5. 3D scanning and printing¶

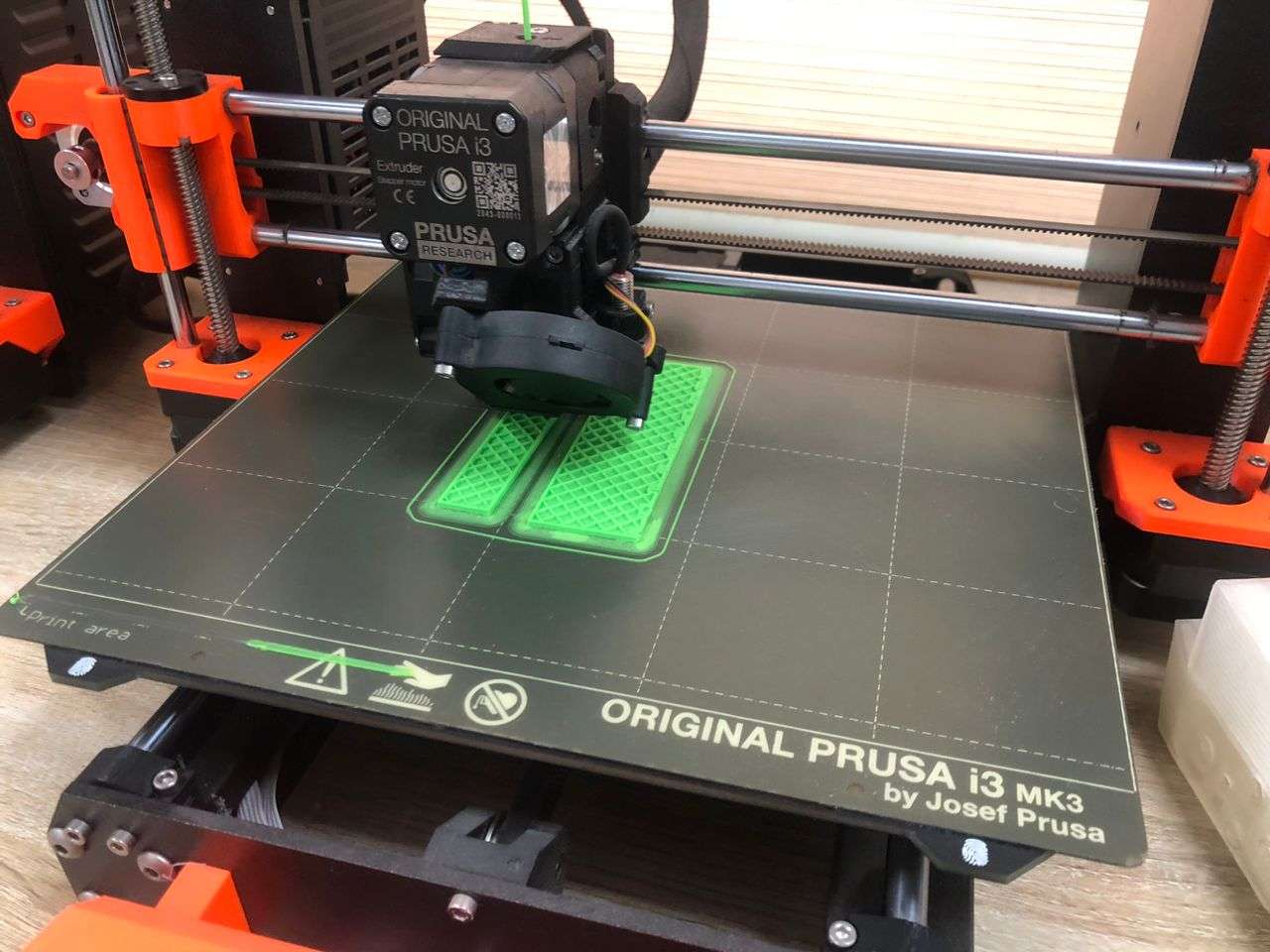

In our lab, we have five (5) Prusa original i3 mk3 3D printers.

We used the files from the class page to test several key parameters of the printer as follows:

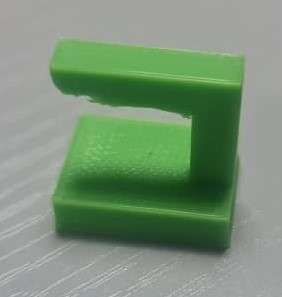

With Supports¶

Overhang¶

Evaluated printer’s ability to print overhanging features without drooping or deformations by testing various overhang angles.

The result shows with support the overhang is printed and comes out looking good.

