4. Electronics production¶

Group 1 (Ito-Yamada)¶

characterize the design rules for your in-house PCB production process send a PCB out to a board house

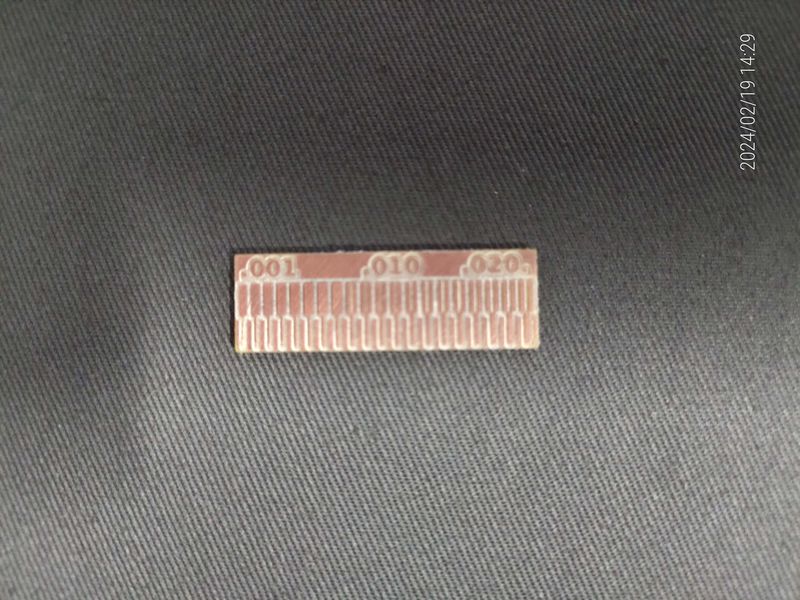

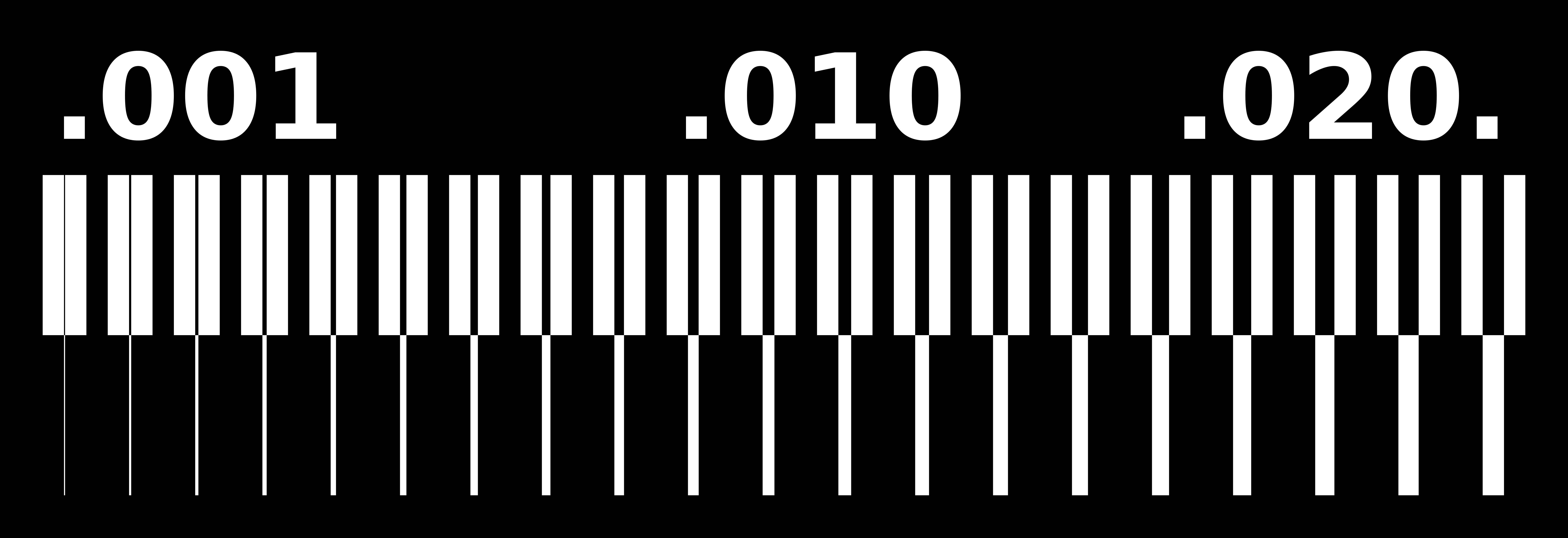

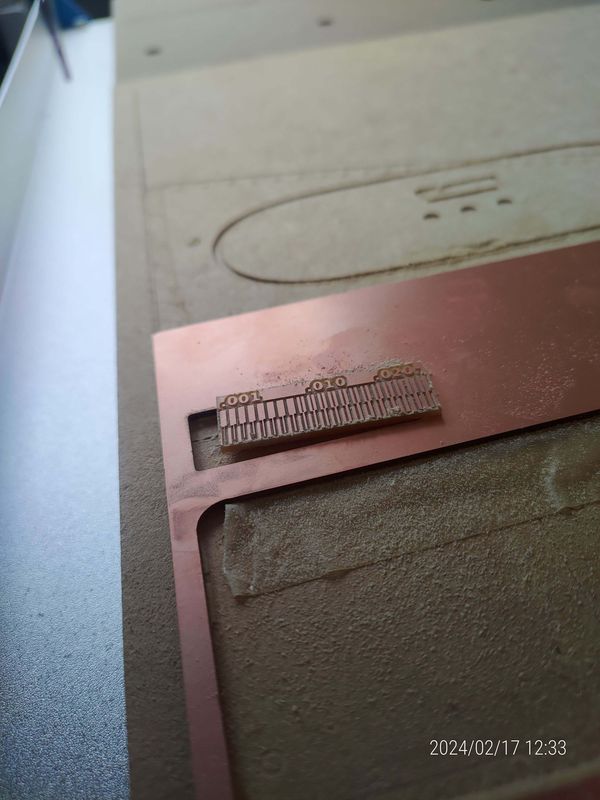

