Juan Ranera

Fab Academy 2013 Participant

Research, Development and Innovation department of Esclatec

This week we have started to work with the printers cutting. After use Rhino and know its potential, this week I've been working with Inkscape. Inkscape is a free vector graphics editor very easy to learn. I read several tutorials to know more about the basic tools and I began to draw my press-fit construction kit. I enjoyed a lot using this program.

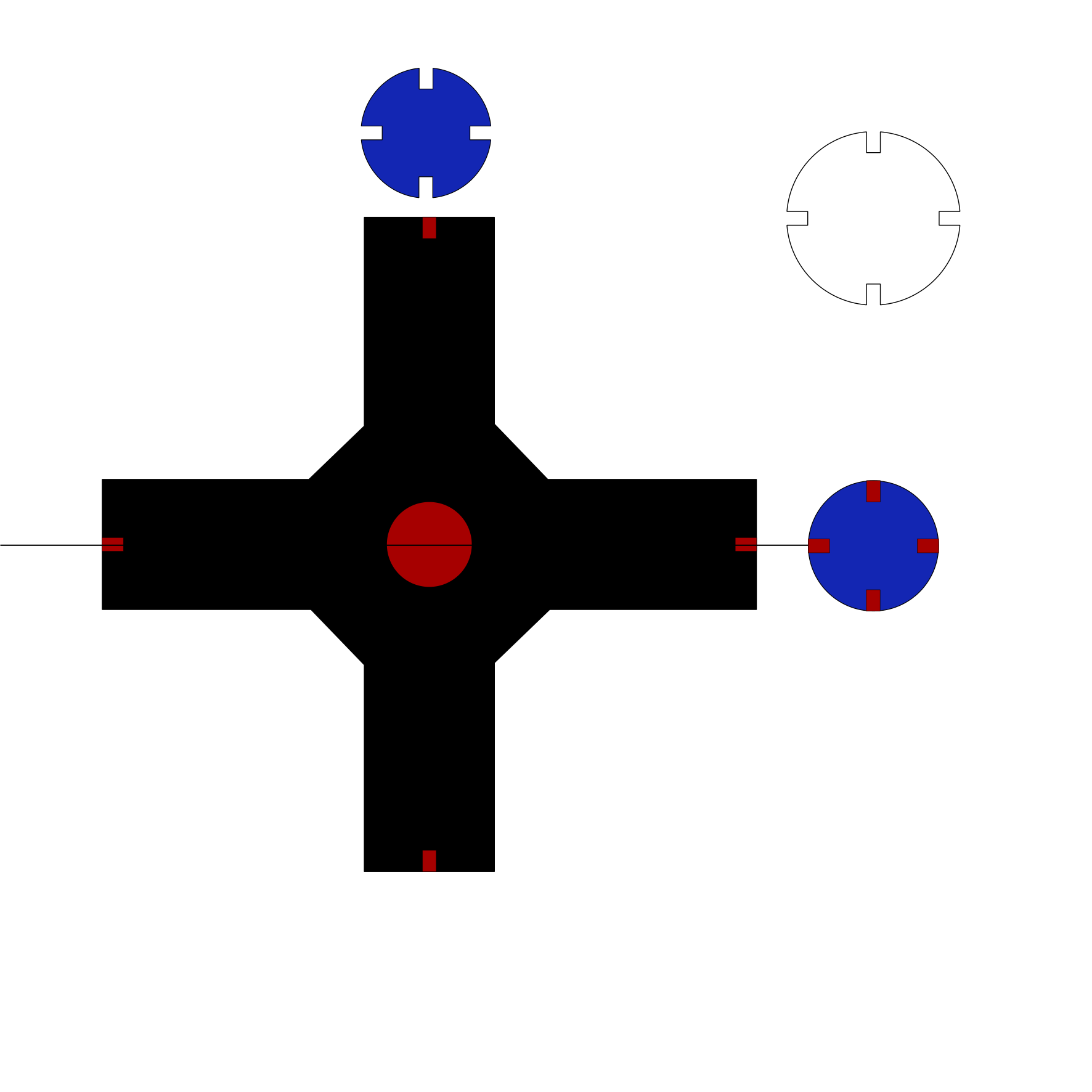

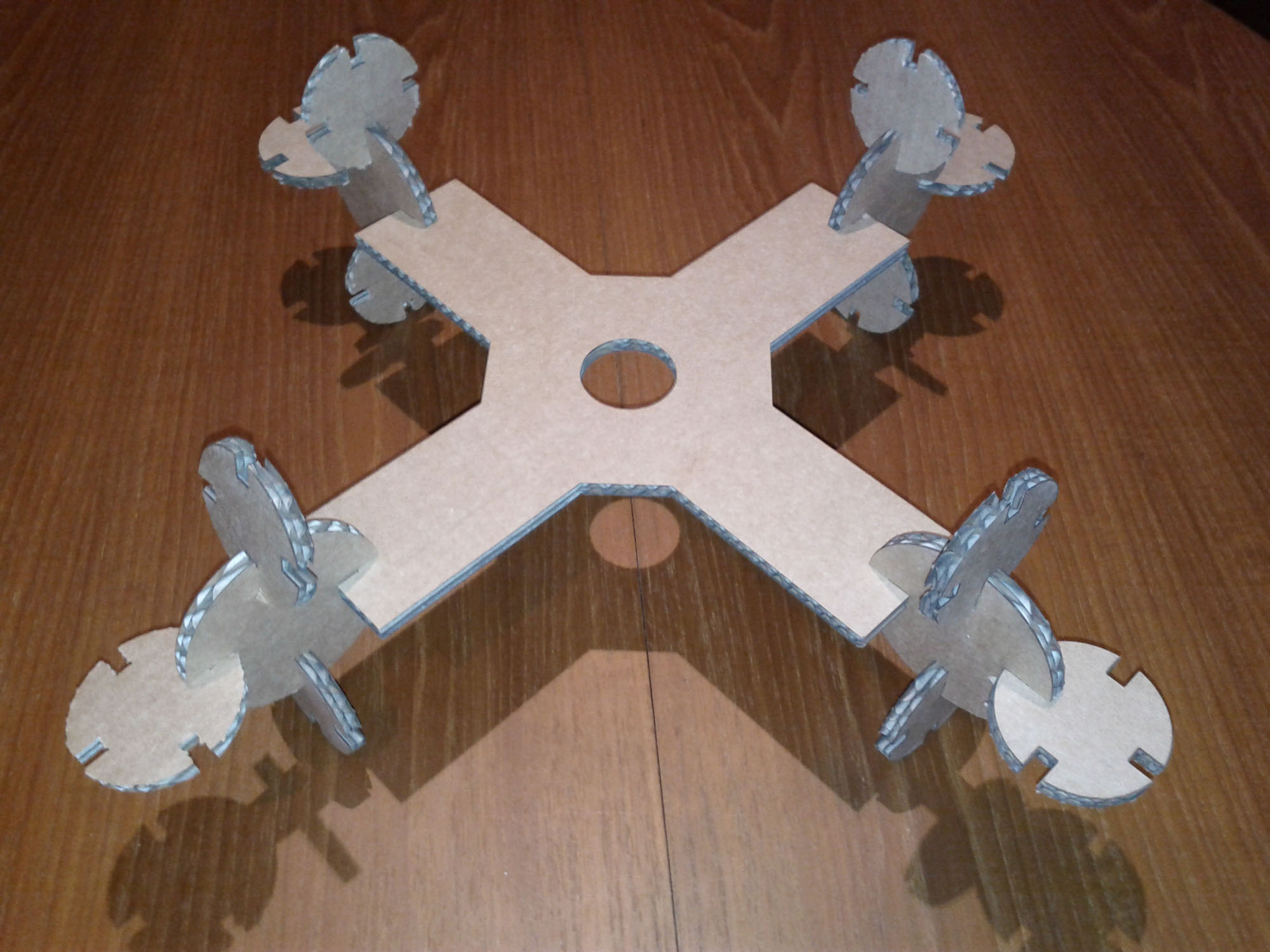

My idea was to make a mock-up of my platform for my final project. A cross-shaped where I've inserted four circumferences simulating an omnidirectional wheel at each end.

