Composites

For this assignment i wanted to explore the new mechanical properties of a composite with glassfiber, so i decided to make a bow using poliester resin and glassfiber. This is the process:

I m using the Woven Rovin fiber, to have a better order and to manage better how much fiber am i using. I selected the in groups of 5 fibers, i also made an excel document to know the relation between the quantity of fiber and the strengt of the bow.

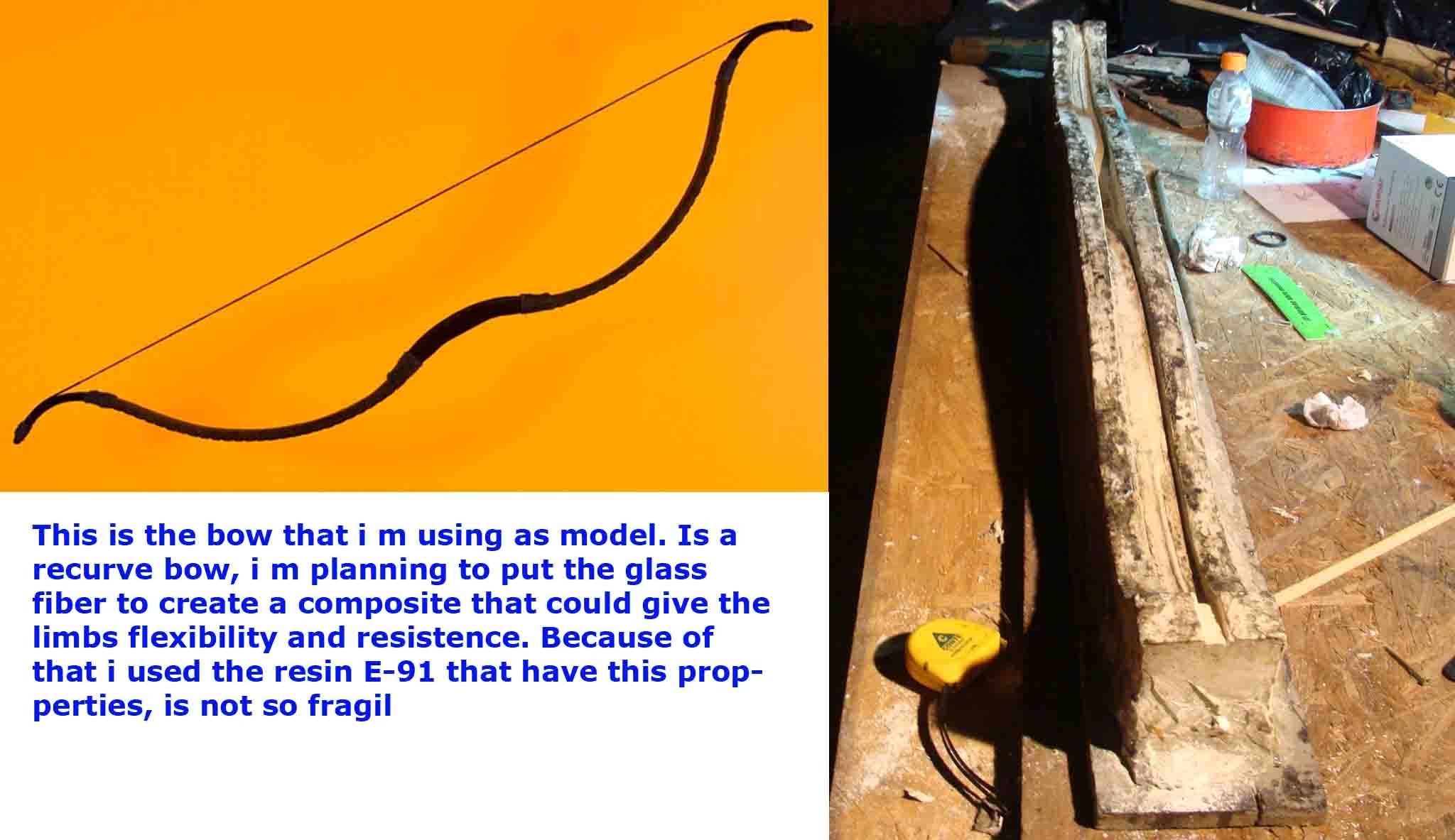

I decided to do a recurve bow like the one in this photo. So i make a mold with gypsum and a vegetal fiber, is also a composite but easy to do, using the technic of formwork.

