week 7

- computer-controlled machining

- Assignment: Make something big.

Make something big. Starting by the last words of our class, begeans my milling exercise.

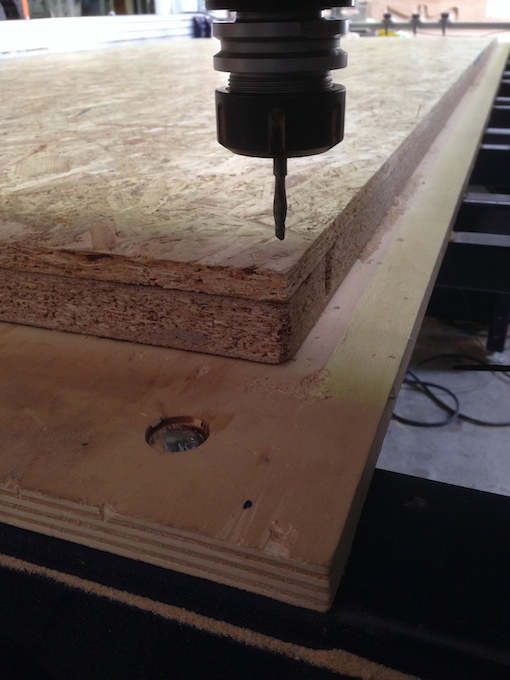

The machine we used is a ShopBot which is controlled through quite a complex software plugged in Rhino and operates through a wide series of tools.

These are the main subject to take care of, because fragile and, most important, their size is directly part of the design.

We used a 6mm drill size and this measure has been a constraint for all conjunction shapes of the components.

Regarding the type of design this is the main difference with the laser cutter: internal squared corners need an excess of path for the tool, giving to their shape a bone look.

As well as laser cutter, designs must take care of the tickness of the wood, which can be thicker with this system.

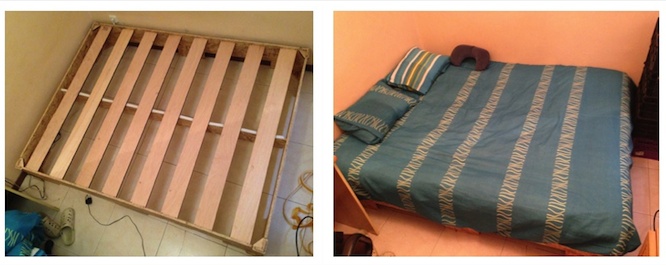

My project is a double size bed structure 190X150X29 to be derived from a 250X125X1,43 wood sheet.

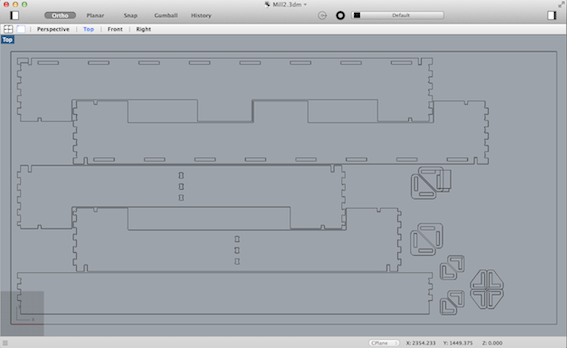

Once positioned all the components considering the tool paths, which prevent from attacching the objects expecially at their junctions, it is to select the screw positions for anchoring the wood on the bench, without interfering with the machine job.

Then, if the design presents holes as in my case, or junctions, it is to set an internal, inline or external path of the tool, using a multi program option.

Axis Z must be calibrated almost manually using a metal sheet as electric close-circuit contact for 0 height.

For security, the machine has a separated command button for the driller.

My shapes were out of the bench two hour later and, due to a very variable size of the thickness, it has been mandatory a sand paper final work to smooth and clean all the edges, especially the junctions.

Apart a couple of errors of mine in finishing the project and considering the non-compact nature of the wood, my bed, is very precize.

The only negative aspect of this techinic, in my personal opinion, is the waste of material which is important to consider if using this technic or more 3D sculpting, with other type of machines.

Assembling was hard because of the expansion of the wood. At the end I delivered at home for testing and it work perfectly.