-

00. FA20 Hyunho

-

01. Principles and Practices, Project management

-

02. Computer-Aided design

-

03. Computer controlled cutting

-

04. Electronics production

-

05. 3D Scanning and printing

-

06. Electronics design

-

07. Computer controlled machining

-

08. Embedded programming

-

09. Input devices

-

10. Applications and implications

-

11. Output devices

-

12. Interface and application programming

-

13. Invention, intellectual property, and income

-

14. Networking and communications

-

15. Molding and casting

-

16. Wildcard week

-

17. Mechanical design, Machine design

-

18. Project development

-

19. Final Project

Week6

Electronics Design

Group Assignment Link

Assignment

I started by referring to the Fab Academy Tutorial

Eagle Tutorial Link

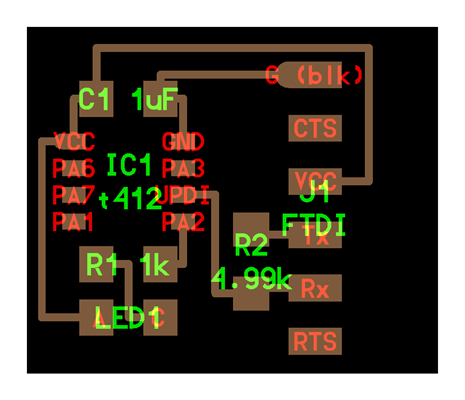

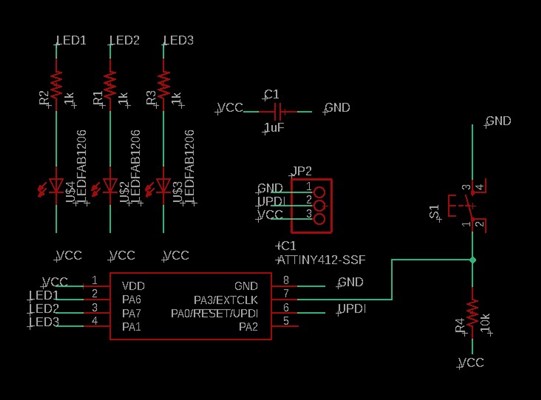

This is 412 Hello-EcoBoard

I'm not going to use a serial monitor

So I don't need FTDI fins

I will programming using the updi pin

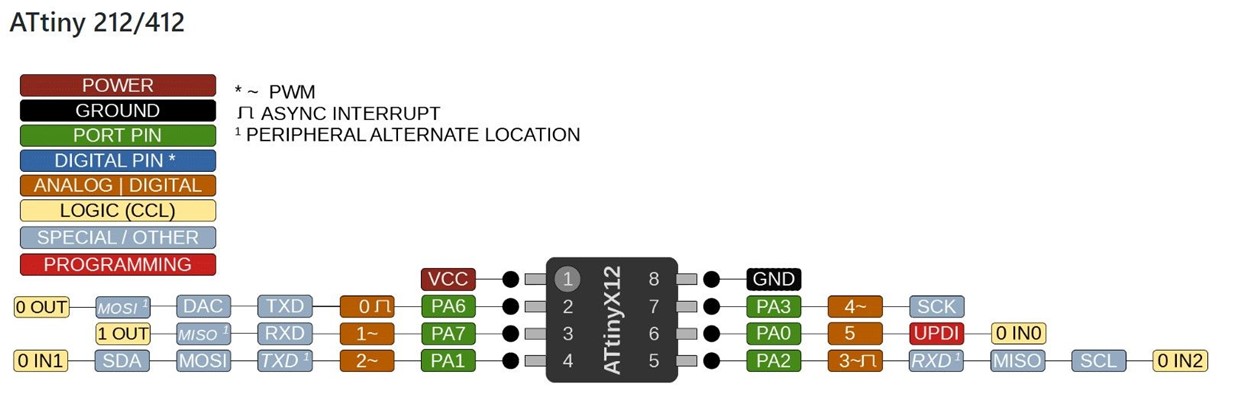

