week 3

- computer-controlled cutting

- Assignment: design and make a press fit

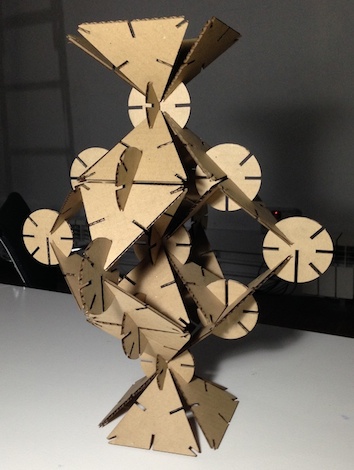

Third week, first machine! Here we go with laser and vinil cutters. I appreciated in particular laser cutter skills as it is possible to cut and engrave on a wide range of not reflective and mainly organic materials (avoid glue attached materials due to fire azard). The exercise for us consisted in a press-fit design to be realized with our modellers (as Apple user, I had finally to face the problem of a Rhino Mac version that is not at the "Window's one" level and made me decide for installing PC stuff on my machine, sadly). Then we had to cut and eventually engrave card board "domino's pieces", depending on projects, and create some structure

.

For the exercise, i opted for a combination of triangles and circles in order to obtain the most wide range of structure building possibilities. These two shapes have offered many ongle options and quite a good mechanical rigidty. At the moment I think laser cutter will be part of my personal project work flow for the realization of my bin's back-shell.

A very important thing to keep in mind when designing a press fit structure is to calculate a little bit of tolerance related at material thickness.

So if you have 3 mm cardboard as we had, design the insert sockets at least bigger of 0.2 mm in order to let the pieces sliding smoothly one on the other.

Here you can check the file I did for this assignment.