week 14

- mechanical, machine design

This week assignment is to design the mechanical or structural part of our personal final project.

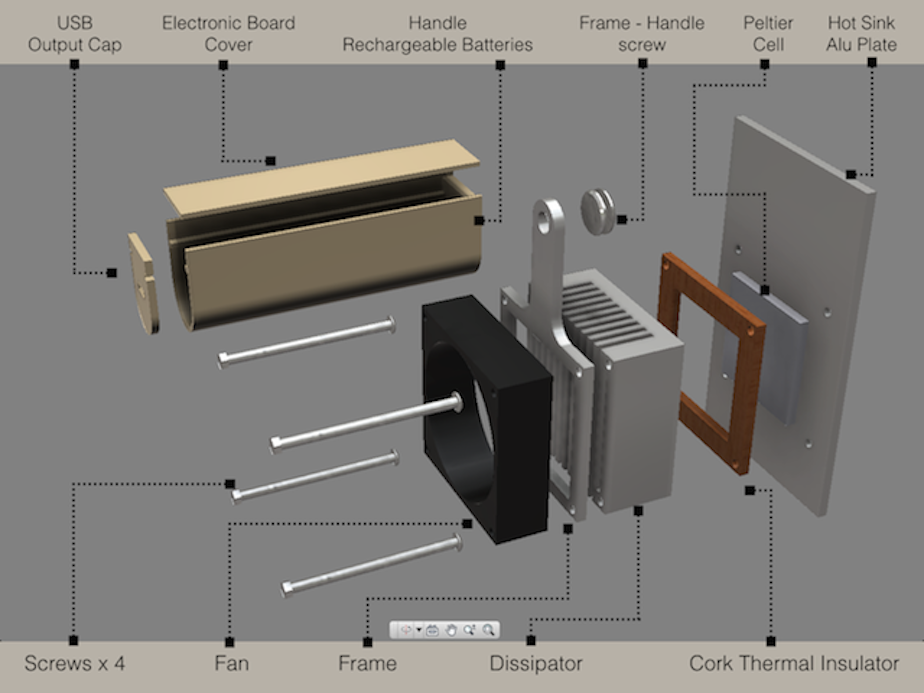

My project hasn't any mechanical part, so I designed the way to assemble the components of my "portable Thermoelectric Generator".

The generator is made of an Aluminum plate, the Peltier module, an insulator sheet, a CPU dissipator and a CPU fan.

As the electricity produced has to be stored in rechargeable batterys through a circuit board, I decided to compact all these parts in an handle attached to an aluminum frame. The project considers a USB Output socket integrated in the after cap.

4 long screws tie together all the components and a fifth shorter screw ties the frame to the handle.

As I am trying to recycle at least the heatsink parts, dissipator and fan, from old computers here in the Lab, the required measures are generally standardized.

Peltier modules vary from 40x40mm to 56x56mm, usually with a 5mm thickness.

Heatsink modules are 80x80mm with a 71.5x71.5mm screw path.

Considering a 3mm Alu plate on the hot side, plus the 5mm of the Cell, I assume that the lenght of the 4 long screws should be 60mm min.

The hanlde, which I planned to 3d print, needs a 50mm min screw ?4,5.

At the moment the only big doubt concerns the frame component itself: The machines we have here in the Lab don't allow me to cut a 3mm (better if it is 5mm) thick aluminum plate.

The idea is to design with Rhino the shape, with the holes for the screws, and cut an aluminum plate with the milling machine.

Below a render made with Autodesk Fusion.