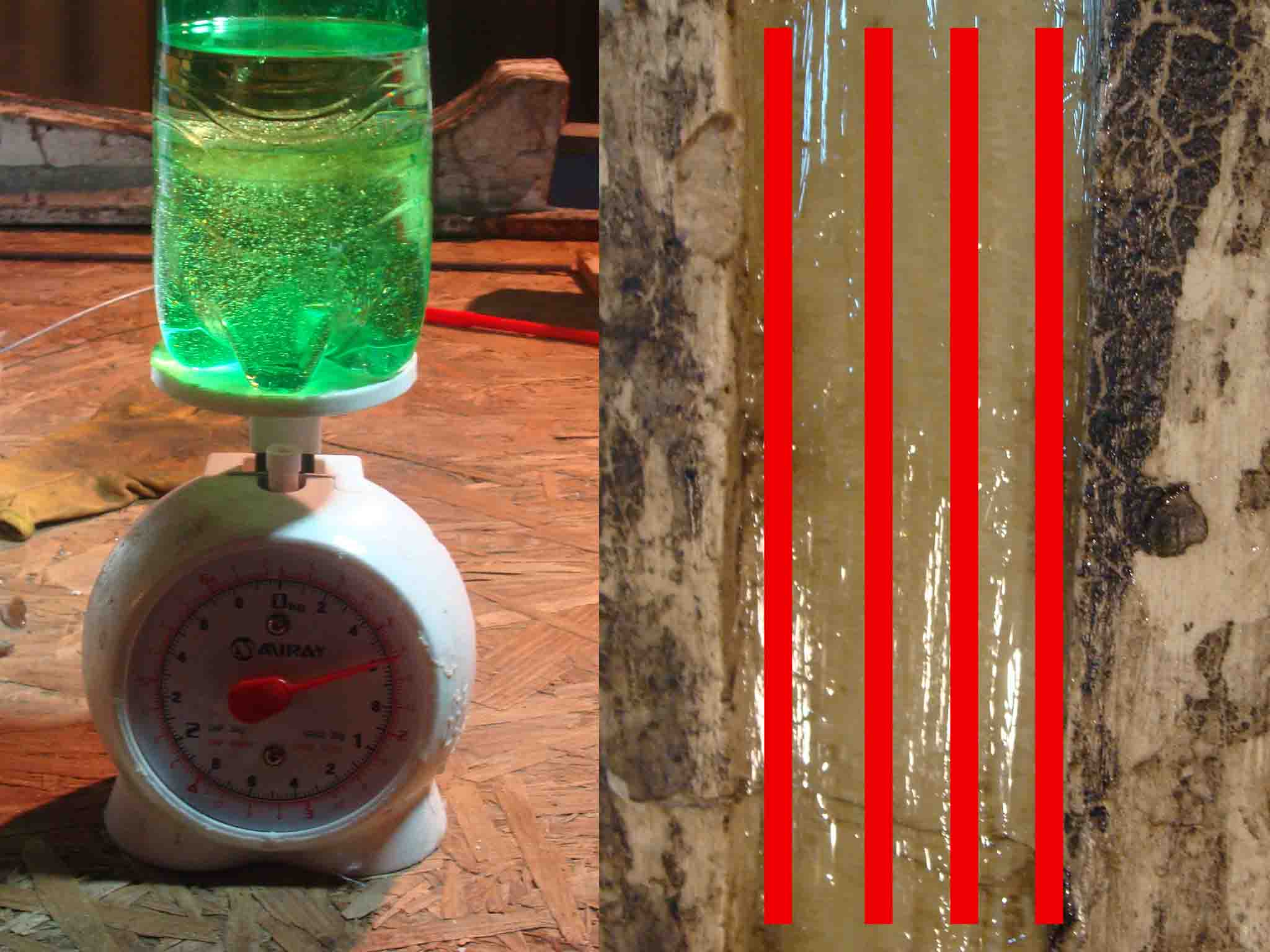

Then i added 4 layers, each layer had 4 groups of glassfiber and each group had 9 fibers of the Woven Rovin. Total 144 fibers of Woven Rovin, this is importat because i had to make a lot of experiments to know that this quantity will be for a bow with a strengt arround 32 lbs.

The process is easy, i just make the fiber wet with the resin. The way to put the fiber on the mold is each group of 9 fiber next to the other this four groups should cover a layer, then i prepare the second group i repeat the process. then i fill the center of the bow with cutted glassfiber and resin then i put the final 2 layers.