LINE TEST DATA¶

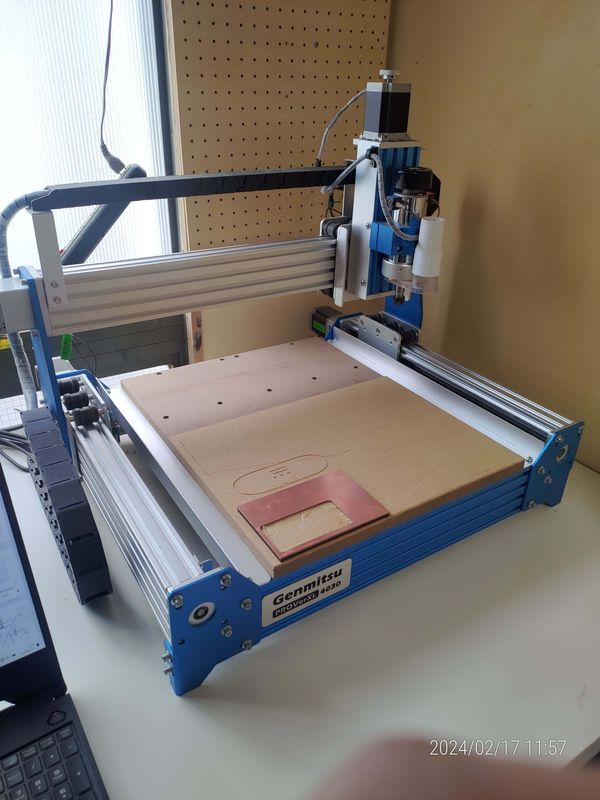

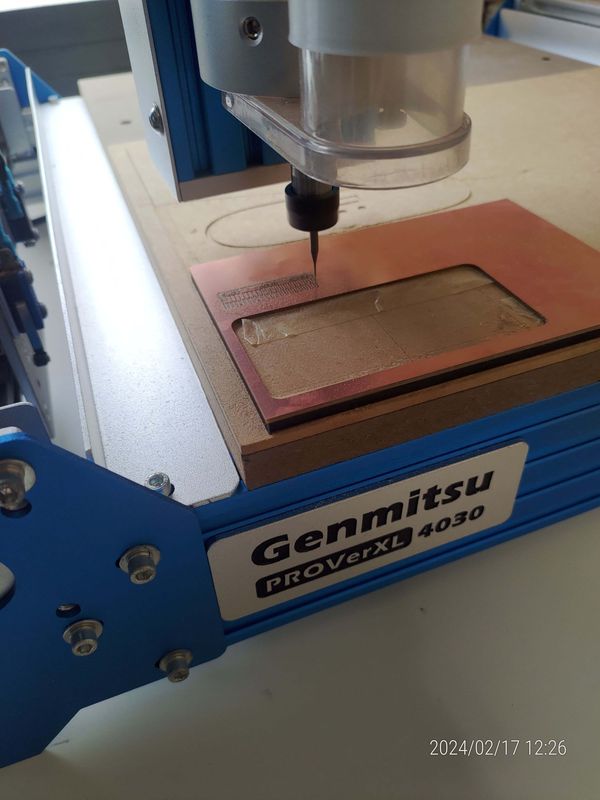

CNC Machine¶

Genmitsu PROVerXL 4030¶¶

Specification¶

Working area: 400 x 300 x 110mm

Control Board Compatibility: GRBL 1.1h

Spindle: 300W 6A, 12,000 RPM