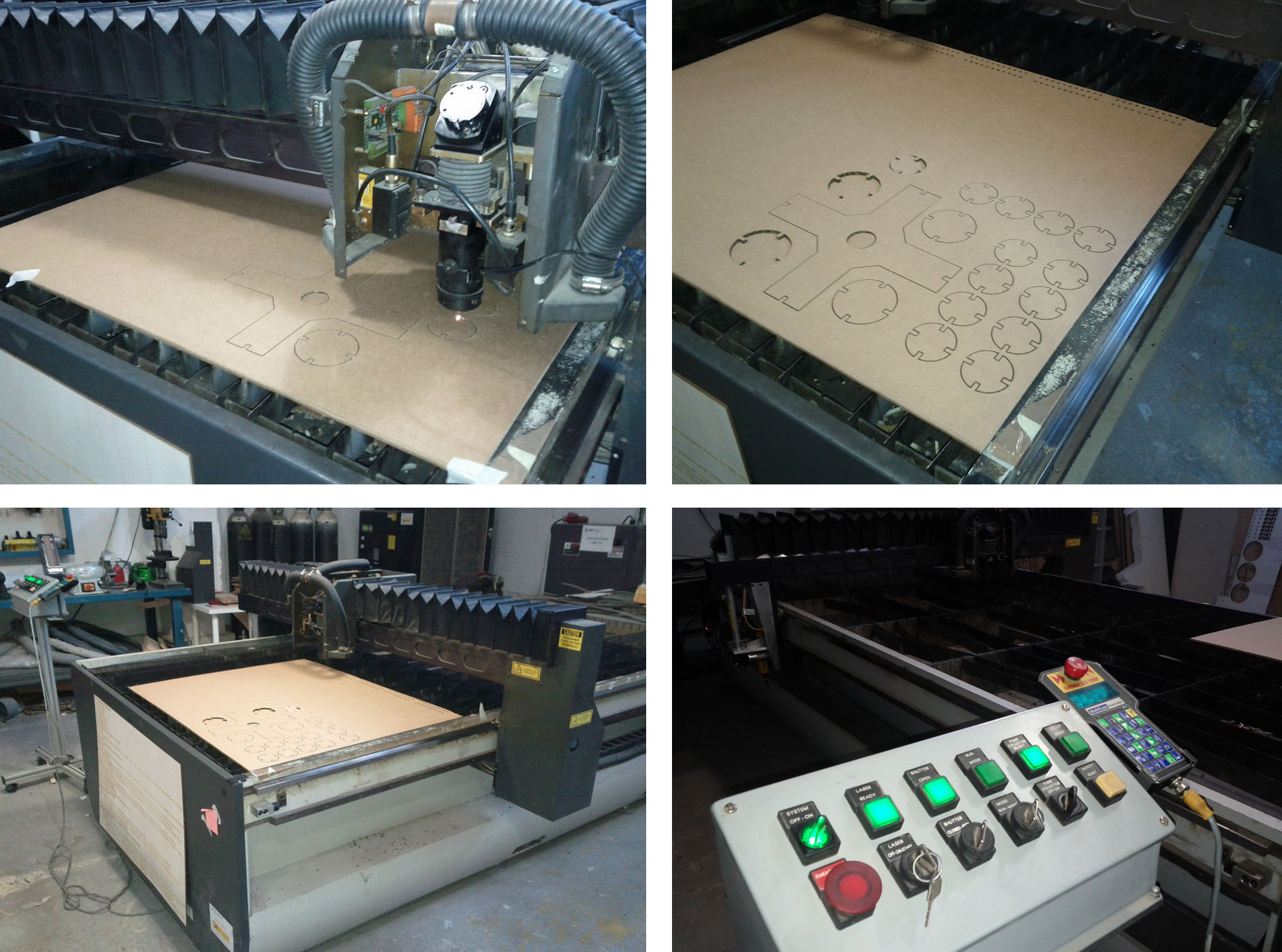

Teachers explained us how we could work with the laser printers and the features about the different models. In our Fablab we have used the Epilog Legend 36 EXT and Spirit GE. We have downloaded Epilog drivers , and we have learned to configure the printer in different ways depending on the kind of the material to cutting. We have used cardboard 7 mm width.

I have done a test to verify the communication with the printer and I have also could print a sample to adjusting the dimensions in the bonding areas.

A printer problem Epilog did we had to use the printer more powerful to cut our designs. This gave us the opportunity to know how to work this big cutter.

Finally I've sent my draw in .dxf format and this is the result.

As I had a little experience with Inskape I've decided to do a logo for my website and I've printed it with another printer in adhesive paper.