Unsupported¶

Angle¶

Tested printer’s performance in printing unsupported overhangs at different angles to assess print quality and stability.

The result for this looks good at all angles without support.

Overhang¶

Investigated printer’s ability to handle unsupported overhangs, analyzing quality across varying degrees of overhang.

Good result until after 7mm overhang

Bridging¶

Explored printer’s bridging capabilities by printing horizontal spans without support structures, examining structural integrity and surface finish.

All structures came out looking good here.

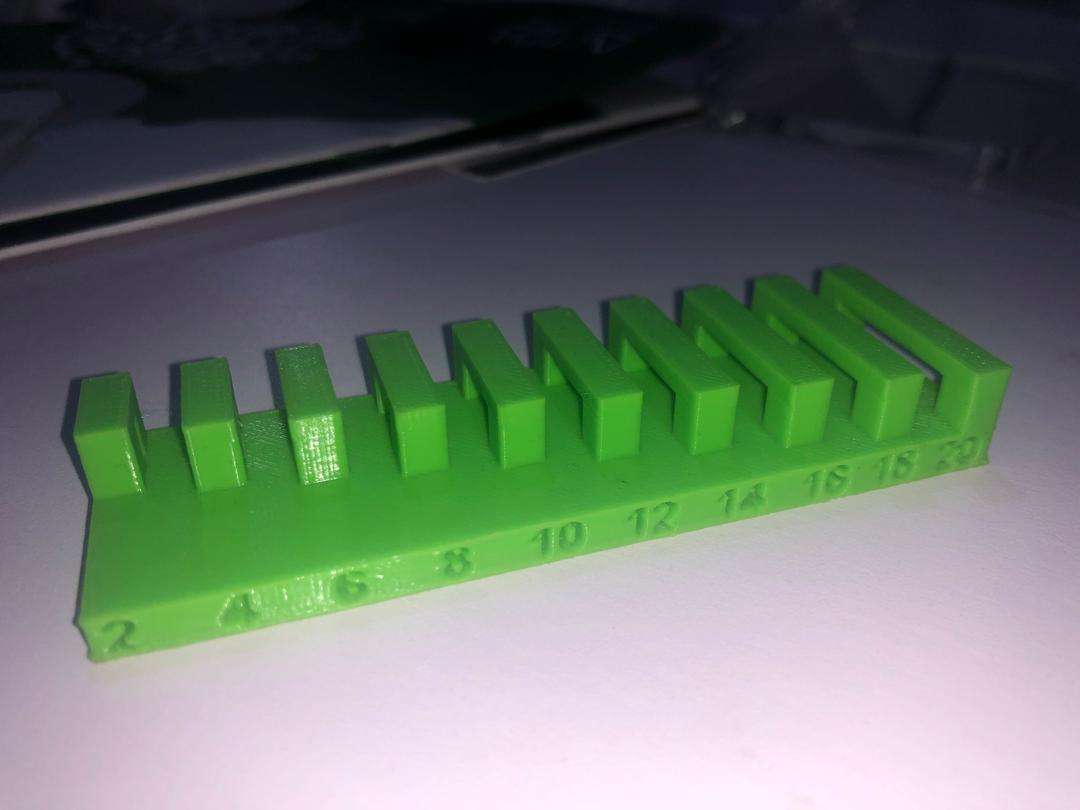

Wall Thickness¶

We systematically tested the printer’s ability to maintain accurate wall thicknesses by printing a series of test models with varying thicknesses. Precise measurements were taken to evaluate deviations from the intended dimensions.

The results indicated consistent performance across different prints, with very minimal variations observed.

Dimensions¶

To assess dimensional accuracy, we conducted thorough measurements of printed models using calibrated tools.

This revealed a high level of precision in reproducing design specifications, with printed dimensions closely matching the intended values. This consistency was maintained across multiple axes, affirming the printer’s reliability in dimensional accuracy.

Anisotropy¶

We investigated the presence of anisotropic properties in printed parts by analyzing their mechanical behavior along different directions. Mechanical tests and visual inspections were conducted to identify any variations in material properties or layer adhesion.

Slight discrepancies were observed, overall, the printed parts exhibited uniformity in material characteristics.

Surface Finish¶

Our assessment of surface finish focused on identifying defects such as layer lines, warping, or artifacts.

We successfully improved surface quality and achieved desired finishes. The results showcased satisfactory surface finish across printed models, meeting quality standards.

Infill¶

Finally, we explored the printer’s infill capabilities by printing models at 15% infill. Structural integrity and weight were evaluated across various infill configurations, demonstrating the printer’s versatility in producing robust parts tailored to specific application requirements.