Max speed: 2000mm/min

Accuracy: 0.1 mm

Overall Machine Size: 641 x 755.5 x 580mm

Machine Weight: 26kg

Collet (in package): 1/8” Shank

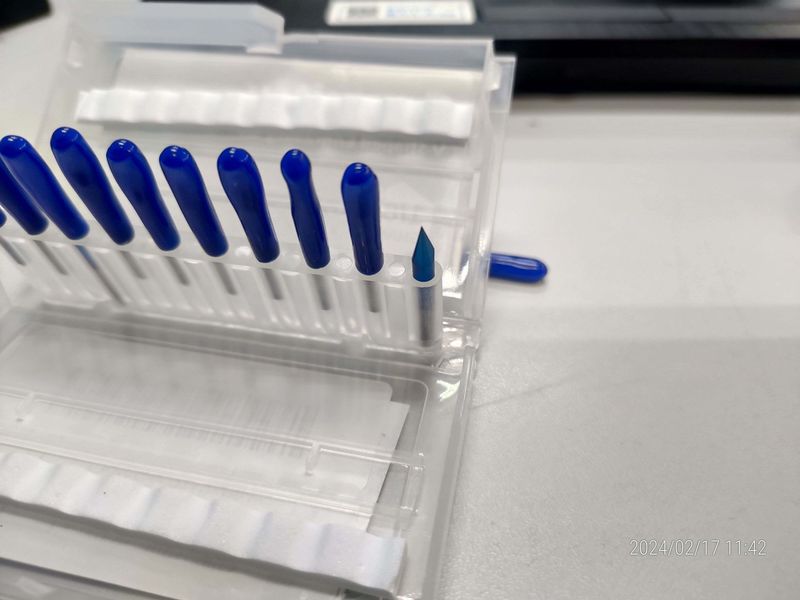

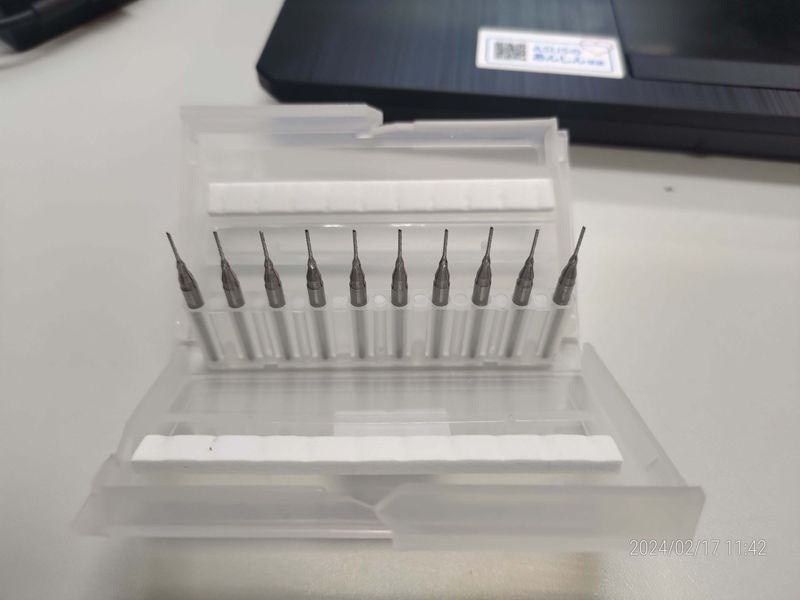

Tools¶

30 Deg V-bit¶

¶

1/64 inch flat endmill¶

Power solvent & Scraper¶

A power solvent and a scraper can be used to remove double-sided tape that is fixed to the circuit board.

Process¶

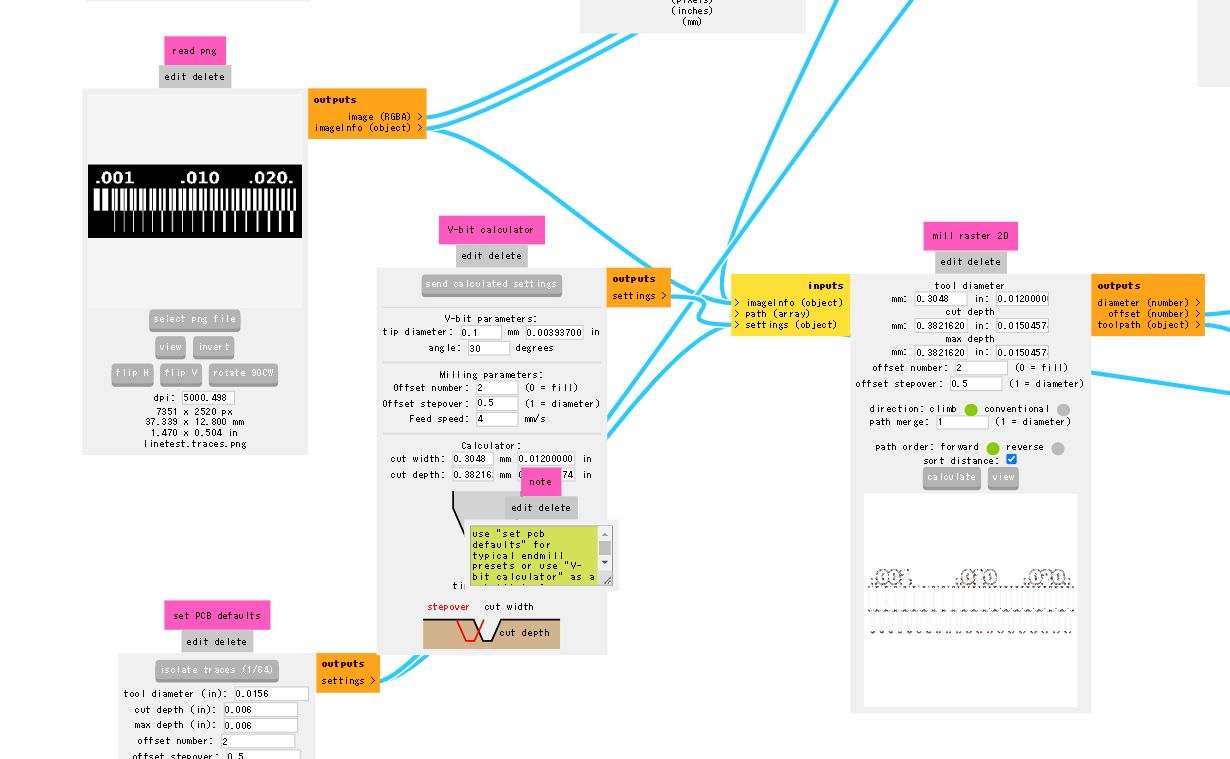

Generate G-code from PNG¶

mods CE(https://modsproject.org/)

Setting with V-bit and 0.7mm¶

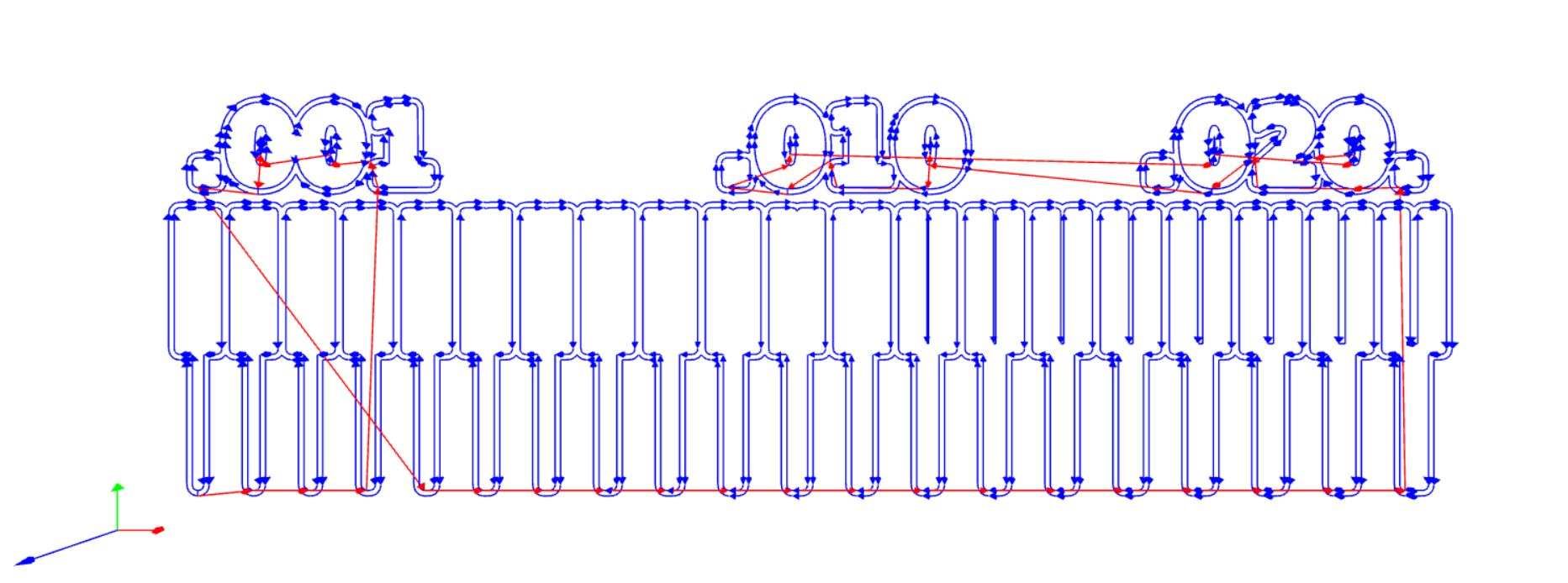

Trace data¶

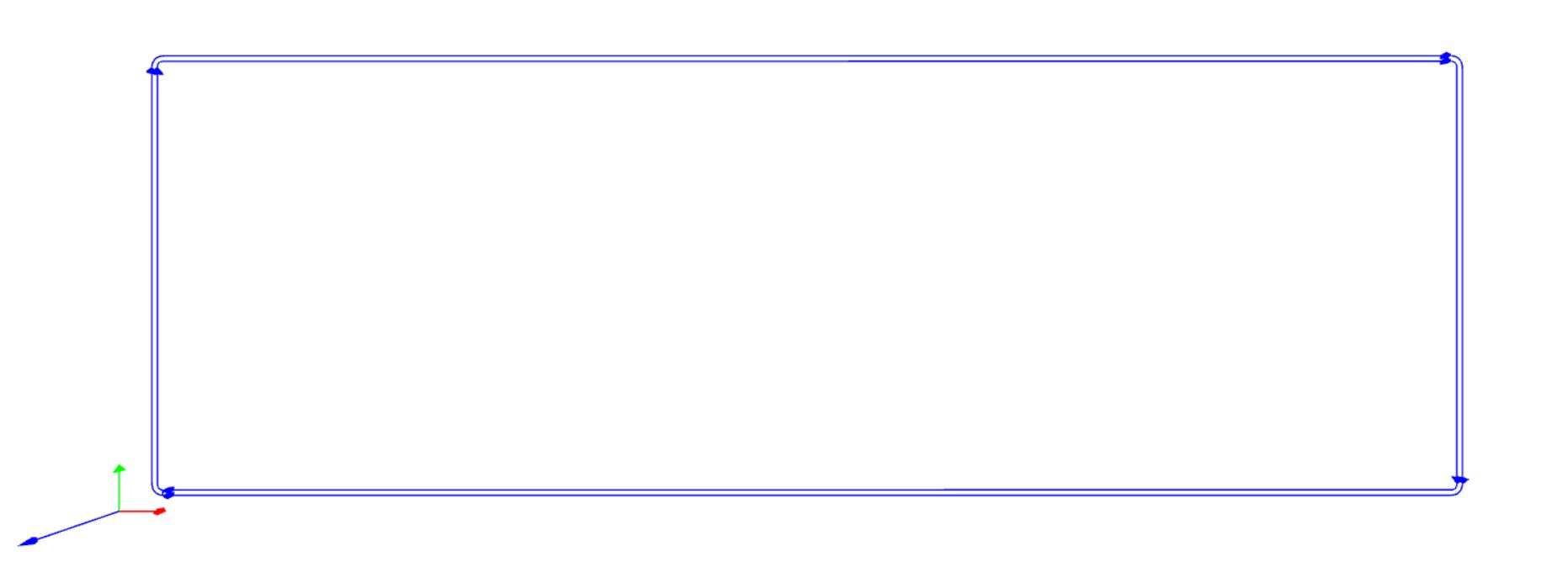

Interior data¶

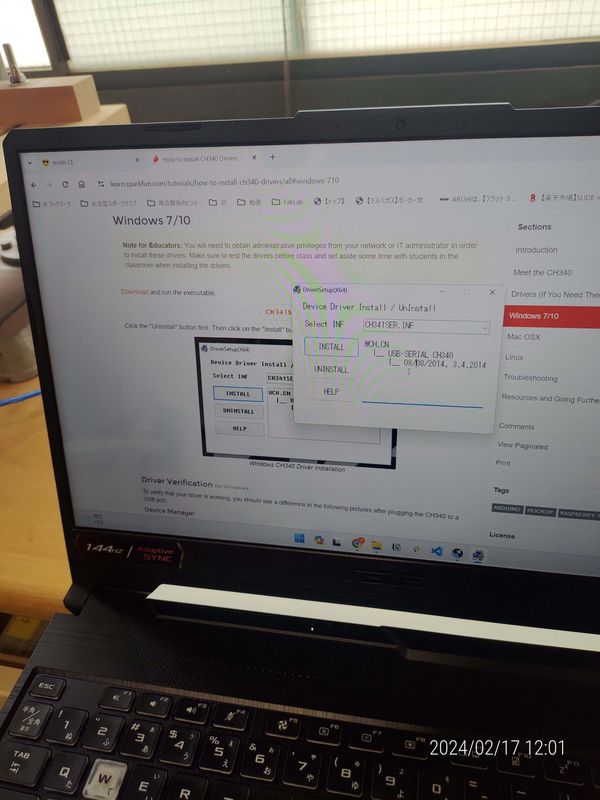

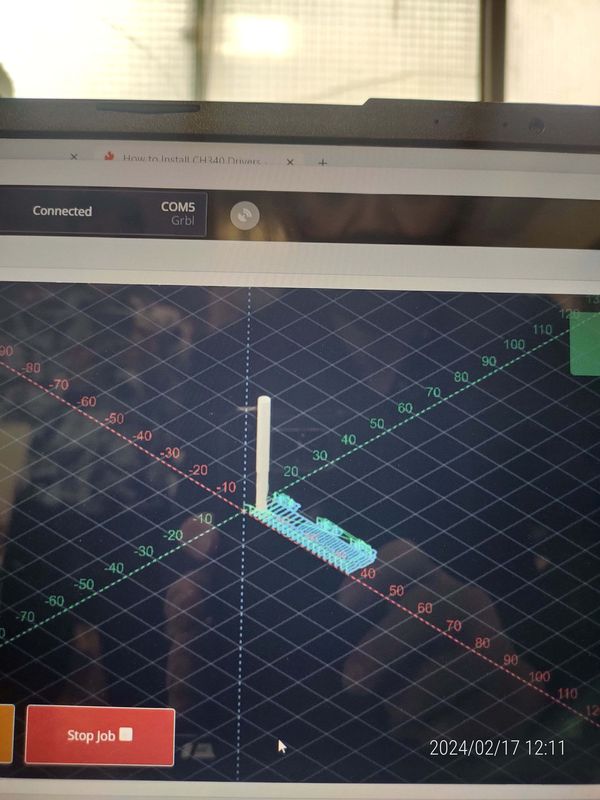

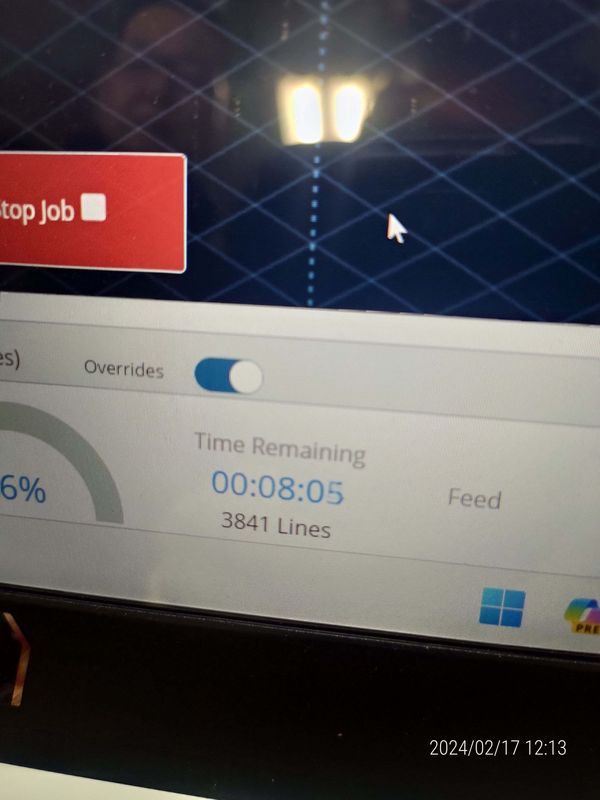

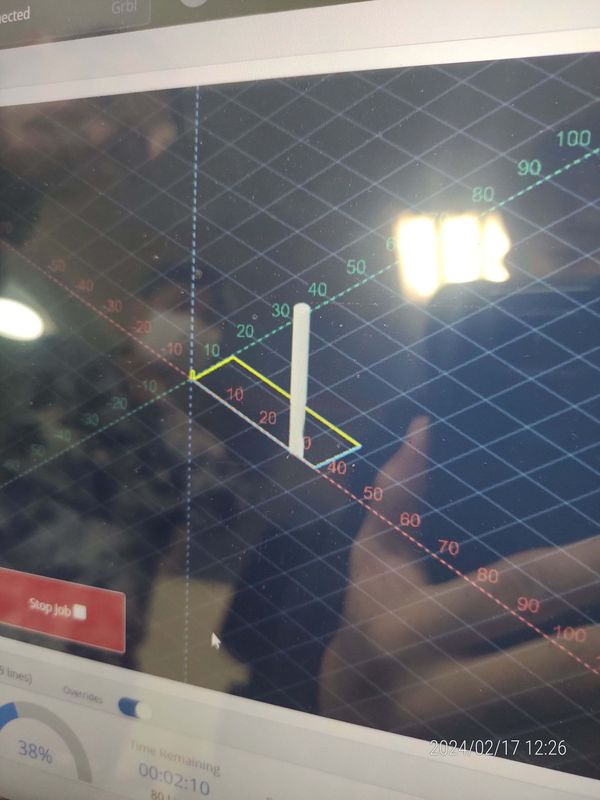

gSender (Send g-code to CNC milling machine)¶

- Driver Instllation

- Connect CNC machine to PC(USB Port)

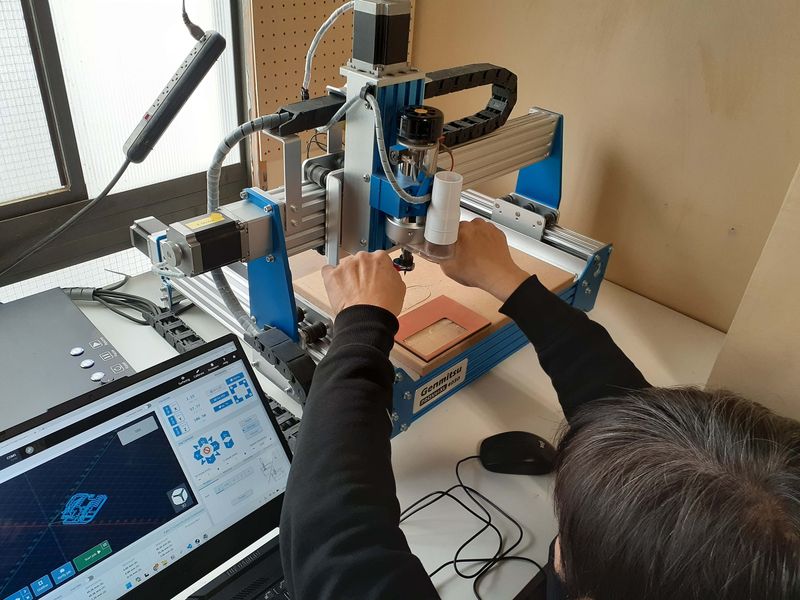

- Moving the drilling motor to the start position.

- Use two monkey wrenches to secure the bit

- What to do after launching g-Sender.

5-1. Select the connected Milling machine from the pulldown menu and establish a connection between the PC and the machine.

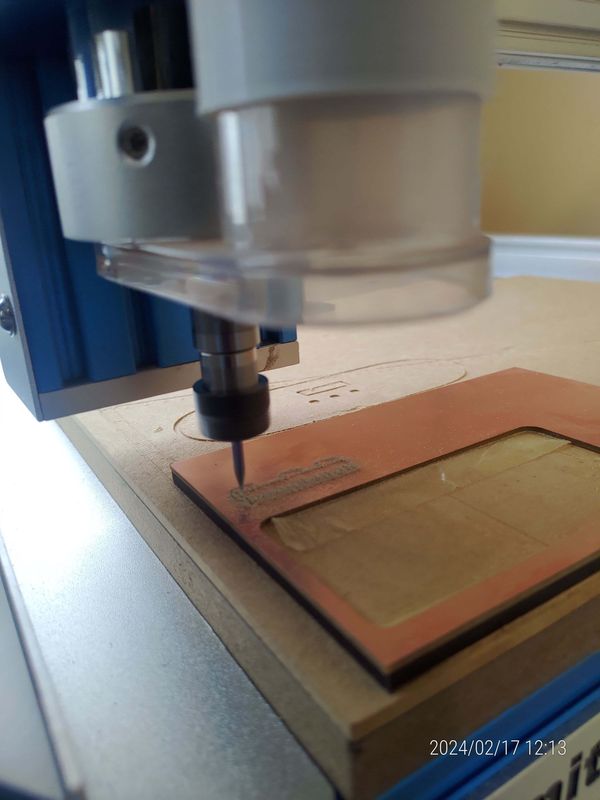

5-2. After loading the milling data, move the bit to the starting position for cutting. For the Z-coordinate, carefully lower the bit while placing a single sheet of paper between the material and the bit. The appropriate zero point is when the paper is caught between the material and the bit, and cannot be moved.

5-3. Once the X, Y, and Z positions are determined, press the respective buttons to set the zero points.

Press “Start Job” button to start the milling.

- Milling the traces first

- Milling the interior

- Rsults