Attiny 412 pinout

0, 1, 2 pins are LED

4pin is a button

5pin will connect UPDI

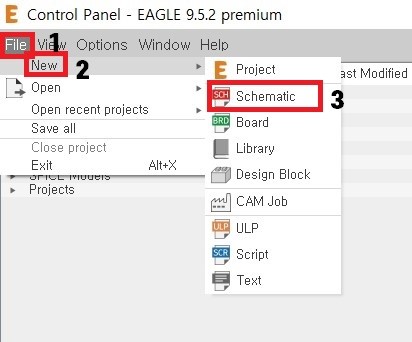

First open Eagle and File > New > Schematic

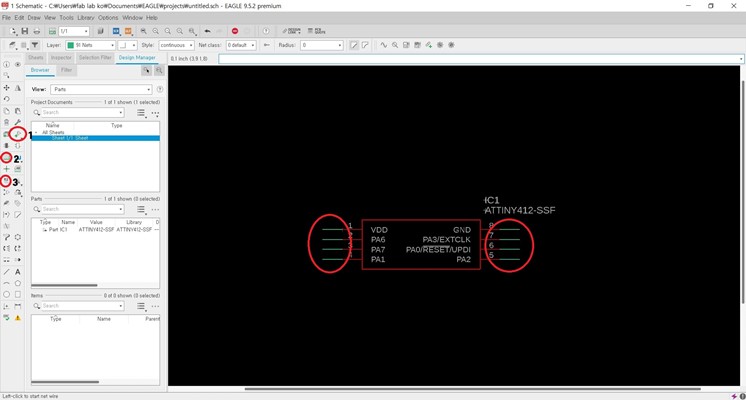

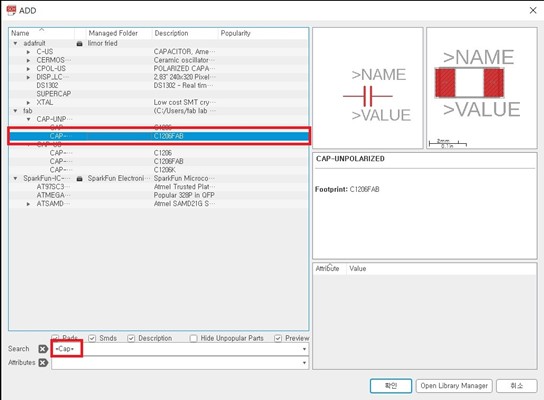

1. add component (Ctrl + Shift + A)

2. draw line (Alt + N)

3. name

Draw a circuit diagram in the order above

When searching for components, it's easy to search by attaching a '*' on both sides

Pre-add 1206 C and R used in fablab

[SnapEDA] - This site makes it easy to find the ibr file containing the desired footprint

[FAB.ibr]

[ATtiny412 datasheet]

[ATtiny412.lbr]

I've added 3 LED and button,

I found the resistance value of 1k through this link

and used a pull-up register

[What is pull-up register?]- I referred to Ji-hwan Kim's works

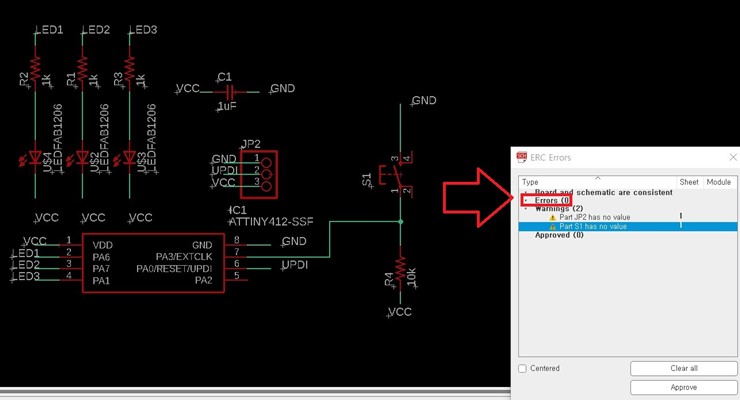

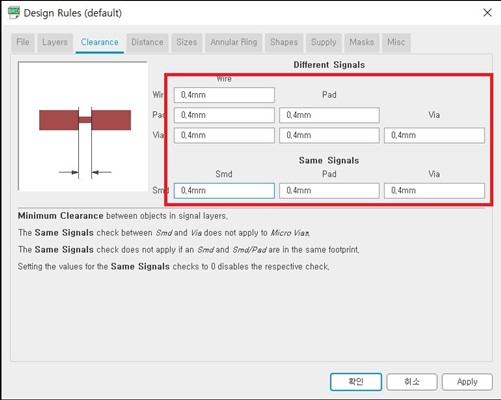

design rule check (Ctrl + Shift + E)

Make sure there are no errors through the and move on to the board

(You can ignore the warning)

Let's move on to the board

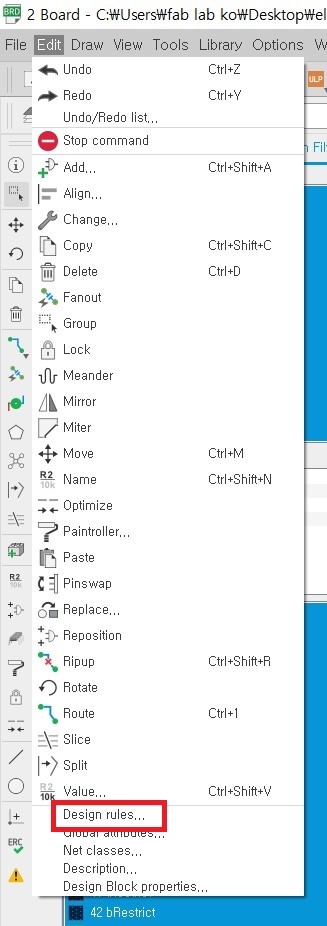

First, set the design rules

In the [4th week of the group work], we learned the minimum value of 0.4mm.

Set all settings to 0.4mm

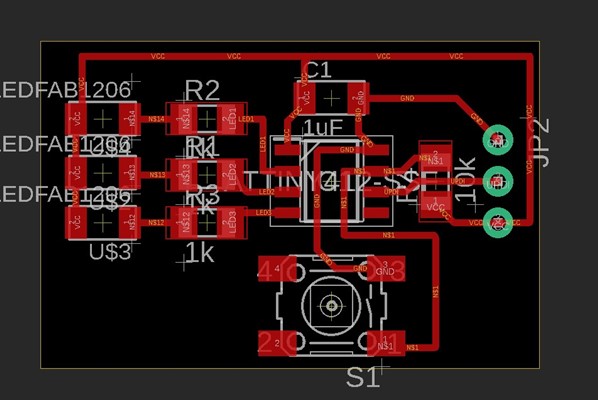

Place the Capacitor closest to MCU VCC and GND to maintain potential difference

Make the yellow box efficient after connecting the wires

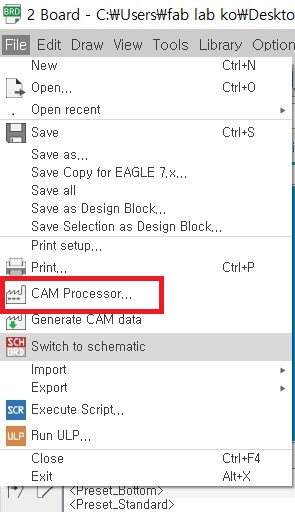

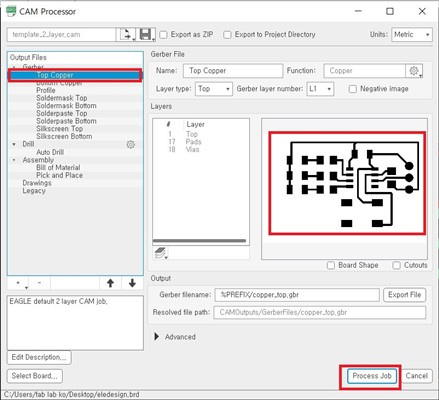

gbr file export

File > CAM Processer

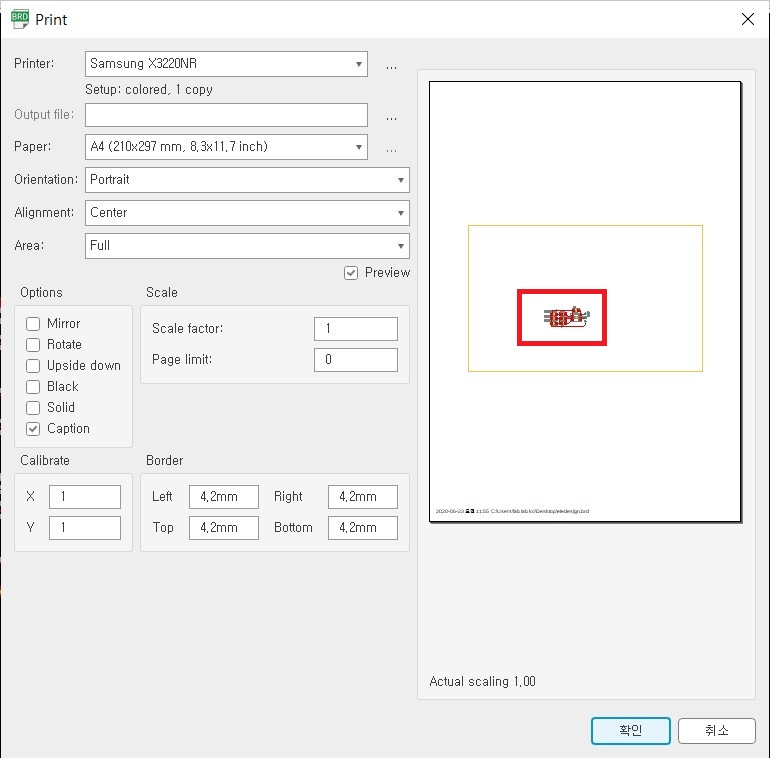

Print through (Ctrl + p) before export

True-size prints can help you size up real-world components and reduce mistakes

Check it again on the top copper and press process job

The gbr file is a great formate that includes both an outline, holes and a copper

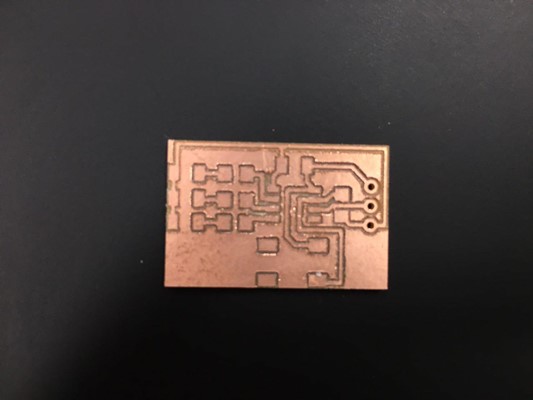

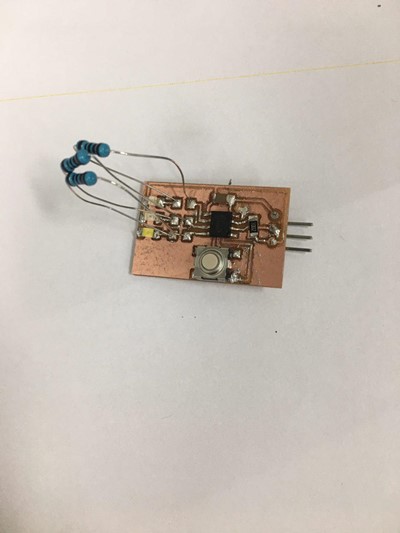

coin-sized circuit board

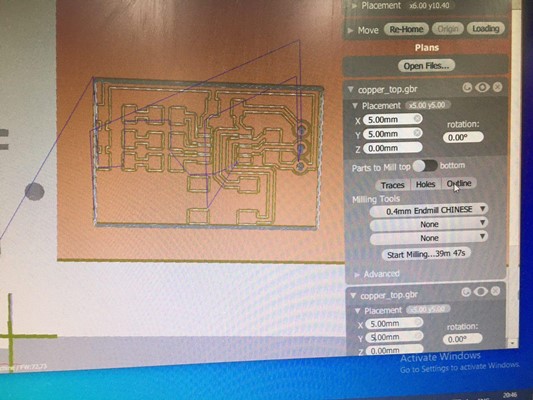

Milling took about 15 minutes

Clearance should be given at least 0.5mm to make it easier to soldering

Bantam PCB use Link(week4 group work)

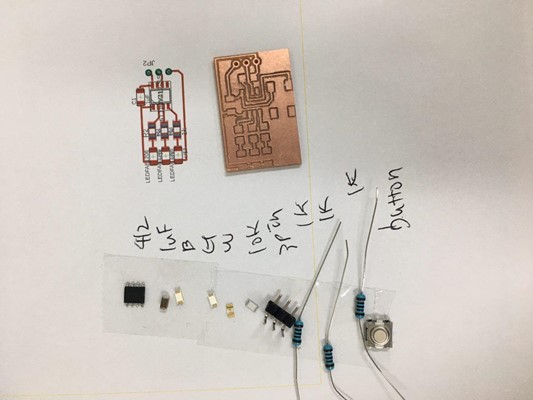

To check components our 1206 resistance is out of stock

So i use a different resistance

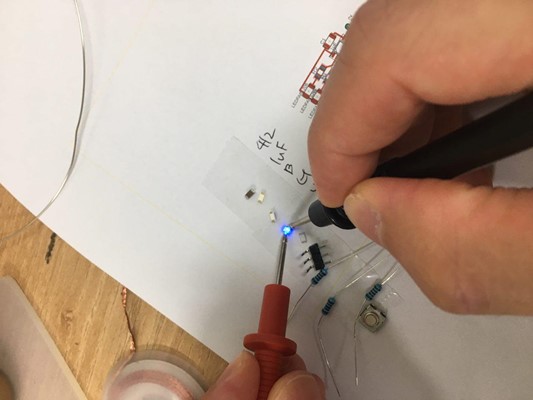

The LEDs are on + and - so be careful

Check the multimeter for the direction of the light

Let the red part go to the VCC

completed circuit board

File

circuit board SCH file

circuit board BRD file