction system on the ShopBot:

The ShopBot at AS220: