Week 12. Molding and Casting¶

Group Assignment:¶

- Review the safety data sheets for each of your molding and casting materials.

- Make and compare test casts with each of them.

- Compare printing vs milling molds.

Some Takeaways:

- If you’re using a tough material like HydroStone for casting, go for a flexible mold made of silicone rubber. This makes it easier to take out your cast once it’s done.

- The drying and curing time might take longer than what’s mentioned in the brochure or datasheet. This could be because of the water quality, room temperature, or if you’re not mixing it vigorously enough.

- When working with HydroStone, wear gloves because the mixture can get hot, and it might irritate your skin if you have allergies.

- To keep the mix consistent, add the HydroStone powder slowly to the water and mix it well.

- Remember to jot down important info and keep it handy for future reference.

Individual Assignment:¶

Disclaimer: All the Assignments and Documentations are done and written by me, however after writing it myself, some I pass it through chatGPT to fix my language and grammar.

- Design a mold around the process you’ll be using, produce it with a smooth surface finish, and use it to cast parts.

Designing Molds¶

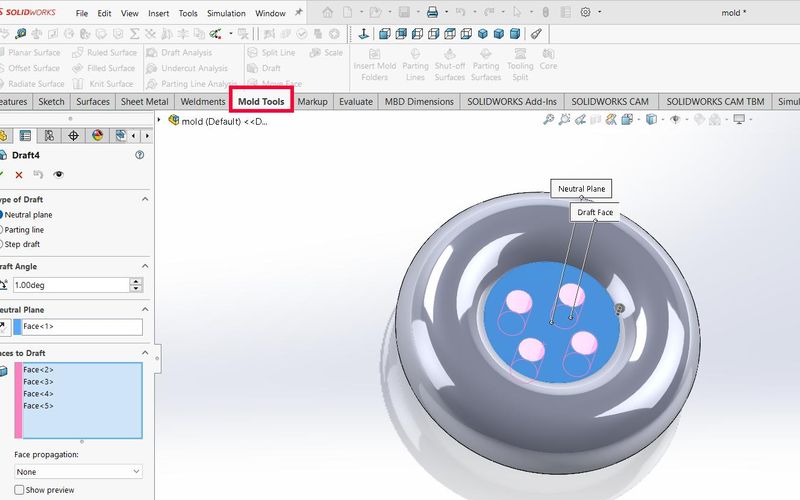

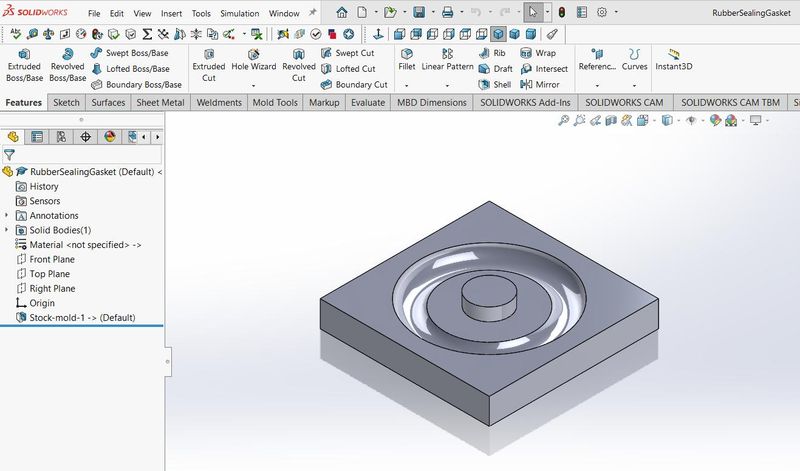

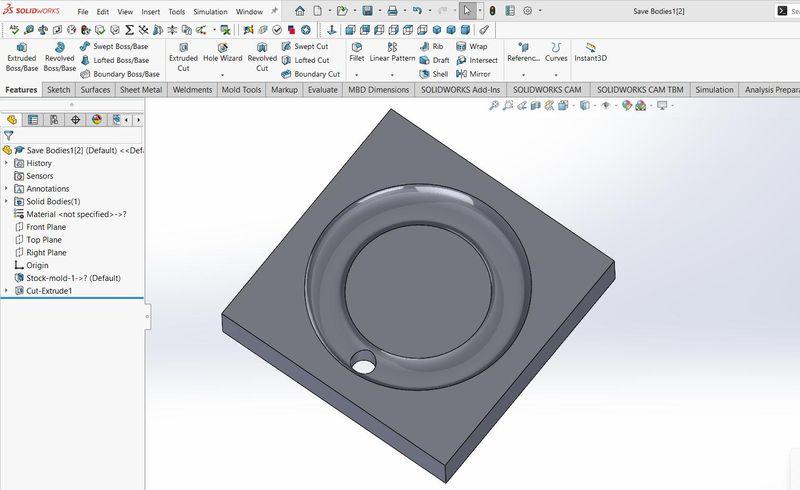

- I began by opening SolidWorks to design the mold for a button. Using the Mold Tool Adds-In software. I followed this Youtube Tutorial as reference.

- Next, I employed the Parting Line tool to separate the mold into two distinct parts, a crucial step in the molding process.

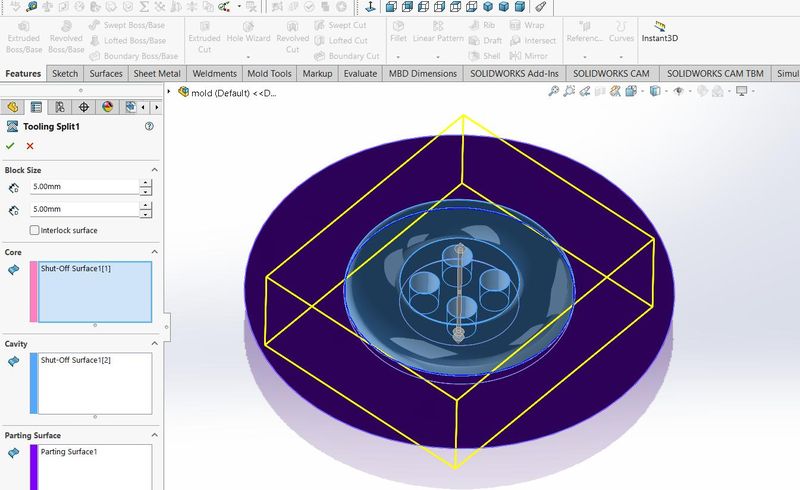

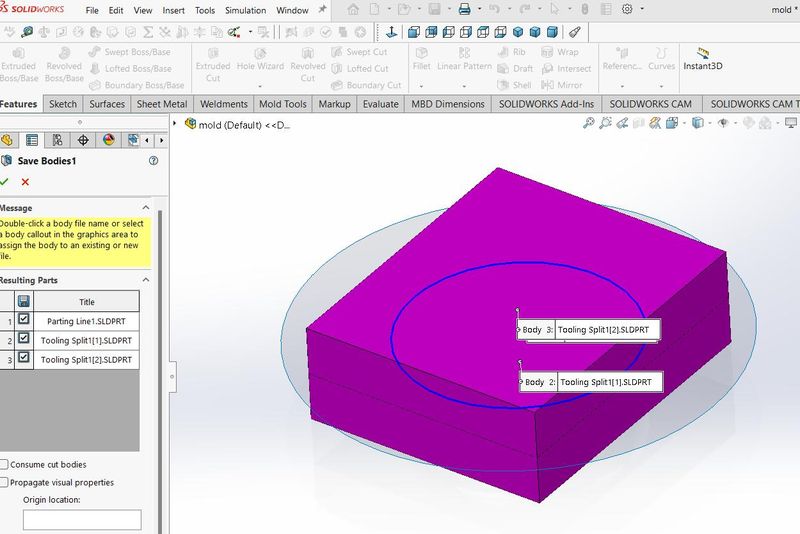

- With the help of Shut Off Surfaces, I refined the mold design, ensuring that there were no unwanted gaps or overlaps and leveraging the Tooling Split feature, I generated the molds with precision and accuracy, ready for production.

- Finally, I saved the separate mold bodies and exported them as STL files, ready for 3D printing to bring the design to life.

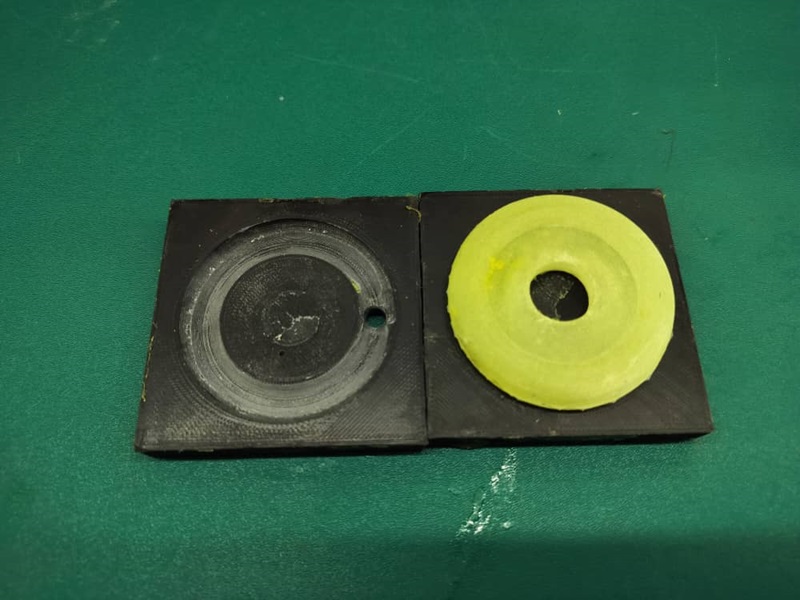

In addition to button molds, I also designed molds for sealing gaskets, and used in the production of rubber gaskets.

3D Printing Mold¶

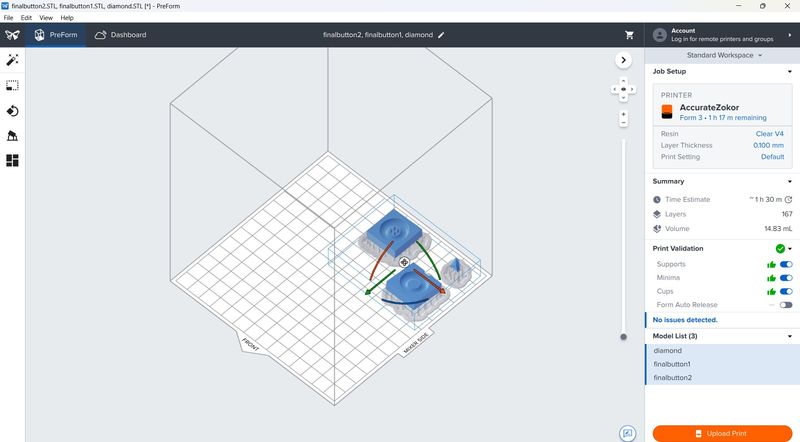

- With printers like Formlabs I achieved a smooth surface finish. Also with Prusa printer I achieved a smooth surface finish as well by setting quality level of 0.05 - 0.1 mm.

- I used PreForm, which is a 3D printing software to prepare the model for my Formlabs printer.

- The molds came out good, with a smooth surface finish.

LSR - 140¶

image source

image source

- I used LSR - 140 to make silicone rubber button products. First, I carefully read through the data sheet of LSR. Where I came to know LSR-1 series are widely used elastomer prized for its hightemperature resistance and flexible, non-stick nature.

LSR - 140 techinical details:

- Hardness : 40 shore A

- Degassing : Required

- Mixing Ratio : 1:1 (by weight)

- Curing Time : 2-4 Hrs

- Physical appearance : Low Viscous Liquid

- Colour - Base : Light Translucent

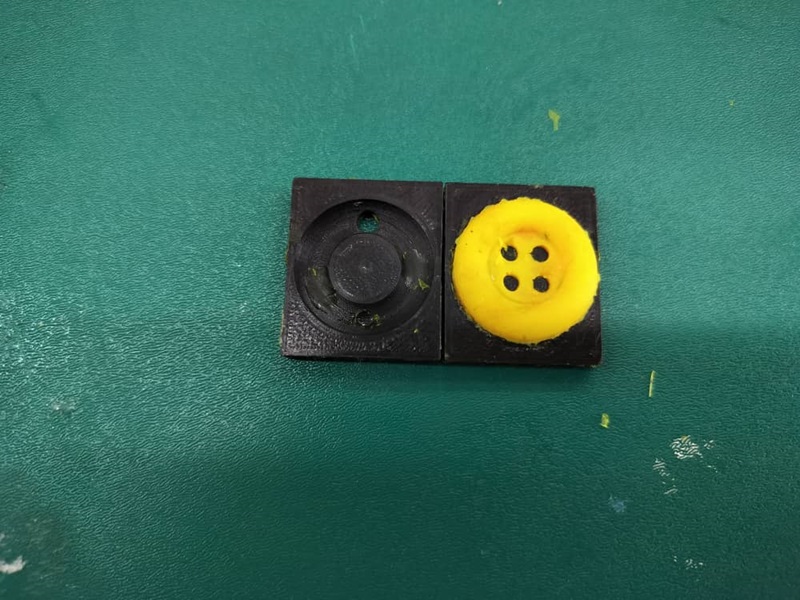

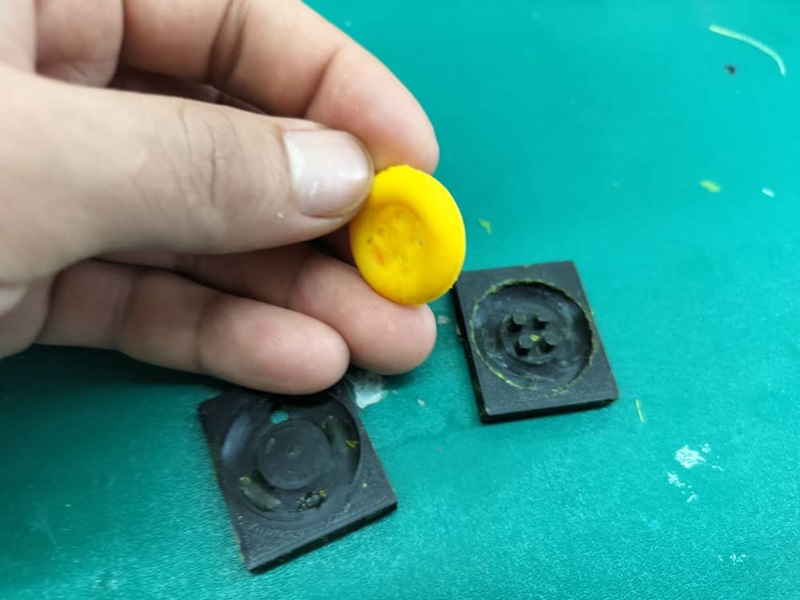

I weighed out equal amounts of part A and part B, mixed them thoroughly, poured the mixture into a mold created by a Formlabs printer.

Afterward, I allowed it to cure for several hours before opening the mold to remove the product.

Here is the product made from silicone rubber.

LIQUID POLYURETHANE RUBBER (FLEXON)¶

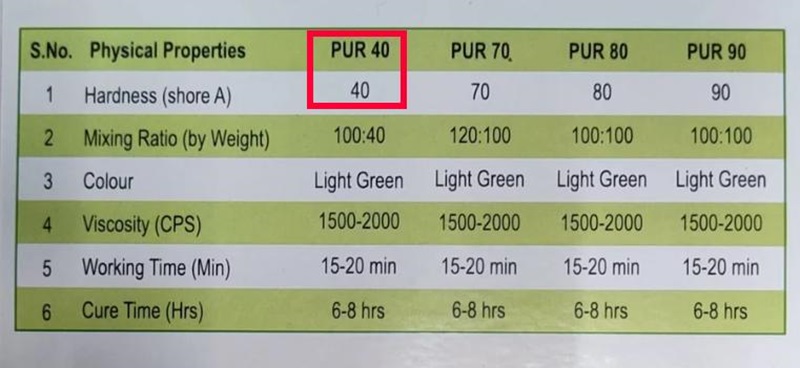

Technical Guidelines for LIQUID POLYURETHANE RUBBER (FLEXON):

Using the same molds, I used PUR 40 as my casting material to create my product. The mixing ratio for PUR 40 was 100:40 by weight. Afterward, I allowed it to cure overnight.

I’ve also utilised Prusa printers to create molds with ultra-detailed precision using a 0.05 ultra-detail print setting, resulting in a smooth surface finish. These molds were then cast using PUR 40 to produce larger-sized buttons.

I also utilized PUR 40 to make rubber sealing gaskets, leveraging its rubber-like properties, which make it particularly suited for this type of product.