week 11

- composite

- Assignment: design and make a 3d mold and produce a fiber composite in it

A composite material is something made essentially with two or more different materilas that summ the properties of each component.

Basically, mainly when talking about fiber-composits, we have a matrix and a reinforcement material.

About reinforcements the most used system is the fiber, both organic and syntetic. Its role is to give to the final composed strength, expecially in tension loads which help in stuctural torsions.

About matrices, we have 3 main families: polimeric, metallic and ceramics.

The most used matrices are polimeric resins as epoxy, vinil or poliester.

These are in liquid state and, when mixed with a catalyzer, a chemical reaction transforms it in a gel, the first step to hardening in a solid. At this point the curing process needs to press the object in its molds as possible as all air and excess of resin is pulled away.

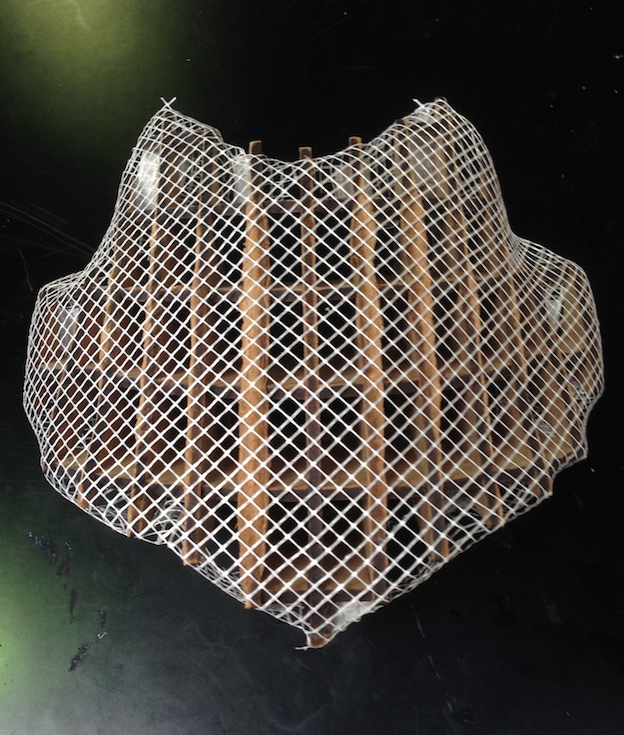

For the assignment, I decided to go for a press-fit mold and cotton fiber to be mixed with epoxy resin.

I realized in Rhino a 3D model of a motorbike wind-shield starting from the exact measures of my Speed Triple instruments that the shield has to match. I imported it into 123d Make for automatically export a dxf file with all the sliced shapes to be cutted with Laser. In my first try, once assembled/interlocked the components, I started to lay in tension a plastic net on the mold in order to minimize the holes of the press-fit

Then I disposed the compost of epoxy and hardner (rapport 2 to 1) on the cotton sheets previously cutted.

Then I disposed the compost of epoxy and hardner (rapport 2 to 1) on the cotton sheets previously cutted.

The most topic operation is to lay down the wet tissues on the mold. Cotton seems to be a little thin to accomplish this job so I'm going to overlap at least 3 layers in total.

The day after the resin was hardened and there was no evedence of the net pattern.

The day after the resin was hardened and there was no evedence of the net pattern.

Even is there has bin a lot of apllications hany made, the shape was as desired.

This last pic is a try I made with a polyurethan foam spryed in the empty spaces of the press fitt mold.

The surface, after sandpapering, is smooth and precise.