This picture shows the mix of E-91 resin plus catalizators. The proportion for mixing is 1.5% of cobalt and 1% of Peroxid mec. It will depend of the weather and humidity conditions.

The other part of the photo show the way to put the layers one beside the other.

Then i have to wait depending of the weather arround 8 hours or maybe less. And this is the final result:

This is the mold with the wet fiber.

And this is the bow alredy dry.

This is me using the bow.

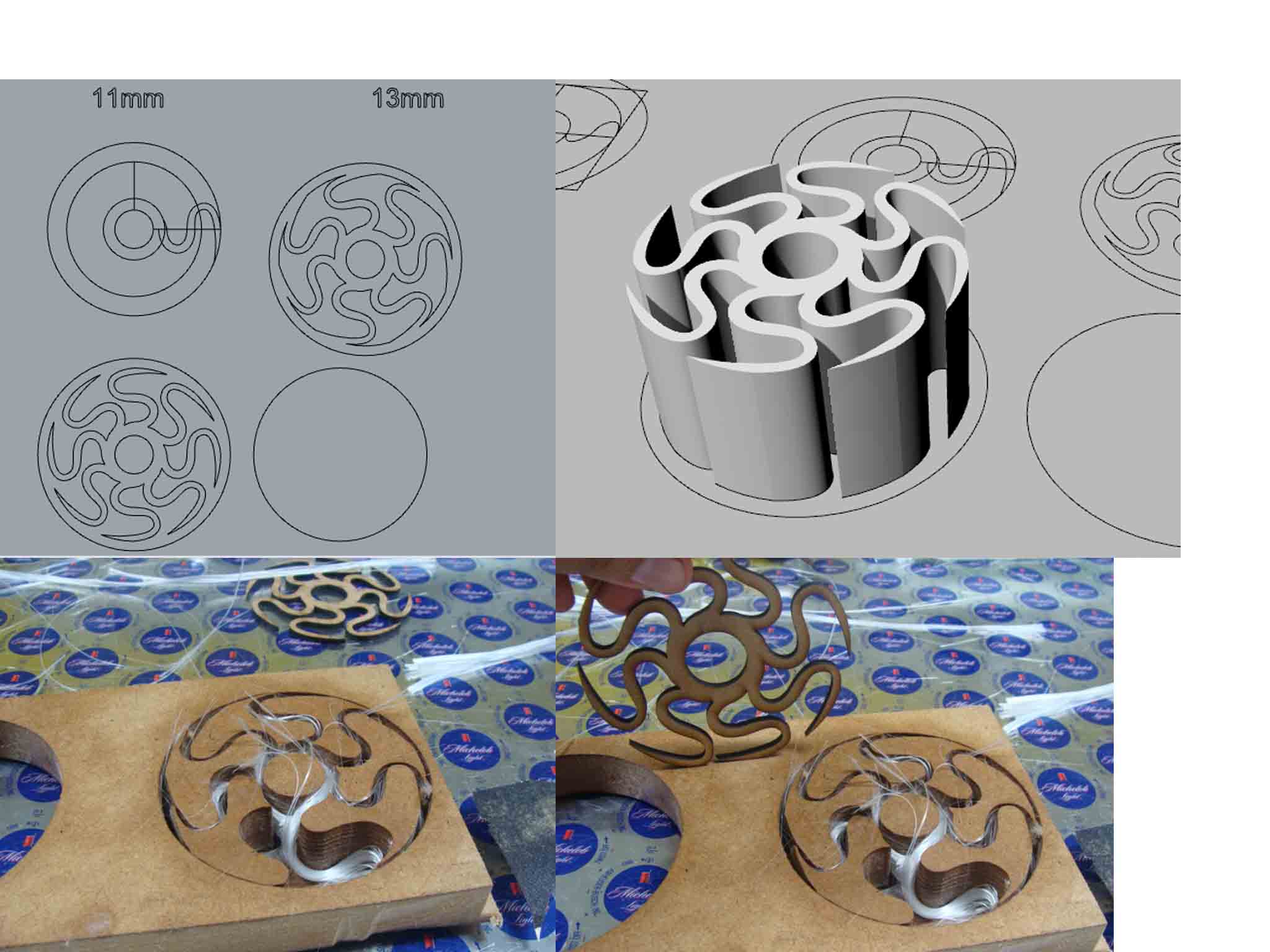

Another future project using composites is to develop a wheel without air, using the same flexibility of a bow, here some photos of this experiment:

Some FILES for making a better mold for bow are on the next LINK click on the "COMPOSITES" file