March, Tuesday 26th 2013

Assigment:

Make something big

For this assigment we were to look for recycled material in the streets.

Here in Barcelona there is an assigned day for each neighborhood for people to throw away furniture they don't want any more.

Since I have to design something depending on the material I found, I only started thinking about the joints at first.

On thursday I found some things in the street. Some Pallets, and other unuseful stuff.

Here are the things I found:

As you can notice, everything is junk.

The only piece wich I find had some value was actually a Panot form Barcelona's sidewalks. It's a very known design made by Juli Capella y Quim Larrea and produced by Escofet, so it has some history. I thought it could be a nice feature to my design.

I was thinking about making a small table with this piece embedded in the top surface.

Later I learned that using pallet wood to mill has no sense at all. I would have to prepare milling jobs for each piece. Nonsense.

So, the only piece useful was the chip board. The wood is no good, but still at least I have a clean surface to work with.

Later, for my luck, I found another recycled piece of MDF.

So in total i have:

- 106x76mm chipboard

- 122x70mm MDF

Knowing that, I startet to design. Still, with this materials I can't make anything that big. I kept my idea of making a table. (without the panot)

Here is the design, and how it will look like:

The table (rendering)

The milled parts (rendering)

Exploded view

Plans

Here in FabLab Barcelona, we have 2 milling machines, but we are a lot of students, so since there was a long queue to cut, I decided to laser cut one part, and the other mill it with the ShopBot.

Legs were lasercutted and tabletop milled.

Workflow with the lasercutter was covered in Week03.

Working with the ShopBot was new to me. But still I found is very simple.

I imported a Rhino file to ShopBot's propietary software and generated the jobs.

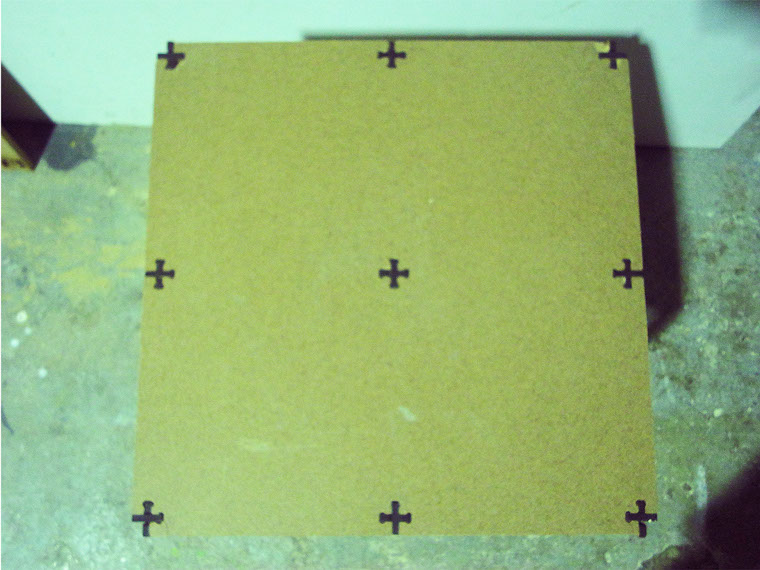

One thing that is important is to fix the board you are about to mill to the cutting table. This can also be generated as a separate job.

In my case I had 2 jobs. One for the bolts to fix my board to the table, wich were only some drills along the perimeter, and the other job was the design itself.

Here are some images of the laser-cut and milling processes:

Legs & Structure (lasercut)

Tabletop (ShopBotted)

Laser cutting is much more precise, so post-work is almost none, compared with the milling were tolerances play a big role.

I was using a 6mm bit, but I send the job to cut 5.75mm for the joints. so afterwards sanding the pieces is a must.

sanding the joints

The whole set & final result